Introduction: Navigating the Global Market for high quality alternators

In the increasingly competitive landscape of international trade, sourcing high-quality alternators can present unique challenges for B2B buyers. Whether you are catering to the automotive, marine, or industrial sectors, the need for reliable power solutions is paramount. This comprehensive guide is designed to assist international buyers, particularly those from Africa, South America, the Middle East, and Europe, in navigating the complexities of the high-quality alternator market.

We delve into various types of alternators, including high-output and custom-built options, ensuring you understand their specific applications and benefits. Additionally, this guide outlines essential criteria for supplier vetting, helping you identify trustworthy manufacturers that align with your operational needs. Cost considerations are also addressed, providing insights into pricing trends and value assessments that empower you to make informed purchasing decisions.

By equipping you with actionable insights and expert knowledge, this guide aims to streamline your sourcing process and enhance your procurement strategy. In a market where quality and reliability are non-negotiable, understanding the nuances of high-quality alternators can significantly impact your business’s efficiency and success.

Inhaltsverzeichnis

- Top 7 High Quality Alternators Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for high quality alternators

- Understanding high quality alternators Types and Variations

- Key Industrial Applications of high quality alternators

- 3 Common User Pain Points for ‘high quality alternators’ & Their Solutions

- Strategic Material Selection Guide for high quality alternators

- In-depth Look: Manufacturing Processes and Quality Assurance for high quality alternators

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘high quality alternators’

- Comprehensive Cost and Pricing Analysis for high quality alternators Sourcing

- Alternatives Analysis: Comparing high quality alternators With Other Solutions

- Essential Technical Properties and Trade Terminology for high quality alternators

- Navigating Market Dynamics and Sourcing Trends in the high quality alternators Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of high quality alternators

- Strategic Sourcing Conclusion and Outlook for high quality alternators

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding high quality alternators Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Hochleistungsgeneratoren | Enhanced power output (up to 300A), robust construction | Automotive performance upgrades, heavy machinery | Vorteile: Supports advanced electronics, improved reliability. Nachteile: Higher cost, may require custom installation. |

| Dual Alternator Systems | Two alternators working in tandem for increased power | Off-grid systems, commercial vehicles, RVs | Vorteile: Redundant power supply, ideal for high-demand applications. Nachteile: Complex installation, requires additional space. |

| Externally Regulated Alternators | Regulated voltage output, suitable for lithium batteries | Elektrofahrzeuge, Systeme für erneuerbare Energien | Vorteile: Efficient power management, compatibility with modern battery technologies. Nachteile: More expensive than internally regulated options. |

| Internally Regulated Alternators | Built-in regulation, simpler installation process | Standard automotive applications, light-duty vehicles | Vorteile: Cost-effective, easier to install. Nachteile: Limited power output, not suitable for high-demand systems. |

| Racing Alternators | Lightweight, high RPM capabilities, designed for performance | Motorsport, Hochleistungsfahrzeuge | Vorteile: High efficiency, lightweight design. Nachteile: Not suitable for daily driving, can be expensive. |

What Are High Output Alternators and Their Key Characteristics?

High output alternators are designed to deliver significantly more power than standard models, often exceeding 300 amps. These alternators are ideal for applications that require enhanced electrical capacity, such as automotive performance upgrades and heavy machinery. B2B buyers should consider their specific power needs, vehicle compatibility, and potential installation challenges. While these units provide superior reliability and support advanced electronic systems, they come at a higher price point and may necessitate custom installation.

How Do Dual Alternator Systems Enhance Power Supply?

Dual alternator systems consist of two alternators working together to provide increased electrical output. These systems are particularly beneficial for off-grid applications, commercial vehicles, and RVs where power demands can be high. The redundancy offered by dual systems ensures that power supply remains uninterrupted, making them a reliable choice for critical operations. However, potential buyers must account for the complexity of installation and the additional space required for the dual setup, along with a higher upfront cost.

Why Choose Externally Regulated Alternators for Modern Applications?

Externally regulated alternators feature a separate regulator that allows for precise voltage control, making them particularly suitable for lithium battery systems and electric vehicles. This type of alternator is increasingly favored in renewable energy applications due to its efficient power management capabilities. While they provide excellent performance and compatibility with advanced battery technologies, buyers should be aware that externally regulated alternators typically come at a premium compared to their internally regulated counterparts.

What Are the Benefits of Internally Regulated Alternators?

Internally regulated alternators are simpler in design, featuring built-in voltage regulation that makes them easier to install. These units are commonly used in standard automotive applications and light-duty vehicles, providing sufficient power for everyday electrical needs. Their cost-effectiveness and straightforward installation process make them appealing for many businesses. However, buyers must consider that internally regulated alternators may not deliver the power required for high-demand systems, limiting their applicability in more robust settings.

How Do Racing Alternators Cater to High-Performance Needs?

