Einführung: Navigieren auf dem globalen Markt für Wie viel kostet ein Scheinwerferwechsel?

In der schnelllebigen Welt der Kfz-Wartung ist es für internationale B2B-Einkäufer entscheidend zu wissen, wie viel ein Scheinwerferwechsel kostet. Ganz gleich, ob Sie Teile für eine Fahrzeugflotte beschaffen oder eine Werkstatt leiten, die Kosten können je nach Scheinwerfertyp, Marke und Modell des Fahrzeugs und regionalen Preisunterschieden erheblich variieren. Dieser Leitfaden befasst sich mit der Komplexität der Kosten für den Austausch von Scheinwerfern und bietet Einblicke in verschiedene Lampentypen - von sparsamen Halogenoptionen bis hin zu fortschrittlichen LED-Systemen - sowie in die damit verbundenen Arbeitskosten und Installationsüberlegungen.

B2B-Einkäufer aus Afrika, Südamerika, dem Nahen Osten und Europa, einschließlich Schlüsselmärkten wie Deutschland und Saudi-Arabien, stehen vor besonderen Herausforderungen, wenn sie sich auf dem globalen Markt für Automobilteile bewegen. Diese umfassende Ressource gibt nicht nur einen Überblick über die verschiedenen Scheinwerfertypen und ihre Anwendungen, sondern bietet auch praktische Ratschläge zur Lieferantenprüfung und zu kosteneffizienten Beschaffungsstrategien. Dieser Leitfaden gibt Entscheidungsträgern das nötige Wissen an die Hand, um fundierte Kaufentscheidungen zu treffen, und zielt darauf ab, die betriebliche Effizienz zu steigern und sicherzustellen, dass die Sicherheitsstandards in allen Fahrzeugflotten eingehalten werden. Verschaffen Sie Ihrem Unternehmen den nötigen Einblick, um Ihre Prozesse für den Austausch von Scheinwerfern zu optimieren und die Komplexität des Automobilmarktes zu bewältigen.

Inhaltsverzeichnis

- Top 3 Wie viel kostet der Austausch eines Scheinwerfers Hersteller & Lieferanten Liste

- Einführung: Navigieren auf dem globalen Markt für Wie viel kostet ein Scheinwerferwechsel?

- Wie viel kostet der Austausch von Scheinwerfern? Arten und Variationen

- Key Industrial Applications of wie viel kostet ein Scheinwerfer Ersatz

- 3 häufige Schmerzpunkte für ‘wie viel kostet der Austausch von Scheinwerfern’ und ihre Lösungen

- Leitfaden für die strategische Materialauswahl für die Kosten eines Scheinwerferwechsels

- Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie viel kostet der Austausch von Scheinwerfern?

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Austausch von Scheinwerfern?’

- Umfassende Kosten- und Preisanalyse für Wie viel kostet ein Scheinwerferwechsel Sourcing

- Analyse der Alternativen: Vergleich der Kosten für einen Scheinwerferwechsel mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für Wie viel kostet ein Scheinwerferwechsel?

- Marktdynamik und Beschaffungstrends in der Branche "Wie viel kostet ein Scheinwerferwechsel?

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch von Scheinwerfern

- Strategische Beschaffung Schlussfolgerung und Ausblick für Wie viel kostet ein Scheinwerferwechsel?

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Wie viel kostet der Austausch von Scheinwerfern? Arten und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Halogenlampen | Erschwinglich, kurze Lebensdauer (500-1.000 Stunden), weit verbreitet | Allgemeine Kfz-Reparaturen, Fuhrparkdienste | Vorteile: Geringe Kosten; leicht zu ersetzen. Nachteile: Häufiges Auswechseln erforderlich; weniger energieeffizient. |

| HID (High-Intensity Discharge)-Lampen | Hellere Beleuchtung, längere Lebensdauer (2.000-10.000 Stunden) | Luxusfahrzeuge, Hochleistungsfahrzeuge | Vorteile: Hervorragende Helligkeit; bessere Sicht. Nachteile: Höhere Kosten; komplexe Installation. |

| LED-Glühbirnen (Licht emittierende Dioden) | Lange Lebensdauer (bis zu 40.000 Stunden), energieeffizient, hohe Anschaffungskosten | Moderne Fahrzeuge, Elektroautos | Vorteile: Energieeffizient, wartungsarm. Nachteile: Teuer im Vorfeld; mögliche Kompatibilitätsprobleme. |

| Scheinwerfer-Baugruppen | Kompletter Austausch der Einheit, unterschiedliche Komplexität und Kosten | Kollisionsreparatur, Fahrzeugrestaurierung | Vorteile: Umfassende Lösung, die einen guten Sitz gewährleistet. Nachteile: Hohe Kosten; arbeitsintensive Installation. |

| Adaptive Scheinwerfersysteme | Fortschrittliche Technologie (Auto-Leveling, Matrix-LEDs), hohe Kosten | Hochwertige Fahrzeuge, sicherheitsorientierte Flotten | Vorteile: Erhöhte Sicherheit; verbesserte Sichtbarkeit. Nachteile: Sehr hohe Wiederbeschaffungskosten; komplexe Installation. |

Was sind Halogenglühlampen und ihre B2B-Relevanz?

Halogenglühlampen sind heute der häufigste Scheinwerfertyp in Fahrzeugen. Sie sind eine kostengünstige Option für Unternehmen, die einen Fuhrpark verwalten oder allgemeine Kfz-Reparaturen durchführen. Aufgrund ihrer kürzeren Lebensdauer müssen sie jedoch häufig ausgetauscht werden, was im Laufe der Zeit zu höheren Wartungskosten führen kann. Für B2B-Kunden eignen sich Halogenlampen für Anwendungen mit hohen Stückzahlen, bei denen die Kosten im Vordergrund stehen, aber sie sind möglicherweise nicht die beste Wahl für Fahrzeuge, die länger haltende Lösungen benötigen.

Wie unterscheiden sich HID-Lampen für Geschäftsanwendungen?

HID-Lampen bieten im Vergleich zu Halogenlampen eine hellere Ausleuchtung und haben eine längere Lebensdauer, was sie zu einer beliebten Wahl für Luxus- und Hochleistungsfahrzeuge macht. Ihr Einbau kann kompliziert sein und Fachwissen erfordern, was zu höheren Arbeitskosten führen kann. B2B-Käufer sollten HID-Glühlampen in Betracht ziehen, wenn es sich um Fahrzeuge der Oberklasse handelt oder wenn eine bessere Sicht erforderlich ist, wobei die anfänglichen Kosten gegen die langfristigen Vorteile abzuwägen sind.

Was sind die Vorteile der Verwendung von LED-Lampen in modernen Fahrzeugen?

LED-Lampen werden aufgrund ihrer Energieeffizienz und langen Lebensdauer immer beliebter, was sie zu einer attraktiven Option für moderne und elektrische Fahrzeuge macht. Zwar sind die Anschaffungskosten höher, aber der geringere Bedarf an Ersatzlampen und der niedrigere Energieverbrauch können im Laufe der Zeit zu erheblichen Einsparungen führen. B2B-Einkäufer sollten die Kompatibilität mit bestehenden Systemen prüfen und den langfristigen Wert berücksichtigen, wenn sie in LED-Technologie für ihre Flotten investieren.

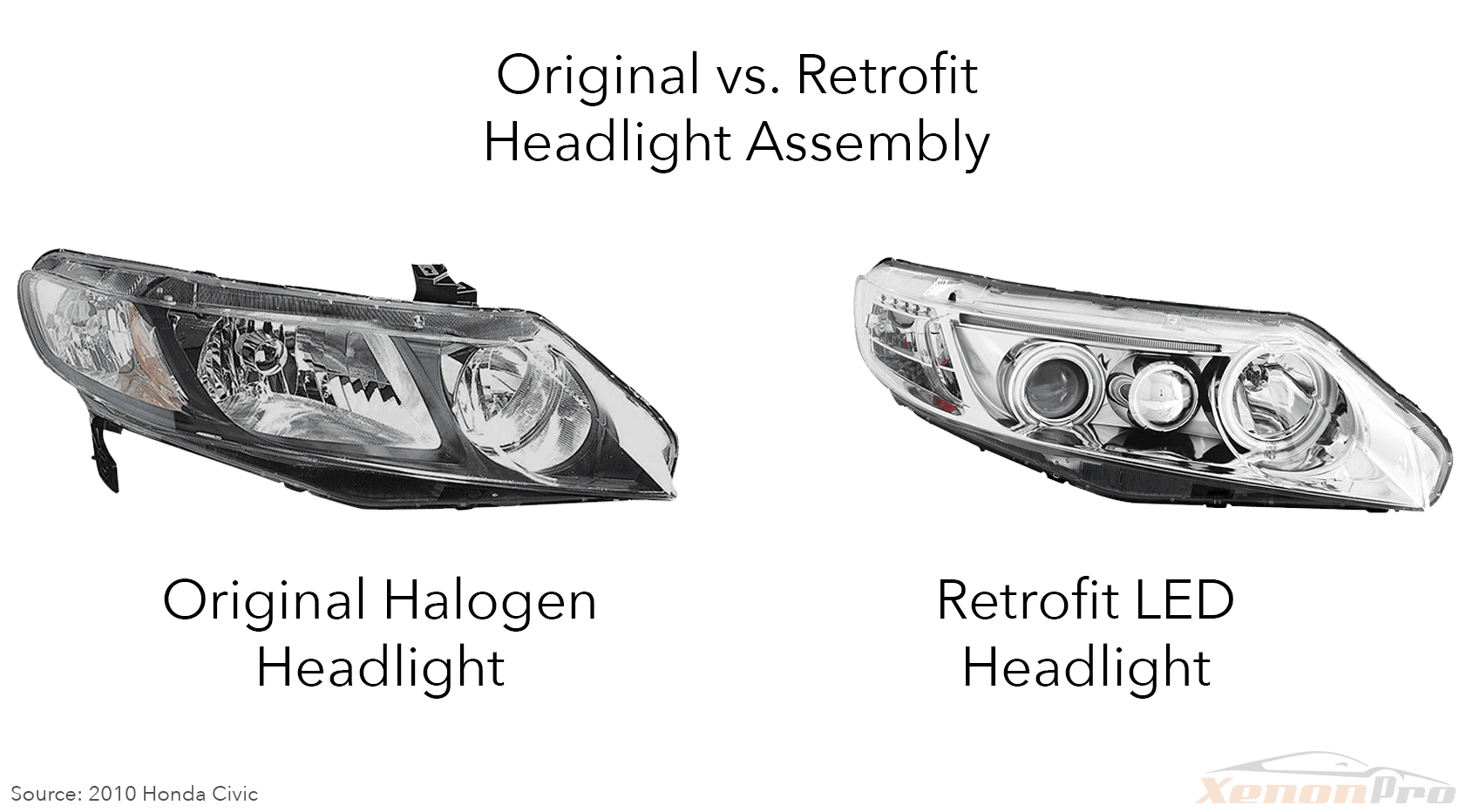

Warum sollten Sie sich für Scheinwerferbaugruppen für umfassende Lösungen entscheiden?

