Einleitung: Navigieren auf dem globalen Markt der Kosten für Kfz-Generatoren

In the competitive landscape of the automotive industry, understanding car alternator costs is crucial for international B2B buyers looking to optimize their supply chains. Sourcing quality car alternators at competitive prices while ensuring reliability and performance can be a significant challenge, particularly for businesses operating across diverse markets such as Africa, South America, the Middle East, and Europe. This guide delves into the complexities of car alternator pricing, covering various types, applications, and the factors that influence costs.

Throughout this comprehensive resource, buyers will gain insights into the differences between new and remanufactured alternators, explore the implications of amperage ratings and voltage specifications, and learn how to effectively vet suppliers. We will also provide actionable strategies for negotiating better pricing and securing favorable terms with manufacturers and distributors, thus empowering informed purchasing decisions.

By equipping B2B buyers with the knowledge to navigate this essential component of automotive systems, this guide aims to enhance procurement strategies and foster long-term partnerships in the global market. Whether you’re based in Vietnam or Germany, understanding the nuances of car alternator costs will enable you to make decisions that not only meet your operational needs but also drive profitability in your business.

Inhaltsverzeichnis

- Top 2 Car Alternator Cost Manufacturers & Suppliers List

- Einleitung: Navigieren auf dem globalen Markt der Kosten für Kfz-Generatoren

- Kosten von Lichtmaschinen für Kraftfahrzeuge - Typen und Variationen

- Wichtigste industrielle Anwendungen von Auto-Lichtmaschinen Kosten

- 3 häufige Schmerzpunkte für ‘Kosten für die Lichtmaschine’ und ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für die Kosten von Kfz-Generatoren

- Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für Kfz-Generatoren

- Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘auto lichtmaschine kosten’

- Umfassende Kosten- und Preisanalyse für die Beschaffung von Lichtmaschinen für Autos

- Analyse der Alternativen: Vergleich der Kosten einer Lichtmaschine mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für die Kosten von Kfz-Generatoren

- Navigation der Marktdynamik und der Beschaffungstrends im Sektor der Kosten für Kfz-Generatoren

- Häufig gestellte Fragen (FAQs) für B2B-Käufer von Auto-Lichtmaschinen Kosten

- Strategische Beschaffung - Schlussfolgerung und Ausblick für die Kosten von Lichtmaschinen für Kraftfahrzeuge

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Kosten von Lichtmaschinen für Kraftfahrzeuge - Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Neue Lichtmaschinen | Brand new components, typically come with warranties. | OEM replacements, high-volume retail sales. | Pros: Reliable performance, warranty coverage. Cons: Higher upfront costs. |

| Überholte Lichtmaschinen | Rebuilt from used parts, inspected and tested for quality. | Cost-sensitive markets, smaller repair shops. | Pros: Lower cost, eco-friendly. Cons: Potential variability in quality. |

| Hochleistungsgeneratoren | Higher amperage ratings, designed for performance vehicles. | Specialty shops, performance upgrades. | Pros: Enhanced power supply for aftermarket accessories. Cons: Can be pricier and require specific compatibility checks. |

| Schiffsgeneratoren | Designed to withstand harsh marine environments, often waterproof. | Marine repair facilities, boat manufacturers. | Pros: Durable and corrosion-resistant. Cons: Limited application outside marine use. |

| Hochleistungsgeneratoren | Built for larger vehicles or commercial use, with robust designs. | Trucking companies, construction equipment. | Pros: High durability, designed for extreme conditions. Cons: Heavier and more expensive than standard models. |

Was sind die wichtigsten Merkmale neuer Lichtmaschinen?

New alternators are manufactured from scratch, ensuring that all components are brand new and meet original equipment manufacturer (OEM) specifications. They typically come with warranties that provide peace of mind for buyers. New alternators are ideal for businesses focused on quality and reliability, particularly in OEM replacement markets where performance and warranty support are critical. However, the higher upfront cost can be a consideration for budget-sensitive buyers.

How Do Remanufactured Alternators Compare in the Market?

Remanufactured alternators are created by refurbishing used units, which are then thoroughly inspected and tested to meet stringent quality standards. This option is particularly appealing to cost-sensitive markets, such as small repair shops and budget-focused automotive businesses. While they offer a lower price point and are more environmentally friendly, buyers should be aware that the quality can vary based on the remanufacturing process and supplier reputation.

What Are the Benefits of High-Output Alternators?

High-output alternators are designed to deliver greater amperage, making them suitable for performance vehicles that require additional electrical power for aftermarket accessories like sound systems or additional lighting. These alternators are often sought after by specialty automotive shops focusing on performance upgrades. Although they provide enhanced power supply, buyers should consider the increased cost and ensure compatibility with the vehicle’s electrical system.

Was macht Marine-Generatoren so einzigartig?

Marine alternators are specifically designed to operate in marine environments, featuring robust construction and often corrosion-resistant materials. They are essential for marine repair facilities and boat manufacturers, as they need to withstand harsh conditions like moisture and saltwater exposure. While they excel in durability, their application is limited primarily to marine vehicles, which may not justify the investment for buyers outside this niche.

Warum sollten Sie sich für Hochleistungsgeneratoren für gewerbliche Anwendungen entscheiden?

Heavy-duty alternators are engineered for larger vehicles, such as trucks and construction equipment, where reliability and power output are paramount. They are built to withstand extreme conditions and heavy usage, making them ideal for trucking companies and businesses in construction. However, their robust design often results in a higher price point and increased weight, which buyers must consider in their purchasing decisions.

