Introduction: Navigating the Global Market for relay starter solenoid

In today’s competitive landscape, sourcing reliable relay starter solenoids is a critical challenge for B2B buyers across various sectors. Whether you’re operating in the automotive, industrial, or agricultural machinery industries, understanding the intricacies of these essential components can significantly impact operational efficiency and product reliability. This comprehensive guide explores the various types of relay starter solenoids, their applications, and the nuances of supplier vetting. By delving into factors such as cost considerations and market trends, we equip international buyers—particularly from regions like Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Saudi Arabia—with the insights necessary to make informed purchasing decisions.

Navigating the global market for relay starter solenoids involves understanding not only the technical specifications but also the cultural and economic contexts that influence supplier relationships. This guide aims to demystify the complexities involved, providing actionable strategies to assess quality, negotiate prices, and establish long-term partnerships with reputable manufacturers. With a focus on empowering buyers, we address common pitfalls and offer solutions that enhance procurement processes. By leveraging this knowledge, businesses can ensure they select the right components that meet their operational needs while optimizing costs and improving overall performance.

Inhaltsverzeichnis

- Top 1 Relay Starter Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for relay starter solenoid

- Understanding relay starter solenoid Types and Variations

- Key Industrial Applications of relay starter solenoid

- 3 Common User Pain Points for ‘relay starter solenoid’ & Their Solutions

- Strategic Material Selection Guide for relay starter solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for relay starter solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘relay starter solenoid’

- Comprehensive Cost and Pricing Analysis for relay starter solenoid Sourcing

- Alternatives Analysis: Comparing relay starter solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for relay starter solenoid

- Navigating Market Dynamics and Sourcing Trends in the relay starter solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of relay starter solenoid

- Strategic Sourcing Conclusion and Outlook for relay starter solenoid

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding relay starter solenoid Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Electromagnetic Solenoid | Operates using electromagnetic force; directly engages the starter motor. | Automobilbau, Schwermaschinenbau | Vorteile: High current capacity, reliable performance. Nachteile: Kann empfindlich auf Spannungsschwankungen reagieren. |

| Mini Relay | Compact design, typically used in modern vehicles; activates high-current circuits. | Automotive, electronics, and appliances | Vorteile: Platzsparend, effizient. Nachteile: Limited current capacity compared to larger relays. |

| Continuous Duty Relay | Designed for prolonged operation; can handle continuous current without overheating. | Industrial machinery, marine applications | Vorteile: Durable, reliable for long-term use. Nachteile: Höhere Anschaffungskosten. |

| Verriegelungsrelais | Maintains its position after being activated; requires less power to hold. | Automation systems, security systems | Vorteile: Energy-efficient, reduces power consumption. Nachteile: Komplexere Schaltkreise. |

| Halbleiterrelais | Uses semiconductor devices instead of mechanical parts; no moving components. | High-tech applications, industrial automation | Vorteile: Long lifespan, high-speed switching. Nachteile: Can be more expensive than traditional relays. |

What Are the Key Characteristics of Electromagnetic Solenoids?

Electromagnetic solenoids are widely utilized in automotive applications due to their ability to directly engage the starter motor with a significant amount of current. They are particularly suitable for high-torque scenarios, such as heavy machinery and commercial vehicles. B2B buyers should consider factors such as current ratings and durability in harsh environments when sourcing these solenoids, as they must withstand frequent use and potential exposure to various elements.

How Do Mini Relays Differ in Functionality?

Mini relays are compact and efficient, commonly found in modern vehicles and electronic devices. They activate high-current circuits but occupy minimal space, making them ideal for applications with limited room for components. When purchasing mini relays, buyers should evaluate their current capacity and compatibility with existing systems, as well as their reliability under varying temperatures and conditions.

Why Choose Continuous Duty Relays for Industrial Applications?

Continuous duty relays are engineered for prolonged operation without overheating, making them ideal for industrial machinery and marine applications. Their durability ensures they can handle demanding tasks over extended periods. Buyers should focus on the relay’s specifications, including current ratings and thermal management features, to ensure they meet the operational demands of their applications.

What Are the Advantages of Using Latching Relays?

Latching relays are unique in that they maintain their position after being activated, requiring less power to hold their state. This makes them particularly beneficial in automation and security systems where energy efficiency is a priority. B2B buyers should consider the complexity of integrating latching relays into their systems, as well as the potential for reduced power consumption in their overall operations.

What Makes Solid State Relays a Preferred Choice in High-Tech Applications?

Solid state relays utilize semiconductor technology instead of mechanical parts, offering high-speed switching and a longer lifespan. They are ideal for high-tech applications and industrial automation where reliability and speed are critical. When procuring solid state relays, buyers should assess their switching capabilities, thermal characteristics, and cost-effectiveness compared to traditional relays, as these factors will influence their overall performance and value in complex systems.

Key Industrial Applications of relay starter solenoid

| Branche/Sektor | Specific Application of relay starter solenoid | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Engine Starting Systems | Ensures reliable engine start, reducing downtime | Compatibility with vehicle models and voltage ratings |

| Landwirtschaft | Landwirtschaftliche Maschinen | Enhances operational efficiency in starting engines | Durability in harsh environments and resistance to dust |

| Bauwesen | Schwere Ausrüstung | Improves reliability of equipment starting processes | Sourcing from reputable manufacturers for quality assurance |

| Marine | Boat Engine Systems | Facilitates quick and reliable engine startups | Corrosion resistance and marine-grade specifications |

| Industrielle Ausrüstung | Generator Systems | Ensures dependable power generation for operations | Compliance with international safety standards |

How is the Relay Starter Solenoid Used in the Automotive Sector?

