Introduction: Navigating the Global Market for car alternator parts

In the fast-evolving automotive landscape, sourcing high-quality car alternator parts poses a significant challenge for international B2B buyers. As the backbone of a vehicle’s electrical system, these components are crucial for converting mechanical energy into electrical energy, powering everything from the ignition system to onboard electronics. This guide serves as a comprehensive resource for understanding the diverse types of alternator parts, their applications across various vehicle models, and the intricacies of supplier vetting.

Navigating the global market requires a keen eye for quality and cost, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. With fluctuating market conditions and varying standards of manufacturing, the need for reliable sourcing partners cannot be overstated. This guide empowers B2B buyers by providing actionable insights into evaluating suppliers, understanding pricing structures, and ensuring compliance with international quality standards.

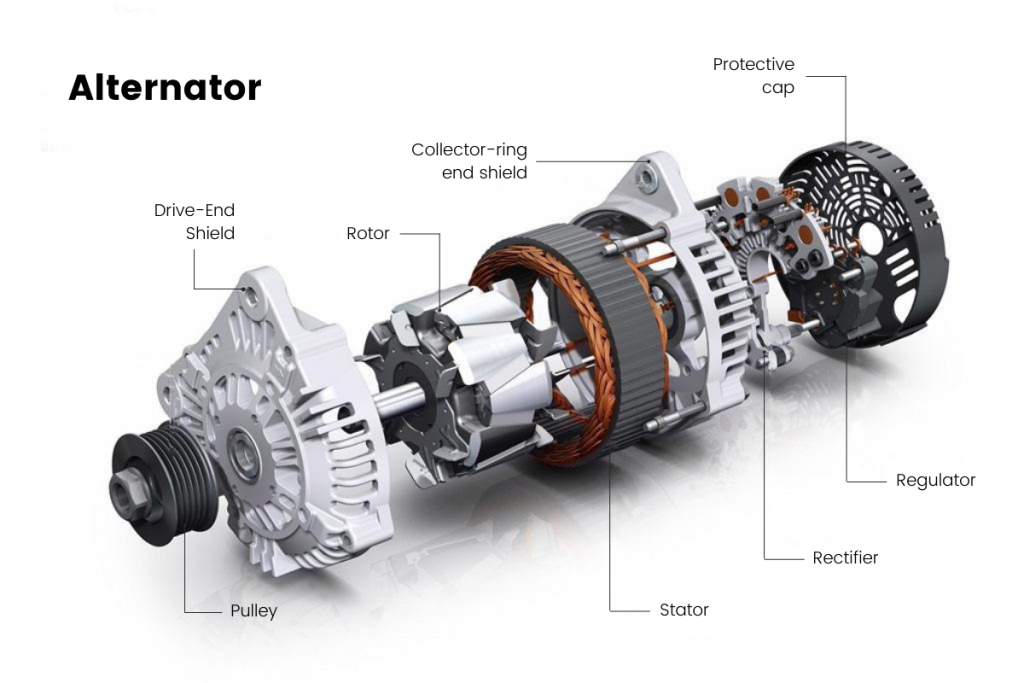

By delving into the specifics of alternator components—such as rotors, stators, rectifiers, and voltage regulators—this resource equips decision-makers with the knowledge needed to make informed purchasing choices. Whether you are looking to streamline your supply chain or enhance your product offerings, this guide will illuminate the path to successful procurement of car alternator parts in the global market.

Inhaltsverzeichnis

- Top 3 Car Alternator Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car alternator parts

- Understanding car alternator parts Types and Variations

- Key Industrial Applications of car alternator parts

- 3 Common User Pain Points for ‘car alternator parts’ & Their Solutions

- Strategic Material Selection Guide for car alternator parts

- In-depth Look: Manufacturing Processes and Quality Assurance for car alternator parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator parts’

- Comprehensive Cost and Pricing Analysis for car alternator parts Sourcing

- Alternatives Analysis: Comparing car alternator parts With Other Solutions

- Essential Technical Properties and Trade Terminology for car alternator parts

- Navigating Market Dynamics and Sourcing Trends in the car alternator parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car alternator parts

- Strategic Sourcing Conclusion and Outlook for car alternator parts

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding car alternator parts Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Herkömmlicher Generator | Standard design with rotor and stator; uses brushes and slip rings | Automotive manufacturing, aftermarket repairs | Vorteile: Kostengünstig, weit verbreitet. Nachteile: Less efficient at high RPMs, more maintenance due to brushes. |

| Intelligenter Generator | Advanced technology with integrated voltage regulation; often includes digital interfaces | Electric vehicles, hybrids, fleet management | Vorteile: Higher efficiency, reduced emissions. Nachteile: Higher initial cost, requires compatible systems. |

| Hochleistungs-Lichtmaschine | Designed to produce more power; larger size and heavier components | Performance vehicles, heavy-duty applications | Vorteile: Supports high-energy systems, ideal for aftermarket upgrades. Nachteile: Increased weight, potential compatibility issues with standard vehicles. |

| Kompakter Wechselstromgenerator | Smaller size, lightweight design; often used in modern vehicles | OEM production, compact car manufacturing | Vorteile: Platzsparend, leicht. Nachteile: Limited power output, may not suit high-demand applications. |

| Marine-Lichtmaschine | Corrosion-resistant materials, designed for high humidity and saltwater environments | Marine applications, boat manufacturing | Vorteile: Langlebig, zuverlässig unter rauen Bedingungen. Nachteile: Higher cost, specific to marine applications. |

Was sind die wichtigsten Merkmale herkömmlicher Wechselstromgeneratoren?