Wichtigste industrielle Anwendungen von Auto-Lichtmaschinen Kosten

| Branche/Sektor | Spezifische Anwendung der Kosten für Kfz-Lichtmaschinen | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Production of electric vehicles (EVs) | Cost-effective sourcing of high-efficiency alternators to enhance vehicle performance and sustainability. | Supplier reliability, quality certifications, and adaptability to different EV models. |

| Schwere Maschinen | Power generation for construction equipment | Ensures consistent power supply for operations, reducing downtime and maintenance costs. | Amperage ratings, durability in harsh environments, and compatibility with various machinery. |

| Transport & Logistik | Flottenmanagement für Nutzfahrzeuge | Reduces operational costs through efficient power management and improved battery life. | Volume pricing, delivery timelines, and warranty options for bulk purchases. |

| Erneuerbare Energien | Integration with solar and wind energy systems | Facilitates energy storage solutions, enhancing overall system efficiency and reliability. | Compatibility with existing systems, efficiency ratings, and supplier support for installation. |

| Schiffsindustrie | Power supply for boats and yachts | Enhances onboard systems’ reliability, improving safety and operational efficiency. | Corrosion resistance, weight specifications, and compliance with maritime standards. |

How is car alternator cost utilized in automotive manufacturing for electric vehicles (EVs)?

In the automotive manufacturing sector, particularly for electric vehicles, the cost of car alternators plays a crucial role in production budgets. High-efficiency alternators help optimize energy usage, thereby extending battery life and enhancing vehicle performance. Manufacturers must consider sourcing from reliable suppliers who can provide alternators that meet specific amperage and voltage requirements. This is vital for ensuring that the alternators can support the advanced electrical systems found in modern EVs, making cost management essential for maintaining competitive pricing.

What benefits does car alternator cost bring to the heavy machinery industry?

In heavy machinery applications, such as construction equipment, the cost of car alternators is pivotal for power generation. These alternators ensure a consistent power supply, which is crucial for operations that demand high reliability. By investing in quality alternators, businesses can reduce downtime and maintenance costs significantly. When sourcing alternators, buyers should focus on durability and compatibility with various machinery types, as well as the amperage ratings required for demanding operational environments.

How does car alternator cost impact transportation and logistics?

For the transportation and logistics sector, the car alternator cost is a key factor in fleet management. Efficient power management through reliable alternators can lead to reduced operational costs and extended battery life for commercial vehicles. Fleet operators should prioritize volume pricing and favorable delivery timelines when sourcing alternators, as these factors can significantly impact overall fleet efficiency and maintenance budgets.

What role does car alternator cost play in renewable energy systems?

In the renewable energy sector, particularly with solar and wind energy systems, the cost of car alternators is integral to the integration of energy storage solutions. These alternators facilitate the conversion of energy into usable power, enhancing the efficiency and reliability of the entire system. Buyers must consider compatibility with existing setups and efficiency ratings when sourcing alternators, as these elements are critical for optimizing energy management in renewable applications.

Why is car alternator cost significant in the marine industry?

In the marine industry, the cost of car alternators is essential for ensuring reliable power supply on boats and yachts. A well-functioning alternator enhances the reliability of onboard systems, which is crucial for safety and operational efficiency. When sourcing alternators for marine applications, businesses should pay attention to corrosion resistance and compliance with maritime standards, as these factors can significantly affect the longevity and performance of the equipment in harsh marine environments.

3 häufige Schmerzpunkte für ‘Kosten für die Lichtmaschine’ und ihre Lösungen

Scenario 1: Fluctuating Prices in the Market

Das Problem: B2B buyers often encounter unpredictable pricing for car alternators due to fluctuations in raw material costs, currency exchange rates, and market demand. For instance, a buyer in South America may find that the cost of alternators increases sharply due to a surge in copper prices, which is a key component in alternator manufacturing. This variability can lead to budget overruns and difficulty in maintaining competitive pricing for their products.

Die Lösung: To mitigate the impact of fluctuating prices, buyers should establish long-term partnerships with reliable suppliers who can offer fixed pricing contracts or price stability guarantees. Engaging in bulk purchasing can also be beneficial, allowing buyers to lock in lower rates. Additionally, incorporating a flexible pricing model in contracts with customers can help absorb some of the cost increases, ensuring that the business remains profitable despite market shifts. Utilizing market intelligence tools to monitor trends in raw material costs can also provide advance notice of potential price increases, allowing businesses to adjust their strategies proactively.

Scenario 2: Quality Assurance Concerns

Das Problem: A common challenge faced by B2B buyers is ensuring the quality of car alternators, especially when sourcing from international suppliers. Issues such as counterfeit products or subpar remanufactured alternators can lead to increased warranty claims and reputational damage. For example, a buyer in Europe may discover that the low-cost alternators sourced from a new supplier are failing prematurely, resulting in lost sales and customer dissatisfaction.

Die Lösung: To combat quality assurance concerns, it is essential for buyers to implement stringent vetting processes for suppliers. This includes requesting certifications (like ISO 9001) and conducting audits to assess manufacturing practices. Establishing a quality control checklist that includes performance metrics and testing standards can ensure that all products meet the required specifications before reaching customers. Additionally, investing in a reliable warranty and return policy can provide reassurance to both the buyer and their clients, fostering trust and long-term relationships.