In the automotive industry, relay starter solenoids are integral components of engine starting systems. They facilitate the transition from a low-power signal from the ignition switch to a high-power signal needed to engage the starter motor. This conversion is essential for reliable engine starts, particularly in regions with variable climate conditions, such as Africa and Europe. Buyers must ensure compatibility with specific vehicle models and voltage ratings to prevent operational failures.

What Role Does the Relay Starter Solenoid Play in Agriculture?

In agricultural machinery, relay starter solenoids are crucial for starting engines in tractors and other heavy equipment. They enhance operational efficiency by ensuring that machinery starts reliably, which is vital during planting and harvesting seasons. Buyers in this sector should focus on sourcing solenoids that can withstand harsh environmental conditions, including exposure to dust and moisture, to minimize maintenance costs and downtime.

How Does the Relay Starter Solenoid Benefit Construction Equipment?

Heavy construction equipment relies on relay starter solenoids to initiate engine operation efficiently. These solenoids improve the reliability of starting processes, essential for keeping projects on schedule. When sourcing solenoids for construction applications, businesses should prioritize suppliers known for quality assurance and durability, given the demanding operational environments and the potential for wear and tear.

Why are Relay Starter Solenoids Important in Marine Applications?

In marine applications, relay starter solenoids are vital for starting boat engines quickly and reliably. They must be designed to withstand marine conditions, including exposure to saltwater and humidity. Buyers in this sector should consider sourcing solenoids with corrosion-resistant properties and marine-grade specifications to ensure long-lasting performance and safety during operations.

How Do Relay Starter Solenoids Support Industrial Equipment Operations?

In industrial settings, relay starter solenoids are commonly used in generator systems to ensure dependable power generation. They play a critical role in initiating the generator engine, which is essential for uninterrupted operations in various industries. International buyers should ensure that the solenoids comply with safety standards relevant to their local regulations, which can vary significantly across regions like South America and the Middle East.

3 Common User Pain Points for ‘relay starter solenoid’ & Their Solutions

Szenario 1: Intermittierende Startprobleme, die den Flottenbetrieb beeinträchtigen

Das Problem: B2B buyers managing fleets often face the frustrating challenge of intermittent starting issues with vehicles, which can lead to unplanned downtimes. This situation not only affects operational efficiency but also incurs additional costs in repairs and lost productivity. When a vehicle fails to start, it may be due to a malfunctioning relay starter solenoid, causing delays in service delivery or logistics operations. Fleet managers are particularly concerned about maintaining reliability and ensuring that every vehicle is ready for use when needed.

Die Lösung: To mitigate this problem, fleet managers should implement a proactive maintenance schedule that includes regular diagnostics of the relay starter solenoid. It’s essential to source high-quality solenoids that match the specific vehicle models in the fleet. Buyers should collaborate with trusted suppliers who provide detailed specifications and compatibility information for each solenoid. Furthermore, implementing a system for tracking the performance of each vehicle can help identify patterns of failure related to the solenoids, allowing for timely replacements before they lead to a complete breakdown. Regular training for maintenance staff on the identification of solenoid-related issues will enhance the fleet’s overall reliability.