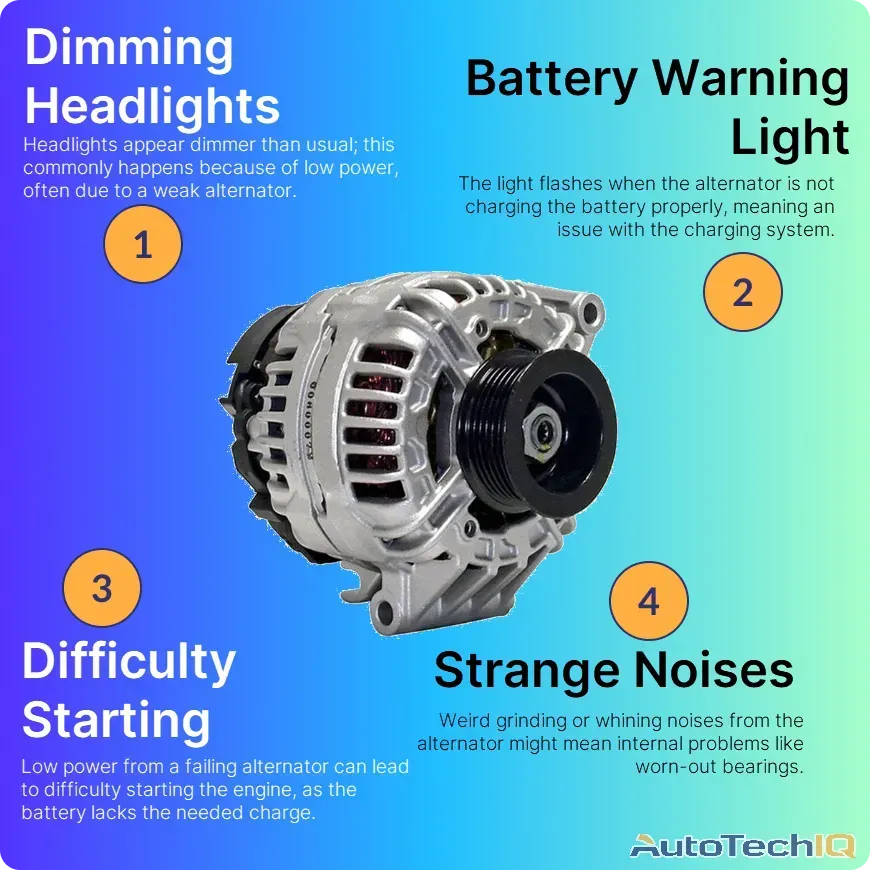

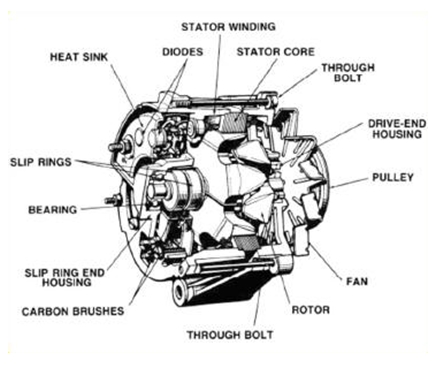

Conventional alternators are the standard choice for most vehicles, characterized by their rotor and stator design, which employs brushes and slip rings for current conduction. These components are relatively simple and cost-effective, making them suitable for automotive manufacturing and aftermarket repairs. However, buyers should be aware that while they are widely available, they require regular maintenance due to wear on the brushes, and their efficiency may decline at higher RPMs.

Wie verbessern intelligente Lichtmaschinen die Fahrzeugeffizienz?

Smart alternators represent a significant advancement in alternator technology, integrating digital interfaces and sophisticated voltage regulation. This design allows for better energy management, particularly in electric and hybrid vehicles, where efficiency is paramount. B2B buyers should consider the higher initial costs against the long-term savings in fuel and maintenance. Smart alternators are ideal for fleet management and applications requiring precise energy control, making them a valuable investment for businesses focused on sustainability.

What Makes High-Output Alternators Suitable for Performance Applications?

High-output alternators are engineered to deliver more electrical power, making them essential for performance vehicles and heavy-duty applications. These alternators are larger and heavier, designed to support high-energy systems such as advanced audio setups and additional lighting. While they provide significant benefits for aftermarket upgrades, buyers should consider the increased weight and potential compatibility issues with standard vehicles. Their ability to meet high demand makes them a popular choice among performance enthusiasts.

Why Are Compact Alternators Ideal for Modern Vehicle Designs?

Compact alternators are specifically designed for modern vehicles, prioritizing lightweight and space-saving features. Their smaller size is ideal for OEM production and compact car manufacturing, allowing for more efficient use of engine space. However, their power output is limited, which may not meet the needs of high-demand applications. B2B buyers in the automotive sector should evaluate whether the reduced size aligns with their vehicle design requirements and energy needs.

What Are the Advantages of Marine Alternators for Boat Manufacturing?

Marine alternators are built to withstand harsh marine environments, utilizing corrosion-resistant materials to ensure reliability in high humidity and saltwater conditions. These alternators are crucial for marine applications, where durability is essential. While they come at a higher cost, their resilience makes them a worthwhile investment for boat manufacturers and marine service providers. Buyers should assess the specific needs of their applications to determine the suitability of marine alternators for their operations.

Key Industrial Applications of car alternator parts

| Branche/Sektor | Specific Application of car alternator parts | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Production of electric vehicles (EVs) | Enhanced energy efficiency and battery reliability | Quality assurance, compliance with international standards, supplier reputation |

| Transport & Logistik | Fleet maintenance and repair | Reduced downtime and increased operational efficiency | Availability of parts, delivery timelines, and warranty terms |

| Erneuerbare Energien | Integration in hybrid energy systems | Sustainable energy solutions and reduced emissions | Compatibility with existing systems, supplier certifications |

| Bergbau und schwere Ausrüstung | Powering auxiliary systems in machinery | Improved equipment reliability and performance | Durability in harsh environments, sourcing from reputable manufacturers |

| Aftermarket-Dienstleistungen | Replacement parts for vehicle repairs | Kostengünstige Lösungen für die Fahrzeugwartung | Bulk purchasing options, lead times, and return policies |

How Are Car Alternator Parts Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, particularly in the production of electric vehicles (EVs), car alternator parts play a critical role. These components convert mechanical energy into electrical energy, ensuring efficient battery charging and power supply to various vehicle systems. For international buyers, especially in regions like Africa and South America, sourcing high-quality alternator parts is essential for maintaining product reliability and performance. Compliance with international standards and supplier reputation are key considerations for ensuring that the parts meet the stringent demands of modern automotive technology.

What Is the Role of Car Alternator Parts in Transportation & Logistics?

In the transportation and logistics industry, car alternator parts are vital for fleet maintenance and repair. These components ensure that vehicles remain operational by providing a reliable source of electrical power, which is critical for vehicle accessories and systems. Reduced downtime translates to increased efficiency and profitability for fleet operators. B2B buyers in the Middle East and Europe must consider the availability of parts, delivery timelines, and warranty terms to mitigate risks associated with fleet operations.

How Do Car Alternator Parts Contribute to Renewable Energy Solutions?

Car alternator parts are increasingly being integrated into hybrid energy systems, contributing to renewable energy solutions. They help in efficiently converting mechanical energy from renewable sources into electrical energy, enhancing system reliability and reducing emissions. For businesses in Europe and the Middle East focusing on sustainability, sourcing compatible alternator components is crucial. Buyers should prioritize suppliers that offer certifications and demonstrate compatibility with existing energy systems to ensure seamless integration.