Scenario 3: Diverse Vehicle Specifications and Compatibility

Das Problem: Another significant pain point for B2B buyers is dealing with a wide range of vehicle specifications and compatibility issues. Different vehicle models require specific alternators, and a mismatch can result in costly returns and delays. For instance, a buyer in Africa may order a batch of alternators only to find that several models do not fit the vehicles they were intended for, leading to inventory pile-ups and cash flow problems.

Die Lösung: To address compatibility issues, buyers should invest in comprehensive cataloging systems that include detailed specifications for each vehicle model. Utilizing advanced inventory management software that tracks vehicle compatibility with alternators can streamline the ordering process. Collaborating closely with manufacturers to obtain updated data on vehicle specifications will also facilitate better alignment of inventory with market demand. Furthermore, offering a return policy that is clear and customer-friendly can help mitigate the risks associated with ordering errors, ensuring that buyers can adapt quickly to changing needs.

Strategischer Leitfaden zur Materialauswahl für die Kosten von Kfz-Generatoren

What Are the Key Materials Used in Car Alternators and Their Cost Implications?

When selecting materials for car alternators, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in car alternators: aluminum, copper, steel, and plastic. Each material has distinct properties that influence the overall cost and performance of the alternator.

Aluminium: Eine leichte und korrosionsbeständige Option

Wichtige Eigenschaften: Aluminum is known for its lightweight nature and excellent corrosion resistance, making it suitable for automotive applications where weight savings are crucial. It can withstand moderate temperatures and pressures, which is essential for alternator performance.

Vor- und Nachteile: The main advantage of aluminum is its low weight, which can enhance fuel efficiency in vehicles. However, it is generally less durable than steel and may not withstand high-impact situations. The manufacturing process for aluminum can be more complex, potentially increasing costs.

Auswirkungen auf die Anwendung: Aluminum’s corrosion resistance makes it ideal for vehicles operating in humid or coastal environments. However, it may not be the best choice for heavy-duty applications where higher durability is required.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should consider local environmental conditions when selecting aluminum components. Compliance with international standards, such as ASTM, is crucial to ensure quality and reliability.

Kupfer: Der elektrische Leiter der Wahl

Wichtige Eigenschaften: Copper is renowned for its excellent electrical conductivity, which is vital for the efficient operation of alternators. It also has good thermal conductivity, allowing it to dissipate heat effectively.

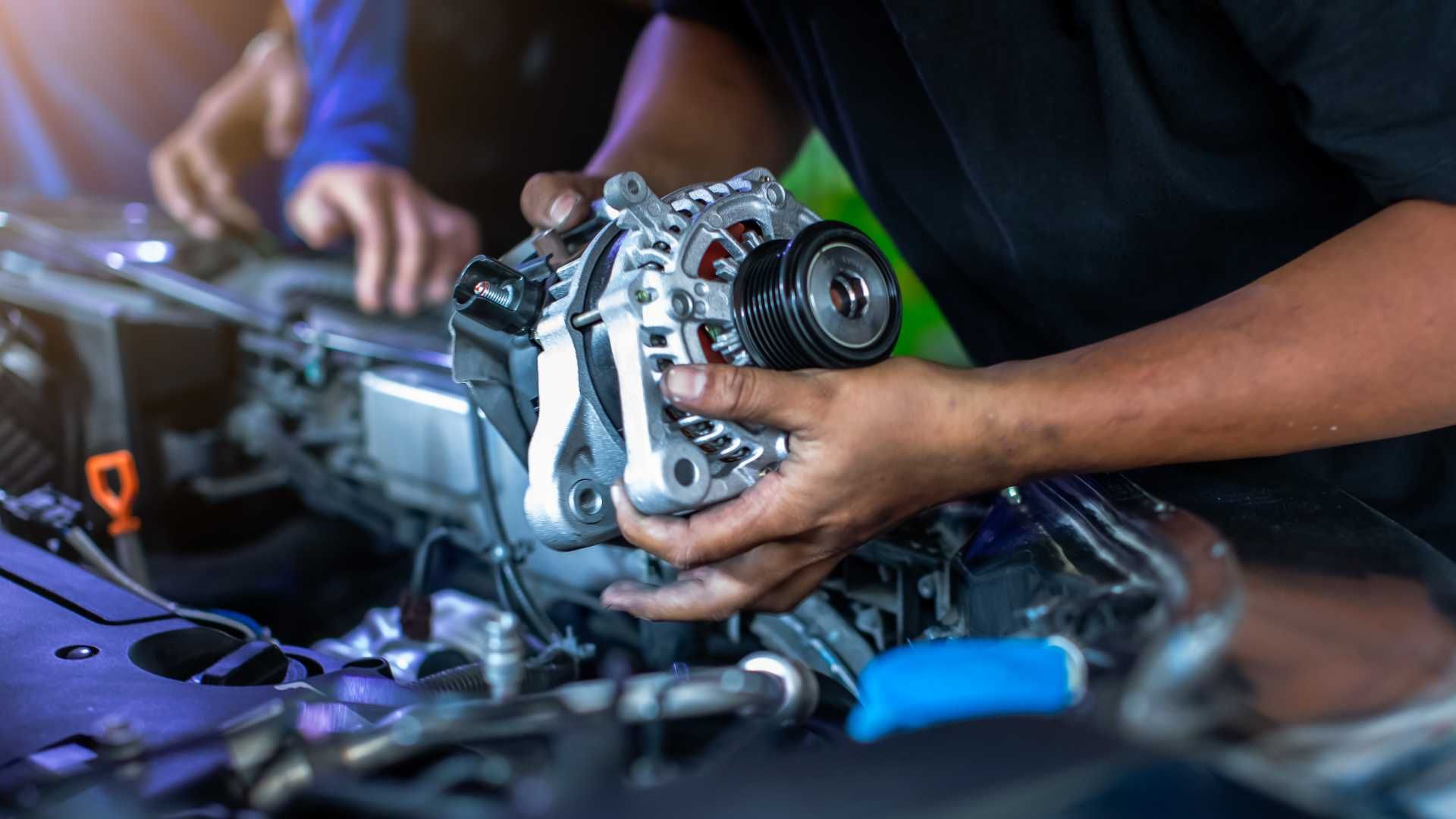

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which ensures optimal performance. However, copper is more expensive than aluminum and can be prone to corrosion if not properly coated or treated.