Scheinwerferbaugruppen sind komplette Einheiten, die verschiedene Komponenten wie Glühlampen, Reflektoren und Linsen enthalten können. Sie sind für umfassende Reparaturen unverzichtbar, insbesondere bei Schäden oder Fehlfunktionen. Sie können zwar kostspielig sein, gewährleisten aber, dass alle Teile nahtlos zusammenarbeiten, was für die Sicherheit entscheidend ist. B2B-Einkäufer in der Kfz-Reparatur oder -Restaurierung sollten hochwertigen Baugruppen den Vorzug geben, um die Integrität des Fahrzeugs und die Kundenzufriedenheit zu erhalten.

Was sind die Vorteile von adaptiven Scheinwerfersystemen für die Sicherheit?

Adaptive Scheinwerfersysteme sind der neueste Stand der Kfz-Beleuchtungstechnologie. Sie verfügen über eine automatische Leuchtweitenregulierung und Matrix-LEDs, die sich den Fahrbedingungen anpassen. Diese Systeme sind zwar nicht ganz billig, aber die Sicherheitsvorteile, die sie bieten, können die Kosten für Unternehmen rechtfertigen, die sich auf hochwertige oder sicherheitsorientierte Fahrzeuge konzentrieren. B2B-Käufer sollten die Vorteile einer verbesserten Sichtbarkeit gegen die Komplexität und die Kosten der Installation abwägen, wenn sie diese fortschrittlichen Systeme in Betracht ziehen.

Key Industrial Applications of wie viel kostet ein Scheinwerfer Ersatz

| Branche/Sektor | Spezifische Anwendung von Wie viel kostet ein Scheinwerferwechsel? | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Transparente Preise für den Austausch von Scheinwerfern | Verbessert das Vertrauen und die Zufriedenheit der Kunden, was zu Folgegeschäften führt | Kenntnis der lokalen Marktpreise und Beschaffung von Qualitätsteilen |

| Logistik und Flottenmanagement | Budgetierung der Scheinwerferwartung für Flotten | Reduziert Ausfallzeiten und erhöht die Sicherheit und gewährleistet die Einhaltung von Vorschriften | Großeinkaufsoptionen und zuverlässige Lieferanten für Teile |

| Automobilbau | Kostenanalyse für die Integration fortschrittlicher Scheinwerfersysteme | Informationsgrundlage für Produktionsentscheidungen und Preisstrategien für neue Modelle | Zuverlässigkeit der Lieferanten und Einhaltung der Sicherheitsstandards |

| Versicherungsgesellschaften | Schätzung der Reparaturkosten für Schäden an Scheinwerfern | Verbessert die Effizienz der Schadenbearbeitung und die Kundenzufriedenheit | Genaue Einschätzung der Kosten für Teile und Arbeit in verschiedenen Regionen |

| Einzelhandel mit Autoteilen | Preisstrategien für Scheinwerferbirnen und -baugruppen | Steigert den Umsatz durch wettbewerbsfähige Preise und sachkundiges Marketing | Beschaffung bei Herstellern mit starker Marktpräsenz |

Wie können Kfz-Werkstätten die Kosten für den Austausch von Scheinwerfern besser einschätzen?

Kfz-Werkstätten können davon profitieren, dass sie die mit dem Austausch von Scheinwerfern verbundenen Kosten kennen, indem sie ihren Kunden transparente Preise anbieten. Diese Praxis schafft Vertrauen und erhöht die Kundenzufriedenheit, was für die Wiederholung von Aufträgen entscheidend ist. Die Werkstätten sollten die lokalen Marktpreise für Teile und Arbeit kennen, um sicherzustellen, dass sie wettbewerbsfähig bleiben und gleichzeitig Qualitätskomponenten einkaufen. Dieses Wissen ermöglicht es den Werkstätten, genaue Kostenvoranschläge zu erstellen und so ihre Servicequalität zu verbessern.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Was ist bei der Budgetierung für Logistik und Flottenmanagement zu beachten?

In der Logistik und im Fuhrparkmanagement ist die Budgetierung der Scheinwerferwartung unerlässlich, um Ausfallzeiten zu minimieren und die Einhaltung von Sicherheitsvorschriften zu gewährleisten. Ein gut gewarteter Fuhrpark verringert nicht nur die betrieblichen Risiken, sondern verbessert auch den Ruf des Unternehmens. Um die Kosten zu senken, sollten Flottenmanager die Möglichkeit des Großeinkaufs von Scheinwerferbirnen und -baugruppen in Betracht ziehen. Zuverlässige Lieferanten, die gleichbleibende Qualität und pünktliche Lieferungen liefern können, sind für die Aufrechterhaltung eines unterbrechungsfreien Fuhrparkbetriebs unerlässlich.

Wie können Automobilhersteller die Kostenanalyse für Scheinwerfersysteme nutzen?

Automobilhersteller können die Kostenanalyse für den Austausch von Scheinwerfern als Grundlage für ihre Produktionsentscheidungen nutzen, insbesondere bei der Integration fortschrittlicher Beleuchtungstechnologien. Das Verständnis der Preislandschaft für verschiedene Arten von Scheinwerfersystemen, wie LED oder HID, ermöglicht es den Herstellern, ihre Produktangebote und Preismodelle effektiv zu gestalten. Zu den wichtigsten Überlegungen gehören die Zuverlässigkeit der Zulieferer und die Einhaltung von Sicherheitsstandards, die für die Aufrechterhaltung des Markenrufs und die Gewährleistung der Sicherheit der Kunden von entscheidender Bedeutung sind.

Wie profitieren Versicherungsgesellschaften von der Schätzung der Reparaturkosten?

Versicherungsunternehmen können Einblicke in die Kosten für den Ersatz von Scheinwerfern nutzen, um die Reparaturkosten für Schäden an Scheinwerfern genau zu schätzen. Dies erhöht die Effizienz der Schadenbearbeitung und verbessert die allgemeine Kundenzufriedenheit. Um eine faire und zeitnahe Regulierung zu gewährleisten, müssen die Versicherer über die unterschiedlichen Kosten für Teile und Arbeit in den verschiedenen Regionen informiert sein, insbesondere in diversen Märkten wie Afrika und Südamerika.

Welche Preisstrategien sollte der Einzelhandel mit Autoteilen in Betracht ziehen?

Zulieferer von Autoteilen sollten auf der Grundlage einer umfassenden Marktforschung wirksame Preisstrategien für Scheinwerferlampen und -baugruppen entwickeln. Wenn sie die Kostenspanne für verschiedene Scheinwerfertypen kennen, können sie wettbewerbsfähige Preise festlegen und gleichzeitig ihre Gewinnspannen maximieren. Darüber hinaus kann die Beschaffung von Herstellern mit einer starken Marktpräsenz die Zuverlässigkeit ihres Produktangebots erhöhen und sie zu einer ersten Wahl für Verbraucher machen, die nach qualitativ hochwertigen Kfz-Teilen suchen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

3 häufige Schmerzpunkte für ‘wie viel kostet der Austausch von Scheinwerfern’ und ihre Lösungen

Szenario 1: Unerwartete Kosten für den Austausch von Scheinwerfern

Das Problem: B2B-Kunden sehen sich oft mit unerwarteten Kosten konfrontiert, wenn es um den Austausch von Scheinwerfern geht, insbesondere im Fuhrparkmanagement oder beim Fahrzeugleasing. Ein Transportunternehmen könnte zum Beispiel feststellen, dass ein großer Teil seiner Flotte auf einmal Scheinwerfer ersetzen muss, was zu unvorhergesehenen Budgetüberschreitungen führt. Dieses Szenario belastet nicht nur die finanziellen Ressourcen, sondern kann auch den Betrieb stören, wenn Fahrzeuge wegen unzureichender Beleuchtung ausfallen, was sich auf die Sicherheit und Effizienz auswirkt.

Die Lösung: Um das Risiko unerwarteter Kosten für den Austausch von Scheinwerfern zu verringern, sollten B2B-Einkäufer einen proaktiven Wartungsplan einführen, der regelmäßige Inspektionen der Scheinwerferleistung beinhaltet. Der Aufbau von Beziehungen zu zuverlässigen Automobilzulieferern und Dienstleistern kann auch Großeinkaufsvereinbarungen erleichtern, wodurch die Stückkosten für Scheinwerfer gesenkt werden können. Darüber hinaus sollten Käufer in qualitativ hochwertigere Glühbirnen mit längerer Lebensdauer und besserer Leistung investieren, was die Häufigkeit des Austauschs verringern kann. Der Einsatz von Flottenmanagement-Software kann dabei helfen, den Zustand der Scheinwerfer zu verfolgen und vorherzusagen, wann ein Austausch fällig ist, so dass das Budget besser verteilt werden kann und Betriebsunterbrechungen minimiert werden.