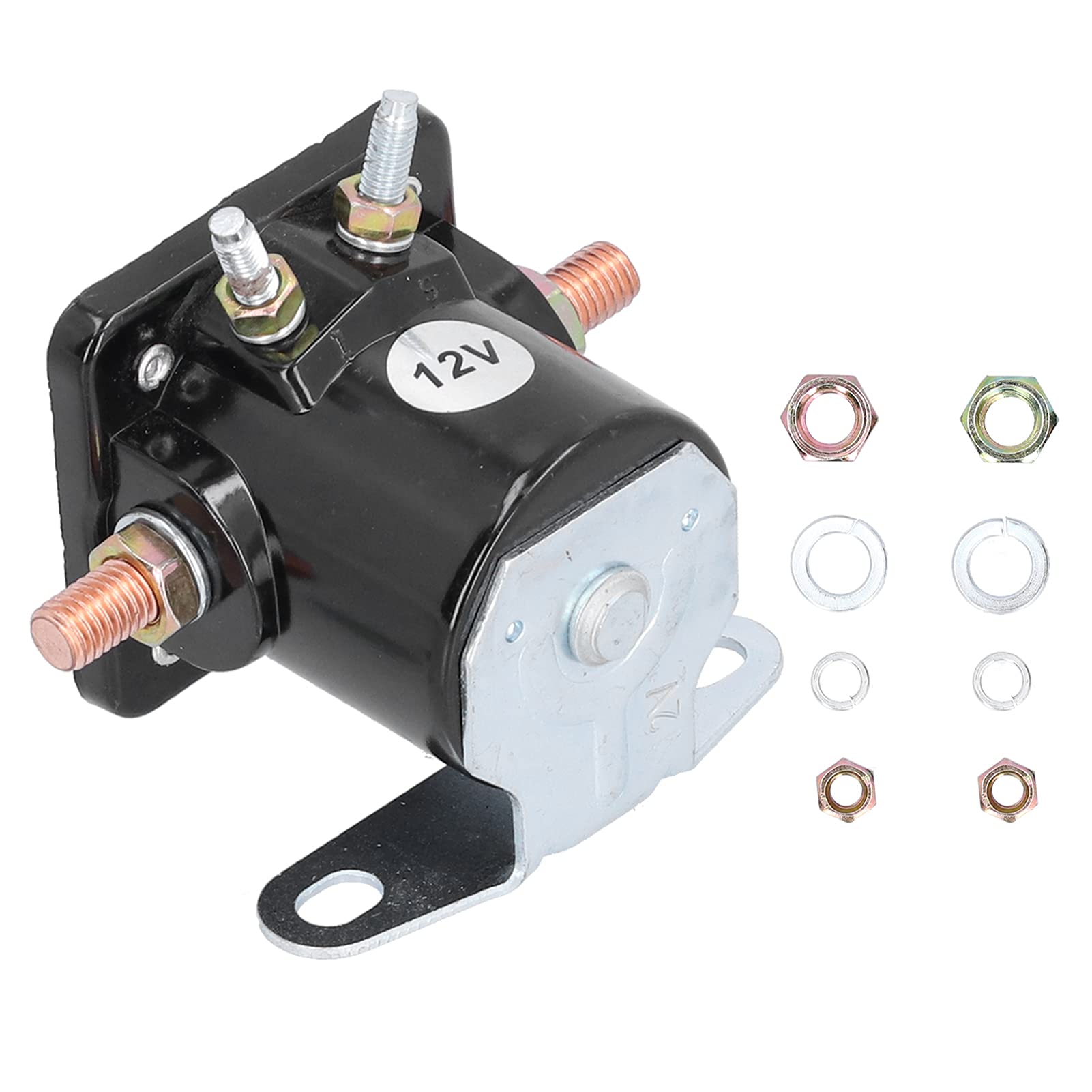

Illustrative image related to relay starter solenoid

Scenario 2: Misunderstanding Between Relay and Solenoid Specifications

Das Problem: Confusion between relay and solenoid specifications can lead to incorrect purchases, resulting in wasted resources and delayed projects. B2B buyers may struggle to determine which component is needed for specific applications, especially since some manufacturers use both types in their vehicles. This lack of clarity can create significant challenges in procurement and inventory management, particularly in regions where sourcing quality parts is difficult.

Die Lösung: To address this pain point, buyers should invest time in understanding the differences between relays and solenoids, including their applications and specifications. Engaging with suppliers who offer technical support can clarify these distinctions and ensure accurate ordering. Buyers should also consider maintaining a comprehensive database of vehicles and their corresponding parts, including detailed specifications for each component. This can streamline the procurement process and reduce the risk of errors. Additionally, leveraging technology such as inventory management software that integrates specifications and compatibility can further minimize confusion and optimize purchasing strategies.

Scenario 3: Difficulty in Identifying Faulty Starter Components

Das Problem: B2B buyers often encounter challenges in diagnosing issues related to starter components, particularly in environments where technical expertise is limited. A faulty starter solenoid may present symptoms similar to other electrical issues, leading to misdiagnosis and unnecessary part replacements. This can be especially problematic in regions where access to skilled technicians is scarce, resulting in increased operational costs and vehicle downtime.

Die Lösung: To overcome this challenge, companies should develop a clear diagnostic protocol for identifying faulty starter solenoids. This protocol should include specific tests and checks that can be performed even by less experienced technicians. Investing in training programs that focus on electrical systems and starter components can significantly enhance the diagnostic capabilities of the workforce. Furthermore, creating partnerships with local automotive experts or service centers can provide additional resources for accurate diagnosis and repair. Providing detailed troubleshooting guides and visual aids can also empower technicians to diagnose issues more effectively, leading to quicker resolutions and reduced downtime.

Strategic Material Selection Guide for relay starter solenoid

What Materials Are Commonly Used for Relay Starter Solenoids?

When selecting materials for relay starter solenoids, understanding the properties, advantages, and limitations of each option is crucial for ensuring optimal performance and durability. Below is an analysis of four common materials utilized in the manufacturing of relay starter solenoids, tailored for international B2B buyers.

How Does Copper Perform in Relay Starter Solenoids?

Wichtige Eigenschaften: Copper is known for its excellent electrical conductivity and thermal properties, making it ideal for applications requiring efficient energy transfer. It can withstand moderate temperatures and pressures, typically rated up to 200°C.

Illustrative image related to relay starter solenoid

Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which enhances the solenoid’s performance. However, it is susceptible to corrosion, especially in harsh environments, which can lead to reduced longevity. Additionally, copper can be more expensive than alternative materials, and its manufacturing process can be complex due to the need for precise machining.

Auswirkungen auf die Anwendung: Copper is highly compatible with various media, including automotive fluids and electrical systems. However, its susceptibility to corrosion necessitates protective coatings or treatments, particularly in regions with high humidity or saline conditions, such as coastal areas in Africa and South America.

What Role Does Aluminum Play in Relay Starter Solenoids?

Wichtige Eigenschaften: Aluminum offers a good balance of strength and weight, with a temperature rating up to 150°C. It is also resistant to corrosion due to the formation of a protective oxide layer.

Illustrative image related to relay starter solenoid

Vor- und Nachteile: The lightweight nature of aluminum makes it an attractive option for applications where weight reduction is critical. However, its lower electrical conductivity compared to copper can impact performance. Additionally, while aluminum is generally less expensive, it may require more robust designs to ensure durability.

Auswirkungen auf die Anwendung: Aluminum’s corrosion resistance makes it suitable for diverse environments, including the Middle East, where high temperatures and humidity can be challenging. Buyers should ensure compliance with relevant standards such as ASTM for material specifications.

Why Is Steel Considered for Relay Starter Solenoids?

Wichtige Eigenschaften: Steel is known for its high strength and durability, with temperature ratings often exceeding 300°C. It is less conductive than copper but provides significant mechanical strength.

Vor- und Nachteile: The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. However, its lower corrosion resistance means it may require additional treatments, such as galvanization, to prevent rust. Steel is often more affordable than copper, making it an economical choice for manufacturers.

Auswirkungen auf die Anwendung: Steel’s mechanical properties make it ideal for applications requiring high strength, but its compatibility with certain media can be a concern. Buyers in regions like Europe should consider compliance with DIN standards for steel quality and performance.