Auswirkungen auf die Anwendung: Copper is ideal for wiring and winding in alternators, where efficient electrical flow is essential. Its performance can be compromised in environments with high humidity unless adequately protected.

Überlegungen für internationale Käufer: Buyers should be aware of copper’s fluctuating market prices and potential supply chain issues. Compliance with standards like JIS in Japan or DIN in Germany can also impact procurement processes.

Steel: A Durable and Cost-Effective Material

Wichtige Eigenschaften: Steel is known for its high strength and durability, making it suitable for components that must withstand significant mechanical stress. It has a high temperature tolerance but can be susceptible to corrosion if not treated.

Vor- und Nachteile: Steel’s primary advantage is its durability, which makes it ideal for heavy-duty applications. However, its weight can be a disadvantage in applications where weight reduction is critical. The manufacturing process for steel can also be less complex, potentially lowering costs.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

Auswirkungen auf die Anwendung: Steel is often used in the structural components of alternators, where strength is paramount. Its performance in corrosive environments can be enhanced with coatings or treatments.

Überlegungen für internationale Käufer: Buyers in the Middle East and Europe may favor steel for its robustness. Understanding local regulations regarding material specifications and environmental standards is essential for compliance.

Plastic: A Lightweight Alternative for Non-Structural Components

Wichtige Eigenschaften: Plastic is lightweight and can be molded into complex shapes, making it suitable for non-structural components of alternators. It has moderate temperature resistance but can degrade under extreme conditions.

Vor- und Nachteile: The main advantage of plastic is its low cost and versatility in design. However, it lacks the strength and durability of metals, which can limit its use in critical applications.

Auswirkungen auf die Anwendung: Plastic is often used for housings and covers in alternators, where weight savings are beneficial. Its compatibility with various media makes it suitable for specific applications, but it may not withstand high temperatures.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

Überlegungen für internationale Käufer: Buyers should consider the environmental impact of plastic and local regulations regarding its use. Compliance with standards can vary by region, affecting procurement decisions.

Übersichtstabelle zur Materialauswahl für Kfz-Generatoren

| Material | Typischer Anwendungsfall für die Kosten einer Kfz-Lichtmaschine | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Weniger haltbar als Stahl | Mittel |

| Kupfer | Wiring and winding | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und anfällig für Korrosion | Hoch |

| Stahl | Strukturelle Komponenten | Hohe Festigkeit und Haltbarkeit | Heavier and can corrode without treatment | Niedrig |

| Kunststoff | Gehäuse und Abdeckungen | Geringe Kosten und vielseitiges Design | Lacks strength and durability | Niedrig |

This analysis provides a comprehensive overview of material selection for car alternators, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für Kfz-Generatoren

Was sind die wichtigsten Schritte im Herstellungsprozess von Kfz-Generatoren?

The manufacturing of car alternators encompasses several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets stringent performance and reliability standards.

How Is Material Prepared for Car Alternator Production?

The process begins with the selection of high-quality raw materials, such as aluminum for the housing and copper for the windings. These materials are sourced from certified suppliers to ensure consistency and reliability. Once sourced, the materials undergo quality checks to confirm their specifications, such as conductivity for copper and tensile strength for aluminum.

What Forming Techniques Are Commonly Used in Alternator Manufacturing?

In the forming stage, various techniques are employed to shape the components. For instance, aluminum housings are typically produced through die casting, which allows for complex shapes and high precision. Copper windings are created through wire drawing and winding processes, ensuring uniform thickness and resistance. Each component’s dimensions are closely monitored to maintain tolerances, which are crucial for optimal performance.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

How Are Car Alternators Assembled?

During the assembly phase, components are meticulously put together. This involves placing the rotor and stator within the housing, followed by the installation of the voltage regulator and other electronic components. Automated assembly lines are often utilized to increase efficiency and reduce human error, but skilled workers are also involved in critical tasks, such as wiring and soldering. Assembly is conducted in a clean environment to prevent contamination.

What Finishing Processes Are Applied to Ensure Quality?

After assembly, alternators undergo finishing processes that may include polishing, painting, or coating. These processes not only enhance the product’s appearance but also improve corrosion resistance and longevity. Final inspections are conducted to ensure that each alternator meets the required specifications before packaging.

What Quality Assurance Measures Are Essential for Car Alternators?

Quality assurance (QA) is paramount in alternator manufacturing, as these components must withstand harsh automotive environments. Several international standards and industry-specific regulations guide the QA processes.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

ISO 9001 is one of the most recognized international quality management standards that manufacturers may adhere to. This standard emphasizes a process-oriented approach to quality management and continuous improvement. Compliance with ISO 9001 assures B2B buyers that the manufacturer has robust quality management systems in place.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards may apply, depending on the intended application of the alternators. These certifications ensure that the products meet specific safety and performance criteria.

Was sind die wichtigsten QC-Kontrollpunkte bei der Herstellung von Generatoren?