Racing alternators are specifically engineered for motorsports and high-performance vehicles, emphasizing lightweight construction and high RPM capabilities. These alternators are designed to maximize efficiency while minimizing weight, which is crucial in competitive racing environments. While they provide exceptional power output for performance applications, B2B buyers should note that racing alternators are not intended for daily driving and can be more expensive than standard options.

Key Industrial Applications of high quality alternators

| Branche/Sektor | Specific Application of High Quality Alternators | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | High-performance vehicles and racing applications | Enhanced power delivery for advanced systems, improved reliability | OEM specifications, custom designs, power output requirements |

| Erneuerbare Energien | Off-grid solar and wind energy systems | Reliable energy storage and supply for remote locations | Voltage compatibility, durability under harsh conditions |

| Kommerzieller Transport | Fleet vehicles and service trucks | Increased efficiency and reduced downtime | Load capacity, ease of installation, service support |

| Construction & Heavy Equipment | Construction machinery and equipment | Consistent power for operation in demanding environments | High durability, resistance to vibrations, backup solutions |

| Marineanwendungen | Workboats and recreational vessels | Reliable power for navigation and onboard systems | Saltwater resistance, size and weight constraints, compliance with marine regulations |

High-quality alternators are crucial in the automotive sector, particularly for high-performance vehicles and racing applications. These alternators provide increased power output to support advanced electrical systems such as high-end audio, lighting, and performance enhancements. Buyers in this sector often seek OEM specifications and custom designs to ensure compatibility with specific vehicle models and performance requirements. Additionally, understanding the power output needs is essential for optimal performance during competitive events.

In renewable energy, high-quality alternators are integral to off-grid solar and wind energy systems. They facilitate the conversion of generated energy into usable power, ensuring reliable energy storage and supply for remote locations. For international buyers, especially in regions with limited grid access, sourcing alternators that can withstand extreme weather conditions and ensure voltage compatibility is vital. Durability and efficiency are paramount, as these systems often operate in challenging environments.

For commercial transportation, high-quality alternators are essential in fleet vehicles and service trucks, where they enhance efficiency and reduce downtime. These alternators support the growing electrical demands of modern vehicles, including GPS systems, refrigeration units, and onboard diagnostics. Buyers should consider load capacity and ease of installation when sourcing alternators, as these factors directly impact operational efficiency and maintenance.

In construction and heavy equipment, high-quality alternators provide consistent power to machinery operating in demanding environments. These alternators must be robust enough to endure vibrations and harsh conditions while delivering the required electrical output. Buyers should prioritize durability and the availability of backup solutions to minimize operational disruptions, which can be costly in construction projects.

Marine applications also benefit from high-quality alternators, particularly in workboats and recreational vessels. These alternators supply reliable power for navigation, communication, and onboard systems, which are critical for safety and efficiency at sea. Buyers in this sector must ensure that alternators are resistant to saltwater corrosion, meet size and weight constraints, and comply with marine regulations to ensure seamless integration into their vessels.

3 Common User Pain Points for ‘high quality alternators’ & Their Solutions

Scenario 1: Insufficient Power Output for Heavy-Duty Applications

Das Problem: B2B buyers in industries such as construction, agriculture, or emergency services often face the challenge of insufficient power output from standard alternators. When equipment demands exceed the alternator’s output, it leads to system failures, downtime, and ultimately, financial losses. For instance, a fleet of vehicles used for emergency response may find their electrical systems struggling to power essential equipment, causing delays in critical operations.

Die Lösung: To address this challenge, businesses should consider upgrading to high-output alternators specifically designed for heavy-duty applications. When sourcing these alternators, look for specifications that indicate higher amperage ratings tailored to your equipment’s power needs. Ensure that the alternators are compatible with your vehicle or machinery, focusing on features such as temperature resistance and durability. Additionally, consult with manufacturers or suppliers who can provide guidance on optimal power requirements based on your operational demands. Regular maintenance checks should also be implemented to monitor performance and avoid unexpected failures.

Scenario 2: Challenges with Installation and Compatibility

Das Problem: Many B2B buyers encounter difficulties during the installation of high-quality alternators due to compatibility issues with existing vehicle systems or equipment configurations. Incompatibility can lead to electrical failures, damage to the alternator, or even hazards during operation. This is particularly common in custom builds or when retrofitting older equipment with modern alternators.

Die Lösung: To mitigate installation challenges, it is crucial to engage with suppliers who offer detailed technical support and installation guides. Before purchasing, verify that the alternator matches the specifications of the existing electrical system, including mounting options and wiring requirements. Suppliers that provide comprehensive diagrams and wiring kits can significantly simplify the installation process. Additionally, consider seeking out professional installation services, especially for complex setups. This proactive approach ensures that the alternator is not only compatible but also optimally integrated into your system.