Szenario 2: Die Variabilität der Preise für den Austausch von Scheinwerfern verstehen

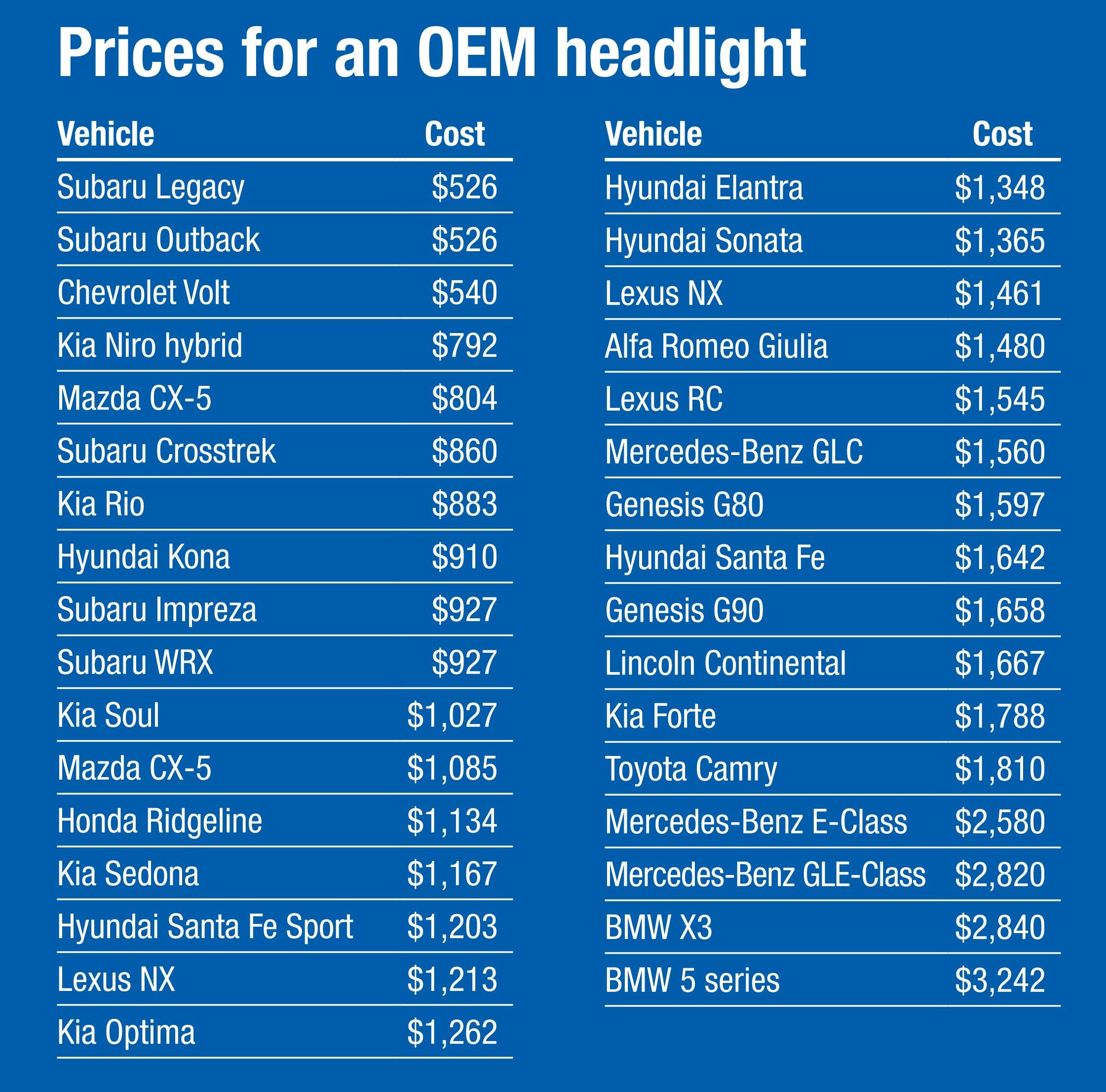

Das Problem: Für Käufer ist es oft schwierig, die großen Preisunterschiede bei Ersatzscheinwerfern zu verstehen, die von $10 für Halogenlampen bis zu mehreren Tausend Dollar für moderne LED- oder HID-Systeme reichen können. Diese Verwirrung kann zu falschen Kaufentscheidungen führen, die möglicherweise dazu führen, dass man zu viel Geld für unnötige Funktionen ausgibt oder sich für minderwertige Produkte entscheidet, die Sicherheit und Leistung beeinträchtigen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Die Lösung: Um die Preisschwankungen bei Scheinwerferersatzteilen zu bewältigen, sollten sich B2B-Käufer gründlich über die spezifischen Scheinwerferanforderungen für ihr Fahrzeugmodell informieren. Dazu gehört das Nachschlagen im Fahrzeughandbuch oder die Beratung durch renommierte Automobilexperten. Käufer sollten auch die Preise verschiedener Anbieter und Plattformen vergleichen, um sicherzustellen, dass sie wettbewerbsfähige Preise erhalten. Darüber hinaus kann das Wissen um die Unterschiede zwischen den verschiedenen Glühbirnenarten - z. B. die Langlebigkeit von LEDs im Vergleich zur Kosteneffizienz von Halogenlampen - dabei helfen, eine sachkundige Entscheidung zu treffen, die Kosten und Leistung in Einklang bringt. Die Einführung eines standardisierten Einkaufsprotokolls auf der Grundlage von Fahrzeugtypen und deren jeweiligen Beleuchtungsanforderungen kann den Beschaffungsprozess rationalisieren und die Kosten kontrollieren.

Szenario 3: Komplexer Austausch von Scheinwerferbaugruppen

Das Problem: Bei vielen modernen Fahrzeugen müssen komplette Scheinwerferbaugruppen und nicht nur Glühbirnen ausgetauscht werden, insbesondere wenn die Baugruppe beschädigt ist. Diese Komplexität kann für B2B-Einkäufer überwältigend sein, insbesondere in Branchen, in denen die Betriebszeit von Fahrzeugen entscheidend ist, wie z. B. in der Logistik oder bei Rettungsdiensten. Der Zeitaufwand und die Kosten, die mit diesem Austausch verbunden sind, können den Geschäftsbetrieb erheblich beeinträchtigen.

Die Lösung: Um den Herausforderungen zu begegnen, die mit dem Austausch komplexer Scheinwerferbaugruppen verbunden sind, sollten B2B-Käufer ihre Wartungsteams vorrangig in den spezifischen Verfahren für ihre Fahrzeugmodelle schulen. Die Zusammenarbeit mit erfahrenen Kfz-Technikern, die sie bei den effizientesten Austauschverfahren beraten können, ist ebenfalls von Vorteil. Darüber hinaus kann die Erstellung eines detaillierten Bestands an Teilen und Baugruppen, die für jeden Fahrzeugtyp im Fuhrpark benötigt werden, den Austauschprozess rationalisieren und Ausfallzeiten reduzieren. Käufer können auch Optionen für verlängerte Garantien oder Servicepakete von Herstellern prüfen, die Scheinwerferbaugruppen abdecken, um sicherzustellen, dass unerwartete Kosten effektiv verwaltet werden. Durch proaktive Wartung und Schulung können Unternehmen Unterbrechungen minimieren und die betriebliche Effizienz aufrechterhalten.

Leitfaden für die strategische Materialauswahl für die Kosten eines Scheinwerferwechsels

Wenn es um den Ersatz von Scheinwerfern geht, haben die in den Glühbirnen und Baugruppen verwendeten Materialien einen erheblichen Einfluss auf Leistung, Haltbarkeit und Kosten. Hier analysieren wir vier gängige Materialien, die in Scheinwerferkomponenten verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vorteile, Nachteile und Auswirkungen für internationale B2B-Käufer.

Was sind die wichtigsten Eigenschaften von Halogenlampen für den Ersatz von Scheinwerfern?

Halogenglühlampen sind aufgrund ihrer Einfachheit und Kosteneffizienz eine gängige Wahl für viele Fahrzeuge. Diese Lampen arbeiten bei hohen Temperaturen, in der Regel zwischen 300°C und 400°C, wodurch sie helles Licht bei kompakter Größe erzeugen können. Halogenglühlampen sind außerdem relativ stoß- und vibrationsfest und eignen sich daher für verschiedene Fahrbedingungen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Vorteile: Der Hauptvorteil von Halogenglühlampen ist ihr niedriger Preis, der in der Regel zwischen $10 und $40 liegt. Sie sind leicht auszutauschen und haben ein einfaches Herstellungsverfahren, was die Produktionskosten niedrig hält.

Nachteile: Halogenlampen haben jedoch eine kürzere Lebensdauer, die im Allgemeinen zwischen 500 und 1.000 Stunden liegt. Ihre Leistung kann im Laufe der Zeit nachlassen, was zu einer Verdunkelung führt, die einen häufigeren Austausch erforderlich machen kann.

Auswirkungen auf die Anwendung: Halogenglühlampen eignen sich am besten für Standardfahrzeuganwendungen. Sie sind mit den meisten Fahrzeugen kompatibel, erfüllen aber möglicherweise nicht die Helligkeits- und Effizienzstandards, die für Hochleistungs- oder Luxusfahrzeuge erforderlich sind.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Überlegungen für internationale Käufer: Käufer sollten sich vergewissern, dass sie die örtlichen Vorschriften bezüglich der Beleuchtungsnormen einhalten, wie z. B. die der Europäischen Union oder der SAE in den USA. Halogenlampen sind weithin akzeptiert, aber es kann Qualitätsunterschiede geben, die eine sorgfältige Auswahl des Lieferanten erfordern.

Wie sehen HID (High-Intensity Discharge)-Glühbirnen für den Scheinwerferwechsel im Vergleich aus?

HID-Glühbirnen sind für ihre hohe Helligkeit und Effizienz bekannt und arbeiten bei Temperaturen von 3000 bis 6000 K. Sie erzeugen Licht durch einen elektrischen Lichtbogen zwischen zwei Elektroden, für dessen Betrieb ein Vorschaltgerät erforderlich ist. HID-Lampen haben eine längere Lebensdauer als Halogenlampen und halten oft zwischen 2.000 und 10.000 Stunden.