Why Are Car Alternator Parts Important in Mining & Heavy Equipment?

In the mining and heavy equipment sector, car alternator parts are essential for powering auxiliary systems in machinery. These parts enhance the reliability and performance of heavy equipment, which is often subjected to harsh operating conditions. B2B buyers in Africa and South America must prioritize sourcing durable components that can withstand extreme environments. Partnering with reputable manufacturers that offer robust warranties can help ensure long-term performance and reduce maintenance costs.

What Is the Importance of Car Alternator Parts in Aftermarket Services?

In the aftermarket services industry, car alternator parts are critical for vehicle repairs and maintenance. They provide cost-effective solutions that ensure vehicles operate efficiently and reliably. For international buyers, especially in regions with diverse vehicle models, bulk purchasing options and favorable return policies are important considerations. This ensures that businesses can maintain a steady supply of parts to meet customer demands while minimizing inventory risks.

3 Common User Pain Points for ‘car alternator parts’ & Their Solutions

Scenario 1: Sourcing High-Quality Alternator Parts for Diverse Markets

Das Problem: B2B buyers often struggle with sourcing high-quality car alternator parts that meet the specific standards and requirements of different regional markets. Factors such as varying quality standards, compatibility issues with local vehicle models, and the potential for counterfeit parts can complicate procurement. For buyers in regions like Africa and South America, where aftermarket parts may not always align with OEM specifications, the risk of purchasing subpar components can lead to increased vehicle downtime and repair costs.

Die Lösung: To address these challenges, it is crucial for buyers to establish relationships with reputable suppliers who have a proven track record in the automotive parts industry. Conduct thorough research on suppliers, looking for those who provide certifications and quality assurance documentation. Additionally, consider sourcing from manufacturers that offer a wide range of parts compatible with multiple vehicle brands and models. Utilizing online platforms with user reviews and ratings can help in identifying reliable suppliers. Finally, engage in direct communication with suppliers to clarify specifications and compatibility, ensuring that the parts you purchase meet the necessary quality standards for your target market.

Scenario 2: Understanding the Technical Specifications of Alternator Components

Das Problem: Many B2B buyers lack a comprehensive understanding of the technical specifications and functions of various alternator components, such as voltage regulators, rectifiers, and slip rings. This knowledge gap can lead to misordering parts, which not only affects inventory management but also impacts customer satisfaction when the wrong parts are delivered. In regions with complex automotive ecosystems, this issue can be exacerbated by the diversity of vehicle technologies in use.

Die Lösung: To mitigate this issue, buyers should invest in training sessions or workshops that focus on the technical aspects of alternator parts. Collaborating with manufacturers or industry experts to conduct these sessions can provide valuable insights into the specifications and functions of each component. Additionally, creating detailed product catalogs with technical information and diagrams can serve as a reference guide for your team. Utilizing digital tools, such as online databases or apps that provide real-time technical specifications, can also enhance your team’s knowledge and facilitate more informed purchasing decisions.

Scenario 3: Managing Inventory and Reducing Lead Times for Alternator Parts

Das Problem: Effective inventory management poses a significant challenge for B2B buyers dealing with car alternator parts, especially in regions where demand can fluctuate dramatically. Over-ordering can lead to excess stock and increased holding costs, while under-ordering can result in stockouts and lost sales opportunities. Moreover, long lead times from suppliers can exacerbate these issues, particularly for businesses that rely on quick turnaround times to meet customer demands.

Die Lösung: Implementing an inventory management system that utilizes demand forecasting can help buyers accurately predict the required stock levels for alternator parts. By analyzing historical sales data and market trends, businesses can make more informed decisions about inventory purchases. Establishing strategic partnerships with suppliers that offer just-in-time delivery can also minimize lead times and reduce the need for large inventory holdings. Additionally, consider diversifying your supplier base to include local and international options, which can provide flexibility and faster response times to market changes. Regularly reviewing and adjusting your inventory strategy based on sales performance and supplier capabilities will ensure that your business remains agile in the face of changing demand.

Strategic Material Selection Guide for car alternator parts

When selecting materials for car alternator parts, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of three common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse markets.

What are the Key Properties of Aluminum for Alternator Parts?

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent thermal conductivity. It can withstand high temperatures, making it suitable for the heat generated during operation. Aluminum also exhibits good corrosion resistance, particularly when anodized, which is crucial for longevity in various environmental conditions.

Vor- und Nachteile: The primary advantage of aluminum is its low weight, which contributes to overall vehicle efficiency. Additionally, it is relatively inexpensive compared to other metals. However, aluminum can be less durable than steel, particularly under high-stress conditions, which may lead to structural failure over time.

Auswirkungen auf die Anwendung: Aluminum’s thermal properties ensure efficient heat dissipation, which is vital for maintaining the performance of the alternator. It is compatible with various media, including automotive fluids, making it a versatile choice.

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards such as ASTM and DIN for aluminum grades. In markets like Africa and South America, where road conditions can be harsh, selecting a high-grade aluminum alloy may be beneficial.

Why is Copper Preferred for Electrical Components in Alternators?

Copper is the preferred material for electrical components such as windings, slip rings, and brushes due to its excellent electrical conductivity. It can handle high currents and has a high melting point, making it suitable for the demanding environment within an alternator.

Vor- und Nachteile: The key advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is more expensive than aluminum and can be prone to corrosion if not properly insulated, which may affect longevity.

Auswirkungen auf die Anwendung: Copper’s high conductivity is essential for effective power generation and distribution within the alternator. It is compatible with various electrical systems, ensuring reliable performance.

Überlegungen für internationale Käufer: Buyers must be aware of copper pricing fluctuations and consider sourcing strategies. Compliance with electrical standards and regulations in different regions, such as IEC standards in Europe, is crucial for ensuring product acceptance.