How Does Plastic Factor Into Relay Starter Solenoid Design?

Wichtige Eigenschaften: Plastics, particularly engineering-grade thermoplastics, can withstand temperatures up to 100°C and offer excellent electrical insulation properties.

Vor- und Nachteile: The primary advantage of plastic is its lightweight nature and resistance to corrosion, making it suitable for various environments. However, plastics may not withstand high temperatures as effectively as metals, and their mechanical strength can be lower, potentially leading to failure under heavy loads.

Auswirkungen auf die Anwendung: Plastic components are often used in solenoid housings or insulation parts, where weight savings and corrosion resistance are priorities. Buyers should ensure that the chosen plastic meets relevant international standards for automotive applications, particularly in regions like Africa and South America where environmental conditions can vary significantly.

Summary Table of Material Selection for Relay Starter Solenoids

| Material | Typical Use Case for relay starter solenoid | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Electrical contacts in solenoids | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Aluminium | Lightweight solenoid housings | Gutes Verhältnis von Stärke zu Gewicht | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Heavy-duty solenoid components | Hohe Festigkeit und Haltbarkeit | Lower corrosion resistance | Niedrig |

| Kunststoff | Isolierung und Gehäuseteile | Leicht und korrosionsbeständig | Lower temperature and mechanical strength | Mittel |

This analysis provides B2B buyers with a comprehensive understanding of material options for relay starter solenoids, allowing for informed decision-making based on performance requirements and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for relay starter solenoid

What Are the Main Stages of Manufacturing a Relay Starter Solenoid?

The manufacturing process of a relay starter solenoid is intricate, involving several critical stages. Each stage is designed to ensure the final product meets the stringent demands of performance and reliability.

Materialvorbereitung: Welche Materialien werden verwendet?

The first step involves selecting high-quality materials, which typically include copper for electrical contacts, steel for the housing, and various plastics for insulation. The copper is often plated with nickel or tin to enhance conductivity and prevent corrosion. Steel components may undergo a treatment process to improve durability and resistance to environmental factors.

How Are Relay Starter Solenoids Formed?

Once the materials are prepared, they undergo forming processes such as stamping, machining, and molding. Stamping is used for creating metal components, while plastic parts are typically produced through injection molding. These techniques ensure that each part is precisely manufactured to fit together seamlessly.

What Is the Assembly Process Like?

The assembly stage involves integrating all components, including the coil, plunger, and housing. Automated assembly lines are frequently employed to increase efficiency and reduce human error. During this stage, attention to detail is paramount; components must be aligned correctly to ensure optimal performance. Workers may also perform manual checks to confirm the assembly’s integrity before moving on to the finishing stage.

Welche Veredelungstechniken werden üblicherweise verwendet?

The finishing process may include painting, coating, or plating. This is not only for aesthetic reasons but also to provide additional protection against corrosion and wear. A common practice involves applying a powder coat to the outer housing, which enhances durability and resistance to environmental challenges.

What Quality Assurance Practices Are Essential for Relay Starter Solenoids?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each relay starter solenoid meets both international and industry-specific standards.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

For B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, understanding the relevant international standards is crucial. ISO 9001 is the cornerstone of quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, certifications like CE mark for compliance with European safety standards and API standards for automotive components are often significant for buyers.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These checkpoints typically include:

Illustrative image related to relay starter solenoid

-

Eingangsqualitätskontrolle (IQC): This step verifies the quality of raw materials and components before production begins. Suppliers must meet stringent specifications to be approved.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing stages, regular inspections are conducted to ensure compliance with design specifications. This may involve measuring tolerances and checking for defects.

-

Endkontrolle (FQC): After assembly, the final product undergoes thorough testing. This may include functional tests to ensure the solenoid operates correctly under various conditions.

Welche Prüfverfahren werden üblicherweise zur Qualitätssicherung eingesetzt?

Testing methods are vital to validate the performance and reliability of relay starter solenoids. Common testing techniques include:

-

Elektrische Prüfung: This assesses the solenoid’s electrical characteristics, such as resistance and current draw. It ensures that the solenoid can handle the required load without failure.

-

Haltbarkeitsprüfung: Solenoids are subjected to various environmental conditions, including temperature fluctuations and humidity, to simulate real-world usage. This testing helps identify potential failures before the product reaches the market.

-

Funktionsprüfung: This involves physically operating the solenoid under controlled conditions to verify its performance. It ensures that the solenoid activates and deactivates as intended.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

When sourcing relay starter solenoids, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some actionable strategies:

What Audits and Reports Should Be Reviewed?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should request documentation of past audits, quality control reports, and certifications. Regular audits can help identify weaknesses in a supplier’s processes and ensure compliance with international standards.

Is Third-Party Inspection a Viable Option?

Engaging a third-party inspection service is another way to confirm a supplier’s quality assurance practices. These organizations can conduct independent assessments of the manufacturing process, ensuring that products meet both buyer specifications and regulatory standards. This is especially important for buyers in regions with varying levels of local compliance.

Illustrative image related to relay starter solenoid

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

B2B buyers from Africa, South America, the Middle East, and Europe face unique challenges regarding quality control. It is essential to understand that regulations and standards may vary significantly across different regions. Therefore, buyers should ensure that their suppliers are familiar with local laws and compliance requirements.

How Can Buyers Navigate These Differences?

Buyers should establish clear communication channels with suppliers to address potential quality control issues. This can involve setting specific quality expectations, timelines for delivery, and procedures for handling defects. By fostering a collaborative relationship, buyers can help ensure that suppliers remain aligned with their quality assurance goals.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance practices for relay starter solenoids is crucial for B2B buyers looking to ensure reliability and performance in their sourcing efforts. By being informed about the stages of manufacturing, relevant standards, and effective quality control measures, buyers can make more educated decisions, reducing the risk of sourcing subpar products. Engaging in thorough due diligence will ultimately lead to stronger supplier relationships and enhanced operational success.

