Introduction: Navigating the Global Market for how much does a motor cost to replace

In today’s competitive landscape, understanding how much a motor costs to replace can present a significant challenge for international B2B buyers. With variations in pricing influenced by factors such as engine type, labor costs, and geographical location, decision-makers must navigate a complex market landscape. This comprehensive guide delves into the various dimensions of motor replacement costs, covering the types of motors available, their applications across industries, and essential strategies for vetting suppliers effectively.

By examining the nuances of engine replacement—from new and remanufactured options to OEM and aftermarket parts—this guide equips buyers with the insights needed to make informed purchasing decisions. Additionally, we will explore regional considerations that may impact costs and availability, particularly for businesses operating in Africa, South America, the Middle East, and Europe. For instance, understanding local labor rates and parts sourcing can help streamline budget planning and execution.

Ultimately, this guide aims to empower B2B buyers with the knowledge required to navigate the complexities of motor replacement, ensuring they achieve the best balance of cost, quality, and performance for their operational needs. With a focus on practical advice and actionable insights, buyers can confidently approach their motor replacement projects, optimizing their investments and minimizing downtime.

Inhaltsverzeichnis

- Top 3 How Much Does A Motor Cost To Replace Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does a motor cost to replace

- Understanding how much does a motor cost to replace Types and Variations

- Key Industrial Applications of how much does a motor cost to replace

- 3 Common User Pain Points for ‘how much does a motor cost to replace’ & Their Solutions

- Strategic Material Selection Guide for how much does a motor cost to replace

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does a motor cost to replace

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does a motor cost to replace’

- Comprehensive Cost and Pricing Analysis for how much does a motor cost to replace Sourcing

- Alternatives Analysis: Comparing how much does a motor cost to replace With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does a motor cost to replace

- Navigating Market Dynamics and Sourcing Trends in the how much does a motor cost to replace Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does a motor cost to replace

- Strategic Sourcing Conclusion and Outlook for how much does a motor cost to replace

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how much does a motor cost to replace Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| New Engine | Brand new, factory-installed, no previous use | Fleet vehicles, luxury cars | Vorteile: Verlässlichkeit, Garantie; Nachteile: High cost. |

| Remanufactured Engine | Rebuilt to OEM specifications, some reused components | Commercial trucks, older vehicles | Vorteile: Kostengünstig, zuverlässig; Nachteile: Mögliche Schwankungen in der Qualität. |

| Used Engine | Previously owned, variable condition and history | Budget repairs, older model cars | Vorteile: Low cost; Nachteile: Uncertain reliability, limited warranty. |

| Performance Engine | Enhanced features for increased power and efficiency | Racing, high-performance vehicles | Vorteile: Überlegene Leistung; Nachteile: Higher cost, specialized installation. |

| OEM Parts | Original equipment manufacturer parts, guaranteed compatibility | All vehicle types needing specific repairs | Vorteile: Assurance of quality; Nachteile: Higher price compared to aftermarket. |

What Are the Characteristics of a New Engine Replacement?

New engines are ideal for businesses looking for reliability and performance without the risk of previous wear and tear. These engines are typically sourced directly from manufacturers and come with comprehensive warranties. They are suitable for fleet vehicles and luxury cars where reliability is paramount. However, the high cost associated with new engines can be a significant factor for businesses with tight budgets.

How Does a Remanufactured Engine Differ from a New Engine?

Remanufactured engines are rebuilt to meet original equipment manufacturer (OEM) specifications, ensuring a high level of performance. They often incorporate reused components that have been refurbished, making them a cost-effective option for businesses managing older vehicles or commercial fleets. While they provide a balance between cost and reliability, businesses should consider the potential variability in quality and warranty terms offered by different suppliers.

What Should Buyers Know About Used Engines?

Used engines present a budget-friendly alternative for companies looking to extend the life of older vehicles. These engines can be acquired at a fraction of the cost of new or remanufactured options. However, the condition and history of used engines can vary widely, making it essential for buyers to conduct thorough inspections and obtain warranties when possible. This option is best suited for businesses with older fleets where cost savings are prioritized over performance guarantees.

What Are the Benefits of Choosing a Performance Engine?

Performance engines are designed for enhanced power and efficiency, making them an attractive choice for businesses involved in racing or requiring high-performance vehicles. While they offer significant performance benefits, these engines come at a higher price point and may require specialized installation. Businesses must evaluate whether the performance gains justify the additional costs and complexities involved.

Why Choose OEM Parts for Engine Replacement?

OEM parts are made by the same manufacturer as the original components, ensuring compatibility and quality. They are essential for businesses that prioritize reliability and want to maintain the integrity of their vehicles. While OEM parts tend to be more expensive than aftermarket alternatives, the assurance of quality and fit can reduce long-term maintenance costs and downtime, making them a wise investment for many businesses.

Key Industrial Applications of how much does a motor cost to replace

| Branche/Sektor | Specific Application of how much does a motor cost to replace | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Fertigung | Replacement of motors in production machinery | Minimizes downtime and maintains production efficiency | Availability of OEM vs. aftermarket parts, local labor costs |

| Landwirtschaft | Motor replacement in irrigation systems | Ensures reliable water supply for crops | Compatibility with existing systems, warranty options |

| Transport | Engine replacement in commercial vehicles | Erhöht die Zuverlässigkeit der Flotte und reduziert die Betriebskosten | Cost of new vs. remanufactured engines, labor rates |

| Bauwesen | Motor replacement in heavy machinery | Improves equipment performance and safety | Quality of replacement parts, lead times for sourcing |

| Energiesektor | Replacement of motors in power generation equipment | Ensures continuous energy supply and operational reliability | Compliance with industry standards, sourcing from reputable suppliers |

How is ‘how much does a motor cost to replace’ applied in Manufacturing?