Scenario 3: Concerns About Quality and Reliability

Das Problem: In the B2B landscape, buyers are often wary of the quality and reliability of high-output alternators, particularly when purchasing from international suppliers. Concerns about subpar materials or manufacturing processes can lead to doubts about performance and longevity, risking operational reliability and increasing maintenance costs.

Die Lösung: To alleviate these concerns, buyers should prioritize sourcing from reputable manufacturers known for high-quality production standards. Look for certifications or industry accolades that signify a commitment to quality. Additionally, conducting thorough due diligence, including reading customer reviews and testimonials, can provide insights into the experiences of other businesses. Engaging directly with suppliers to ask about warranties, return policies, and their manufacturing processes can also enhance confidence in the purchase. Establishing a long-term relationship with a trusted supplier can lead to better pricing and support, further ensuring that you receive reliable products that meet your operational needs.

Strategic Material Selection Guide for high quality alternators

When selecting materials for high-quality alternators, it is essential to consider the specific properties and characteristics of each material. This analysis will focus on four common materials used in the manufacturing of alternators: aluminum, copper, steel, and composite materials. Each material has distinct advantages and disadvantages that can significantly impact the performance and suitability of the alternator for various applications.

What Are the Key Properties of Aluminum in High-Quality Alternators?

Aluminum is widely used in alternator housings and components due to its lightweight and good thermal conductivity. It typically has a temperature rating of around 150°C and exhibits excellent corrosion resistance, making it suitable for various environments.

Vor- und Nachteile von Aluminium:

Aluminum’s lightweight nature enhances fuel efficiency and reduces wear on vehicle components. However, it can be more expensive than steel and may require additional treatments to improve its strength, which can complicate manufacturing processes.

Auswirkungen auf die Anwendung:

Aluminum is compatible with most automotive fluids and can withstand the thermal demands of high-performance applications. Its corrosion resistance is particularly beneficial in humid or coastal regions, making it a preferred choice for international buyers in areas like Brazil and Saudi Arabia.

How Does Copper Benefit High-Quality Alternators?

Copper is primarily used in the windings of alternators due to its excellent electrical conductivity, which is essential for efficient power generation. It can handle high temperatures, typically rated up to 200°C, and has good resistance to corrosion.

Vor- und Nachteile von Kupfer:

The main advantage of copper is its superior conductivity, which translates into better performance and efficiency. However, copper is significantly more expensive than aluminum and can add weight to the alternator, potentially affecting vehicle dynamics.

Auswirkungen auf die Anwendung:

Copper is compatible with various automotive fluids and is favored for applications requiring high electrical performance. International buyers should consider the cost implications and availability of copper in their regions, as fluctuations in the copper market can affect pricing.

What Role Does Steel Play in High-Quality Alternators?

Steel is often used for structural components and brackets in alternators due to its strength and durability. It typically has a temperature rating of around 300°C, making it suitable for high-stress applications.

Vor- und Nachteile von Stahl:

Steel’s strength makes it ideal for heavy-duty applications, but it is heavier than aluminum, which can negatively impact fuel efficiency. Additionally, steel is prone to corrosion unless properly treated, which can increase manufacturing complexity.

Auswirkungen auf die Anwendung:

Steel’s robustness makes it suitable for commercial and industrial applications, particularly in regions with extreme weather conditions. Buyers in the Middle East and Africa should ensure compliance with local standards for steel quality and treatment to prevent corrosion-related issues.

How Do Composite Materials Enhance High-Quality Alternators?

Composite materials are increasingly being used in alternators for their lightweight and high strength-to-weight ratio. They can withstand temperatures of up to 150°C and provide good resistance to corrosion.

Pros and Cons of Composite Materials:

Composites offer significant weight savings and can be molded into complex shapes, enhancing design flexibility. However, they can be more expensive and may require specialized manufacturing techniques, which can complicate production.

Auswirkungen auf die Anwendung:

Composites are suitable for high-performance applications where weight reduction is critical. International buyers should assess the availability of composite materials and the associated costs in their regions, particularly in emerging markets.

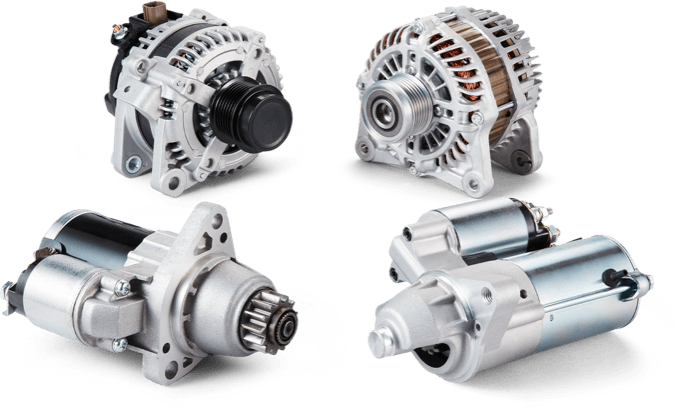

Illustrative image related to high quality alternators

Summary Table of Material Selection for High-Quality Alternators

| Material | Typical Use Case for high quality alternators | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Leichtbaukomponenten | Leicht und korrosionsbeständig | Higher cost than steel | Mittel |