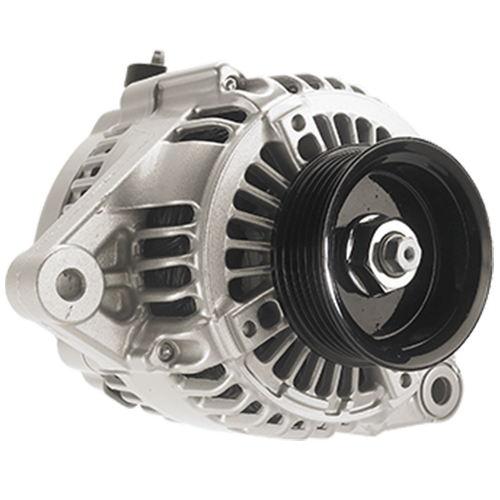

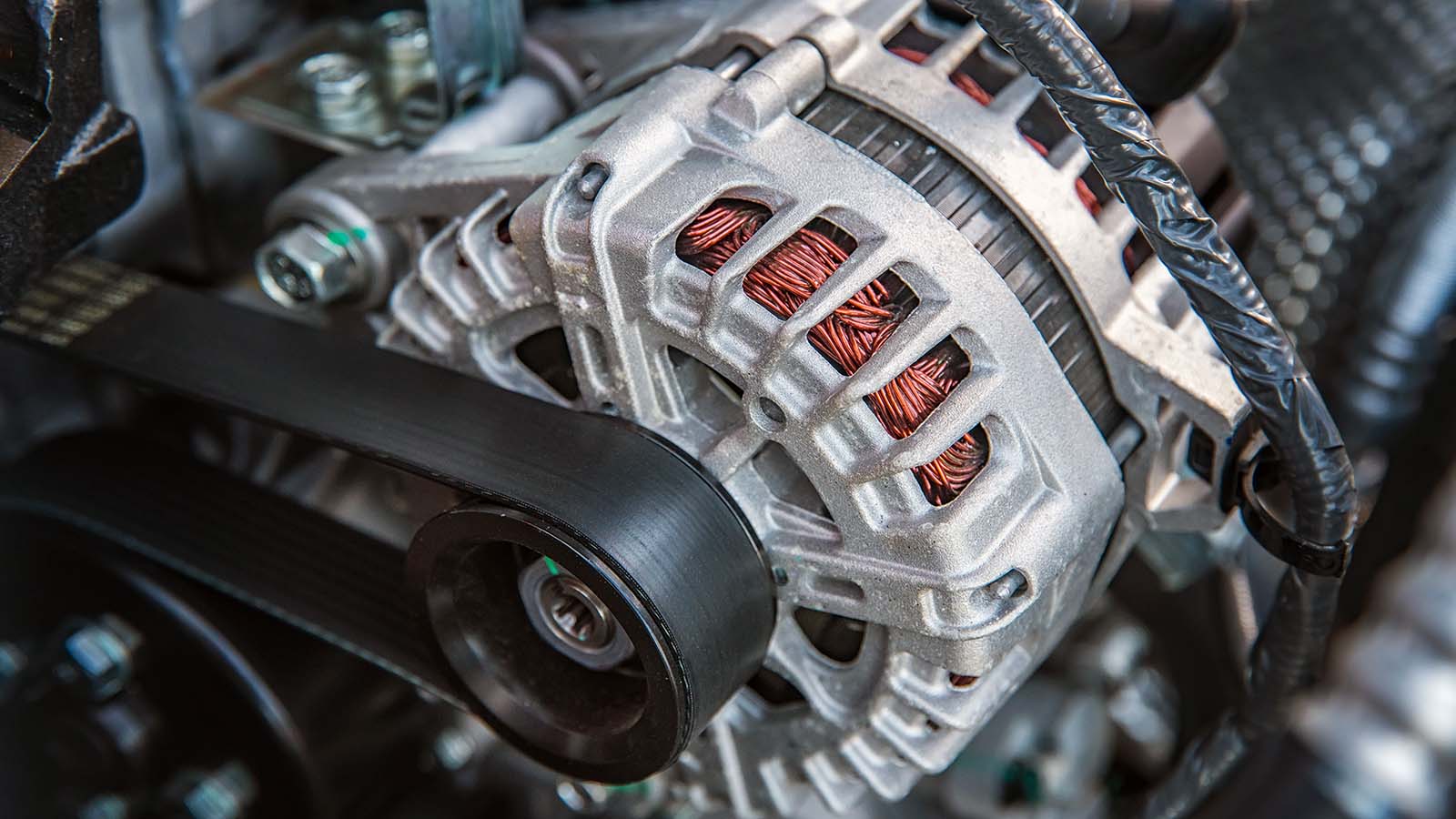

Illustrative image related to car alternator parts

How Does Steel Contribute to the Durability of Alternator Components?

Steel is commonly used for internal components like the rotor shaft and bearings due to its strength and durability. It can withstand high mechanical stress and is less likely to deform under load compared to lighter materials.

Vor- und Nachteile: Steel’s primary advantage is its robustness, which enhances the overall durability of the alternator. However, it is heavier than aluminum and can be more expensive to manufacture due to machining requirements.

Auswirkungen auf die Anwendung: The strength of steel makes it suitable for components that experience significant wear and tear. It is compatible with various automotive environments, including high-temperature and high-vibration conditions.

Illustrative image related to car alternator parts

Überlegungen für internationale Käufer: Buyers should consider the availability of high-quality steel grades that comply with international standards. In regions with high humidity, such as parts of the Middle East, corrosion-resistant coatings may be necessary.

What Role Does Plastic Play in Modern Alternator Design?

Plastic is increasingly used for components like housings and insulators due to its lightweight and insulating properties. It can withstand moderate temperatures and is resistant to corrosion, making it a viable alternative to metals in specific applications.

Vor- und Nachteile: The main advantage of plastic is its low weight and cost-effectiveness. However, it may not withstand extreme temperatures or mechanical stress as well as metals, which could limit its application in high-performance alternators.

Auswirkungen auf die Anwendung: Plastic components can reduce the overall weight of the alternator, contributing to fuel efficiency. They are suitable for non-load-bearing applications where insulation is required.

Überlegungen für internationale Käufer: Buyers should ensure that the plastics used meet relevant safety and performance standards, particularly in automotive applications. In regions with varying climates, selecting high-temperature-resistant plastics is essential.

Illustrative image related to car alternator parts

Summary Table of Material Selection for Car Alternator Parts

| Material | Typical Use Case for car alternator parts | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Outer housing | Lightweight and excellent thermal conductivity | Weniger haltbar unter hoher Belastung | Mittel |

| Kupfer | Electrical windings and slip rings | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und Korrosionsanfälligkeit | Hoch |

| Stahl | Rotor shaft and bearings | Hohe Festigkeit und Haltbarkeit | Heavier and more expensive to manufacture | Mittel |

| Kunststoff | Non-load-bearing housings and insulators | Leicht und kostengünstig | Begrenzte Temperatur- und Belastbarkeit | Niedrig |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in car alternator parts, enabling informed purchasing decisions that align with performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for car alternator parts

What Are the Key Stages in the Manufacturing Process for Car Alternator Parts?