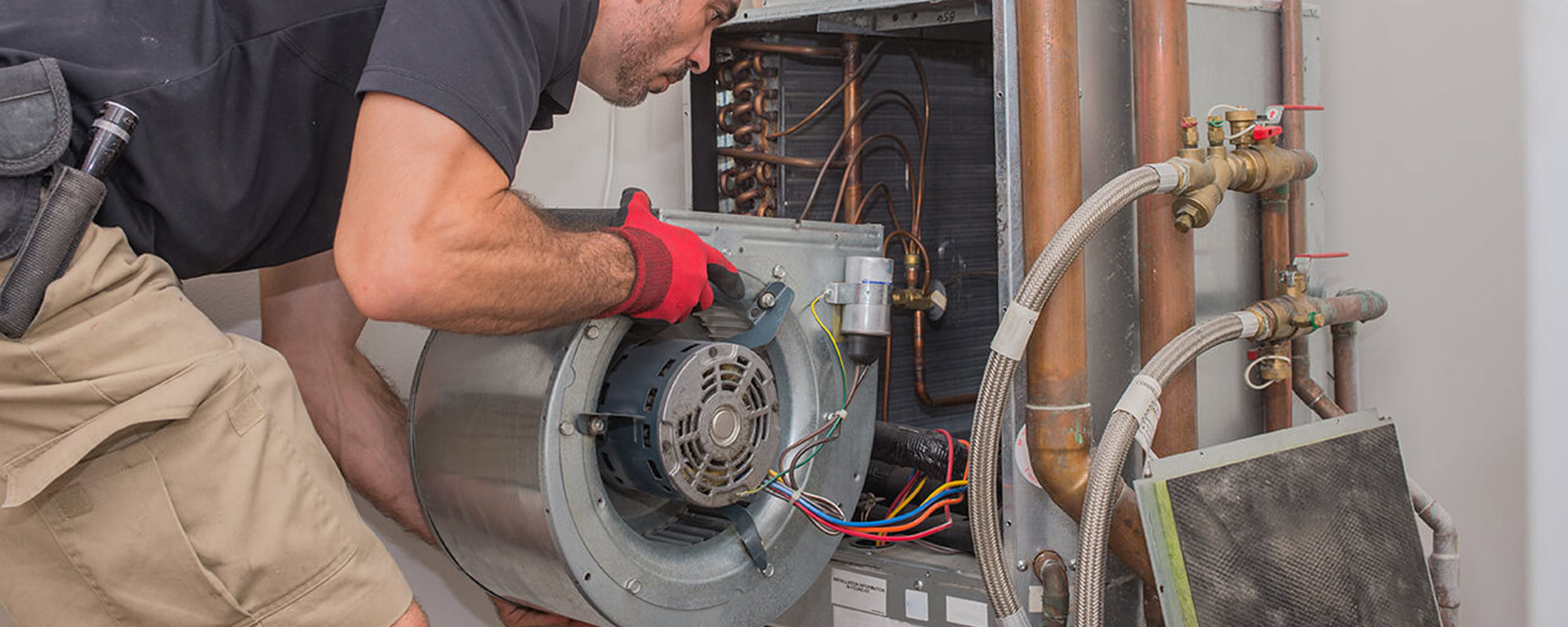

In the manufacturing sector, motors are critical components of production machinery. When a motor fails, understanding the cost of replacement is essential for budgeting and minimizing operational downtime. International buyers should consider not only the price of the motor itself but also labor costs, which can vary significantly based on location. Additionally, the choice between OEM and aftermarket parts can impact reliability and long-term maintenance costs. By budgeting effectively for motor replacements, businesses can ensure continuous production and avoid costly interruptions.

What role does motor replacement play in Agriculture?

In agriculture, motors are vital for irrigation systems, impacting crop yield and quality. The cost of replacing a motor can significantly affect the overall operating budget, especially in regions with limited access to reliable parts. Farmers and agricultural businesses must evaluate the cost-effectiveness of new versus refurbished motors while ensuring compatibility with existing irrigation systems. Timely replacement helps maintain a consistent water supply, ultimately enhancing productivity and profitability in agricultural operations.

How does motor replacement affect Transportation?

For the transportation sector, particularly in commercial fleets, the cost of engine replacement can be substantial. Fleet managers must assess whether to invest in new or remanufactured engines based on the vehicle’s remaining lifespan and overall condition. Understanding labor costs associated with replacement is crucial, as complex engines may require specialized technicians. By making informed decisions on engine replacements, transportation businesses can enhance reliability, reduce downtime, and ultimately lower operational costs, ensuring a competitive edge in the marketplace.

Why is motor replacement important in Construction?

In the construction industry, heavy machinery relies on efficient motors for optimal performance. The cost of replacing these motors can be a significant portion of project budgets, making it essential for businesses to plan accordingly. Factors such as the quality of replacement parts, lead times for sourcing, and the complexity of installation all influence the total cost. Ensuring that motors are replaced promptly can improve equipment safety and performance, reducing the risk of project delays and enhancing overall productivity on job sites.

How does the Energy Sector benefit from motor replacement?

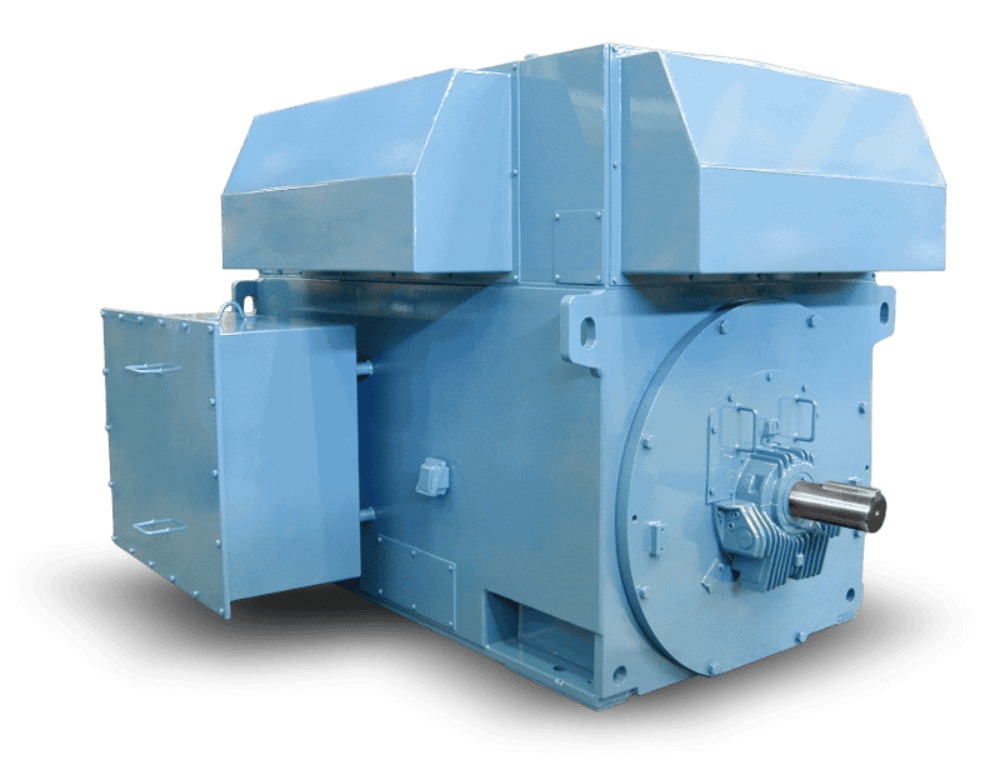

In the energy sector, motors are integral to power generation and distribution systems. The cost of replacing these motors can impact operational budgets and service reliability. International buyers must consider compliance with industry standards when sourcing replacement motors, as well as the potential for long-term savings through energy-efficient options. By prioritizing timely motor replacements, energy companies can ensure continuous service delivery, enhance operational efficiency, and maintain a competitive advantage in a rapidly evolving market.

3 Common User Pain Points for ‘how much does a motor cost to replace’ & Their Solutions

Scenario 1: Unforeseen Costs During Engine Replacement

Das Problem: B2B buyers often underestimate the total costs associated with engine replacement. While they may anticipate the price of the engine itself, they frequently overlook additional expenses such as labor, fluids, and other necessary components. This can lead to budget overruns, causing financial strain and potential project delays, particularly for businesses in sectors reliant on operational vehicles.

Die Lösung: To mitigate unexpected costs, buyers should conduct thorough research and prepare a detailed budget that includes not only the engine’s price but also estimated labor costs and ancillary expenses. Engaging with multiple suppliers to obtain quotes for both engines and associated parts can provide a clearer picture of total costs. Additionally, incorporating a contingency of 15-20% into the budget can help cover unforeseen expenses. For businesses operating in regions with varying labor costs, it’s advisable to evaluate local repair shops and their pricing structures to find the most cost-effective solution.

Scenario 2: Difficulty in Sourcing Quality Replacement Engines

Das Problem: Sourcing high-quality replacement engines can be a significant challenge for B2B buyers, especially when dealing with less common vehicle models or specific engine types. This difficulty can lead to delays in procurement, impacting operational efficiency and increasing downtime for vehicles that are critical to business operations.