Vorteile: Der Hauptvorteil von HID-Glühlampen ist ihre überragende Helligkeit und Energieeffizienz, die die Sichtbarkeit bei Nacht erheblich verbessern kann. Sie sind ideal für Hochleistungsfahrzeuge und solche, die fortschrittliche Beleuchtungssysteme benötigen.

Nachteile: Der Hauptnachteil sind die höheren Kosten, die oft über $100 pro Glühbirne liegen. Darüber hinaus kann die Installation komplex sein und spezielle Kenntnisse und Werkzeuge erfordern, was die Arbeitskosten erhöhen kann.

Auswirkungen auf die Anwendung: HID-Glühbirnen eignen sich für Luxus- und Hochleistungsfahrzeuge, sind aber aufgrund ihrer spezifischen elektrischen Anforderungen möglicherweise nicht mit allen Fahrzeugtypen kompatibel.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Überlegungen für internationale Käufer: Die Einhaltung internationaler Normen, wie z. B. der ECE-Vorschriften in Europa, ist entscheidend. Käufer sollten auch die Verfügbarkeit von Ersatzteilen und Serviceunterstützung in ihren Regionen berücksichtigen.

Was sind die Vorteile von LED-Lampen beim Austausch von Scheinwerfern?

LED-Lampen werden aufgrund ihrer Langlebigkeit und Energieeffizienz immer beliebter. Im Vergleich zu Halogen- und HID-Lampen arbeiten sie bei niedrigeren Temperaturen, in der Regel zwischen 60 und 80 °C, was das Risiko von Hitzeschäden an den umliegenden Komponenten verringert. LED-Glühbirnen können bis zu 40.000 Stunden halten, was sie zu einer kostengünstigen Langzeitlösung macht.

Vorteile: LEDs bieten eine hervorragende Helligkeit und Klarheit, wobei eine breite Palette von Farbtemperaturen verfügbar ist. Sie sind außerdem sehr langlebig und widerstandsfähig gegen Stöße und Vibrationen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Nachteile: Die Anschaffungskosten für LED-Glühbirnen können hoch sein und liegen oft zwischen $100 und $300, je nach Komplexität der Baugruppe. Außerdem erfordern einige LED-Systeme für eine optimale Leistung eine komplexe Elektronik, was die Installation erschweren kann.

Auswirkungen auf die Anwendung: LED-Glühbirnen eignen sich für eine breite Palette von Anwendungen, von Standardfahrzeugen bis hin zu High-End-Modellen mit fortschrittlichen Beleuchtungssystemen.

Überlegungen für internationale Käufer: Internationale Käufer sollten sich der unterschiedlichen Qualitätsstandards und Zertifizierungen für LED-Produkte bewusst sein. Die Einhaltung lokaler Vorschriften ist unerlässlich, insbesondere in Regionen mit strengen Gesetzen zur Kfz-Beleuchtung.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Wie wirken sich Verbundwerkstoffe auf die Kosten der Scheinwerfermontage aus?

In Scheinwerferbaugruppen werden häufig Verbundwerkstoffe verwendet, um Gewicht zu sparen und die Haltbarkeit zu verbessern. Diese Materialien können hohen Temperaturen standhalten und sind korrosionsbeständig, so dass sie für verschiedene Umweltbedingungen geeignet sind.

Vorteile: Die Verwendung von Verbundwerkstoffen kann die Herstellungskosten senken und die Gesamtlebensdauer der Scheinwerferbaugruppe verlängern. Außerdem sind sie leichter als herkömmliche Glas- oder Metallkomponenten.

Nachteile: Die Anschaffungskosten von Verbundwerkstoffen können jedoch höher sein, und ihre Leistung kann je nach der verwendeten Formulierung variieren.

Auswirkungen auf die Anwendung: Verbundwerkstoffe sind ideal für moderne Fahrzeugkonstruktionen, bei denen Gewichtsreduzierung und Kraftstoffeffizienz im Vordergrund stehen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Überlegungen für internationale Käufer: Käufer sollten darauf achten, dass Verbundwerkstoffe internationalen Sicherheits- und Leistungsnormen entsprechen, wie sie beispielsweise von ASTM oder DIN vorgegeben werden.

Zusammenfassende Tabelle zur Materialauswahl für die Kosten des Scheinwerferwechsels

| Material | Typischer Anwendungsfall für die Frage, wie viel ein Scheinwerferwechsel kostet | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Halogenlampen | Standard-Fahrzeuganwendungen | Geringe Kosten | Kurze Lebenserwartung | Niedrig |

| HID-Glühbirnen | Luxus- und Hochleistungsfahrzeuge | Hervorragende Helligkeit | Hohe Kosten und komplexe Installation | Hoch |

| LED-Glühbirnen | Breite Palette von Fahrzeuganwendungen | Langlebigkeit und Energieeffizienz | Hohe Anschaffungskosten | Hoch |

| Verbundwerkstoffe | Moderne Fahrzeugscheinwerferbaugruppen | Leicht und langlebig | Höhere anfängliche Materialkosten | Mittel |

Dieser strategische Leitfaden für die Materialauswahl liefert wertvolle Einblicke für internationale B2B-Einkäufer, die sich mit den komplexen Kosten für den Austausch von Scheinwerfern auseinandersetzen möchten, um fundierte Entscheidungen zu treffen, die den regionalen Normen und Marktanforderungen entsprechen.

Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie viel kostet der Austausch von Scheinwerfern?

Was sind die wichtigsten Schritte im Herstellungsprozess von Ersatzscheinwerfern?

Der Herstellungsprozess von Ersatzscheinwerfern umfasst mehrere kritische Phasen, von denen jede einzelne zur Qualität und Funktionalität des Endprodukts beiträgt. Das Verständnis dieser Phasen kann B2B-Käufern helfen, fundierte Kaufentscheidungen zu treffen.

Materialvorbereitung: Welche Materialien werden bei der Herstellung von Scheinwerfern verwendet?

Der erste Schritt bei der Herstellung von Ersatzscheinwerfern ist die Materialvorbereitung. Qualitativ hochwertige Materialien sind für die Haltbarkeit und Leistung von entscheidender Bedeutung. Zu den gängigen Materialien gehören:

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

- Glas oder Polycarbonat: Diese Materialien werden für Brillengläser verwendet und müssen eine hohe Klarheit, Stoßfestigkeit und UV-Beständigkeit aufweisen.

- Reflektierende Beschichtungen: Für diese Beschichtungen, die zur Verbesserung der Lichtausbeute eingesetzt werden, werden häufig Aluminium oder spezielle Polymere verwendet.

- Elektrische Komponenten: Verkabelung und Steckverbinder müssen den Industriestandards für Leitfähigkeit und Hitzebeständigkeit entsprechen.

- Gehäuse Materialien: In der Regel aus hochschlagfestem Kunststoff oder Aluminium, um die internen Komponenten vor Umwelteinflüssen zu schützen.

B2B-Einkäufer sollten sich vergewissern, dass die Lieferanten hochwertige Materialien verwenden, um die Leistungsanforderungen und die Langlebigkeit zu erfüllen.

Wie werden die Scheinwerferkomponenten geformt und zusammengebaut?

Nach der Materialvorbereitung werden in einem nächsten Schritt die verschiedenen Komponenten des Scheinwerfers geformt. Dies beinhaltet:

- Spritzgießen: Wird häufig für die Herstellung von Kunststoffgehäusen und Linsen verwendet, um präzise Formen und Abmessungen zu gewährleisten.

- Bearbeitung: Diese Technik wird bei Metallteilen angewandt und gewährleistet, dass die Komponenten nahtlos zusammenpassen.

- Anwendung der Beschichtung: Reflektierende Beschichtungen werden durch spezielle Verfahren wie die Vakuumbeschichtung aufgebracht, die eine gleichmäßige Abdeckung und Haftung gewährleisten.

Sobald die Bauteile geformt sind, folgt die Montage. Diese Phase umfasst:

- Komponentenintegration: Alle Teile, einschließlich Glühbirnen, Verkabelung und Gehäuse, werden montiert. Aus Gründen der Effizienz werden häufig automatisierte Montagelinien eingesetzt.

- Versiegelung und Prüfung: Die Baugruppe ist versiegelt, um sie vor Feuchtigkeit und Staub zu schützen, was für die Aufrechterhaltung der Leistung auf lange Sicht entscheidend ist.

Welche Veredelungsprozesse gibt es bei der Scheinwerferproduktion?

Die Endbearbeitung ist von entscheidender Bedeutung, um sicherzustellen, dass Ersatzscheinwerfer nicht nur gut funktionieren, sondern auch ästhetischen Ansprüchen genügen. Zu den wichtigsten Endbearbeitungsverfahren gehören:

- Polieren: Die Gläser sind poliert, um Klarheit zu schaffen und Lichtverzerrungen zu reduzieren.

- Beschichtung: Schutzbeschichtungen können auf Brillengläser aufgetragen werden, um die UV-Beständigkeit zu erhöhen und ein Vergilben zu verhindern.

- Etikettierung und Verpackung: Die ordnungsgemäße Kennzeichnung gewährleistet die Einhaltung der internationalen Vorschriften, während die Verpackung das Produkt während des Transports schützen muss.

Dieser Feinschliff ist entscheidend dafür, dass die Scheinwerfer sowohl funktional als auch optisch den Erwartungen entsprechen.

Welche Qualitätssicherungsmaßnahmen sind bei der Herstellung von Scheinwerfern unerlässlich?

Die Qualitätssicherung (QS) ist ein Eckpfeiler des Herstellungsprozesses, um zu gewährleisten, dass die Ersatzscheinwerfer sicher, effektiv und langlebig sind. B2B-Einkäufer sollten mehrere internationale und branchenspezifische Normen kennen, die die Qualitätskontrolle regeln.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

Die Hersteller halten sich häufig an internationale Normen wie z. B.:

- ISO 9001: Diese Norm umreißt Kriterien für ein Qualitätsmanagementsystem und ist auf jede Organisation anwendbar, unabhängig von ihrer Größe oder Branche. Sie legt den Schwerpunkt auf einen prozessorientierten Ansatz zur Qualitätssicherung.