| Kupfer | Windings for electrical efficiency | Hervorragende elektrische Leitfähigkeit | High cost and added weight | Hoch |

| Stahl | Strukturelle Komponenten und Halterungen | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Korrosion | Mittel |

| Komposit | High-performance lightweight components | Ausgezeichnetes Verhältnis von Festigkeit zu Gewicht | Höhere Kosten und komplexe Herstellung | Hoch |

In conclusion, the selection of materials for high-quality alternators should be carefully considered based on the specific application requirements, cost implications, and regional availability. Understanding the properties and characteristics of each material will enable international B2B buyers to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for high quality alternators

Was sind die wichtigsten Schritte im Herstellungsprozess von hochwertigen Generatoren?

The manufacturing of high-quality alternators involves a series of meticulously coordinated processes that ensure durability, performance, and efficiency. Understanding these stages is crucial for B2B buyers looking to source reliable products.

Material Preparation: What Materials Are Used and Why?

The first stage in alternator manufacturing is material preparation. High-quality alternators typically use materials such as high-grade aluminum for housings, copper for windings, and robust steel for shafts. Aluminum is favored for its lightweight properties and excellent thermal conductivity, which enhances efficiency. Copper windings are essential for optimal electrical conductivity, allowing the alternator to generate more power with less energy loss.

During this phase, materials undergo rigorous inspections to ensure they meet industry standards. Suppliers should provide certifications to confirm the quality of raw materials used in their products.

Umformung: Wie werden Lichtmaschinenbauteile geformt?

Once the materials are prepared, the next stage is forming. This involves several techniques, including:

- Gießen: Often used for the alternator housing, where molten metal is poured into molds to create the desired shape.

- Bearbeitung: Precision machining is applied to components such as the rotor and stator, ensuring exact dimensions and smooth finishes for optimal performance.

- Wickeln: The copper wire is wound around the stator in precise patterns to create electromagnetic fields. This process is critical, as the quality of the winding directly affects the alternator’s efficiency.

Quality control checks are performed at this stage to ensure that all components meet the required specifications before moving on to assembly.

Assembly: What Techniques Are Used to Ensure Quality?

The assembly process is where individual components come together to form the complete alternator. Skilled technicians or automated systems assemble the rotor, stator, and housing while ensuring that all parts fit seamlessly.

During assembly, particular attention is paid to:

- Alignment: Proper alignment of the rotor and stator is crucial for minimizing friction and maximizing output.

- Sealing: High-quality seals are used to protect the internal components from dust and moisture, which can lead to premature failure.

At this stage, Quality Control (QC) checkpoints are established to validate that the assembly process adheres to manufacturing standards.

Finishing: How Is the Final Product Prepared for Distribution?

The finishing stage involves several processes designed to enhance the alternator’s durability and aesthetic appeal. Common techniques include:

Illustrative image related to high quality alternators

- Anstriche und Beschichtungen: Protective coatings are applied to prevent corrosion and wear. This is especially important for alternators used in harsh environments, such as those in construction or marine applications.

- Abschließende Inspektion: A comprehensive inspection is conducted to ensure that the alternator meets all specifications, including electrical performance, mechanical integrity, and aesthetic quality.

Once the finishing touches are complete, the alternators are packaged and prepared for distribution.

Auf welche Qualitätssicherungsstandards sollten B2B-Einkäufer achten?

Quality assurance is paramount in the manufacturing of high-quality alternators. Understanding the relevant standards can help B2B buyers make informed decisions.

Welche internationalen Normen sind für die Herstellung von Lichtmaschinen relevant?

Key international standards that manufacturers should comply with include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE-Kennzeichnung: This certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API-Standards: Particularly relevant for alternators used in industrial applications, these standards ensure that products meet the rigorous demands of the oil and gas industry.

Compliance with these standards not only enhances product quality but also builds trust with international buyers.

Illustrative image related to high quality alternators

Was sind die wichtigsten QC-Kontrollpunkte im Herstellungsprozess?

Quality Control (QC) checkpoints are essential in maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Eingangsqualitätskontrolle (IQC): Materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process-Qualitätskontrolle (IPQC): Ongoing inspections are conducted during manufacturing to identify and rectify issues in real time.

- Endkontrolle (FQC): The finished alternators undergo thorough testing for electrical performance, mechanical durability, and aesthetic quality before being shipped.