Illustrative image related to relay starter solenoid

Practical Sourcing Guide: A Step-by-Step Checklist for ‘relay starter solenoid’

In the competitive landscape of B2B procurement, sourcing a reliable relay starter solenoid is critical for ensuring the operational efficiency of automotive and machinery applications. This guide provides a step-by-step checklist to help you navigate the sourcing process effectively.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before you start reaching out to suppliers, it’s essential to clearly outline the technical specifications required for the relay starter solenoid. Consider factors such as voltage rating, current capacity, and compatibility with existing systems. This clarity will help you communicate effectively with potential suppliers and ensure you receive products that meet your needs.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify suppliers that specialize in relay starter solenoids. Look for companies with a proven track record in the automotive or machinery sectors. Utilize platforms such as industry directories, trade shows, and online marketplaces to compile a list of potential suppliers.

Illustrative image related to relay starter solenoid

- Focus on Local and International Options: Depending on your location, consider both local suppliers for faster shipping and international ones for a broader range of options.

Schritt 3: Bewerten Sie die Glaubwürdigkeit von Lieferanten

Before making a commitment, vet the credentials of potential suppliers. Verify their certifications, such as ISO 9001, which indicates a commitment to quality management practices. Additionally, check for compliance with international standards relevant to your industry.

- Dokumentation anfordern: Ask for product specifications, quality assurance processes, and past performance records to assess their reliability.

Schritt 4: Assess Product Quality

Quality is paramount when sourcing relay starter solenoids. Request samples or detailed product specifications to evaluate the materials used and manufacturing processes. Look for indicators such as warranties or guarantees that can provide additional assurance of product durability.

- Conduct Testing if Possible: If feasible, conduct performance tests on samples to ensure they meet your operational requirements.

Schritt 5: Understand Pricing Structures

Understanding the pricing structure is crucial for budget management. Request detailed quotations from suppliers, including costs related to shipping, taxes, and potential duties. Ensure that you compare similar product specifications to make an accurate assessment.

- Bedingungen aushandeln: Don’t hesitate to negotiate terms, especially if you are considering bulk purchases or long-term partnerships.

Schritt 6: Review Delivery and Lead Times

Timely delivery is essential to maintain your operational schedule. Inquire about lead times and shipping options. Understanding the supplier’s production capacity and logistics capabilities will help you assess whether they can meet your deadlines.

- Establish Clear Expectations: Clearly communicate your delivery requirements to avoid potential disruptions in your operations.

Schritt 7: Seek References and Testimonials

Finally, reach out to previous customers for references or testimonials about their experiences with the supplier. This can provide valuable insights into the supplier’s reliability, customer service, and product performance.

- Evaluate Customer Feedback: Look for patterns in feedback to gauge overall satisfaction and identify any recurring issues.

By following this checklist, B2B buyers can streamline the sourcing process for relay starter solenoids, ensuring they make informed decisions that align with their operational needs and quality expectations.

Comprehensive Cost and Pricing Analysis for relay starter solenoid Sourcing

What Are the Key Cost Components for Sourcing Relay Starter Solenoids?

When evaluating the cost structure for sourcing relay starter solenoids, several critical components contribute to the overall pricing. These components include:

-

Materialien: The choice of materials is fundamental in determining the cost. High-quality copper for windings, robust steel for housings, and durable plastics for insulation can significantly influence pricing. Buyers should consider the trade-off between lower-cost materials and the potential for increased failure rates, which could lead to higher long-term costs.

-

Arbeit: Labor costs can vary widely based on geographic location and local wage standards. In regions with higher labor costs, such as Europe, the manufacturing expenses will be elevated. Conversely, sourcing from regions with lower labor costs, like certain parts of Africa or South America, may present cost savings but could also come with quality control challenges.

-

Fertigungsgemeinkosten: This includes costs associated with factory operations, such as utilities, administrative expenses, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, impacting the final price for buyers.

-

Werkzeuge: Initial tooling costs can be significant, especially for custom solenoids. These costs are amortized over production runs, meaning larger orders can dilute tooling expenses per unit. Buyers should inquire about tooling fees and how they are structured in relation to order size.

-

Qualitätskontrolle (QC): Ensuring the reliability of solenoids requires investment in quality control processes. Rigorous testing and certification can add to the upfront costs but are essential for minimizing returns and warranty claims in the long run.

-

Logistik: Shipping and handling costs can vary based on the location of the supplier and the destination market. International shipping may involve tariffs and taxes, which should be factored into the total cost.

-

Marge: Suppliers will typically build in a profit margin, which can vary depending on the competitive landscape and the perceived value of the product. Understanding the market rates for similar products can help buyers gauge whether they are receiving a fair price.

What Factors Influence Pricing for Relay Starter Solenoids?

Several factors can influence the pricing of relay starter solenoids, particularly for international B2B buyers:

-

Volumen und Mindestbestellmenge (MOQ): Bulk purchasing often leads to discounts. Buyers should negotiate MOQs that align with their inventory needs to benefit from lower unit costs.

-

Spezifikationen und Anpassung: Custom specifications can lead to higher costs due to unique tooling and material requirements. Clearly defining needs upfront can help mitigate unexpected charges.

-

Materialqualität und Zertifizierungen: High-quality materials and recognized certifications (such as ISO) can increase costs but also enhance reliability and performance. Buyers should evaluate the importance of certifications in their sourcing decisions.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but often offer better quality assurance and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost management in international transactions. These terms dictate who is responsible for shipping costs, insurance, and tariffs, which can significantly impact the final price.