- ISO/TS 16949: Diese Norm richtet sich speziell an Automobilzulieferer und konzentriert sich auf die kontinuierliche Verbesserung, die Fehlervermeidung und die Reduzierung von Abweichungen und Verschwendung in der Lieferkette.

Die Kenntnis dieser Normen kann B2B-Käufern helfen, die Zuverlässigkeit potenzieller Lieferanten zu beurteilen.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle bei der Herstellung von Scheinwerfern?

Qualitätskontrollpunkte sind ein wesentlicher Bestandteil, um sicherzustellen, dass alle Produkte den vorgegebenen Standards entsprechen. Zu den wichtigsten Kontrollpunkten gehören:

- Eingangsqualitätskontrolle (IQC): Kontrolle der Rohstoffe bei ihrer Ankunft, um sicherzustellen, dass sie den Spezifikationen entsprechen, bevor die Produktion beginnt.

- In-Process-Qualitätskontrolle (IPQC): Kontinuierliche Überwachung während des Fertigungsprozesses, um Fehler frühzeitig zu erkennen. Dazu gehören Messungen der Abmessungen und Funktionstests.

- Endkontrolle (FQC): Eine gründliche Inspektion der fertigen Produkte, einschließlich Funktionstests, Messungen der Lichtleistung und physische Inspektionen auf Mängel.

Die Umsetzung dieser Kontrollpunkte trägt dazu bei, während des gesamten Herstellungsprozesses hohe Qualitätsstandards aufrechtzuerhalten.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

B2B-Einkäufer müssen sicherstellen, dass ihre Lieferanten über solide Qualitätskontrollmaßnahmen verfügen. Hier sind einige wirksame Möglichkeiten, die Qualität der Lieferanten zu überprüfen:

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Welche Prüfungspraktiken sollten angewandt werden?

- Lieferantenaudits: Die Durchführung regelmäßiger Audits bei den Lieferanten kann dazu beitragen, die Einhaltung der Qualitätsstandards zu überprüfen. Dazu gehört die Überprüfung ihrer Prozesse, Ausrüstung und Qualitätsaufzeichnungen.

- Inspektionen durch Dritte: Die Beauftragung von externen Prüfstellen kann eine unvoreingenommene Bewertung der Qualitätskontrollverfahren eines Lieferanten liefern.

Welche Arten von Berichten sollten angefordert werden?

- Berichte zur Qualitätskontrolle: Die Lieferanten sollten ihre Qualitätskontrollverfahren dokumentieren, einschließlich Testergebnissen und Prüfprotokollen.

- Zertifizierungsdokumente: Das Anfordern von Kopien von Zertifizierungen für einschlägige Qualitätsstandards (z. B. ISO, CE) kann eine Garantie für das Qualitätsengagement eines Lieferanten sein.

Was sind die besonderen Aspekte der Qualitätskontrolle für internationale B2B-Einkäufer?

Für B2B-Einkäufer aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa ist es entscheidend, die Feinheiten der Qualitätskontrolle zu verstehen.

- Einhaltung gesetzlicher Vorschriften: Jede Region kann spezifische Vorschriften haben, die sich auf die Qualitätsstandards für Automobilkomponenten auswirken. Käufer sollten sich mit diesen Vorschriften vertraut machen, um deren Einhaltung zu gewährleisten.

- Kulturelle Faktoren: Verschiedene Regionen haben möglicherweise unterschiedliche Erwartungen an Qualität und Service. Das Verständnis dieser kulturellen Nuancen kann helfen, stärkere Partnerschaften zu bilden.

Indem sie sich auf die oben beschriebenen Herstellungsverfahren und Qualitätssicherungsmaßnahmen konzentrieren, können B2B-Einkäufer fundiertere Entscheidungen in Bezug auf Ersatzscheinwerfer treffen und so sicherstellen, dass sie zuverlässige, hochwertige Produkte auswählen, die ihren spezifischen Anforderungen entsprechen.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Austausch von Scheinwerfern?’

Einführung

Dieser Leitfaden dient als praktische Checkliste für B2B-Einkäufer, die sich über die Möglichkeiten des Scheinwerferwechsels informieren und diese beschaffen möchten. Ganz gleich, ob Sie einen Fuhrpark verwalten oder Teile für eine Werkstatt beschaffen, die Kenntnis der Kosten und Faktoren, die mit dem Austausch von Scheinwerfern verbunden sind, kann Ihre Kaufentscheidungen verbessern und die Einhaltung der Sicherheitsvorschriften gewährleisten.

Schritt 1: Beurteilen Sie die Anforderungen an Ihr Fahrzeug

Es ist wichtig, die spezifischen Scheinwerferanforderungen Ihres Fahrzeugs zu kennen. Verschiedene Marken und Modelle können unterschiedliche Arten von Glühbirnen verwenden, z. B. Halogen, HID oder LED. Konsultieren Sie das Handbuch Ihres Fahrzeugs oder eine zuverlässige Ersatzteildatenbank, um die genauen Spezifikationen für den Austausch zu ermitteln.

Schritt 2: Bestimmung der Kostenparameter

Legen Sie ein Budget für den Austausch von Scheinwerfern fest, indem Sie sowohl die Kosten für Teile als auch die Arbeitskosten abschätzen. Scheinwerferbirnen können zwischen $10 für einfache Halogenmodelle und über $100 für moderne HID- oder LED-Optionen liegen. Berücksichtigen Sie außerdem die Arbeitskosten, die je nach Komplexität der Installation erheblich variieren können und in der Regel zwischen $30 und $300 liegen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Schritt 3: Qualitätsstandards für die Forschung

Vergewissern Sie sich, dass die Ersatzglühlampen den Industriestandards für Sicherheit und Leistung entsprechen. Achten Sie auf Glühbirnen mit der Aufschrift “DOT” (Department of Transportation), da diese nachweislich den staatlichen Sicherheitsnormen entsprechen. Vermeiden Sie billige Glühbirnen ohne Markenzeichen, die möglicherweise nicht den erforderlichen Vorschriften entsprechen.

Schritt 4: Bewertung der Lieferantenoptionen

Recherchieren Sie gründlich über potenzielle Lieferanten, bevor Sie einen Kauf tätigen. Fordern Sie Unternehmensprofile, Produktkataloge und Referenzen von anderen Unternehmen in Ihrer Branche an. Vergewissern Sie sich, dass sie zuverlässig und in der Lage sind, kontinuierlich Qualitätsprodukte zu liefern.

Schritt 5: Vergleichen Sie die Preise und Garantieleistungen

Holen Sie Angebote von mehreren Anbietern ein, um die Preise effektiv zu vergleichen. Achten Sie auf die Garantien, die auf die Lampen und Baugruppen gewährt werden, denn sie können ein Hinweis auf die Qualität sein und Ihnen Sicherheit geben. Eine gute Garantie kann auch langfristig Kosten sparen, wenn die Lampen früher als erwartet ersetzt werden müssen.

Schritt 6: Installationsoptionen berücksichtigen

Entscheiden Sie, ob Sie den Einbau selbst vornehmen oder professionelle Monteure damit beauftragen wollen. Wenn Sie sich für den Selbsteinbau entscheiden, sollten Sie sicherstellen, dass Sie über die erforderlichen Werkzeuge und Kenntnisse verfügen, um den Austausch sicher durchzuführen. Bei komplexen Baugruppen kann die Beauftragung von Fachleuten kostengünstiger sein, um mögliche Schäden zu vermeiden.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Schritt 7: Trends und Innovationen beobachten

Bleiben Sie auf dem Laufenden über die Fortschritte in der Scheinwerfertechnologie und die sich ändernden Vorschriften. Neuere Fahrzeuge erfordern unter Umständen anspruchsvollere Beleuchtungssysteme, die sich erheblich auf die Austauschkosten auswirken können. Wenn Sie sich über diese Trends auf dem Laufenden halten, können Sie fundierte Entscheidungen treffen und die Sicherheitsstandards einhalten.

Anhand dieser Checkliste können B2B-Einkäufer die Komplexität der Kosten für den Austausch von Scheinwerfern überblicken und sicherstellen, dass sie fundierte Kaufentscheidungen treffen, bei denen Sicherheit und Effizienz im Vordergrund stehen.

Umfassende Kosten- und Preisanalyse für Wie viel kostet ein Scheinwerferwechsel Sourcing

Was sind die wichtigsten Kostenfaktoren für den Austausch von Scheinwerfern?

Für internationale B2B-Einkäufer ist es wichtig, die Kostenstruktur für den Austausch von Scheinwerfern zu verstehen. Zu den wichtigsten Kostenkomponenten gehören Material, Arbeit, Fertigungsgemeinkosten, Werkzeuge, Qualitätskontrolle, Logistik und Gewinnspannen.

-

Materialien: Die Art des Scheinwerfers spielt eine wichtige Rolle bei den Kosten. Halogenlampen kosten in der Regel zwischen $10 und $40, während HID- oder LED-Lampen über $100 kosten können. Die Preise für komplette Scheinwerferbaugruppen können je nach verwendeter Technologie und Fahrzeugspezifikationen drastisch variieren, von $30 bis über $4.000.

-

Arbeit: Die Arbeitskosten können je nach Komplexität der Installation schwanken. Der professionelle Einbau kostet in der Regel zwischen $30 und $300. Sind umfangreiche Arbeiten erforderlich, wie z. B. das Entfernen des Stoßfängers, können die Arbeitskosten erheblich steigen. Beim Selbsteinbau kann der Käufer Arbeitskosten sparen, muss aber den Zeitaufwand und die benötigten Werkzeuge berücksichtigen.

-

Fertigungsgemeinkosten: Dazu gehören die Kosten, die mit der Herstellung der Scheinwerferkomponenten verbunden sind, z. B. Betriebskosten, Versorgungsleistungen und Löhne der Mitarbeiter. Bei höherwertigen Produkten fallen in der Regel höhere Fertigungsgemeinkosten an, die sich im Endpreis niederschlagen.