The manufacturing process for car alternator parts is a multi-stage endeavor that requires precision and adherence to international standards. This process typically includes material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process involves sourcing high-quality raw materials, primarily aluminum for the housing and copper for windings. Suppliers often conduct rigorous audits to ensure the materials meet specified grades. Once sourced, materials undergo a series of treatments, such as heat treatment for aluminum and purifying processes for copper, to enhance their mechanical properties and conductivity.

Forming: What Techniques Are Used to Shape Alternator Components?

Forming techniques vary depending on the component being produced. For the aluminum housing, die-casting is commonly used, allowing for complex shapes while maintaining a lightweight structure. The rotor and stator components typically undergo stamping and machining processes to ensure precise dimensions. Advanced CNC (Computer Numerical Control) machines are often employed to achieve high accuracy, particularly for intricate parts like slip rings and rectifiers.

Assembly: How Are Components Integrated to Form a Complete Alternator?

The assembly stage is crucial for ensuring that all components work harmoniously. This process usually involves a combination of manual and automated techniques. Skilled technicians install the rotor into the stator and secure the components using torque specifications to prevent mechanical failures. Quality control checkpoints are implemented throughout this phase, ensuring that each component is correctly positioned and that electrical connections are secure.

Finishing: What Post-Production Treatments Enhance Performance?

Finishing processes include surface treatment and coating to enhance durability and corrosion resistance. Common methods such as anodizing for aluminum components and applying protective coatings help prolong the lifespan of alternator parts. Final inspections ensure that all parts meet the required aesthetic and functional standards before packaging.

What Quality Control Standards Should B2B Buyers Look For in Alternator Manufacturing?

Quality control (QC) is integral to the manufacturing of car alternator parts, particularly for international B2B buyers. Adhering to recognized standards not only assures product quality but also enhances supplier credibility.

Which International Standards Are Relevant for Car Alternator Parts?

ISO 9001 is one of the most widely recognized international quality management standards applicable to the manufacturing sector. Compliance with ISO 9001 indicates that a supplier has established a quality management system that focuses on continuous improvement and customer satisfaction. Other industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for parts used in specific automotive applications may also be relevant.

What Are the Common QC Checkpoints in the Manufacturing Process?

Die Kontrollpunkte für die Qualitätskontrolle sind strategisch über den gesamten Herstellungsprozess verteilt:

-

Eingangsqualitätskontrolle (IQC): Before production begins, incoming materials are inspected for compliance with specifications. This step ensures that only materials meeting quality standards enter the manufacturing process.

-

In-Process-Qualitätskontrolle (IPQC): During manufacturing, random samples are tested to monitor production quality. This includes dimensional checks and functional tests to identify defects early.

-

Endkontrolle (FQC): Once assembly is complete, a comprehensive final inspection is conducted. This includes electrical testing, load testing, and visual inspections to confirm that all specifications are met.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

Due diligence is essential for B2B buyers looking to establish long-term relationships with suppliers. Verification of a supplier’s quality control procedures can be accomplished through several methods:

What Are the Key Steps for Conducting Supplier Audits?

Conducting a thorough supplier audit is an effective way to assess quality control practices. This can include site visits to observe manufacturing processes, review documentation, and interview key personnel. During the audit, buyers should look for evidence of compliance with international standards, such as ISO 9001 certifications, and assess the effectiveness of the QC checkpoints outlined earlier.

How Important Are Quality Reports and Testing Documentation?

Requesting quality reports and testing documentation is vital for transparency. Suppliers should provide data on previous quality inspections, including any non-conformance reports and corrective actions taken. This information can give B2B buyers insights into the supplier’s reliability and responsiveness to quality issues.

Why Consider Third-Party Inspections for Added Assurance?

Engaging a third-party inspection service can provide an additional layer of quality assurance. These independent entities can perform random inspections and testing on-site, ensuring that the products meet international standards before shipment. This step can be particularly beneficial for buyers in regions like Africa and South America, where local supply chains may not always offer the same level of quality assurance.

What Are the Unique Quality Control Challenges for International B2B Buyers?

International B2B buyers face unique challenges in ensuring quality control, particularly when dealing with suppliers in regions like the Middle East and Europe.

How Do Cultural Differences Impact Quality Expectations?

Cultural differences can influence perceptions of quality and manufacturing standards. Buyers should be aware of these differences and establish clear communication regarding quality expectations. This may involve defining specific quality metrics and tolerances in the initial contract to avoid misunderstandings later.

What Should Buyers Know About Regulatory Compliance in Different Regions?

Regulatory compliance varies significantly by region. Buyers should familiarize themselves with local regulations affecting product standards and import requirements. For instance, CE marking is mandatory for products sold in the European market, while different certifications may apply in Africa or the Middle East.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance practices for car alternator parts is crucial for B2B buyers. By recognizing the key stages of production, adhering to international standards, and implementing robust verification methods, buyers can ensure they source high-quality products that meet their specific needs. This comprehensive approach not only protects investments but also fosters long-term relationships with reliable suppliers across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator parts’

Einführung

This practical sourcing guide is designed to assist B2B buyers in procuring car alternator parts efficiently and effectively. By following this step-by-step checklist, buyers can ensure they select high-quality components that meet their technical specifications and align with their business needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before reaching out to suppliers, clearly outline the technical specifications of the alternator parts you need. This includes details such as the type of alternator (e.g., AC or DC), voltage requirements, and compatibility with specific vehicle models.

– Überlegungen: Identify the essential components such as rotors, stators, rectifiers, and voltage regulators. Understanding these requirements will streamline communication with suppliers and prevent costly errors.

Illustrative image related to car alternator parts

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify potential suppliers who specialize in automotive parts, particularly alternator components. Utilize online directories, trade platforms, and industry-specific forums to compile a list of candidates.

– Tipp: Look for suppliers with a strong reputation in the market. Reading customer reviews and testimonials can provide insights into their reliability and product quality.

Schritt 3: Lieferantenzertifizierungen bewerten

Before moving forward, verify that suppliers hold relevant certifications and comply with international quality standards. This step is crucial for ensuring product safety and reliability.

– Key Certifications to Look For: ISO 9001, IATF 16949, and any regional certifications that may apply. Certifications can indicate a supplier’s commitment to quality and adherence to industry regulations.

Schritt 4: Detaillierte Kostenvoranschläge anfordern

Reach out to shortlisted suppliers and request detailed quotations for the alternator parts. Ensure that the quotes include pricing, lead times, minimum order quantities, and shipping options.