Quality control (QC) is integrated at various stages of the manufacturing process, with key checkpoints including:

-

Eingangsqualitätskontrolle (IQC): This step involves inspecting raw materials and components upon receipt. Only materials that meet quality standards are accepted for production.

-

In-Process-Qualitätskontrolle (IPQC): Throughout the manufacturing process, in-process inspections are conducted to monitor the assembly and forming stages. This ensures that any deviations from specifications are caught early.

-

Endkontrolle (FQC): Before shipping, finished alternators undergo rigorous testing, including electrical performance tests, durability tests, and visual inspections. This final check is crucial for identifying any defects that may have occurred during assembly or finishing.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are several methods to ensure due diligence:

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

What Audit Procedures Should Be Followed?

Conducting audits is a proactive approach to verify a supplier’s quality control processes. Buyers can request audits by third-party organizations that specialize in quality assessments. These audits often evaluate compliance with ISO standards and assess the effectiveness of the manufacturer’s quality management system.

How Important Are Quality Reports and Documentation?

Requesting quality reports from suppliers can provide insights into their QC practices. These reports should detail inspection results, test outcomes, and any corrective actions taken for non-conformities. Buyers should ensure that these documents are comprehensive and transparent.

Welche Rolle spielen Inspektionen durch Dritte?

Engaging third-party inspection services during the manufacturing process can add an extra layer of assurance. These services can conduct inspections at various stages, including IQC, IPQC, and FQC, providing independent verification of the manufacturer’s claims regarding quality.

What Nuances Should International B2B Buyers Consider in QC?

International B2B buyers must be aware of specific nuances related to quality control in different regions. For instance, regulatory requirements can vary significantly between Europe and Africa. Buyers should familiarize themselves with local standards and expectations to ensure compliance. Additionally, cultural differences in manufacturing practices may impact quality assurance, necessitating a flexible and informed approach to supplier management.

In summary, the manufacturing and quality assurance processes for car alternators are complex yet essential for ensuring the reliability and performance of automotive electrical systems. By understanding these processes and implementing thorough verification methods, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘auto lichtmaschine kosten’

This guide aims to assist B2B buyers in effectively sourcing car alternators, focusing on cost considerations and supplier evaluation. Understanding the intricacies of the procurement process can lead to informed decisions and optimal pricing strategies.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before starting the sourcing process, outline the specific technical requirements for the alternators needed. This includes amperage, voltage, and whether you require new or remanufactured units. Clearly defined specifications help streamline communication with suppliers and ensure compatibility with your vehicles.

- Amperage and Voltage: Determine the amperage range suitable for your application, typically ranging from 90 to 250 amps.

- Neu vs. Wiederaufbereitet: Assess if you prefer new units for reliability or remanufactured ones for cost savings.

Schritt 2: Forschung Marktpreise

Understanding the market price range for the specific alternators you need is essential. Conducting market research will help you establish a baseline for negotiations and ensure you are not overpaying.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

- Compare Multiple Suppliers: Gather quotes from various suppliers to gauge average pricing.

- Berücksichtigen Sie die Gesamtbetriebskosten (TCO): Factor in shipping, taxes, and potential warranty services when evaluating costs.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This helps to assess reliability and service quality.

- Zertifizierungen prüfen: Ensure suppliers have necessary certifications, such as ISO 9001, which indicates adherence to quality management standards.

- Review Customer Feedback: Look for reviews or testimonials from other businesses that have purchased from the supplier.

Schritt 4: Überprüfen Sie die Garantie- und Rückgabebedingungen

Understanding the warranty and return policies of potential suppliers is critical for mitigating risks. A robust warranty can provide peace of mind regarding the longevity and reliability of your purchase.

- Dauer der Garantie: Look for warranties that cover a significant period or offer lifetime coverage.

- Return Conditions: Clarify the conditions under which returns are accepted to avoid potential losses.

Schritt 5: Assess Supply Chain Logistics

Logistics can significantly impact the overall cost and delivery timeline. Evaluate the supplier’s logistics capabilities to ensure they can meet your delivery requirements.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

- Shipping Options: Discuss available shipping methods and costs to find the most efficient option.

- Lead Times: Confirm lead times for production and shipping to align with your project timelines.

Schritt 6: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Once you have identified a preferred supplier, engage in negotiations to secure favorable terms. This can include pricing, payment terms, and delivery schedules.

- Mengenrabatte: Inquire about discounts for larger orders, which can significantly lower your overall costs.

- Zahlungsflexibilität: Discuss payment options that work best for your cash flow situation, such as net-30 or net-60 terms.

Schritt 7: Aufbau einer langfristigen Beziehung

Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and easier negotiations in the future.

- Regelmäßige Kommunikation: Maintain open lines of communication to address any issues promptly and reinforce your partnership.

- Feedback Loop: Provide feedback on product quality and service to help the supplier improve and cater to your needs better.

By following this checklist, B2B buyers can navigate the complexities of sourcing car alternators effectively, ensuring they achieve the best value and quality for their investments.

Umfassende Kosten- und Preisanalyse für die Beschaffung von Lichtmaschinen für Autos

What Are the Key Cost Components in Car Alternator Pricing?

When analyzing the cost structure of car alternators, several components play crucial roles in determining the final price. Materialien are the primary cost driver, including copper for windings, aluminum for casings, and various electronic components. The quality and sourcing of these materials can significantly influence costs. Arbeit costs vary by region and can be affected by local wage standards, skill levels, and labor laws.