Welche Tipps können Käufern helfen, bessere Preise zu verhandeln?

-

Verhandlung: Führen Sie mit den Lieferanten Gespräche über die Preisgestaltung und seien Sie bereit, Mengenverpflichtungen oder langfristige Verträge für bessere Preise zu nutzen.

-

Kosteneffizienz: Look beyond the initial purchase price. Evaluate the Total Cost of Ownership (TCO), which includes installation, maintenance, and potential failure costs, to make informed purchasing decisions.

-

Preisgestaltung für internationale Käufer: Recognize that currency fluctuations, geopolitical factors, and local market conditions can affect prices. Conducting thorough market research can provide insights into fair pricing.

-

Haftungsausschluss für Richtpreise: Keep in mind that prices can fluctuate based on various factors, including market demand and raw material availability. Always request updated quotes to ensure accuracy.

By understanding these components and strategies, B2B buyers can make informed decisions in sourcing relay starter solenoids that align with their operational needs and financial goals.

Alternatives Analysis: Comparing relay starter solenoid With Other Solutions

Exploring Alternatives to Relay Starter Solenoids

In the automotive and industrial sectors, the relay starter solenoid is a common component used to engage the engine’s starter. However, various alternatives exist that can perform similar functions. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific application needs.

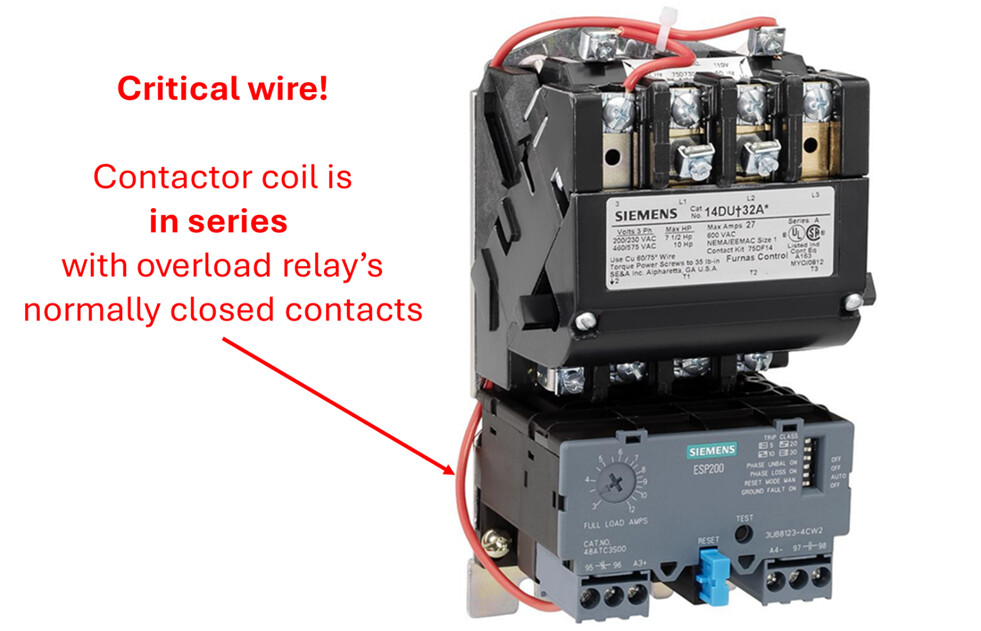

| Vergleichsaspekt | Relay Starter Solenoid | Halbleiterrelais | Contactor |

|---|---|---|---|

| Leistung | High power switching capability; reliable for most applications | Fast switching; minimal wear and tear | High current capacity; suitable for large loads |

| Kosten | Moderate price point | Höhere Anschaffungskosten | Variable cost, typically lower than solid-state for large applications |

| Einfache Implementierung | Unkomplizierte Installation | Requires proper heat dissipation setup | More complex; needs careful wiring and configuration |

| Wartung | Generally low; can fail over time | Virtually maintenance-free | Regular checks for wear on contacts |

| Bester Anwendungsfall | Standard-Automobilanwendungen | High-speed switching applications | Industrial machinery and heavy equipment |

What Are the Advantages and Disadvantages of Solid State Relays?

Solid state relays (SSRs) serve as an alternative to relay starter solenoids, particularly in applications requiring rapid switching. SSRs utilize semiconductor devices to switch circuits, leading to faster response times and reduced wear over time. They are ideal for high-frequency applications where mechanical wear could be an issue. However, they come at a higher initial cost and require a suitable heat dissipation setup, which can complicate installation.

How Do Contactors Compare to Relay Starter Solenoids?

Contactors are another viable alternative, particularly suited for heavy-duty applications. They can handle larger loads and are often used in industrial machinery. While contactors can be more complex to implement due to wiring requirements, they generally offer a lower cost for handling significant current loads compared to solid-state alternatives. However, they do require periodic maintenance to check for contact wear and ensure reliable operation.

Wie können B2B-Einkäufer die richtige Lösung auswählen?

Choosing the right solution between relay starter solenoids and their alternatives ultimately depends on the specific needs of your application. Consider factors such as the required performance level, installation complexity, maintenance needs, and budget constraints. For standard automotive use, relay starter solenoids are often sufficient. However, for applications requiring rapid switching or handling heavy electrical loads, solid-state relays or contactors may provide enhanced performance and reliability. By evaluating these aspects carefully, B2B buyers can select the most suitable solution to meet their operational requirements.

Illustrative image related to relay starter solenoid

Essential Technical Properties and Trade Terminology for relay starter solenoid

What Are the Key Technical Properties of Relay Starter Solenoids?