– What to Compare: Look for transparency in pricing and any additional costs that may arise, such as customs duties or freight charges. This will help you assess the overall cost-effectiveness of each supplier.

Schritt 5: Bewertung der Qualitätskontrollprozesse

Inquire about the quality control measures each supplier implements to ensure their products meet specified standards. Understanding their manufacturing processes and quality assurance protocols is vital for maintaining the integrity of your supply chain.

– Zu stellende Fragen: How do they test their products? What measures are in place to handle defective parts? A supplier with robust quality control can mitigate risks associated with product failures.

Schritt 6: Verify Delivery and Logistics Capabilities

Evaluate the suppliers’ logistics capabilities, including their shipping methods and delivery timelines. Timely delivery is crucial for maintaining your production schedules and meeting customer demands.

– Überlegungen: Ask about their experience with international shipping, especially if you are importing parts from regions like Asia or Europe. Understanding their logistics strategies will help you plan effectively.

Illustrative image related to car alternator parts

Schritt 7: Klare Kommunikationskanäle einrichten

Ensure that you have established clear communication channels with your chosen supplier. Effective communication is essential for addressing any issues that may arise during the procurement process.

– Best Practices: Designate a point of contact for all transactions and establish protocols for updates regarding order status, shipping, and any potential delays.

By following this checklist, B2B buyers can enhance their sourcing strategy for car alternator parts, ensuring they partner with reliable suppliers and secure high-quality components for their automotive needs.

Comprehensive Cost and Pricing Analysis for car alternator parts Sourcing

When sourcing car alternator parts, understanding the comprehensive cost structure is crucial for B2B buyers, particularly in international markets like Africa, South America, the Middle East, and Europe. This section delves into the various cost components, pricing influencers, and offers strategic tips for buyers to enhance their sourcing decisions.

What Are the Key Cost Components for Car Alternator Parts?

The cost structure for car alternator parts typically includes several critical components:

-

Materialien: The primary materials used in alternators include aluminum for the housing, copper for the windings, and various plastics and rubber for seals and insulators. The fluctuating prices of these materials can significantly impact overall costs, making it essential to monitor market trends.

-

Arbeit: Labor costs vary significantly depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality. It is important to evaluate the skill level of the workforce and the associated labor costs.

-

Fertigungsgemeinkosten: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and administrative costs. Efficient production processes can help minimize overhead, directly affecting the pricing of alternator parts.

-

Werkzeuge: Tooling costs involve the initial investment in molds and machinery required for production. These costs can be substantial, especially for custom parts, and should be amortized over the expected production volume to understand their impact on unit pricing.

-

Qualitätskontrolle (QC): Ensuring that alternator parts meet quality standards requires investment in quality control processes. This can include testing and inspection, which are critical for maintaining reliability and compliance with industry standards.

-

Logistik: Shipping and handling costs can vary widely based on the distance, shipping method, and regulatory requirements of different countries. Efficient logistics management is essential to minimize these costs.

-

Marge: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics and competitive landscape can provide insights into reasonable margin expectations.

How Do Pricing Influencers Affect Car Alternator Parts Costs?

Several factors can influence pricing in the alternator parts market:

-

Menge/Mindestbestellmenge: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs, making it advantageous for buyers to consolidate orders.

-

Spezifikationen und Anpassung: Custom parts or those with specific specifications generally incur higher costs due to additional tooling and engineering. Buyers should weigh the necessity of customization against potential cost savings from standard parts.

-

Materialqualität und Zertifizierungen: Higher-quality materials and certifications (such as ISO) can increase costs but may enhance performance and longevity. Buyers must consider the Total Cost of Ownership (TCO) rather than just the initial purchase price.

-

Lieferantenfaktoren: The reputation and reliability of suppliers play a vital role in pricing. Established suppliers may command higher prices due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. They define responsibilities for shipping, insurance, and tariffs, influencing the total landed cost of parts.

What Are Effective Buyer Tips for Sourcing Car Alternator Parts?

-

Effektiv verhandeln: Leverage the competitive landscape by soliciting quotes from multiple suppliers. Negotiation can lead to better pricing, especially when placing large orders or long-term contracts.

-

Fokus auf Kosteneffizienz: Evaluate the overall cost structure, not just the unit price. Consider factors such as logistics, duty fees, and potential warranty claims that could affect the TCO.

-

Preisdifferenzen verstehen: International buyers should be aware of regional pricing differences. Economic factors, currency fluctuations, and local demand can all impact pricing strategies.

-

Beziehungen aufbauen: Establishing strong relationships with suppliers can lead to favorable terms, priority service, and insights into upcoming changes in pricing or material availability.

-

Informiert bleiben: Regularly monitor market trends and material prices to anticipate cost changes. This proactive approach can aid in budgeting and strategic planning.

In summary, a comprehensive understanding of the cost structure and pricing influencers in car alternator parts sourcing is critical for international B2B buyers. By implementing strategic sourcing practices and considering the Total Cost of Ownership, buyers can optimize their procurement process and achieve better outcomes.

Alternatives Analysis: Comparing car alternator parts With Other Solutions

Understanding Alternatives to Car Alternator Parts

In the automotive industry, car alternator parts are crucial for converting mechanical energy into electrical power. However, there are alternative solutions that can achieve similar results, each with unique characteristics and applications. This analysis will compare traditional car alternator parts with two viable alternatives: hybrid systems und battery management systems (BMS).

Vergleichstabelle

| Vergleichsaspekt | Car Alternator Parts | Hybrid Systems | Batterie-Management-Systeme (BMS) |

|---|---|---|---|

| Leistung | Reliable, efficient power generation | Enhanced fuel efficiency, reduced emissions | Optimizes battery usage and lifespan |

| Kosten | Moderate Anfangsinvestition | Higher upfront costs | Variable costs depending on complexity |

| Einfache Implementierung | Standard in most vehicles | Requires specialized integration | Can be complex, depending on the battery type |

| Wartung | Regular checks needed for wear | Less frequent, but specialized knowledge required | Requires monitoring and software updates |

| Bester Anwendungsfall | Conventional combustion engine vehicles | Eco-friendly vehicles and hybrids | Electric vehicles and energy storage systems |

Detaillierte Aufschlüsselung der Alternativen

What Are Hybrid Systems and Their Benefits?

Hybrid systems combine traditional internal combustion engines with electric propulsion, leveraging both technologies to optimize performance. They reduce fuel consumption and emissions while providing the ability to store energy generated during braking. The main advantage is their efficiency in urban driving conditions where frequent stops allow for battery recharging. However, the initial investment is significantly higher due to the complexity of the system and the need for specialized components. Maintenance can also be less frequent but requires specialized technicians.