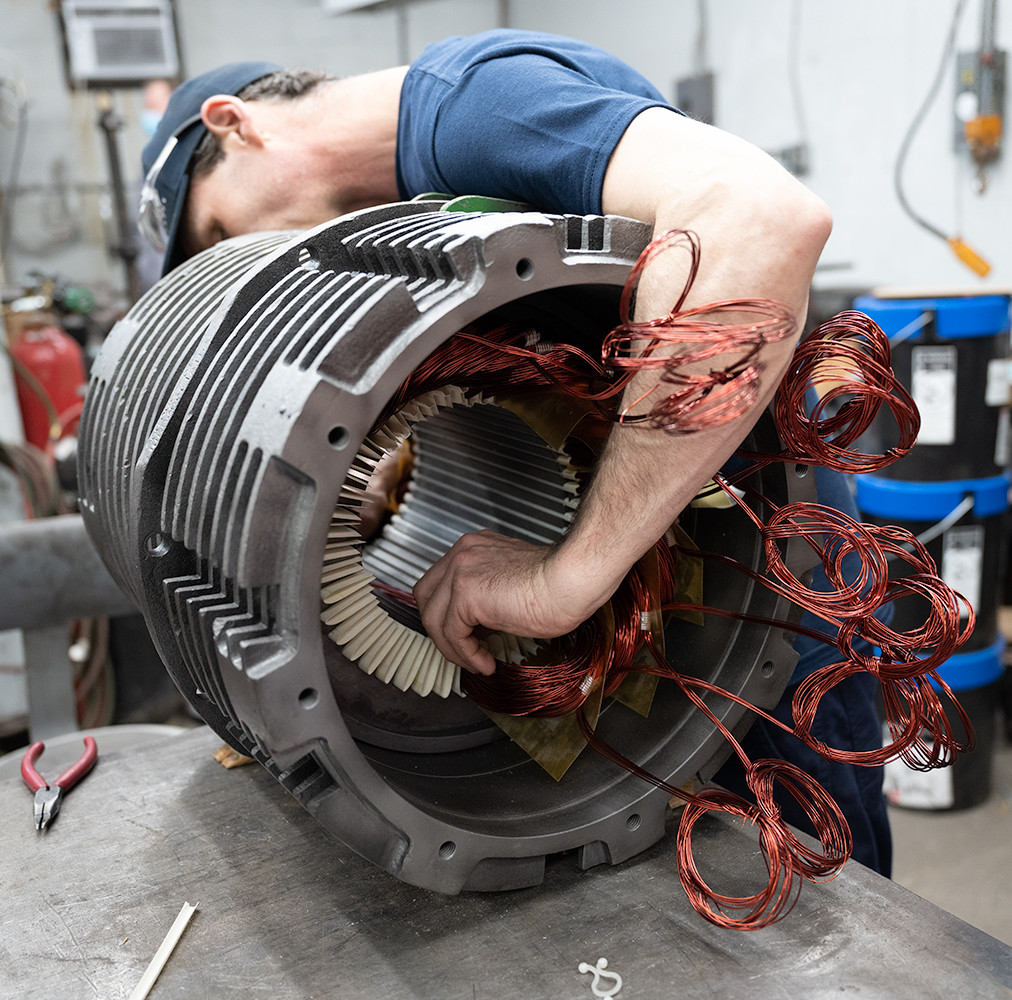

Illustrative image related to how much does a motor cost to replace

Die Lösung: To streamline the sourcing process, buyers should establish relationships with reputable suppliers who specialize in their specific engine requirements. This can include reaching out to manufacturers, certified distributors, or trusted aftermarket suppliers. It is also beneficial to verify the supplier’s credentials and warranty offerings, ensuring that they provide quality assurance. Utilizing online platforms and industry forums can help identify trusted sources and gather insights from other businesses’ experiences. Creating a standardized specification sheet for the desired engine can further aid in communicating with suppliers, ensuring that the right engine is sourced efficiently.

Scenario 3: Navigating the Complexities of Engine Replacement Labor Costs

Das Problem: Many B2B buyers are unaware of how labor costs can significantly affect the overall price of engine replacement. Factors such as the complexity of the engine, the geographical location of the service provider, and the expertise required can lead to variations in labor pricing. Buyers often find themselves blindsided by labor costs that exceed initial estimates, jeopardizing project budgets.

Die Lösung: To effectively navigate labor costs, buyers should seek multiple estimates from qualified automotive service providers before making a decision. It is essential to inquire about the hourly rate and the estimated time required for the engine replacement, as this can vary widely based on the vehicle type and engine complexity. Buyers should also consider the benefits of hiring specialized mechanics who may charge a higher hourly rate but can complete the job more efficiently, ultimately saving on total labor costs. Moreover, establishing a clear communication channel with the service provider regarding any potential additional repairs that may arise during the replacement process can help manage expectations and prevent unexpected financial burdens.

Strategic Material Selection Guide for how much does a motor cost to replace

What Materials Impact the Cost of Motor Replacement?

When considering the cost of motor replacement, the materials used in the manufacturing of the motor and its components can significantly influence both performance and pricing. Here, we analyze four common materials used in motor construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to how much does a motor cost to replace

What Are the Key Properties of Aluminum in Motor Manufacturing?

Aluminum is a widely used material in motor manufacturing due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and is resistant to corrosion, making it suitable for various environments. The use of aluminum can enhance fuel efficiency due to its reduced weight, which is particularly advantageous in automotive applications.

Vor- und Nachteile: Aluminum is durable yet lightweight, which contributes to better performance and efficiency. However, it can be more expensive than steel and may require specialized manufacturing processes, such as casting or machining. Additionally, while aluminum is resistant to corrosion, it can be prone to wear under high-stress conditions.

Auswirkungen auf die Anwendung: Aluminum is particularly well-suited for applications where weight reduction is crucial, such as in electric motors and high-performance vehicles. Its compatibility with various media makes it a versatile choice for international buyers.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should consider the availability of aluminum and its compliance with international standards such as ASTM and JIS. The cost can vary significantly based on local market conditions.

How Does Steel Compare as a Material for Motors?

Steel is another common material used in motor construction, known for its strength and durability. It generally has a higher temperature rating than aluminum, often exceeding 200°C, and offers excellent resistance to wear and tear.

Vor- und Nachteile: The main advantage of steel is its robustness, making it ideal for heavy-duty applications. However, it is heavier than aluminum, which can impact fuel efficiency. Additionally, steel is more susceptible to corrosion unless properly treated, which can increase maintenance costs.

Auswirkungen auf die Anwendung: Steel is often used in applications requiring high strength and durability, such as industrial motors and heavy machinery. Its compatibility with various lubricants and coolants is a key factor in its selection.

Illustrative image related to how much does a motor cost to replace

Überlegungen für internationale Käufer: In regions like Europe and the Middle East, buyers should be aware of the specific grades of steel that comply with local regulations and standards. The cost of steel can fluctuate based on global market trends.