When considering the procurement of relay starter solenoids, it is essential to understand several critical technical properties that influence performance and compatibility. Here are the key specifications:

-

Werkstoffgüte

The materials used in the construction of relay starter solenoids significantly impact their durability and performance. Common materials include copper for electrical components due to its excellent conductivity, and high-grade plastics or metals for the housing to ensure resistance against heat and corrosion. Understanding material grades helps buyers assess longevity and reliability, particularly in harsh operating environments. -

Aktuelle Bewertung

This specification indicates the maximum current the solenoid can handle without overheating or failing. It is typically measured in Amperes (A). For B2B buyers, knowing the current rating is crucial for ensuring compatibility with specific vehicle systems and avoiding potential electrical failures, which can lead to costly downtime and repairs. -

Spulenwiderstand

Measured in Ohms, coil resistance affects how efficiently the solenoid operates. A solenoid with too high or too low resistance may not function properly, leading to issues like delayed engagement or excessive power draw. Buyers should consider this specification to ensure optimal performance and energy efficiency in their applications. -

Betriebstemperaturbereich

This property defines the temperature limits within which the solenoid can function effectively. A wide operating temperature range is particularly important for applications in regions with extreme climates. Buyers must evaluate the temperature specifications to ensure the solenoid will perform reliably under local conditions. -

Actuation Type

Relay starter solenoids can be either normally open (NO) or normally closed (NC). The actuation type determines how the solenoid engages when power is applied. Understanding this distinction is vital for buyers to ensure the solenoid aligns with their system requirements, as incorrect specifications can lead to malfunction. -

Montagekonfiguration

The design and dimensions for mounting can vary significantly among different solenoid models. This includes bolt patterns and physical dimensions. Ensuring that the solenoid fits within the designated space in a vehicle is critical for installation and functionality, making this an essential property for buyers to verify.

What Are Common Trade Terms Related to Relay Starter Solenoids?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms:

-

OEM (Originalgerätehersteller)

Refers to companies that produce components used in the assembly of vehicles. OEM parts are typically preferred due to their guaranteed compatibility and quality, making them a popular choice for B2B buyers looking for reliable solutions. -

MOQ (Mindestbestellmenge)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels effectively and negotiate favorable terms, especially when dealing with international suppliers. -

RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers often use RFQs to compare offers and make informed purchasing decisions, ensuring they receive competitive pricing and favorable conditions. -

Incoterms (Internationale Handelsklauseln)

A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify responsibilities regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international buyers to avoid misunderstandings and ensure smooth logistics. -

Vorlaufzeit

This refers to the time required from placing an order to receiving the product. For B2B buyers, knowing the lead time is essential for planning and managing supply chains effectively, particularly in industries where timely delivery is critical. -

Garantiezeitraum

The duration for which the manufacturer guarantees the product against defects. A longer warranty period can be a significant selling point, providing assurance of quality and reliability to B2B buyers who seek to minimize risk in their purchases.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure successful procurement of relay starter solenoids.

Navigating Market Dynamics and Sourcing Trends in the relay starter solenoid Sector

What Are the Current Market Dynamics and Key Trends in the Relay Starter Solenoid Sector?

The global relay starter solenoid market is witnessing significant growth driven by several key factors. The automotive sector, particularly in emerging markets such as Africa, South America, and the Middle East, is experiencing a surge in vehicle production and sales. This growth is fueled by rising disposable incomes and increasing urbanization, leading to a higher demand for reliable automotive components. Additionally, advancements in automotive technology, including the shift towards electric vehicles (EVs), are reshaping the landscape of starter solenoids. Manufacturers are adapting their product offerings to meet the specific requirements of electric and hybrid vehicles, which often utilize advanced solenoid technology for efficient power management.

Emerging B2B tech trends are also influencing sourcing strategies. The integration of Internet of Things (IoT) technologies in automotive applications allows for real-time monitoring and diagnostics of starter solenoids, enhancing maintenance and reducing downtime. Furthermore, the rise of e-commerce platforms is transforming traditional procurement processes, enabling international buyers from regions like Nigeria and Saudi Arabia to source components more efficiently and transparently.

Market dynamics are further impacted by the competitive landscape, where suppliers must balance quality and cost. International buyers are increasingly looking for suppliers who can provide not only competitive pricing but also superior quality assurance and after-sales support. Strategic partnerships and collaborations are becoming essential for companies aiming to secure their supply chains amid global disruptions.

How Does Sustainability and Ethical Sourcing Impact the Relay Starter Solenoid Market?

Sustainability is becoming a critical focus in the relay starter solenoid sector as environmental concerns gain traction globally. The production and disposal of automotive components, including starter solenoids, can have significant environmental impacts. Buyers are increasingly prioritizing suppliers who implement eco-friendly manufacturing practices and materials. This trend is particularly relevant in regions like Europe, where stringent regulations on emissions and waste management are in place.

Ethical sourcing is also gaining importance, with businesses seeking to ensure that their supply chains are free from unethical labor practices and environmental degradation. Buyers are encouraged to seek suppliers with certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. Additionally, the use of recyclable materials in the production of relay starter solenoids is becoming a value proposition that appeals to environmentally conscious consumers and businesses alike.

Incorporating sustainable practices not only enhances a company’s brand image but also aligns with the growing consumer demand for responsible sourcing. As international buyers navigate the complexities of sourcing, understanding and prioritizing sustainability can lead to long-term partnerships and market competitiveness.

What Is the Brief Evolution of Relay Starter Solenoids in the Automotive Industry?

The evolution of relay starter solenoids is closely tied to advancements in automotive technology. Initially, starter solenoids were mechanical devices that relied on simple electromagnetic principles to engage the starter motor. Over the decades, these components have undergone significant transformations, becoming more compact and efficient due to advancements in materials and manufacturing processes.