Implementing these checkpoints allows manufacturers to maintain high standards and minimize defects.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

B2B buyers must take proactive steps to ensure that their suppliers adhere to robust quality control practices. Here are some effective strategies:

Illustrative image related to high quality alternators

What Steps Can Buyers Take to Audit Supplier QC Practices?

-

Dokumentation anfordern: Buyers should ask for quality assurance documentation, including certifications, inspection reports, and compliance records. This information helps assess the supplier’s commitment to quality.

-

Durchführung von Audits: Periodic audits of suppliers can provide insights into their manufacturing processes and QC practices. This can be done by third-party organizations or internal teams, depending on the buyer’s capabilities.

-

Utilize Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing facilities can ensure that they meet international standards. These agencies can provide objective reports on the supplier’s quality control measures.

-

Seek References: Inquire about previous clients and projects to gauge the supplier’s track record. Feedback from other businesses can provide valuable insights into the reliability and quality of the supplier’s products.

Was sind die spezifischen QC-Überlegungen für internationale Einkäufer?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must be aware of specific QC nuances:

-

Einhaltung gesetzlicher Vorschriften: Understand local regulations that may affect product specifications and certifications. For example, CE marking is crucial for products sold in Europe, while other regions may have different standards.

-

Cultural and Logistical Factors: Consider cultural differences in communication and expectations. Additionally, logistics can impact delivery timelines and quality; ensure suppliers have robust logistics capabilities to meet international demands.

-

Garantie und Support: Verify the warranty terms and after-sales support offered by suppliers. Reliable customer service can significantly influence the overall quality experience for international buyers.

By thoroughly understanding the manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make more informed decisions when sourcing high-quality alternators. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘high quality alternators’

This practical sourcing guide is designed to assist international B2B buyers in procuring high-quality alternators. By following this checklist, you can ensure that you select reliable suppliers and products that meet your specific requirements, ultimately enhancing your operational efficiency and product performance.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding your technical requirements is the first step in sourcing high-quality alternators. Consider the power output, voltage, and type of alternator you need—whether it’s for automotive, industrial, or marine applications. Clearly defined specifications will help you communicate effectively with suppliers and ensure the products meet your operational demands.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research on potential suppliers to gauge their reputation and reliability. Look for companies with a proven track record in manufacturing high-quality alternators, especially those that serve your industry or region. Pay attention to customer reviews, industry certifications, and any awards or recognitions that highlight their commitment to quality.

Schritt 3: Lieferantenzertifizierungen bewerten

Before making a commitment, verify that your potential suppliers hold relevant certifications. Certifications such as ISO 9001 or specific automotive industry standards indicate that a supplier adheres to rigorous quality management practices. These certifications can serve as a proxy for the reliability and performance of the alternators they produce.

Schritt 4: Produktmuster anfordern

Don’t hesitate to request samples of the alternators you are considering. Testing a sample allows you to evaluate the quality, performance, and compatibility with your existing systems. Ensure that the sample is representative of the product you intend to purchase, as it will provide insight into the overall quality you can expect from larger orders.

Schritt 5: Assess Warranty and Support Services

A strong warranty and support service can be indicative of a supplier’s confidence in their product. Review the warranty terms and conditions, and ensure they offer adequate coverage for defects or failures. Additionally, reliable customer support is crucial; assess how responsive they are to inquiries and whether they provide technical assistance when needed.

Illustrative image related to high quality alternators

Schritt 6: Preise und Zahlungsbedingungen vergleichen

While cost should not be the sole determining factor, it is essential to compare prices among different suppliers. Look for transparent pricing structures and consider the total cost of ownership, which includes shipping, duties, and potential tariffs. Additionally, review payment terms to ensure they align with your financial planning and cash flow needs.

Schritt 7: Finalize the Agreement and Monitor Performance

Once you’ve selected a supplier, draft a detailed purchase agreement that outlines all terms, including delivery schedules, payment terms, and quality expectations. After the purchase, monitor the performance of the alternators to ensure they meet your specifications and operational needs. Continuous feedback will help you assess the supplier’s performance and make adjustments for future orders.

By following these steps, you can streamline your sourcing process for high-quality alternators, ensuring that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for high quality alternators Sourcing

Understanding the cost structure and pricing dynamics of high-quality alternators is crucial for international B2B buyers, especially those sourcing from diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will provide insights into the cost components, price influencers, and practical tips for negotiating favorable terms.

Illustrative image related to high quality alternators

What Are the Main Cost Components of High-Quality Alternators?

The cost of high-quality alternators is influenced by several key components:

-

Materialien: The choice of materials plays a significant role in pricing. High-grade copper, specialized alloys, and advanced magnetic materials increase production costs but are essential for enhancing durability and performance.

-

Arbeit: Skilled labor is necessary for assembling alternators, particularly for custom or high-output models. Labor costs can vary significantly based on the region of manufacture, impacting the final price.

-

Fertigungsgemeinkosten: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can mitigate these costs, enabling suppliers to offer competitive pricing.