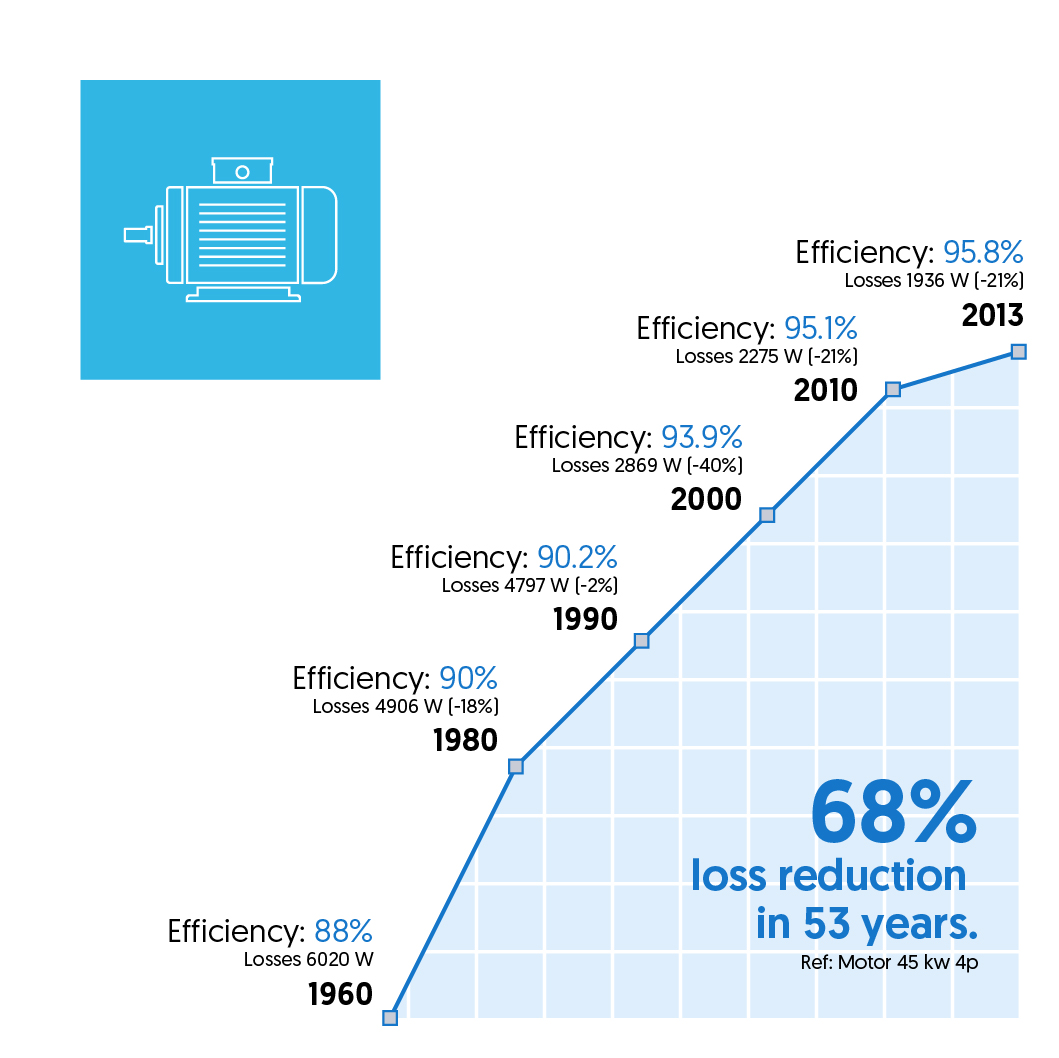

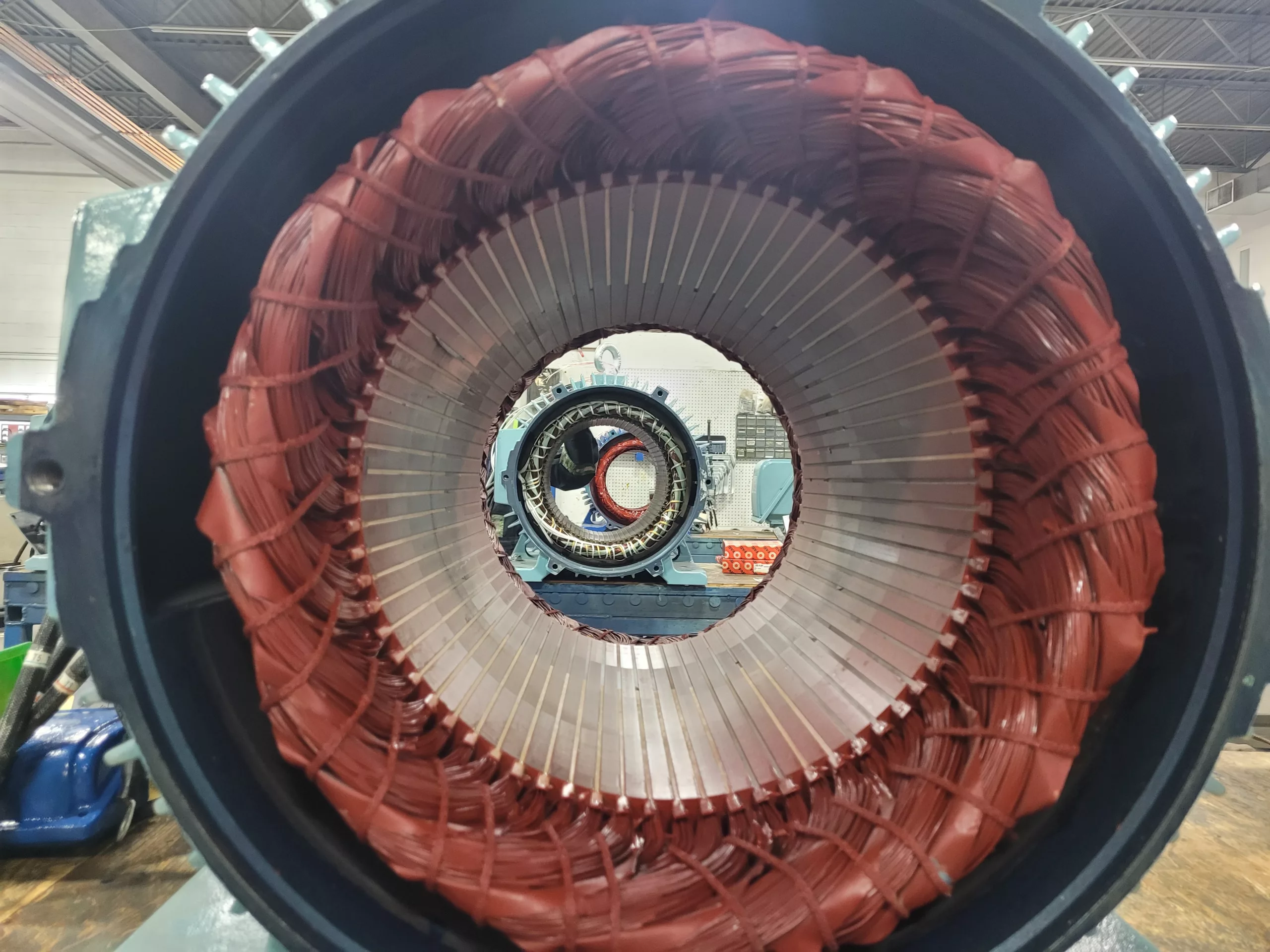

What Role Does Copper Play in Motor Efficiency?

Copper is frequently used in motor windings and electrical connections due to its excellent electrical conductivity. It can operate effectively at temperatures up to 200°C and is resistant to corrosion, making it a reliable choice for electrical components.

Vor- und Nachteile: The key advantage of copper is its superior conductivity, which enhances motor efficiency. However, it is more expensive than aluminum and can be subject to market volatility. Additionally, copper is heavier, which can be a disadvantage in applications where weight is a concern.

Auswirkungen auf die Anwendung: Copper is essential for applications requiring high electrical performance, such as electric motors and generators. Its compatibility with various electrical systems is crucial for international buyers.

Überlegungen für internationale Käufer: Buyers in developing regions should consider the availability and cost of copper, as well as compliance with international standards. The demand for copper can lead to price fluctuations, impacting overall motor replacement costs.

How Does Plastic Contribute to Motor Component Design?

Plastics are increasingly being used in motor components, particularly in non-structural applications such as housings and insulation. They can withstand temperatures up to 100°C and are resistant to many chemicals.

Vor- und Nachteile: The primary advantage of plastic is its lightweight nature and resistance to corrosion, which can reduce overall motor weight. However, plastics may not offer the same durability as metals and can degrade under extreme temperatures or mechanical stress.