-

Werkzeuge: Für den Einbau bestimmter Scheinwerferbaugruppen kann Spezialwerkzeug erforderlich sein. Dies gilt insbesondere für fortschrittliche Systeme, die eine präzise Ausrichtung und Kalibrierung erfordern.

-

Qualitätskontrolle (QC): Um die Sicherheit und Zuverlässigkeit von Scheinwerfersystemen zu gewährleisten, sind strenge Qualitätskontrollverfahren erforderlich. Produkte, die internationale Sicherheitsnormen erfüllen, wie z. B. die DOT-Zertifizierung in den USA, können aufgrund der zusätzlichen Kosten für die Einhaltung der Normen höhere Preise erzielen.

-

Logistik: Die Versandkosten können je nach Entfernung und Transportart variieren. Für internationale Einkäufer ist das Verständnis der Incoterms für eine effiziente Verwaltung der Logistikkosten unerlässlich.

-

Marge: Die Lieferanten schlagen in der Regel eine Marge auf, um ihre Kosten zu decken und die Rentabilität zu gewährleisten. Die Margen können je nach Marktposition des Lieferanten und der Einzigartigkeit des Produkts stark variieren.

Welche Faktoren beeinflussen die Preise für den Austausch von Scheinwerfern?

Die endgültigen Kosten für den Austausch von Scheinwerfern für B2B-Kunden können von mehreren Preisfaktoren beeinflusst werden:

-

Volumen und Mindestbestellmenge (MOQ): Großeinkäufe können zu erheblichen Preisnachlässen führen, so dass es für Unternehmen kostengünstiger ist, Scheinwerferkomponenten in größeren Mengen zu beschaffen.

-

Spezifikationen und Anpassung: Sonderscheinwerfer, die für bestimmte Fahrzeuge oder Funktionen entwickelt werden, können zusätzliche Kosten verursachen. Je spezieller das Produkt ist, desto höher ist der Preis.

-

Materialqualität und Zertifizierungen: Hochwertige Materialien und Komponenten, die strengen Qualitätsstandards entsprechen, sind in der Regel teurer, bieten aber auch eine längere Lebensdauer und mehr Sicherheit.

-

Lieferantenfaktoren: Der Ruf und die Zuverlässigkeit der Lieferanten können die Preisgestaltung beeinflussen. Etablierte Lieferanten mit nachgewiesener Erfolgsbilanz verlangen möglicherweise mehr, bieten aber auch bessere Garantien und einen besseren Kundendienst.

-

Incoterms: Unterschiedliche Versandvereinbarungen können die Gesamtkosten beeinflussen. Das Verständnis von Begriffen wie FOB (Free on Board) oder CIF (Cost, Insurance, and Freight) kann Käufern helfen, ihre Logistikkosten effektiv zu verwalten.

Welche Tipps sollten Käufer für Kosteneffizienz berücksichtigen?

Für internationale Einkäufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, können verschiedene Strategien die Kosteneffizienz verbessern:

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

-

Preise aushandeln: Führen Sie Gespräche mit Lieferanten, um bessere Preise zu erzielen, insbesondere bei Großaufträgen. Der Aufbau enger Beziehungen kann oft zu günstigen Konditionen führen.

-

Gesamtbetriebskosten (TCO) bewerten: Berücksichtigen Sie nicht nur den Anschaffungspreis, sondern auch die Installationskosten, die erwartete Lebensdauer und mögliche Wartungskosten. Qualitativ hochwertige Produkte sind zwar im Vorfeld teurer, können aber auf lange Sicht Einsparungen bringen.

-

Lokale Märkte erforschen: Machen Sie sich mit der lokalen Preisdynamik und dem Wettbewerb vertraut, um sicherzustellen, dass Sie eine fundierte Kaufentscheidung treffen.

-

Bleiben Sie über die Nuancen der Preisgestaltung informiert: Beobachten Sie Trends in der Scheinwerfertechnologie und Preisunterschiede auf verschiedenen Märkten. Dies kann Aufschluss darüber geben, wann ein Kauf oder eine Nachrüstung sinnvoll ist.

Schlussfolgerung

Zusammenfassend lässt sich sagen, dass die Kosten für den Austausch von Scheinwerfern von verschiedenen Komponenten und der Marktdynamik beeinflusst werden. Wenn internationale B2B-Einkäufer diese Faktoren verstehen, können sie fundierte Entscheidungen treffen, die ihre Investitionen maximieren und die Sicherheit und Zuverlässigkeit ihrer Fahrzeugflotten gewährleisten. Berücksichtigen Sie immer die langfristigen Auswirkungen Ihrer Einkäufe, um eine optimale Kosteneffizienz zu erreichen.

Analyse der Alternativen: Vergleich der Kosten für einen Scheinwerferwechsel mit anderen Lösungen

Alternativen zu den Kosten für den Austausch von Scheinwerfern erforschen

Wenn man die Kosten für den Austausch von Scheinwerfern in Betracht zieht, ist es wichtig, verschiedene Alternativen zu prüfen, die ähnliche Ziele erreichen können, sei es die Verbesserung der Sichtbarkeit, die Gewährleistung der Sicherheit oder die Erhaltung der Fahrzeugästhetik. Das Wissen um diese Alternativen hilft B2B-Käufern, fundierte Entscheidungen auf der Grundlage von Leistung, Kosten und Zweckmäßigkeit zu treffen.

| Vergleichsaspekt | Wie viel kostet der Austausch von Scheinwerfern? | Scheinwerfer-Restaurierungssätze | LED-Umrüstsätze |

|---|---|---|---|

| Leistung | Je nach Typ unterschiedlich; für die Sicherheit unerlässlich | Stellt die Klarheit wieder her; begrenzt auf die Leistung der vorhandenen Glühlampen | Hervorragende Helligkeit und Effizienz |

| Kosten | $30 bis $4,000+ (Glühlampe oder Baugruppe) | $10 bis $50 pro Satz | $50 bis $300+ |

| Einfache Implementierung | Mäßig; kann professionelle Hilfe erfordern | Einfacher DIY-Prozess | Mäßig; einige erfordern technische Kenntnisse |

| Wartung | Regelmäßiger Austausch erforderlich | Erfordert eine erneute Anwendung | Langlebig (bis zu 40.000 Stunden) |

| Bester Anwendungsfall | Unverzichtbar für funktionsfähige Fahrzeuge | Kostengünstig für gealterte Linsen | Nachrüstung von Fahrzeugbeleuchtungssystemen |

Was sind Scheinwerfer-Restaurationssätze und ihre Vor- und Nachteile?

Scheinwerfer-Restaurationssätze sind eine kostengünstige Lösung, um beschlagene oder verfärbte Scheinwerfergläser aufzuhellen. Diese Kits enthalten in der Regel Schleifpapier, Politur und ein Versiegelungsmittel. Einer der Hauptvorteile sind die niedrigen Kosten, die in der Regel zwischen $10 und $50 liegen und somit auch für preisbewusste Käufer erschwinglich sind. Darüber hinaus sind Restaurationssets einfach in der Anwendung und ermöglichen es den Nutzern, mit minimalen technischen Kenntnissen Ergebnisse zu erzielen. Sie verbessern jedoch nur die Leistung des vorhandenen Scheinwerfers und beheben möglicherweise nicht die zugrunde liegenden Probleme, wie z. B. den Verschleiß der Glühbirne oder elektrische Probleme.

Wie unterscheiden sich LED-Umrüstsätze von herkömmlichen Austauschgeräten?

LED-Umrüstsätze bieten eine moderne Alternative zu herkömmlichen Scheinwerfern und sorgen für mehr Helligkeit und Energieeffizienz. Die Kosten für diese Kits liegen in der Regel zwischen $50 und $300, je nach Fahrzeugtyp und Qualität der Komponenten. LED-Leuchten halten deutlich länger als Halogen- oder HID-Lampen, oft bis zu 40.000 Stunden. Der Einbau kann jedoch komplexer sein und erfordert manchmal professionelle Hilfe oder technische Kenntnisse. Außerdem verbessern sie zwar die Sichtbarkeit, aber die Kompatibilität mit älteren Fahrzeugen kann ein Problem darstellen.

Die richtige Wahl für Ihre Bedürfnisse treffen

Bei der Entscheidung zwischen dem Austausch von Scheinwerfern und ihren Alternativen sollten B2B-Käufer ihre spezifischen Bedürfnisse berücksichtigen, einschließlich Kostenbeschränkungen, Fahrzeugtypen und gewünschte Leistungsergebnisse. Für Unternehmen mit Flottenfahrzeugen kann die Investition in LED-Umrüstsätze langfristige Einsparungen und verbesserte Sicherheit bieten. Umgekehrt können Scheinwerfer-Restaurierungssätze für Unternehmen mit älteren Fahrzeugen eine praktische kurzfristige Lösung sein. Letztendlich führt die Abwägung der Vor- und Nachteile jeder Option zu einer optimalen Entscheidung, die auf die individuellen Anforderungen des jeweiligen Käufers zugeschnitten ist.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Wesentliche technische Eigenschaften und Fachterminologie für Wie viel kostet ein Scheinwerferwechsel?

Was sind die wichtigsten technischen Eigenschaften, die die Kosten für den Austausch von Scheinwerfern beeinflussen?

Wenn man den Austausch von Scheinwerfern in Erwägung zieht, können verschiedene technische Eigenschaften die Gesamtkosten und die Leistung der betreffenden Komponenten erheblich beeinflussen. Für B2B-Einkäufer, die eine fundierte Kaufentscheidung treffen wollen, ist es wichtig, diese Spezifikationen zu verstehen.

1. Glühlampentyp und Technologie

Für Scheinwerfer können verschiedene Glühlampentypen verwendet werden, darunter Halogen, HID (High-Intensity Discharge) und LED (Light Emitting Diode). Halogenlampen sind in der Regel am preiswertesten, haben aber eine kürzere Lebensdauer (etwa 500-1.000 Stunden). Im Gegensatz dazu bieten HID- und LED-Optionen eine bessere Sicht und eine längere Lebensdauer (bis zu 40.000 Stunden bei LEDs), sind aber auch teurer. Die Wahl des Lampentyps wirkt sich direkt auf die Austauschkosten und die langfristigen Wartungskosten aus.