-

Werkzeuge: Custom tooling for specific alternator designs can add to upfront costs. However, these costs are often amortized over larger production runs, which can lead to lower per-unit costs for high-volume orders.

-

Qualitätskontrolle (QC): Rigorous QC processes ensure that alternators meet performance and safety standards, which is crucial for maintaining brand reputation. Enhanced QC measures may increase costs but are necessary for high-quality assurance.

-

Logistik: Shipping and handling costs are particularly significant for international buyers. Factors such as distance, shipping mode, and customs duties can affect total costs.

-

Marge: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition and the perceived value of the product.

How Do Price Influencers Impact the Cost of Alternators?

Several factors can influence the pricing of high-quality alternators:

-

Volumen und Mindestbestellmenge (MOQ): Lieferanten gewähren oft Rabatte für Großeinkäufe. Die Kenntnis der MOQ kann Käufern helfen, bessere Preise auszuhandeln.

-

Spezifikationen und Anpassung: Custom specifications, such as unique mounting configurations or output ratings, can lead to higher costs due to additional design and manufacturing requirements.

-

Materialqualität und Zertifizierungen: Alternators that comply with industry standards or possess certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and reliability.

-

Lieferantenfaktoren: Established suppliers with a strong reputation may charge a premium. Conversely, emerging manufacturers may offer competitive pricing to gain market share.

-

Incoterms: The agreed-upon Incoterms (e.g., FOB, CIF) affect logistics costs and responsibilities, which can influence the overall price. Buyers should be clear about these terms to avoid unexpected expenses.

What Are the Key Tips for Negotiating Prices on High-Quality Alternators?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Verstehen der Gesamtbetriebskosten (TCO): Evaluate not just the purchase price but also long-term costs, including maintenance, warranty, and replacement intervals. A higher upfront cost may be justified if the alternator offers superior longevity and performance.

-

Mengenrabatte ausnutzen: If your business model allows for it, consider consolidating orders to meet MOQ thresholds. This can lead to substantial savings.

-

Erkunden Sie mehrere Anbieter: Don’t settle for the first quote. Comparing prices and terms from multiple suppliers can give you leverage in negotiations and help identify the best overall deal.

-

Assess Shipping Options: Investigate various shipping methods and routes to find the most cost-effective logistics solution. Consider the balance between speed and cost.

-

Achten Sie auf preisliche Nuancen: International buyers should be cautious about currency fluctuations and potential tariffs that could affect pricing. Having a clear understanding of these factors can aid in budgeting and negotiations.

Schlussfolgerung

Navigating the cost and pricing landscape of high-quality alternators requires a detailed understanding of the various components and influencers. By applying strategic negotiation techniques and considering the total cost of ownership, B2B buyers can optimize their sourcing decisions and secure favorable terms. Remember, the prices provided by suppliers may vary, so it’s essential to approach negotiations with a comprehensive understanding of your needs and the market dynamics.

Alternatives Analysis: Comparing high quality alternators With Other Solutions

In today’s rapidly evolving energy landscape, B2B buyers often seek alternatives to traditional high-quality alternators. While high-quality alternators offer substantial power output and reliability, several alternative solutions can also meet the power demands of various applications. This analysis compares high-quality alternators with other viable options, helping businesses make informed decisions based on their specific needs.

| Vergleichsaspekt | High Quality Alternators | Battery Banks | Solarstromanlagen |

|---|---|---|---|

| Leistung | High output, reliable power delivery | Moderate power, dependent on capacity and discharge rates | Variable output, dependent on sunlight availability |

| Kosten | Higher initial investment, long-term value | Moderate to high, depending on capacity and technology | Initial high cost, long-term savings on energy costs |

| Einfache Implementierung | Requires specific mounting and wiring | Relatively easy to install, depends on existing setup | Requires installation of panels and inverters, more complex |

| Wartung | Low, with periodic checks | Moderate, needs regular monitoring and replacement | Low, but panels may need cleaning and inverter checks |

| Bester Anwendungsfall | Heavy-duty vehicles, performance applications | Off-grid systems, backup power for homes | Renewable energy needs, eco-friendly solutions |

How Do Battery Banks Compare to High-Quality Alternators?

Battery banks provide a viable alternative to high-quality alternators, especially in applications where energy storage is critical. They store energy for later use, making them ideal for off-grid systems or as backup power sources. The main advantage of battery banks is their ability to provide power even when the primary source is unavailable. However, they have limitations in terms of discharge rates and capacity, which can impact performance in high-demand situations. Additionally, while installation can be straightforward, proper management and maintenance are necessary to ensure longevity.

What About Solar Power Systems as an Alternative?