Illustrative image related to how much does a motor cost to replace

Auswirkungen auf die Anwendung: Plastics are well-suited for applications where weight reduction and corrosion resistance are critical, such as in consumer electronics and small motors. Their versatility allows for a wide range of designs.

Überlegungen für internationale Käufer: Buyers should ensure that the plastics used comply with relevant safety and environmental standards. The cost of high-quality plastics can vary, and sourcing may be an issue in certain regions.

Summary Table of Material Selection for Motor Replacement Costs

| Material | Typical Use Case for how much does a motor cost to replace | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Lightweight motors, electric vehicles | Excellent thermal conductivity | Higher cost, wear under stress | Mittel |

| Stahl | Heavy-duty motors, industrial applications | Hohe Festigkeit und Haltbarkeit | Heavier, susceptible to corrosion | Mittel |

| Kupfer | Electrical windings, connections | Hervorragende elektrische Leitfähigkeit | Expensive, market volatility | Hoch |

| Kunststoff | Nicht-strukturelle Komponenten, Isolierung | Leichtes Gewicht, korrosionsbeständig | Less durable, temperature sensitive | Niedrig |

This analysis provides a comprehensive overview of the materials impacting motor replacement costs, offering valuable insights for international B2B buyers navigating their options.

In-depth Look: Manufacturing Processes and Quality Assurance for how much does a motor cost to replace

Understanding the manufacturing processes and quality assurance measures associated with engine replacements is crucial for B2B buyers, especially when considering costs and reliability. This section delves into the various stages of manufacturing, key quality control (QC) standards, and how businesses can ensure they partner with reputable suppliers.

What Are the Main Stages of Motor Manufacturing?

The manufacturing of motors involves a series of intricate processes that ensure durability, efficiency, and performance. The primary stages include:

1. Materialvorbereitung

The first step in motor manufacturing is material preparation. High-quality materials such as aluminum, steel, and various alloys are sourced based on the engine specifications. This stage involves:

- Auswahl des Materials: Choosing the right material based on mechanical properties, thermal resistance, and cost-effectiveness.

- Material Testing: Conducting tests for tensile strength, corrosion resistance, and other relevant metrics to ensure the materials meet industry standards.

2. Formen

Once materials are prepared, the next step is forming. This includes several techniques such as:

- Gießen: Molten metal is poured into molds to form engine blocks and other components. This method is favored for its ability to create complex shapes.

- Bearbeitung: Components are precisely cut and shaped using CNC machines to ensure they fit together perfectly. This process enhances the accuracy of parts like pistons and crankshafts.

- Schmieden: Some components, particularly those requiring high strength, undergo forging, where metal is shaped under high pressure to enhance structural integrity.

3. Montage

The assembly stage brings together all the manufactured parts. Key activities include:

- Unterbaugruppe: Smaller components are assembled into larger units (e.g., cylinder heads, oil pans).

- Endmontage: All major components are combined to create the complete engine. This stage often involves intricate procedures to ensure all parts are fitted correctly.

4. Fertigstellung

The final stage involves finishing processes that enhance the engine’s performance and longevity:

- Oberflächenbehandlung: Techniques such as anodizing or powder coating are used to improve corrosion resistance and aesthetics.

- Qualitätskontrollen: Before the engine leaves the factory, it undergoes rigorous testing to verify its functionality and adherence to specifications.

What Quality Control Measures Are In Place for Engine Manufacturing?

Quality control is integral to the manufacturing process, ensuring that engines meet both safety and performance standards. Key aspects of QC include:

Internationale Normen und Zertifizierungen

B2B buyers should look for manufacturers that adhere to recognized international standards, such as:

- ISO 9001: This standard outlines the criteria for a quality management system and is essential for ensuring consistent quality across production processes.

- CE-Kennzeichnung: Particularly important in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API-Zertifizierung: For engines, particularly in automotive and industrial applications, API certifications ensure the products meet industry-specific performance standards.

QC Checkpoints Throughout Manufacturing

To maintain high standards, manufacturers implement various QC checkpoints:

- Eingangsqualitätskontrolle (IQC): Hier werden die Rohstoffe bei ihrer Ankunft kontrolliert, um sicherzustellen, dass sie den festgelegten Anforderungen entsprechen.

- In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, regular inspections are conducted to detect defects early and rectify them immediately.

- Endkontrolle (FQC): Once the engine is assembled, it undergoes extensive testing, including operational tests, to confirm it functions as intended.

What Common Testing Methods Are Used in Engine Manufacturing?

Testing is critical in ensuring that engines operate efficiently and reliably. Common testing methods include:

- Hydraulic Testing: This method checks for leaks and verifies the integrity of engine components under pressure.

- Dynamometer Testing: Engines are run on a dynamometer to assess performance metrics like horsepower and torque under various conditions.

- Haltbarkeitsprüfung: Engines are subjected to prolonged operation under simulated real-world conditions to evaluate their longevity and performance stability.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following approaches:

Illustrative image related to how much does a motor cost to replace

Lieferantenaudits

Conducting regular audits of potential suppliers can reveal their manufacturing processes, quality control measures, and overall operational efficiency. Audits can be performed in person or through third-party services, providing an unbiased assessment of the supplier’s capabilities.

Qualitätssicherungsberichte

Requesting detailed quality assurance reports from suppliers can help buyers understand their QC processes and results. These reports should include data on defect rates, compliance with standards, and any corrective actions taken in response to quality issues.

Inspektionen durch Dritte

Engaging third-party inspection agencies can provide an additional layer of assurance. These agencies can carry out independent evaluations of the supplier’s processes and products, ensuring they meet specified standards and requirements.

Illustrative image related to how much does a motor cost to replace

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

B2B buyers from regions like Africa, South America, the Middle East, and Europe face unique challenges and opportunities when it comes to quality control:

- Einhaltung gesetzlicher Vorschriften: Different regions have varying regulatory requirements. Buyers should ensure their suppliers are compliant with local regulations, which may affect the quality and performance of engines.

- Kulturelle Erwägungen: Understanding cultural differences in business practices can enhance communication and foster stronger supplier relationships.

- Logistik und Lieferkettenmanagement: International logistics can impact delivery times and quality. Buyers should work closely with suppliers to ensure timely and safe transport of engines and components.

Schlussfolgerung

For B2B buyers looking to replace motors, understanding the manufacturing processes and quality assurance measures is essential. By familiarizing themselves with the stages of production, relevant quality control standards, and verification methods, businesses can make informed decisions that ensure reliability and performance in their engine purchases. Adopting these insights can help mitigate risks and enhance the overall value of their investments in motor replacements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does a motor cost to replace’

To assist B2B buyers in understanding the costs associated with motor replacement, this practical sourcing guide outlines the essential steps to take when procuring information and services related to engine replacement. With a focus on clarity and actionable insights, this checklist will help you navigate the complexities of motor replacement costs effectively.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before seeking quotes, clearly define the specifications of the motor you need. Consider factors such as engine type (new, remanufactured, or used), size, and compatibility with your existing vehicle or machinery. This foundational knowledge will help you communicate effectively with suppliers and ensure you receive accurate pricing.

Illustrative image related to how much does a motor cost to replace

Schritt 2: Research Engine Replacement Costs

Gather information on the average costs for different types of engines relevant to your needs. Prices can vary significantly based on engine type, vehicle make, and model, ranging from $600 for used engines to over $14,000 for new ones. Understanding the market rates will enable you to set a realistic budget and negotiate effectively with suppliers.

Schritt 3: Potenzielle Lieferanten bewerten

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, certifications, and case studies that demonstrate their expertise in engine replacement. It is also advisable to seek references from other businesses in your industry or region to gauge the supplier’s performance and customer service.