The introduction of electronic ignition systems in the late 20th century marked a pivotal shift, allowing for more precise control over engine start-up processes. This innovation paved the way for the development of solenoids that could handle higher currents and provide faster engagement times. As the automotive industry moves towards electrification, today’s relay starter solenoids are increasingly designed to meet the demands of electric and hybrid vehicles, incorporating smart technology that enhances performance and reliability.

In summary, the relay starter solenoid sector is rapidly evolving, driven by market demands and technological advancements, making it essential for international B2B buyers to stay informed about trends, sustainability practices, and the historical context of these critical automotive components.

Frequently Asked Questions (FAQs) for B2B Buyers of relay starter solenoid

-

How do I solve issues with a malfunctioning starter solenoid?

To address a malfunctioning starter solenoid, first, conduct a thorough diagnosis. Check for common signs such as a single click sound when turning the key or intermittent starting issues. Ensure that the battery is in good condition and fully charged, as a weak battery can mimic solenoid failure. Inspect wiring for corrosion or loose connections, which can impede power flow. If these checks do not resolve the issue, consider replacing the solenoid, especially if it is not engaging or disengaging properly. -

What is the best starter solenoid for commercial vehicles?

The best starter solenoid for commercial vehicles typically combines durability with high-performance specifications. Look for solenoids that can handle higher amperage, as commercial vehicles often require more power to start. Brands known for reliability, such as Bosch or Denso, are recommended. It’s also crucial to ensure compatibility with your vehicle’s specific make and model. Consulting with a trusted supplier can help identify the most suitable solenoid that meets operational requirements and environmental conditions. -

What are the minimum order quantities (MOQs) for relay starter solenoids?

Minimum order quantities (MOQs) for relay starter solenoids vary significantly by supplier and manufacturer. Generally, MOQs can range from as low as 50 units to several hundred, depending on the supplier’s production capabilities and your specific customization needs. For international buyers, negotiating MOQs is often possible, especially if you establish a long-term partnership. Always inquire about potential discounts for larger orders, which can significantly reduce your unit cost. -

How can I vet suppliers for starter solenoids in international trade?

To vet suppliers for starter solenoids, start by checking their certifications and compliance with international quality standards, such as ISO 9001. Look for reviews and testimonials from previous clients to assess their reliability and service quality. Additionally, request samples to evaluate product quality firsthand. Engaging in direct communication about lead times, payment terms, and return policies can also provide insight into their business practices. Utilizing platforms like Alibaba or Global Sources can help identify reputable suppliers. -

What payment terms should I expect when sourcing starter solenoids internationally?

Payment terms when sourcing starter solenoids can vary widely among suppliers. Common terms include payment in advance, 30% deposit with the balance due before shipment, or net 30/60 days post-delivery. For large orders, some suppliers may offer letter of credit options to secure the transaction. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that terms are documented in a purchase agreement to prevent misunderstandings. -

How can I customize starter solenoids for specific applications?

Customization of starter solenoids for specific applications typically involves discussing your requirements with the supplier. This may include specifications such as size, voltage, current ratings, and mounting configurations. Some manufacturers offer bespoke solutions tailored to unique operational environments, like extreme temperatures or moisture exposure. Requesting prototypes before full-scale production can help ensure that the customized solenoids meet your operational needs effectively. -

What quality assurance measures should I expect from manufacturers?

Quality assurance measures from manufacturers of starter solenoids should include rigorous testing protocols to ensure performance and reliability. Look for suppliers who conduct tests for durability, electrical performance, and compliance with international standards. Certifications such as CE or RoHS can indicate adherence to safety and environmental regulations. Request documentation of quality control processes and inquire about warranties offered on products to safeguard your investment. -

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Anlassermagneten anstellen?

When importing starter solenoids, consider logistics factors such as shipping methods, customs regulations, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that your supplier provides the necessary documentation for customs clearance, including invoices and packing lists. It’s advisable to work with a freight forwarder familiar with your destination country’s import regulations to streamline the process and avoid delays.

Top 1 Relay Starter Solenoid Manufacturers & Suppliers List

1. Reddit – Starter Relay and Solenoid

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: A starter relay is an electromagnetic switch that closes or opens a circuit, while a starter solenoid is an electromagnetic actuator that moves a physical object. The starter solenoid is attached to the starter motor and functions as both a relay and a solenoid, closing the circuit to the starter motor and engaging the starter pinion with the flywheel. Heavy-duty starters may also have a relay (of…

Strategic Sourcing Conclusion and Outlook for relay starter solenoid

How Can Strategic Sourcing Enhance Your Relay Starter Solenoid Procurement?

In conclusion, strategic sourcing for relay starter solenoids is essential for international B2B buyers seeking reliability and performance in automotive components. Understanding the distinct roles of relays and solenoids, as well as recognizing the signs of failure, can help buyers make informed decisions. By prioritizing quality suppliers who adhere to rigorous manufacturing standards, companies can mitigate risks associated with part failures and ensure seamless operations.

Moreover, fostering strong relationships with suppliers not only enhances supply chain resilience but also opens doors to innovative solutions tailored to specific regional needs, particularly in emerging markets like Africa and South America. With the automotive industry evolving rapidly, investing in the right sourcing strategies will position your business for future growth.

As you navigate the complexities of sourcing relay starter solenoids, consider leveraging data analytics and market intelligence to identify trends and opportunities. Now is the time to act—strengthen your procurement strategies and partner with trusted suppliers to secure the components that drive your business forward. Embrace this journey toward excellence in sourcing and watch your operational efficiency soar.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to relay starter solenoid

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.