How Do Battery Management Systems (BMS) Operate?

Battery Management Systems are designed to monitor and manage rechargeable batteries, ensuring optimal performance and longevity. BMS can balance charge levels across individual cells, enhance safety by preventing overcharging, and provide diagnostic data. This technology is particularly vital in electric vehicles and renewable energy applications. While BMS can maximize battery lifespan and efficiency, they may introduce complexity and cost depending on the battery type and system configuration. Regular software updates and monitoring are essential to maintain performance.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

When evaluating the right solution for your automotive power needs, consider the specific requirements of your vehicles and operational context. Car alternator parts are reliable for traditional combustion engines, while hybrid systems and BMS offer advanced solutions for modern eco-friendly vehicles. B2B buyers should assess their budget, the technology’s ease of integration, and maintenance requirements before making a decision. Ultimately, aligning the choice with long-term operational goals will ensure the best return on investment and efficiency.

Essential Technical Properties and Trade Terminology for car alternator parts

What Are the Key Technical Properties of Car Alternator Parts?

When sourcing car alternator parts, understanding their technical specifications is essential for ensuring compatibility, performance, and durability. Here are some critical properties to consider:

1. Material Klasse

The most common material used in alternator construction is aluminum due to its lightweight and non-magnetic properties. High-grade aluminum alloys enhance heat dissipation, which is crucial for the efficient operation of the alternator. Buyers should consider the material grade to avoid premature wear and ensure longevity, especially in regions with extreme temperatures.

Illustrative image related to car alternator parts

2. Toleranzschwellen

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. In alternators, tight tolerances on components like the rotor and stator are vital for efficient energy conversion. A tolerance of ±0.01mm, for example, can significantly impact the alternator’s efficiency and reliability. For B2B buyers, specifying tolerances ensures that parts fit together correctly, minimizing the risk of failure.

3. Electrical Output Rating

This specification indicates the maximum electrical output the alternator can deliver, typically measured in amperes (A). Depending on the vehicle’s electrical demand, different alternators will have varying output ratings. Buyers must match the output rating to the vehicle’s requirements to avoid underperformance or damage to electrical systems.

4. Mechanismus der Kühlung

Alternators are equipped with internal or external cooling fans to manage heat generated during operation. The cooling mechanism’s design can affect the overall performance and lifespan of the alternator. Understanding the cooling properties can help buyers select components that meet the demands of diverse operating environments, particularly in warmer climates.

5. Diode Bridge Configuration

The diode bridge is responsible for converting alternating current (AC) generated by the alternator into direct current (DC) used by the vehicle. Different configurations can affect the efficiency and durability of the alternator. Buyers should inquire about the diode bridge specifications to ensure they meet the electrical demands of their applications.

Illustrative image related to car alternator parts

What Are Common Trade Terminology and Jargon in the Alternator Parts Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B market for car alternator parts. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the assembly of a vehicle. Purchasing OEM parts ensures that the components are designed specifically for the vehicle, guaranteeing compatibility and quality. For international buyers, sourcing OEM parts can enhance reliability and customer satisfaction.

2. MOQ (Mindestbestellmenge)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for buyers to plan their inventory effectively and manage cash flow. Suppliers often set MOQs to ensure cost-effectiveness in production and shipping.

Illustrative image related to car alternator parts

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific quantities of parts. This process helps buyers compare costs and terms among various suppliers. Providing detailed specifications in an RFQ can lead to more accurate and favorable quotes.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to manage logistics and avoid unexpected costs.

5. Aftermarket-Teile

Aftermarket parts are components made by manufacturers other than the original equipment manufacturer. While often less expensive, the quality can vary significantly. B2B buyers should consider the reputation of aftermarket suppliers to ensure they meet the required specifications and performance standards.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right car alternator parts for their specific needs while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the car alternator parts Sector

What Are the Current Market Dynamics and Key Trends in the Car Alternator Parts Sector?

The global car alternator parts market is experiencing significant transformation driven by technological advancements and shifting consumer preferences. As electric vehicles (EVs) gain traction, the demand for lightweight and efficient alternator components is escalating. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be aware of several key trends.

Firstly, the integration of smart technologies, such as IoT-enabled alternators, is becoming prevalent. These components provide real-time monitoring and diagnostics, enhancing vehicle efficiency and reliability. Additionally, the shift towards hybrid and electric vehicles is prompting manufacturers to innovate, resulting in alternators designed to optimize energy conversion and storage.

Sourcing strategies are also evolving. International buyers are increasingly favoring suppliers who offer comprehensive supply chain solutions, including just-in-time inventory management and flexible payment terms. This trend is particularly important in regions facing economic fluctuations, where agile sourcing can mitigate risks. Moreover, partnerships with local suppliers are gaining traction, enabling companies to reduce lead times and enhance service levels.

Finally, the regulatory landscape is influencing sourcing decisions. Compliance with stringent emissions and safety standards is crucial, particularly in Europe and North America. As a result, B2B buyers must prioritize suppliers who can demonstrate adherence to these regulations while providing high-quality components.

How Can Sustainability and Ethical Sourcing Impact the Car Alternator Parts Supply Chain?

Sustainability is becoming a central concern for B2B buyers in the car alternator parts sector. The environmental impact of automotive manufacturing, including the production and disposal of alternators, necessitates a shift towards greener practices. Buyers should prioritize suppliers committed to reducing their carbon footprint, utilizing eco-friendly materials, and implementing sustainable manufacturing processes.

Ethical sourcing is equally important. Buyers must ensure that their supply chains are free from human rights abuses and that workers are treated fairly. This can be achieved by engaging with suppliers who are transparent about their labor practices and who hold certifications indicating compliance with international labor standards.

Illustrative image related to car alternator parts

Green certifications, such as ISO 14001 for environmental management and other industry-specific sustainability certifications, are valuable indicators of a supplier’s commitment to responsible practices. Additionally, sourcing materials with lower environmental impact, such as recycled aluminum for alternator housings, can contribute to a more sustainable supply chain.

Incorporating sustainability and ethical considerations not only enhances corporate reputation but can also lead to cost savings through improved efficiencies and waste reduction. As consumers increasingly demand environmentally responsible products, aligning with these values can provide a competitive edge in the marketplace.

What Is the Brief Evolution and History of Car Alternator Parts?