Schritt 4: Assess Labor Costs and Expertise

Labor costs can significantly impact the overall expense of engine replacement. Inquire about the hourly rates of mechanics and the estimated time required for the installation. A well-established mechanic with experience in your specific type of engine may charge more but can also provide better quality service and peace of mind.

Schritt 5: Garantie und Kundendienst berücksichtigen

Evaluate the warranty options offered by suppliers. A robust warranty can provide assurance against defects and potential issues post-replacement. Additionally, inquire about the availability of after-sales support, as having access to technical assistance can be invaluable if complications arise after the installation.

Illustrative image related to how much does a motor cost to replace

Schritt 6: Plan for Additional Costs

Prepare for potential additional expenses, such as fluids, hoses, and other necessary components that may not be included in the initial quote. It’s prudent to allocate an extra 15-20% of your budget for unforeseen expenses, ensuring you are financially prepared for the entire replacement process.

Schritt 7: Review Payment Options and Financing

Explore the payment options available to you, including financing plans that may ease the financial burden of engine replacement. Some suppliers may offer flexible payment solutions, allowing you to spread the cost over time, which can be beneficial for managing cash flow in your business.

By following this checklist, B2B buyers can make informed decisions regarding engine replacement, ensuring they secure the best value for their investment while minimizing potential risks associated with motor procurement.

Comprehensive Cost and Pricing Analysis for how much does a motor cost to replace Sourcing

What Are the Key Cost Components in Motor Replacement?

When evaluating the cost to replace a motor, several components contribute to the overall price. Materialien encompass the motor itself, which can range from used to new engines, with prices varying significantly based on brand and specifications. For instance, a used engine may cost as low as $600, while a new engine could exceed $14,000. Additionally, the choice of quality certifications und supplier reputation can influence material costs.

Arbeit is another critical component, typically charged at an hourly rate, which can range from $150 to $200 depending on the region and complexity of the installation. The total labor cost may accumulate to between $1,500 and $3,000, factoring in the time required for installation, which can span 10 to 12 hours.

Produktionsgemeinkosten includes expenses related to production, such as factory costs and utilities, which can be significant for new engines. Werkzeuge costs are also essential, particularly if specialized tools are needed for installation or if modifications are required for specific vehicle models.

Außerdem, quality control (QC) procedures can add to the expense, ensuring that the replacement motor meets performance standards and regulatory compliance. Finally, logistics costs associated with shipping the motor to the buyer’s location must be factored in, especially for international purchases.

How Do Price Influencers Affect Motor Replacement Costs?

Several factors can influence the pricing of motor replacements, particularly for international B2B buyers. Volumen und Mindestbestellmenge (MOQ) play a significant role; larger orders may secure discounts, whereas single unit purchases could incur higher per-unit costs.

Spezifikationen und Anpassung of the motor can also drive prices up. Unique requirements for performance or specific vehicle compatibility may necessitate tailored solutions, which typically come at a premium.

Illustrative image related to how much does a motor cost to replace

Die Wahl der Materialien impacts cost as well; high-performance components or OEM parts generally command higher prices compared to generic or aftermarket alternatives. Lieferantenfaktoren such as reliability, warranty offerings, and service levels can also influence the final price.

Verstehen Incoterms is crucial for international transactions, as they dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. Familiarity with these terms can help buyers avoid unexpected costs.

What Are Effective Buyer Tips for Negotiating Motor Replacement Prices?

For international B2B buyers, effective negotiation strategies can lead to significant cost savings. Start by researching market prices and obtaining multiple quotes from different suppliers to establish a baseline. This practice not only provides leverage during negotiations but also ensures competitiveness in pricing.

Betrachten Sie die Gesamtbetriebskosten (TCO), which encompasses not just the initial purchase price but also long-term expenses such as maintenance, warranties, and potential downtime. A lower upfront cost may not always be the best value if it leads to higher maintenance or replacement costs down the line.

Illustrative image related to how much does a motor cost to replace

Be mindful of Preisnuancen specific to different regions. For instance, certain markets may have established norms for pricing based on local economic conditions, labor costs, and availability of parts. Understanding these dynamics can help buyers negotiate more effectively.

Lastly, always clarify terms related to warranty and post-purchase support, as these can significantly affect the overall value of the motor replacement. Opting for suppliers that offer robust support and flexible return policies can mitigate risks associated with international procurement.

Schlussfolgerung

Navigating the complexities of motor replacement costs requires a comprehensive understanding of various cost components and pricing influences. By leveraging effective negotiation strategies and being aware of market dynamics, international B2B buyers can make informed decisions that balance cost and quality effectively. Always remember that while price is a critical factor, the reliability and performance of the motor should remain a top priority to ensure long-term satisfaction and operational efficiency.

Illustrative image related to how much does a motor cost to replace

Alternatives Analysis: Comparing how much does a motor cost to replace With Other Solutions

Exploring Alternatives to Motor Replacement: A Comparative Analysis

In the automotive industry, the decision to replace a motor can be daunting due to the high costs and potential downtime involved. For B2B buyers, understanding alternative solutions can lead to more cost-effective and efficient outcomes. This section compares the costs and benefits of motor replacement with two viable alternatives: engine remanufacturing and electric vehicle (EV) conversion.

Vergleichstabelle

| Vergleichsaspekt | How Much Does A Motor Cost To Replace | Engine Remanufacturing | Electric Vehicle Conversion |

|---|---|---|---|

| Leistung | High performance; new engine specs | Comparable to new; meets OEM standards | Varies; typically lower torque than traditional engines |

| Kosten | $3,000 – $14,000 | $2,000 – $7,000 | $8,000 – $20,000 |

| Einfache Implementierung | Labor-intensive; requires expertise | Less complex; can be done at specialized shops | Requires significant modifications; may need new components |

| Wartung | Higher long-term costs; frequent checks | Lower; often comes with warranty | Varies; generally lower but battery replacements can be costly |

| Bester Anwendungsfall | Older vehicles needing complete overhaul | Vehicles with significant wear but good chassis | Businesses aiming for sustainability or lower fuel costs |

Detaillierte Aufschlüsselung der Alternativen

1. Engine Remanufacturing

Engine remanufacturing involves rebuilding existing engines to meet original equipment manufacturer (OEM) specifications. This solution is often more cost-effective than replacing an engine entirely. The process includes replacing worn-out components and testing the engine to ensure it performs reliably. Pros include significant cost savings and reduced environmental impact compared to new engine production. However, the availability of remanufactured engines can be limited based on vehicle make and model, and buyers may need to ensure that they work with reputable remanufacturers to guarantee quality.