2. Design der Scheinwerfereinheit

Die Konstruktion der Scheinwerferbaugruppe kann sich von Fahrzeugmodell zu Fahrzeugmodell erheblich unterscheiden. Einige moderne Fahrzeuge verfügen über versiegelte Einheiten, die bei Ausfall eines Teils komplett ausgetauscht werden müssen, was zu höheren Kosten führt. Alternativ dazu ermöglichen modulare Konstruktionen den Austausch einzelner Komponenten, was die Gesamtkosten senken kann. Um die Kosten für den Austausch genau abschätzen zu können, ist es wichtig, die Konstruktion der Baugruppe zu kennen.

3. Werkstoffgüte

Die für die Scheinwerfer verwendeten Materialien, wie Polycarbonat oder Glas, können die Haltbarkeit und Leistung beeinflussen. Hochwertige Materialien widerstehen Kratzern und Beschädigungen besser, was zu längeren Austauschintervallen führen kann. Für B2B-Käufer kann die Investition in hochwertigere Materialien langfristig zu Einsparungen führen, da die Notwendigkeit eines häufigen Austauschs minimiert wird.

4. Komplexität der Installation

Die Komplexität des Einbaus variiert je nach Fahrzeug und Art des zu ersetzenden Scheinwerfers. Einige Scheinwerfersysteme erfordern den Ausbau anderer Komponenten, wie z. B. des vorderen Stoßfängers, was die Arbeitskosten erheblich erhöhen kann. Die Kenntnis der Einbauanforderungen hilft den Käufern, bei der Budgetplanung für den Austausch von Scheinwerfern mögliche zusätzliche Ausgaben zu berücksichtigen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Welche allgemeinen Begriffe sind beim Austausch von Scheinwerfern unbedingt zu verstehen?

In der Kfz-Ersatzteilbranche kann die Vertrautheit mit einer bestimmten Terminologie die Kommunikation verbessern und den Beschaffungsprozess rationalisieren. Hier sind einige gängige Begriffe im Zusammenhang mit dem Austausch von Scheinwerfern:

1. OEM (Originalgerätehersteller)

OEM bezieht sich auf Teile, die vom Fahrzeughersteller oder dessen autorisierten Zulieferern hergestellt werden. Diese Komponenten sind so konzipiert, dass sie den Originalspezifikationen des Fahrzeugs entsprechen und Kompatibilität und Zuverlässigkeit gewährleisten. B2B-Käufer bevorzugen OEM-Teile oft wegen ihrer Qualitätssicherung und Garantieabdeckung.

2. MOQ (Mindestbestellmenge)

MOQ ist die kleinste Menge eines Produkts, die ein Lieferant zu verkaufen bereit ist. Für B2B-Einkäufer ist es wichtig, die MOQ zu verstehen, da sie sich auf die Bestandsverwaltung und die Gesamtbeschaffungskosten auswirkt. Einkäufer sollten ihren Bedarf abschätzen, um mit Lieferanten günstige Konditionen auszuhandeln.

3. RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preise und Bedingungen für bestimmte Produkte zu erfragen. Beim Austausch von Scheinwerfern kann eine Anfrage Unternehmen helfen, die Kosten verschiedener Lieferanten zu vergleichen und fundierte Kaufentscheidungen zu treffen.

4. Incoterms (Internationale Handelsklauseln)

Incoterms sind international anerkannte Begriffe, die die Verantwortlichkeiten von Käufern und Verkäufern bei internationalen Transaktionen festlegen. Sie klären, wer für Versand, Versicherung und Zölle verantwortlich ist, was für B2B-Käufer, die Scheinwerferkomponenten aus anderen Ländern importieren, von entscheidender Bedeutung ist.

5. Ersatzteile

Aftermarket-Teile sind Komponenten, die von anderen Unternehmen als dem Originalhersteller hergestellt werden. Sie können preiswerter sein und eine breitere Palette von Optionen bieten. Die Qualität kann jedoch variieren, und B2B-Käufer sollten die Zuverlässigkeit und die Garantiebestimmungen prüfen, wenn sie Ersatzteile auf dem Ersatzteilmarkt in Betracht ziehen.

Durch das Verständnis dieser technischen Eigenschaften und der Fachterminologie können B2B-Einkäufer die Komplexität der Kosten für den Austausch von Scheinwerfern besser durchschauen und sicherstellen, dass sie fundierte Entscheidungen treffen, die ihren betrieblichen Anforderungen entsprechen.

Marktdynamik und Beschaffungstrends in der Branche "Wie viel kostet ein Scheinwerferwechsel?

Wie wirkt sich die aktuelle Marktdynamik auf die Kosten für den Austausch von Scheinwerfern aus?

Der Markt für den Austausch von Scheinwerfern unterliegt erheblichen Veränderungen, die durch technologische Fortschritte, gesetzliche Änderungen und Verbraucherpräferenzen bedingt sind. Weltweit tendiert der Automobilsektor zu anspruchsvolleren Beleuchtungssystemen, einschließlich LED- und HID-Technologien, die eine höhere Leistung bieten, aber auch höhere Kosten verursachen. Für internationale B2B-Einkäufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist das Verständnis dieser Dynamik entscheidend für effektive Beschaffungsstrategien.

Einer der wichtigsten Trends ist die wachsende Nachfrage nach hochwertigen, langlebigen Scheinwerfersystemen, die die Fahrzeugsicherheit erhöhen. Die Käufer sind zunehmend an Produkten interessiert, die nicht nur die gesetzlichen Normen erfüllen, sondern auch Langlebigkeit und Leistungseffizienz bieten. Dieser Wandel ist zum Teil auf die strengeren Fahrzeugsicherheitsvorschriften zurückzuführen, die in verschiedenen Märkten eingeführt wurden und die Hersteller zwingen, in fortschrittlichere Technologien zu investieren.

Darüber hinaus hat das Aufkommen von E-Commerce-Plattformen die Beschaffungsstrategien verändert und B2B-Einkäufern den Zugang zu einer größeren Auswahl an Lieferanten und Produkten ermöglicht. Dieser Trend erleichtert Preisvergleiche und stärkt die Verhandlungsposition, insbesondere bei Großeinkäufen. Allerdings müssen die Einkäufer auch Herausforderungen bewältigen, die mit Unterbrechungen der Lieferkette und schwankenden Preisen aufgrund von Rohstoffkosten zusammenhängen, insbesondere bei komplexen Baugruppen, die möglicherweise spezielle Komponenten erfordern.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Wie wichtig sind Nachhaltigkeit und ethische Beschaffung in der Scheinwerfer-Ersatzteilbranche?

In den letzten Jahren ist das Thema Nachhaltigkeit für B2B-Einkäufer im Automobilsektor, einschließlich derjenigen, die sich mit dem Austausch von Scheinwerfern befassen, zu einem vorrangigen Anliegen geworden. Die Umweltauswirkungen von Herstellungsverfahren und Materialien, die bei der Scheinwerferproduktion verwendet werden, stehen auf dem Prüfstand. Von den Unternehmen wird zunehmend erwartet, dass sie nachhaltige Praktiken anwenden und ihre Lieferketten transparent gestalten.

Bei der ethischen Beschaffung geht es nicht nur um die Einhaltung von Vorschriften; sie ist zu einem Wettbewerbsvorteil geworden. Einkäufer sind eher geneigt, mit Lieferanten zusammenzuarbeiten, die sich dafür einsetzen, ihren ökologischen Fußabdruck zu verringern und umweltfreundliche Materialien zu verwenden. Zertifizierungen wie ISO 14001 oder die Verwendung von recycelten Materialien bei der Herstellung können Kaufentscheidungen erheblich beeinflussen.

Außerdem werden die Verbraucher immer umweltbewusster und verlangen Produkte, die mit ihren Werten übereinstimmen. Für B2B-Einkäufer bedeutet dies, Scheinwerfer zu beschaffen, die nicht nur den Sicherheitsvorschriften entsprechen, sondern auch die Umweltbelastung minimieren. Investitionen in nachhaltige Produkte können den Ruf der Marke verbessern und die Kundenbindung fördern, was sie zu einem entscheidenden Faktor im Beschaffungsprozess macht.

Was ist der historische Kontext der Scheinwerfertechnologie und ihr Einfluss auf die Ersatzteilkosten?

Die Entwicklung der Scheinwerfertechnologie hat die Austauschkosten und Beschaffungsstrategien erheblich beeinflusst. Traditionell waren Glühbirnen der Standard, da sie einfach und kostengünstig waren. Mit der Einführung von Halogen-, HID- und LED-Technologien hat sich die Landschaft jedoch verändert. Diese modernen Optionen bieten eine bessere Beleuchtung und Energieeffizienz, sind jedoch mit höheren Preisen und komplexen Installationsanforderungen verbunden.

Mit der Weiterentwicklung des Fahrzeugdesigns stieg auch der Bedarf an integrierten und hochentwickelten Beleuchtungssystemen. Viele moderne Fahrzeuge verfügen über versiegelte Scheinwerfereinheiten, die nicht vom Benutzer gewartet werden können, d. h. es müssen ganze Einheiten und nicht nur die Glühbirne ausgetauscht werden. Dieser Wandel hat zu höheren Kosten für Teile und Arbeit geführt, was einen strategischen Ansatz bei der Beschaffung erforderlich macht.

Für B2B-Einkäufer ist es wichtig, den historischen Kontext der Scheinwerfertechnologie zu verstehen, um die aktuelle Marktdynamik zu steuern. Das Wissen darüber, wie sich diese Veränderungen auf die Preisgestaltung und die Verfügbarkeit auswirken, kann zu besseren Kaufentscheidungen führen und dabei helfen, langfristig potenzielle Kosteneinsparungsmöglichkeiten zu erkennen.