The evolution of car alternator parts has been marked by significant technological advancements and shifts in automotive design. Initially, vehicles utilized direct current (DC) generators, which were less efficient and required regular maintenance. The introduction of the alternator in the 1960s revolutionized the automotive industry by providing a more reliable and efficient means of generating electrical power.

Illustrative image related to car alternator parts

Modern alternators are designed with advanced materials and components, such as lightweight aluminum casings and integrated cooling systems, to enhance performance and reduce weight. The transition towards electronic voltage regulators has further improved efficiency and reliability, allowing for better power management within vehicles.

As the automotive landscape continues to evolve with the rise of electric and hybrid vehicles, alternator technology is also advancing. Manufacturers are focusing on developing components that meet the demands of modern vehicles, including improved energy efficiency and enhanced durability. This ongoing evolution underscores the importance of staying informed about the latest trends and innovations in the car alternator parts sector for B2B buyers seeking to optimize their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of car alternator parts

-

How do I solve issues with sourcing reliable car alternator parts?

To address sourcing challenges, conduct thorough research to identify reputable suppliers in the car alternator parts industry. Utilize platforms like Alibaba or TradeKey to find suppliers with verified trade records. Request samples to assess product quality and establish clear communication regarding specifications. Additionally, consider supplier audits or third-party inspections to ensure compliance with international quality standards. Networking through industry forums can also yield valuable recommendations for trustworthy suppliers. -

What is the best way to vet suppliers for car alternator parts?

Vetting suppliers involves several critical steps. Start by checking their business licenses and certifications to ensure they comply with industry standards. Review customer testimonials and case studies to gauge their reputation. Request product samples and assess quality against your specifications. Additionally, inquire about their production capabilities, lead times, and after-sales service. A site visit or a third-party audit can also provide deeper insights into their operational practices. -

What are the common payment terms in international B2B transactions for alternator parts?

Payment terms can vary widely, but common practices include a 30% deposit upon order confirmation, with the remaining balance due before shipment. Some suppliers may offer payment through letters of credit (LC) for added security. For new suppliers, consider using escrow services to protect your investment. Always negotiate terms that align with your cash flow while ensuring the supplier feels secure in the transaction. -

What are the minimum order quantities (MOQ) typically required for car alternator parts?

MOQs vary by supplier and can depend on the type of alternator parts you are sourcing. Generally, MOQs can range from 50 to 500 units, depending on the part’s complexity and the supplier’s production capabilities. Discuss your needs with potential suppliers to see if they can accommodate smaller orders or if they offer tiered pricing based on volume. Building a strong relationship may also allow for flexibility in MOQs. -

How can I ensure quality assurance for car alternator parts?

Implement a robust quality assurance process by establishing clear specifications and standards with your supplier. Request documentation such as Certificates of Compliance and inspection reports. Consider conducting pre-shipment inspections through third-party services to verify product quality before shipment. Additionally, develop a return policy for defective parts and maintain open lines of communication with your supplier to address any quality issues promptly. -

What logistics considerations should I keep in mind when importing alternator parts?

Logistics play a crucial role in international trade. Be aware of shipping costs, customs duties, and import regulations in your country. Choose a reliable freight forwarder familiar with your destination’s import processes. Opt for shipping methods that align with your delivery timelines, whether air freight for speed or sea freight for cost-efficiency. Ensure all documentation, including invoices and packing lists, is accurate to avoid delays at customs. -

Can I customize car alternator parts to meet specific needs?

Yes, many suppliers offer customization options for car alternator parts. Discuss your specific requirements, including dimensions, materials, and functionality, to see if the supplier can accommodate your needs. Customization may involve additional costs and longer lead times, so it’s essential to factor these into your planning. Always request prototypes or samples to evaluate the custom parts before placing a larger order. -

What are the trends in the car alternator parts market that I should be aware of?

Stay informed about trends such as the shift towards electric vehicles, which may influence the demand for alternators. Additionally, advancements in technology are leading to more efficient and compact designs. Sustainability is another trend, with a growing emphasis on sourcing environmentally friendly materials. Regularly reviewing industry reports and participating in trade shows can help you stay ahead of market changes and consumer preferences.

Top 3 Car Alternator Parts Manufacturers & Suppliers List

1. HowStuffWorks – Alternators

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation and non-magnetization. Key components include:

– Antriebsriemenscheibe, die an der Rotorwelle befestigt ist und mechanische Energie in elektrische Energie umwandelt.

– Terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes c…

2. Advance Auto Parts – Alternator

Domäne: shop.advanceautoparts.com

Registriert: 1997 (28 Jahre)

Einleitung: Alternator – Advance Auto Parts; 15% OFF ORDERS $35+ | 20% OFF $100+ | ONLINE ONLY USE CODE BLACKFRIDAY; OEM-quality alternators from brands like Carquest, ACDelco, and Bosch; The alternator converts mechanical energy into electricity, powers the vehicle’s electrical system, and maintains battery charge; Failing alternator leads to battery depletion; Various models available: Carquest Premium Alte…

3. DB Electrical – High Output Alternators

Domäne: dbelectrical.com

Registriert: 2000 (25 Jahre)

Einleitung: Alternators & Replacement Parts for Sale | High Output Alternators. Free Same Day Shipping over $50* USA/48 only. High-quality alternators at low prices. DB Electrical alternators feature high-temperature epoxy, heavy-duty rectifiers, high-quality regulators, well-engineered bearings, and high-temperature grease. All alternators meet OEM standards for quality and fitment. Each model undergoes a ri…

Strategic Sourcing Conclusion and Outlook for car alternator parts

In conclusion, strategic sourcing for car alternator parts presents an opportunity for international buyers to enhance their supply chain efficiency while ensuring the quality and reliability of essential automotive components. Key takeaways emphasize the importance of understanding the intricacies of alternator components, such as rotors, stators, and rectifiers, which are critical for optimal vehicle performance. By forging partnerships with reputable suppliers who prioritize quality and innovation, businesses can not only secure a steady supply of parts but also gain a competitive edge in their respective markets.

As the automotive industry continues to evolve, especially in emerging markets across Africa, South America, the Middle East, and Europe, the demand for high-quality alternator parts is set to rise. Buyers should stay ahead of trends by investing in strategic sourcing initiatives that foster collaboration and transparency with suppliers.

Looking forward, we encourage international B2B buyers to engage actively with manufacturers and distributors to explore new sourcing strategies. By doing so, they can ensure not only the sustainability of their operations but also contribute to the overall growth of the automotive sector in their regions. Take the next step—connect with trusted suppliers today and drive your business forward.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.