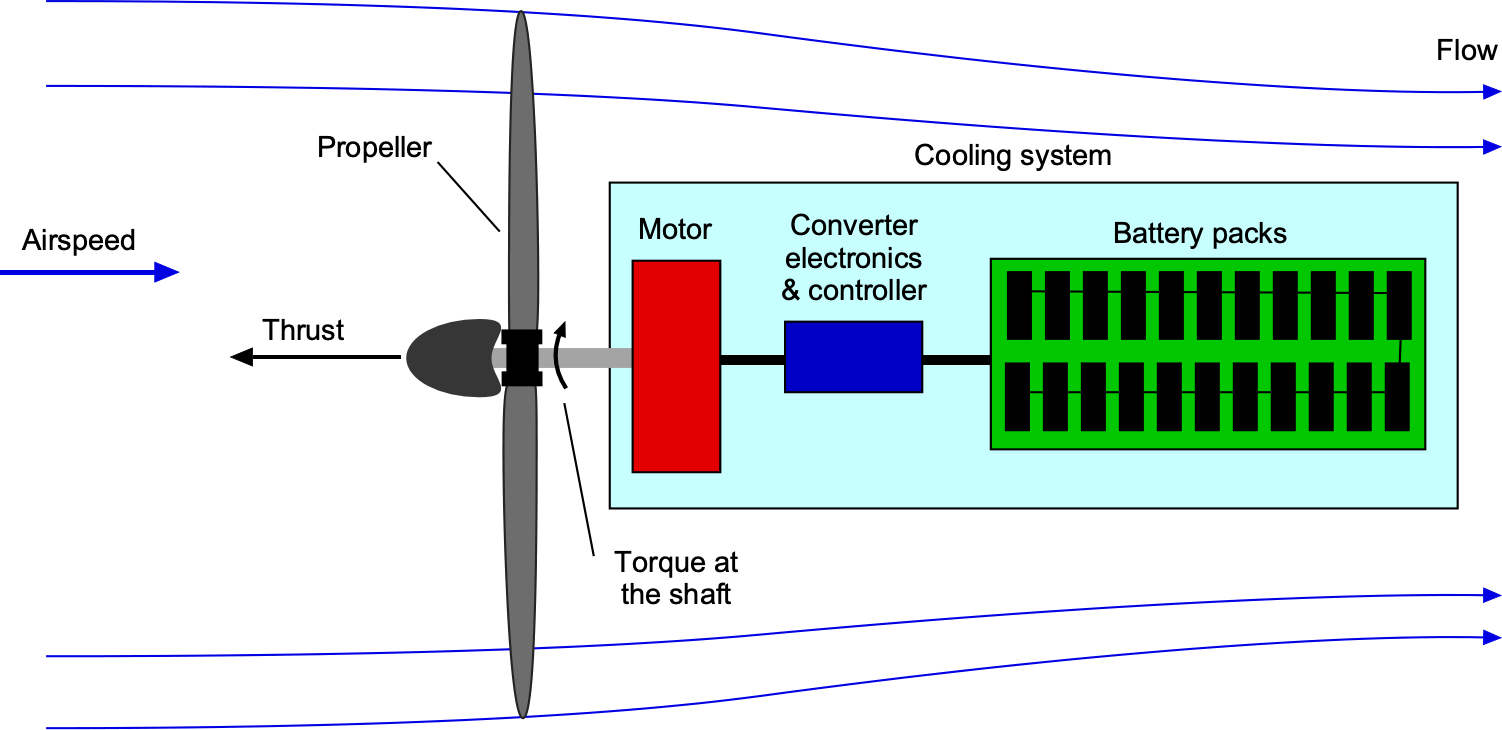

2. Electric Vehicle Conversion

Converting a traditional vehicle to electric power presents a unique alternative to motor replacement. This method involves replacing the internal combustion engine with an electric motor and installing a battery system. While this option can be more expensive initially, ranging from $8,000 to $20,000, it can lead to substantial savings on fuel and maintenance over time. Furthermore, electric vehicles often have lower emissions, aligning with sustainability goals. On the downside, this conversion can be complex and may require specialized knowledge and components, making it less accessible for some businesses.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

When deciding between motor replacement and alternative solutions, B2B buyers should carefully evaluate their specific circumstances. Factors such as budget, the condition of existing vehicles, and long-term operational goals should guide the decision-making process. Engine remanufacturing can offer a balance of reliability and cost-effectiveness, particularly for older vehicles. On the other hand, electric vehicle conversion may suit businesses looking to invest in sustainability and long-term savings, despite the higher initial costs. Ultimately, thorough research and consideration of the unique needs of the fleet will lead to the most beneficial choice.

Illustrative image related to how much does a motor cost to replace

Essential Technical Properties and Trade Terminology for how much does a motor cost to replace

What Are the Key Technical Properties Influencing Motor Replacement Costs?

When evaluating the cost of replacing a motor, understanding specific technical properties is essential for B2B buyers. These properties not only influence the pricing but also impact the longevity and performance of the motor. Here are critical specifications to consider:

-

Werkstoffgüte

Material grade refers to the quality and type of materials used in the motor’s construction. High-grade materials typically enhance durability and performance, leading to longer lifespans and reduced maintenance costs. B2B buyers should prioritize motors made from high-grade materials to ensure reliability and cost-effectiveness over time. -

Engine Displacement

This specification indicates the total volume of all the cylinders in the engine, usually measured in liters. Higher displacement often correlates with greater power output but can also lead to increased fuel consumption. Understanding displacement helps businesses assess whether the motor aligns with their operational efficiency goals. -

Power Output

Measured in horsepower (HP) or kilowatts (kW), power output indicates the engine’s performance capabilities. For businesses requiring specific performance metrics, knowing the power output is crucial for ensuring the motor meets operational demands, especially in sectors like transportation and heavy machinery. -

Drehmoment-Spezifikationen

Torque refers to the rotational force produced by the engine, impacting acceleration and towing capacity. B2B buyers should evaluate torque specifications based on their operational needs, particularly in industries requiring heavy lifting or transport. -

Garantiezeitraum

The warranty period covers the duration for which the manufacturer guarantees the motor against defects. A longer warranty often reflects the manufacturer’s confidence in the product’s quality. For B2B buyers, this can be a crucial factor in budgeting for future costs and ensuring long-term reliability.

What Are Common Trade Terminology and Jargon Related to Motor Replacement Costs?

Familiarity with industry terminology is vital for B2B buyers navigating motor replacement costs. Here are some common terms that can influence procurement decisions:

-

OEM (Originalgerätehersteller)

OEM parts are components made by the original manufacturer of the vehicle. They are typically more expensive but offer guaranteed compatibility and quality. Understanding the distinction between OEM and aftermarket parts is critical for buyers looking for reliability versus cost savings. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units a supplier is willing to sell in a single order. This is particularly relevant for businesses planning to replace multiple motors or components, as it can impact overall budgeting and inventory management. -

RFQ (Angebotsanfrage)

An RFQ is a formal process where a buyer requests pricing information from suppliers. This is an essential step for businesses to compare costs and negotiate terms effectively. A well-structured RFQ can lead to better deals and informed purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers engaging in cross-border transactions to avoid unexpected costs. -

Ersatzteile

These are components not made by the original manufacturer but by other companies. While often less expensive, aftermarket parts can vary in quality and compatibility. Buyers should assess the trade-offs between cost and reliability when considering these options. -

Arbeitskosten

Labor costs encompass the fees associated with the installation and replacement of the motor. This can vary based on location, complexity of the job, and technician expertise. Budgeting for labor costs is essential for businesses to avoid unexpected financial strain during the replacement process.

In conclusion, understanding these technical properties and trade terms empowers B2B buyers to make informed decisions regarding motor replacement costs, ultimately enhancing operational efficiency and cost management.

Illustrative image related to how much does a motor cost to replace

Navigating Market Dynamics and Sourcing Trends in the how much does a motor cost to replace Sector

What Are the Current Market Trends Impacting Engine Replacement Costs?

The global market for engine replacements is influenced by various factors, including technological advancements, economic conditions, and regional demand variations. As automotive technology evolves, there is a growing trend towards electric and hybrid engines, particularly in regions like Europe and parts of South America, where environmental regulations are tightening. This shift is causing a significant impact on the cost of traditional internal combustion engines as demand fluctuates. For international B2B buyers, understanding these dynamics is crucial for making informed purchasing decisions.

Emerging sourcing technologies, such as digital platforms for parts procurement and AI-driven inventory management, are also reshaping the landscape. These technologies facilitate quicker access to suppliers and more competitive pricing, which can significantly affect overall engine replacement costs. For instance, buyers from Africa and the Middle East may leverage these platforms to connect with manufacturers and suppliers who offer the best value for remanufactured engines or OEM parts.