Solar power systems harness energy from the sun, providing a renewable source of electricity that can significantly reduce operational costs in the long run. They are particularly advantageous in regions with abundant sunlight, making them ideal for many areas in Africa and South America. However, the performance of solar systems can be inconsistent due to weather conditions, and initial installation costs can be high. Moreover, they require a more complex setup involving panels, inverters, and possibly battery storage for nighttime use. Regular maintenance is minimal but essential for optimal performance.

Illustrative image related to high quality alternators

Schlussfolgerung: Wie sollten B2B-Einkäufer die richtige Lösung auswählen?

When deciding between high-quality alternators and alternative solutions like battery banks or solar power systems, B2B buyers should consider their specific power needs, budget constraints, and the operational context of their applications. High-quality alternators excel in performance and reliability, making them suitable for heavy-duty and performance-focused vehicles. Conversely, battery banks and solar power systems can offer flexibility and long-term cost savings, particularly in off-grid and environmentally conscious applications. By evaluating these factors, businesses can select the optimal power solution tailored to their unique requirements.

Essential Technical Properties and Trade Terminology for high quality alternators

High-quality alternators are essential components in various applications, from automotive to industrial uses. Understanding the technical properties and trade terminology associated with these products can significantly enhance the purchasing decision for B2B buyers. Below, we explore key specifications and industry terms that are vital in this field.

What Are the Key Technical Properties of High-Quality Alternators?

1. Ausgangsspannung

The output voltage of an alternator is a critical specification that determines its compatibility with different electrical systems. Most automotive alternators operate at 12V or 24V, while high-output versions may deliver 48V or more. For B2B buyers, understanding the required output voltage is essential to ensure the alternator meets the operational needs of the vehicle or machinery.

2. Stromstärke

The amperage rating reflects the maximum current the alternator can produce. Higher amperage ratings are crucial for vehicles with extensive electrical systems, such as those equipped with advanced audio systems or additional lighting. Buyers must assess their power requirements to select an alternator that can handle the load without risking failure.

3. Regulation Type

Alternators can be either internally or externally regulated. An internally regulated alternator contains its voltage regulator, which simplifies installation and maintenance. Conversely, externally regulated alternators allow for more precise voltage control, making them suitable for high-performance applications. Understanding the regulation type helps buyers determine the best fit for their specific use case.

Illustrative image related to high quality alternators

4. Effizienzbewertung

The efficiency rating of an alternator indicates how effectively it converts mechanical energy into electrical energy. Higher efficiency means less energy loss and reduced heat generation, which can enhance the lifespan of the alternator. B2B buyers should prioritize efficiency ratings to ensure that their systems operate optimally and minimize energy costs.

5. Materialzusammensetzung

The materials used in the construction of an alternator affect its durability, weight, and performance. High-quality alternators often utilize materials such as aluminum for the casing and copper for the windings, providing a balance of strength and weight. Buyers should consider material grades to ensure longevity and reliability in demanding applications.

What Are Common Trade Terms Related to High-Quality Alternators?

1. OEM (Originalgerätehersteller)

OEM refers to products made by the original manufacturer of a vehicle or equipment. In the context of alternators, OEM parts are designed to meet the exact specifications of the original components. B2B buyers often seek OEM alternators to guarantee compatibility and performance.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers who need to manage inventory and cash flow effectively. Suppliers may set MOQs based on production costs, making it essential for buyers to negotiate favorable terms.

3. RFQ (Angebotsanfrage)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. In the context of alternators, submitting an RFQ allows buyers to compare offers and negotiate better deals. This process is essential for ensuring cost-effectiveness in procurement.

Illustrative image related to high quality alternators

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, facilitating smoother international transactions for alternators.

5. Ersatzteilmarkt

The aftermarket refers to the secondary market for automotive parts and accessories, including alternators. B2B buyers looking for high-quality replacements often explore aftermarket options, which may offer cost savings without compromising on quality. Understanding the aftermarket landscape can provide buyers with more choices and competitive pricing.

In conclusion, grasping these essential technical properties and trade terminology equips B2B buyers with the knowledge needed to make informed decisions in the high-quality alternator market. By focusing on these specifications and terms, buyers can enhance their procurement strategies and ensure they select the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the high quality alternators Sector

What Are the Current Market Dynamics and Key Trends in the High-Quality Alternators Sector?

The global market for high-quality alternators is experiencing a significant transformation driven by increasing demand for high-output power solutions across various industries. Key factors propelling this growth include the rising reliance on advanced electrical systems in vehicles, especially with the proliferation of electric and hybrid vehicles. Furthermore, sectors such as construction, agriculture, and renewable energy are demanding more robust power solutions to support their operations, which directly influences the alternator market.

Emerging technologies are reshaping sourcing trends, particularly the integration of IoT (Internet of Things) in vehicle electrical systems. B2B buyers are increasingly looking for alternators equipped with smart capabilities that can monitor performance and enhance efficiency. Additionally, the trend towards customization is becoming more pronounced, with manufacturers offering bespoke solutions tailored to specific vehicle requirements, especially for high-demand applications in markets across Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Brazil.