Zusammenfassend lässt sich sagen, dass der Markt für Ersatzscheinwerfer ein komplexer und sich entwickelnder Sektor ist, der von internationalen B2B-Einkäufern verlangt, dass sie über technologische Fortschritte, Nachhaltigkeitstrends und historische Einflüsse informiert bleiben, um strategische Beschaffungsentscheidungen treffen zu können.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch von Scheinwerfern

-

Wie ermittle ich die Kosten für den Austausch von Scheinwerfern für mein Fahrzeug?

Die Kosten für den Austausch von Scheinwerfern variieren je nach Fahrzeugmarke und -modell, dem Typ der Scheinwerferbirne (Halogen, HID oder LED) und der Frage, ob nur die Birne oder die gesamte Baugruppe ausgetauscht werden soll, erheblich. Für den Austausch einer einfachen Glühbirne liegen die Kosten normalerweise zwischen $10 und $100. Wenn jedoch die gesamte Scheinwerferbaugruppe ausgetauscht werden muss, können sich die Kosten auf mehrere Tausend Dollar belaufen, insbesondere bei Luxusfahrzeugen mit modernen Beleuchtungssystemen. Erkundigen Sie sich in jedem Fall im Handbuch Ihres Fahrzeugs oder bei einem seriösen Anbieter nach den genauen Preisen. -

Welches ist der beste Scheinwerferbirnen-Typ für mein Fahrzeug?

Die Wahl der besten Scheinwerferbirne hängt von den technischen Daten Ihres Fahrzeugs, den Fahrbedingungen und Ihren persönlichen Vorlieben ab. Halogenglühlampen sind erschwinglich, haben aber eine kürzere Lebensdauer. HID-Lampen bieten eine größere Helligkeit, sind aber teurer und erfordern spezielle Halterungen. LED-Lampen halten am längsten und bieten eine bessere Sicht, können aber teuer sein. Schauen Sie im Handbuch Ihres Fahrzeugs nach oder wenden Sie sich an Ihren Lieferanten, um den geeigneten Lampentyp zu bestimmen und die Kompatibilität mit dem Beleuchtungssystem Ihres Fahrzeugs sicherzustellen. -

Was sind die wichtigsten Faktoren, die bei der internationalen Beschaffung von Ersatzscheinwerfern zu beachten sind?

Achten Sie bei der Beschaffung von Ersatzscheinwerfern auf Faktoren wie die Einhaltung internationaler Sicherheitsstandards, die Kompatibilität mit lokalen Vorschriften und die Zuverlässigkeit der Lieferanten. Überprüfen Sie, ob die Lieferanten detaillierte Produktspezifikationen und Zertifizierungen vorlegen. Beurteilen Sie außerdem die Logistik, einschließlich der Versandzeiten, Zollbestimmungen und möglicher Zölle. Wenn Sie mit Lieferanten zusammenarbeiten, die Erfahrung auf Ihrem Zielmarkt haben, können Sie den Beschaffungsprozess rationalisieren und sicherstellen, dass Sie Qualitätsprodukte erhalten. -

Wie kann ich die Lieferanten für Scheinwerferersatzteile überprüfen?

Um Lieferanten zu überprüfen, sollten Sie zunächst ihren Ruf anhand von Bewertungen, Erfahrungsberichten und Branchenreferenzen recherchieren. Achten Sie auf Zertifizierungen, die auf die Einhaltung von Qualitäts- und Sicherheitsstandards hinweisen, wie z. B. ISO- oder DOT-Zertifizierungen. Fordern Sie außerdem Produktmuster an und beurteilen Sie die Qualität aus erster Hand. Nehmen Sie direkten Kontakt auf, um die Reaktionsfähigkeit und Zuverlässigkeit des Unternehmens zu prüfen, und berücksichtigen Sie seine Erfahrung im internationalen Handel, insbesondere bei der Beschaffung aus Regionen wie Afrika oder Südamerika. -

Wie lauten die typischen Zahlungsbedingungen für B2B-Transaktionen bei der Beschaffung von Ersatzscheinwerfern?

Die Zahlungsbedingungen können je nach Lieferant und Region sehr unterschiedlich sein. Üblich sind jedoch Netto 30- oder Netto 60-Bedingungen, die eine Zahlung innerhalb von 30 oder 60 Tagen nach Rechnungsdatum ermöglichen. Manche Lieferanten verlangen eine Anzahlung im Voraus, insbesondere bei Großaufträgen. Es ist von entscheidender Bedeutung, die akzeptierten Zahlungsarten (z. B. Banküberweisung, Kreditbedingungen) und etwaige zusätzliche Gebühren zu klären. Eine klare Vereinbarung über die Zahlungsbedingungen hilft, Missverständnisse zu vermeiden und sorgt für reibungslose Transaktionen. -

Was ist die Mindestbestellmenge (MOQ) für Scheinwerferersatzteile?

Die Mindestbestellmenge für Scheinwerfer-Ersatzteile kann je nach Lieferant, Produkttyp und Ihren Verhandlungen stark variieren. Einige Lieferanten haben eine niedrige Mindestbestellmenge von 10-50 Stück, während andere, insbesondere für spezielle oder hochtechnische Baugruppen, Bestellungen in Höhe von Hunderten von Stück verlangen können. Es ist ratsam, Ihren spezifischen Bedarf im Vorfeld mit den Lieferanten zu besprechen, um deren Flexibilität bei den Mindestbestellmengen zu ermitteln und mögliche Rabatte für größere Bestellungen zu prüfen. -

Wie kann ich bei der Beschaffung von Ersatzscheinwerfern die Qualität sicherstellen?

Um die Qualität zu gewährleisten, sollten Sie Unterlagen über den Herstellungsprozess, die verwendeten Materialien und die Einhaltung internationaler Sicherheitsstandards anfordern. Die Durchführung von Inspektionen oder Audits durch Dritte in den Werken des Lieferanten kann ebenfalls zur Überprüfung der Produktqualität beitragen. Ziehen Sie außerdem ein Qualitätskontrollprotokoll in Erwägung, das Produkttests bei Erhalt vorsieht, um sicherzustellen, dass die Scheinwerfer Ihren Spezifikationen und Leistungserwartungen entsprechen. -

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Ersatzscheinwerfern anstellen?

Berücksichtigen Sie bei der Einfuhr von Ersatzscheinwerfern die Versandmethoden, Laufzeiten und Kosten. Prüfen Sie je nach Dringlichkeit und Budget die Optionen für Luftfracht und Seefracht. Informieren Sie sich über die Zollbestimmungen in Ihrem Land, einschließlich der eventuell anfallenden Einfuhrzölle und Steuern. Suchen Sie sich einen zuverlässigen Logistikpartner, der die Komplexität des internationalen Versands bewältigt, und stellen Sie sicher, dass er Erfahrung mit Kfz-Teilen hat, um alle spezifischen Anforderungen effektiv zu erfüllen.

Top 3 Wie viel kostet der Austausch eines Scheinwerfers Hersteller & Lieferanten Liste

1. Ford Fusion - Scheinwerfer-Glühbirnen-Wechsel

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: 2014 Ford Fusion, Austausch der linken vorderen Scheinwerferbirne, geschätzte Arbeitskosten $300 (zuzüglich der Kosten für das Teil), umfangreiche Arbeiten mit Anheben und Entfernen mehrerer Karosserieteile.

2. Honda Clarity - Austausch von Scheinwerfern

Domäne: insideevsforum.com

Registriert: 2017 (8 Jahre)

Einleitung: Der Austausch von Scheinwerfern für den Honda Clarity kostet $1500 pro Scheinwerfer, insgesamt also $3000 für beide. Die Scheinwerfer verwenden eine versiegelte Baugruppe ohne austauschbare Glühbirnen, die wahrscheinlich aus einer Reihe von LEDs besteht. Einige Nutzer vermuten, dass die Schwärzung auf trübe Linsen zurückzuführen ist, die möglicherweise poliert werden könnten. Alternative Optionen für den Kauf von Scheinwerfern sind Online-Quellen, mit Preisen um $1300 für ein Paar. ...

3. Firestone - Austausch von Scheinwerfern

Domäne: firestonecompleteautocare.com

Registriert: 2004 (21 Jahre)

Einleitung: Dieses Unternehmen, Firestone - Headlight Replacement, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

Strategische Beschaffung Schlussfolgerung und Ausblick für Wie viel kostet ein Scheinwerferwechsel?

Zusammenfassend lässt sich sagen, dass es für B2B-Einkäufer im Automobilsektor wichtig ist, die Komplexität der Kosten für den Austausch von Scheinwerfern zu verstehen. Die Preisspanne für Scheinwerferbirnen variiert erheblich - von $10 für einfache Halogenbirnen bis zu über $1.000 für moderne LED- oder HID-Baugruppen. Die Arbeitskosten erschweren die Budgetplanung zusätzlich, da die Kosten für den professionellen Einbau je nach Komplexität der Aufgabe zwischen $30 und mehreren hundert Dollar liegen.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Eine strategische Beschaffung kann bei der Verwaltung dieser Kosten erhebliche Vorteile bringen. Durch den Aufbau von Beziehungen zu zuverlässigen Lieferanten, das Aushandeln von Großeinkaufsverträgen und das Verfolgen des technischen Fortschritts in der Kfz-Beleuchtung können Unternehmen ihre Ausgaben optimieren und gleichzeitig Sicherheit und Konformität gewährleisten.

Da sich der Automobilmarkt vor allem in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa ständig weiterentwickelt, ist es für internationale Einkäufer von entscheidender Bedeutung, über die neuesten Trends in der Scheinwerfertechnologie und Preisgestaltung informiert zu sein. Die Investition in hochwertige Teile erhöht nicht nur die Fahrzeugsicherheit, sondern trägt auch zu langfristigen Kosteneinsparungen bei. Nutzen Sie die Gelegenheit, Ihre Beschaffungsstrategien noch heute zu verfeinern, um sicherzustellen, dass Ihr Unternehmen in diesem dynamischen Umfeld wettbewerbsfähig bleibt.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustratives Bild zu Wie viel kostet der Austausch von Scheinwerfern?

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.