Additionally, the global supply chain has been under pressure due to geopolitical tensions and the lingering effects of the COVID-19 pandemic. This has led to increased costs in shipping and logistics, impacting the final pricing of engine replacements. B2B buyers should be prepared for price volatility and consider establishing long-term relationships with suppliers to mitigate risks associated with sudden cost increases.

Illustrative image related to how much does a motor cost to replace

How Can Sustainability and Ethical Sourcing Influence Engine Replacement Decisions?

Sustainability is becoming a critical factor in the sourcing of engine replacements, especially as global awareness of environmental issues rises. B2B buyers are increasingly prioritizing suppliers who adhere to environmentally friendly practices and offer sustainable products. This trend is particularly prominent in Europe, where regulations often mandate a focus on reducing carbon footprints.

The importance of ethical supply chains cannot be overstated, as consumers and businesses alike demand transparency in sourcing practices. Buyers should seek suppliers who provide certifications for eco-friendly materials and sustainable manufacturing processes. For instance, choosing remanufactured engines not only reduces waste but also often involves less energy consumption compared to producing new engines from scratch.

Moreover, incorporating green certifications into procurement processes can enhance a company’s brand reputation and appeal to environmentally conscious consumers. As global markets continue to shift towards sustainability, B2B buyers in regions like Africa and South America should align their sourcing strategies with these trends to remain competitive and responsible.

What Historical Trends Have Shaped Engine Replacement Costs?

The evolution of engine replacement costs has been significantly influenced by technological advancements and changes in consumer preferences. Historically, the market for engine replacements was dominated by internal combustion engines, which were relatively simple and less costly to produce. However, the introduction of advanced engine technologies, such as turbocharging and hybrid systems, has resulted in increased complexity and, consequently, higher replacement costs.

Illustrative image related to how much does a motor cost to replace

In the past two decades, the rise of globalization has allowed for greater access to parts from diverse suppliers, leading to a more competitive market landscape. This has enabled B2B buyers to find more affordable options, including remanufactured engines, which offer a cost-effective alternative to new engines while maintaining quality and reliability.

As the automotive industry shifts towards electrification, the historical context of engine replacements will continue to evolve. Buyers must stay informed about these changes to navigate the complexities of sourcing and pricing effectively. Understanding the historical trends in engine technology and market dynamics is essential for making strategic purchasing decisions in today’s rapidly changing environment.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does a motor cost to replace

-

How much does it typically cost to replace a motor?

The cost to replace a motor can vary significantly based on several factors, including the type of vehicle, the engine’s make and model, and the geographical location of the repair. On average, B2B buyers can expect to pay between $3,000 and $10,000 for a complete engine replacement. New engines generally cost more than remanufactured options, which provide a more budget-friendly alternative while still maintaining quality. It’s essential to consider labor costs, which can add an additional $1,000 to $3,000, depending on the complexity of the job. -

What factors influence the cost of motor replacement?

Several factors can impact the overall cost of motor replacement. These include the vehicle’s make and model, the type of engine (new, used, or remanufactured), and labor costs associated with the installation. Geographic location plays a crucial role as well, with urban areas often having higher labor rates. Additional costs may arise from necessary parts such as hoses, fluids, and other components required for the installation. Understanding these variables can help B2B buyers budget effectively. -

Are remanufactured engines a reliable option for replacement?

Yes, remanufactured engines can be a reliable and cost-effective option for replacement. These engines are rebuilt to original equipment manufacturer (OEM) specifications, ensuring that they meet performance standards. They often come with warranties similar to new engines, providing assurance of their reliability. For B2B buyers looking to manage costs while ensuring quality, remanufactured engines offer an excellent balance of affordability and performance. -

What should B2B buyers consider when sourcing replacement motors internationally?

When sourcing replacement motors internationally, buyers should consider factors such as supplier reputation, compliance with local regulations, and the availability of parts. It is crucial to vet suppliers thoroughly, checking for certifications and customer reviews to ensure quality. Additionally, understanding international shipping costs, customs duties, and potential tariffs can help in budgeting accurately. Establishing clear communication with suppliers regarding lead times and payment terms is also vital to ensure a smooth procurement process. -

What are the payment terms typically offered by motor suppliers?

Payment terms can vary widely among motor suppliers, but common practices include upfront payments, partial payments upon order confirmation, and balance upon delivery. Some suppliers may offer financing options or credit terms, especially for larger orders. B2B buyers should negotiate terms that align with their cash flow and operational needs. It’s also advisable to clarify any penalties for late payments and the implications of payment methods on order fulfillment. -

What logistics considerations should I keep in mind when replacing a motor?

Logistics play a crucial role in the motor replacement process. Buyers should factor in shipping times, customs clearance, and the availability of local delivery services when sourcing engines internationally. It’s important to establish a reliable logistics partner to ensure timely delivery and to mitigate risks associated with potential delays. Additionally, considering warehousing options and the logistics of returning faulty engines or parts is essential for maintaining operational efficiency. -

How can I ensure quality assurance when purchasing replacement motors?

Ensuring quality assurance when purchasing replacement motors involves several steps. B2B buyers should request certifications and warranties from suppliers, verifying that the engines meet industry standards. Conducting inspections upon receipt can help identify any discrepancies or defects. Establishing a clear return policy with the supplier is also critical, allowing for replacements or refunds in case of quality issues. Building a long-term relationship with trusted suppliers can further enhance quality assurance. -

What is the minimum order quantity (MOQ) for motors when sourcing internationally?

Minimum order quantities (MOQs) for motors can vary significantly based on the supplier and the type of engine. Some suppliers may have MOQs as low as one unit, while others may require bulk orders to offer competitive pricing. For B2B buyers, negotiating MOQs is essential, especially if they are looking to manage inventory costs. It’s beneficial to discuss the potential for trial orders or samples to assess quality before committing to larger quantities.

Top 3 How Much Does A Motor Cost To Replace Manufacturers & Suppliers List

1. Mazda 3 – Engine Replacement Estimate

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: 2011 Mazda 3 engine replacement; total estimate: $6,000; labor costs: $2,400; co-worker estimate: $1,000 – $1,500.

2. Engine Replacement Costs – Key Factors

Domäne: jdpower.com

Registriert: 1995 (30 Jahre)

Einleitung: The cost of replacing a car engine typically ranges from $2,000 to $10,000, influenced by factors such as manufacturer brand, engine displacement, type of engine, make, model, age, availability, and labor costs. Luxury vehicles and high-end sports cars may incur higher costs. Specific factors affecting the cost include warranty coverage for manufacturer defects, the age and availability of the eng…

3. GM – Reman 6.2L Long Block

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, GM – Reman 6.2L Long Block, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how much does a motor cost to replace

In navigating the complexities of motor replacement costs, international B2B buyers must consider various factors that significantly impact pricing, including engine type, labor costs, and the choice between new and remanufactured engines. A comprehensive understanding of these elements enables businesses to make informed decisions that align with their budgetary constraints and operational needs. For instance, opting for remanufactured engines can often yield similar reliability at a fraction of the cost of new engines, especially crucial for businesses in regions where budget flexibility is vital.

Strategic sourcing plays an essential role in optimizing these costs. By establishing reliable relationships with suppliers and understanding local market dynamics, businesses can negotiate better pricing and ensure timely availability of quality parts. This proactive approach not only mitigates unforeseen expenses but also enhances overall operational efficiency.

Looking ahead, we encourage B2B buyers from Africa, South America, the Middle East, and Europe to leverage these insights in their sourcing strategies. By prioritizing thorough cost analysis and supplier collaboration, companies can navigate the complexities of motor replacement with confidence, ensuring their operations remain robust and resilient in an ever-evolving marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.