Additionally, Produktionsgemeinkosten encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Werkzeuge costs for specialized molds and machinery can also add to the initial investment, especially for custom alternators. Qualitätskontrolle (QC) is essential to ensure reliability and performance; therefore, investments in testing and inspection processes are necessary. Finally, Logistik costs, including transportation and warehousing, must be factored in, as they can vary greatly depending on the shipping distances and methods chosen.

How Do Price Influencers Affect Car Alternator Costs?

Several factors influence the pricing of car alternators in the B2B market. Volumen und Mindestbestellmenge (MOQ) can drastically alter pricing; larger orders often lead to discounts due to economies of scale. The specifications and customization of alternators, such as amperage ratings or specialized features, can also affect prices. Higher specifications typically entail more expensive materials and production processes.

Das quality and certifications of the alternators are critical, especially for buyers in regions with stringent regulatory standards. Suppliers with ISO certifications or those who adhere to international quality standards often command higher prices due to the added assurance of product reliability. Furthermore, Lieferantenfaktoren, including reputation, lead times, and financial stability, can influence pricing as buyers may be willing to pay more for established suppliers.

Lastly, understanding Incoterms is vital for international buyers, as they dictate who is responsible for shipping, insurance, and tariffs, impacting the total landed cost of the alternators.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Car Alternators?

To maximize cost-efficiency when sourcing car alternators, buyers should focus on effective negotiation strategies. Building long-term relationships with suppliers can lead to better pricing and terms over time. It is advisable to conduct thorough market research to understand competitive pricing and identify potential leverage points during negotiations.

Käufer sollten auch Folgendes berücksichtigen: Gesamtbetriebskosten (TCO) rather than just the upfront price. Factors such as longevity, warranty terms, maintenance costs, and potential downtime should be evaluated to ensure that the lowest initial cost does not result in higher costs over the product’s lifecycle.

Furthermore, international B2B buyers should be aware of Preisnuancen that may arise due to currency fluctuations, import duties, and local market conditions. Understanding the local context in regions like Africa, South America, the Middle East, and Europe can provide insights into potential cost variations and expectations.

Finally, it’s essential to keep in mind that prices can fluctuate based on market conditions, supplier changes, and raw material availability. Therefore, buyers should always request indikative Preisgestaltung and remain flexible to adapt to market changes.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

In conclusion, a comprehensive understanding of the cost components, price influencers, and strategic negotiation tactics can significantly enhance the sourcing process for car alternators, leading to better outcomes for international B2B buyers.

Analyse der Alternativen: Vergleich der Kosten einer Lichtmaschine mit anderen Lösungen

Introduction: Exploring Alternatives to Car Alternator Costs

When evaluating the cost of car alternators, it’s essential for B2B buyers to consider alternative solutions that may meet their operational needs. These alternatives can provide different benefits in terms of performance, cost-efficiency, and implementation ease. This analysis will compare the traditional car alternator against two viable alternatives: hybrid power systems and solar charging solutions.

Vergleichstabelle

| Vergleichsaspekt | Auto Lichtmaschine Kosten | Hybrides Energiesystem | Solar Charging Solutions |

|---|---|---|---|

| Leistung | Reliable power supply for vehicle electrical systems | Offers backup power and can reduce fuel consumption | Provides renewable energy, dependent on sunlight |

| Kosten | Typically ranges from $100 to $300 per unit | Initial investment of $1,500 to $5,000; long-term savings possible | $500 to $2,000 for systems, dependent on installation |

| Einfache Implementierung | Unkomplizierter Einbau für die meisten Fahrzeuge | Requires professional installation and integration | DIY or professional installation possible, depending on system complexity |

| Wartung | Regular checks needed; long lifespan if maintained | Requires periodic checks and battery replacements | Low maintenance; occasional cleaning of solar panels |

| Bester Anwendungsfall | Standard vehicles needing reliable electrical output | Fleets seeking to reduce fuel costs and emissions | Off-grid applications or vehicles in sunny regions |

Detaillierte Aufschlüsselung der Alternativen

Hybrid Power Systems

Hybrid power systems combine traditional internal combustion engines with electric power sources. This integration provides a secondary power source that can significantly enhance fuel efficiency and reduce emissions. The initial investment is higher than a standard alternator; however, businesses may benefit from long-term savings on fuel costs and maintenance. Hybrid systems are particularly suited for commercial fleets that require reliable power for extended periods. The complexity of installation and potential need for professional assistance can be a drawback for some buyers.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

Solar Charging Solutions

Solar charging solutions harness renewable energy from the sun to charge vehicle batteries. These systems can be installed on various types of vehicles, making them versatile for different applications. The cost of solar systems can vary widely based on size and installation requirements but generally remains lower than hybrid systems. The main advantage is their sustainability and low maintenance needs, as solar panels require minimal upkeep. However, performance is contingent on sunlight availability, which may limit effectiveness in regions with less sun exposure.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

For B2B buyers, selecting the right power solution depends on various factors, including budget, intended use, and environmental considerations. Car alternators remain a reliable choice for standard vehicles, offering straightforward installation and maintenance. However, businesses looking to innovate and reduce operational costs may find hybrid power systems or solar charging solutions more advantageous in the long run. Evaluating the specific requirements of your fleet or operation will help ensure that you choose the most suitable alternative for your needs.

Wesentliche technische Eigenschaften und Fachterminologie für die Kosten von Kfz-Generatoren

What Are the Essential Technical Properties of Car Alternators?

Understanding the technical specifications of car alternators is vital for B2B buyers to ensure they are making informed purchasing decisions. Here are some key properties to consider:

1. Stromstärke (A)

The amperage rating indicates the electrical output capacity of the alternator, typically ranging from 60 to 300 amps. This specification is crucial because it determines how much electrical load the alternator can handle. For businesses operating in regions with high electrical demand (e.g., for vehicles with advanced electronic systems), selecting an alternator with the appropriate amperage is essential to avoid electrical failures.

2. Voltage (V)

Most automotive alternators operate at either 12V or 24V. The voltage rating indicates the electrical potential difference supplied by the alternator. Understanding voltage compatibility is essential for ensuring that the alternator can effectively charge the vehicle’s battery and power electrical components without causing damage.

3. Reglertyp

Alternators can be equipped with either internal or external voltage regulators. The type affects the alternator’s performance and installation complexity. Internal regulators are typically more compact and easier to install, while external regulators may offer better performance under specific conditions. B2B buyers should consider their vehicle’s electrical system requirements when choosing between the two.

4. Typ und Konfiguration der Riemenscheibe

The pulley type (e.g., conventional, decoupler) and its configuration (number of grooves) play a significant role in how the alternator integrates with the vehicle’s drive belt system. Proper pulley selection ensures efficient power transfer from the engine to the alternator, impacting overall vehicle performance. This detail is particularly relevant for buyers in regions with diverse vehicle models and specifications.

5. Methode der Kühlung

Alternators typically employ air cooling, which is essential for maintaining optimal operating temperatures. Understanding the cooling method can help businesses assess the alternator’s reliability and longevity, particularly in hot climates or high-demand applications.

What Are Common Trade Terms Related to Car Alternators?

Familiarizing oneself with industry jargon is essential for effective communication and negotiations in the B2B space. Here are some important terms to know:

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

1. OEM (Originalgerätehersteller)

OEM refers to components made by the vehicle’s original manufacturer. For B2B buyers, OEM alternators are often preferred for their compatibility and reliability. Understanding the distinction between OEM and aftermarket parts can influence purchasing decisions, particularly for businesses focused on quality.

2. MOQ (Mindestbestellmenge)

MOQ specifies the smallest quantity of product that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it affects inventory management and financial planning. Buyers should negotiate MOQs based on their projected sales and stock needs.

3. RFQ (Angebotsanfrage)

An RFQ is a formal request issued by buyers to suppliers asking for pricing and terms for specific products. Understanding how to formulate an RFQ can lead to better pricing and terms, making it a vital skill for B2B procurement professionals.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. Familiarity with terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is essential for B2B buyers to manage shipping costs and risks effectively.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

5. Remanufactured vs. New

Understanding the difference between remanufactured and new alternators is crucial. Remanufactured parts are refurbished to meet original specifications, often at a lower cost than new ones. Buyers need to evaluate the trade-offs between cost savings and performance reliability when making purchasing decisions.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to better purchasing outcomes and enhanced operational efficiency.

Navigation der Marktdynamik und der Beschaffungstrends im Sektor der Kosten für Kfz-Generatoren

What Are the Key Trends Influencing the Global Car Alternator Cost Market?

The global car alternator market is witnessing significant transformations driven by a combination of technological advancements, economic factors, and evolving consumer preferences. One major driver is the increasing demand for electric vehicles (EVs), particularly in regions like Europe and parts of Africa and South America, where governments are incentivizing greener technologies. As EVs rely on advanced alternator systems, manufacturers are innovating to create lightweight, high-efficiency alternators that meet stringent energy standards.

Moreover, the rise of digitalization in supply chain management is reshaping sourcing trends. B2B buyers are increasingly leveraging technologies such as AI and blockchain to enhance transparency and efficiency in their procurement processes. This trend not only helps in tracking the origins of components but also in optimizing inventory management and reducing lead times.

International buyers are also adapting to the fluctuations in raw material costs, particularly copper and aluminum, which are critical for alternator manufacturing. As global supply chains become more interconnected, understanding regional market dynamics, such as tariffs and trade agreements, is essential for making informed sourcing decisions.

Illustratives Bild zu den Kosten einer Lichtmaschine für Autos

Wie beeinflusst die Nachhaltigkeit die Beschaffung von Autogeneratoren?

Sustainability has become a cornerstone of procurement strategies in the automotive sector, particularly in the context of car alternators. The environmental impact of automotive manufacturing is under scrutiny, prompting businesses to adopt ethical sourcing practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

Certifications like ISO 14001 (Environmental Management) and adherence to international labor standards are becoming essential for suppliers to gain credibility in the eyes of B2B buyers. Moreover, the demand for ‘green’ materials is reshaping product offerings, with manufacturers exploring alternatives that minimize environmental footprints. This shift not only meets consumer expectations but can also lead to cost savings in the long run, as energy-efficient products often require less maintenance and result in lower operational costs.

How Has the Car Alternator Market Evolved Over Time?

The car alternator market has undergone significant evolution since its inception, transitioning from simple mechanical systems to complex electronic components. Initially, alternators were designed primarily for basic vehicle electrical needs, but advancements in technology have expanded their role. Today’s alternators are equipped with sophisticated voltage regulators and are integral to the performance of modern vehicles, particularly in supporting advanced electrical systems.

The introduction of hybrid and electric vehicles has further accelerated this evolution, leading to the development of high-output alternators capable of powering various onboard systems efficiently. As the automotive landscape continues to change, understanding this historical context is crucial for B2B buyers looking to navigate current market dynamics effectively.

Schlussfolgerung

In summary, the car alternator market is poised for continued growth, driven by technological advancements, sustainability initiatives, and changing consumer preferences. International B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business objectives and the evolving automotive landscape. By prioritizing ethical sourcing and embracing innovation, companies can not only enhance their operational efficiency but also contribute to a more sustainable future in the automotive industry.

Häufig gestellte Fragen (FAQs) für B2B-Käufer von Auto-Lichtmaschinen Kosten

-

How do I determine the cost of car alternators for bulk purchases?

To accurately determine the cost of car alternators for bulk purchases, start by requesting quotes from multiple suppliers. Consider factors such as the type of alternator (new or remanufactured), amperage rating, and any customization options. Additionally, inquire about shipping costs, taxes, and duties that may apply to your region, particularly if sourcing from international suppliers. It’s also beneficial to establish a long-term relationship with suppliers, which can lead to better pricing and terms over time. -

What are the typical price ranges for car alternators?

Car alternator prices can vary widely based on factors like brand, amperage, and whether the unit is new or remanufactured. Generally, prices can range from $50 to $300 or more per unit. Remanufactured alternators tend to be more cost-effective, often falling between $50 and $150. For bulk purchases, suppliers may offer significant discounts, so it’s crucial to negotiate and discuss pricing structures tailored to your order volume. -

What should I look for when vetting suppliers for car alternators?

When vetting suppliers, focus on their industry reputation, experience, and customer reviews. Verify their certifications and compliance with international quality standards. Request samples or product specifications to assess quality and performance. Additionally, inquire about their manufacturing processes and warranty policies. It’s wise to establish communication with previous clients to gain insights into their experiences with the supplier. -

Can I customize car alternators for specific vehicle models?

Yes, many suppliers offer customization options for car alternators to fit specific vehicle models. Customization may include variations in amperage, voltage, and pulley types. Ensure you provide detailed specifications of the vehicles in question to the supplier. This can lead to a more tailored product that meets your operational needs and enhances customer satisfaction. -

Wie hoch ist die Mindestbestellmenge (MOQ) für Kfz-Generatoren?

Minimum order quantities (MOQs) for car alternators can vary by supplier and product type. Typically, MOQs may range from 10 to 100 units, depending on the manufacturer’s production capabilities and inventory. It’s important to clarify the MOQ upfront to avoid any misunderstandings during the ordering process. If your needs are below the MOQ, some suppliers may still accommodate you but may charge higher prices per unit. -

What payment terms should I expect when sourcing car alternators internationally?

Payment terms can vary widely among suppliers, especially in international transactions. Common terms include upfront payment, a deposit with the balance due upon shipment, or payment against documents. It’s critical to negotiate terms that protect both parties, considering factors like currency exchange rates and transaction fees. Ensure that payment methods are secure and offer recourse in case of disputes. -

How can I ensure quality assurance for car alternators?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Many reputable manufacturers will provide testing reports or quality control procedures. Consider establishing a quality assurance agreement that outlines inspection processes before shipping. Additionally, you may want to conduct random inspections or work with third-party quality assurance firms to verify compliance with your standards. -

What logistics considerations should I keep in mind when importing car alternators?

When importing car alternators, consider logistics factors such as shipping methods, lead times, and customs clearance procedures. Choose a reliable freight forwarder experienced in handling automotive parts to navigate potential challenges. Be aware of import duties and taxes that may apply in your country, as these can significantly impact overall costs. Timely communication with suppliers regarding shipping schedules can also help mitigate delays in delivery.

Top 2 Car Alternator Cost Manufacturers & Suppliers List

1. JD Power – Alternator Replacement Costs

Domäne: jdpower.com

Registriert: 1995 (30 Jahre)

Einleitung: Alternator replacement costs range from $350 to $900, with average part costs between $100 to $350. Luxury models may require alternators costing $500 to $700. Labor costs can add $350 to $500, depending on the vehicle. Rebuilt alternators are available and typically come with a warranty. DIY installation can save on labor costs, but requires some skill and time. An alternator generally lasts 7 to…

2. Car Talk – Alternator Replacement Costs

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: The cost to replace an alternator ranges from $600 to $1,500. An alternator is a critical component that maintains the charge of the battery and powers various electrical systems in the vehicle. It is driven by an accessory belt and converts mechanical energy into electrical energy. Symptoms of a failing alternator include a check engine light, dimming headlights, and the need for jump-starts. Alt…

Strategische Beschaffung - Schlussfolgerung und Ausblick für die Kosten von Lichtmaschinen für Kraftfahrzeuge

In today’s competitive automotive market, understanding the dynamics of car alternator costs is vital for strategic sourcing. B2B buyers must recognize that factors such as brand reputation, amperage requirements, and the choice between new and remanufactured units can significantly influence pricing. By leveraging insights into these variables, businesses can negotiate better terms and ensure they are getting the best value for their investments.

Strategic sourcing not only aids in cost reduction but also enhances supply chain reliability. Establishing strong relationships with suppliers, particularly those offering diverse product ranges and robust warranties, can lead to more favorable pricing structures and improved service delivery. This is especially crucial for buyers operating across regions such as Africa, South America, the Middle East, and Europe, where market conditions and logistical challenges can vary significantly.

As we look to the future, it is essential for international B2B buyers to stay informed about emerging trends and technological advancements in the alternator market. By adopting a proactive sourcing strategy and continuously evaluating supplier performance, businesses can position themselves for success. Engage with reliable suppliers today to ensure your operations remain efficient and cost-effective in the evolving automotive landscape.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.