International buyers are also becoming more strategic in their sourcing decisions, prioritizing suppliers that demonstrate reliability and quick turnaround times. This shift is driven by the need for immediate availability and responsiveness in supply chains, particularly in regions where logistics can pose challenges. As such, fostering strong relationships with manufacturers who can provide high-quality products and exceptional customer service is essential for B2B buyers.

How Is Sustainability and Ethical Sourcing Shaping the High-Quality Alternators Industry?

As global awareness of environmental issues increases, sustainability is becoming a crucial consideration in the sourcing of high-quality alternators. International B2B buyers are now placing greater importance on the environmental impact of their purchases, seeking suppliers who prioritize sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and adherence to environmental regulations.

Ethical supply chains are also gaining traction, with buyers demanding transparency regarding the sourcing of raw materials. Manufacturers that can provide certifications such as ISO 14001 for environmental management or products made from ethically sourced components stand out in a competitive marketplace. Additionally, the growing trend of “green” certifications is influencing purchasing decisions, as businesses increasingly prefer products that align with their sustainability goals.

Furthermore, the integration of eco-friendly technologies in alternator design—such as those utilizing renewable energy sources—can enhance the appeal of products to environmentally conscious buyers. By adopting sustainable practices, manufacturers not only contribute positively to the environment but also build brand loyalty and trust among B2B clients.

Illustrative image related to high quality alternators

What Is the Historical Context of High-Quality Alternators in B2B Sourcing?

The history of high-quality alternators dates back to the early 20th century, evolving significantly with advancements in automotive technology. Initially, alternators were primarily used in commercial vehicles, but the shift towards electrical systems in passenger vehicles during the mid-20th century expanded their application. As the demand for higher efficiency and reliability grew, manufacturers began to innovate, leading to the development of high-output alternators designed to meet the increasing power requirements of modern vehicles.

In recent decades, the evolution of alternators has been closely tied to technological advancements, including the rise of electric and hybrid vehicles, which have further fueled the demand for high-quality, high-output alternators. This historical context is vital for B2B buyers to understand the trajectory of the market, as it highlights the ongoing need for innovation and adaptability in sourcing strategies to meet changing industry standards and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of high quality alternators

-

How do I select the right high-quality alternator for my vehicle?

Choosing the right alternator begins with understanding your vehicle’s power requirements. Assess the electrical load by considering all components that rely on power, such as lighting, audio systems, and additional accessories. Look for alternators that match or exceed your vehicle’s original specifications. It’s also beneficial to consult with the manufacturer or supplier for guidance on specific models that fit your vehicle type and intended usage, whether for commercial fleets or specialized applications. -

What is the best high-output alternator for heavy-duty applications?

For heavy-duty applications, look for alternators designed to deliver high amperage output, typically exceeding 200 amps. Brands that specialize in high-output solutions often provide custom options tailored to specific industrial needs. Ensure that the alternator is engineered for durability and reliability under extreme conditions. Additionally, consider factors such as heat dissipation, build quality, and compatibility with your vehicle’s electrical system to ensure optimal performance. -

What should I consider when vetting suppliers of high-quality alternators?

When vetting suppliers, prioritize their experience in the industry and reputation for quality. Look for customer reviews, case studies, and testimonials that demonstrate their reliability. Evaluate their certifications and adherence to international quality standards, such as ISO 9001. It’s also crucial to assess their capacity for customization, responsiveness to inquiries, and support services, including warranty and after-sales support, which are vital for long-term partnerships. -

What are the typical minimum order quantities (MOQs) for high-quality alternators?

Minimum order quantities (MOQs) can vary significantly between suppliers, often ranging from 10 to 100 units for standard products. Custom alternators may have higher MOQs due to the specialized nature of production. When discussing MOQs, consider your projected sales volume and storage capabilities. Engaging in discussions with suppliers about flexible order arrangements can also help you manage inventory effectively while ensuring access to quality products. -

What payment terms are standard for international purchases of alternators?

Standard payment terms in international B2B transactions often include options like advance payment, letter of credit, or net 30/60/90 days. Suppliers may require a deposit upfront, particularly for custom orders, with the balance due upon shipment or delivery. It’s essential to negotiate terms that provide security for both parties. Consider using escrow services for large transactions to mitigate risks associated with international trade. -

How can I ensure the quality of alternators before purchasing?

To ensure quality, request detailed product specifications and certifications from the supplier. Many reputable manufacturers conduct rigorous quality assurance tests on their products, including performance under load and durability assessments. Ask for samples or trial units to evaluate their performance in real-world conditions. Additionally, inquire about the supplier’s return policy and warranty coverage to protect your investment against defects. -

Welche logistischen Aspekte sollte ich bei der Einfuhr von Generatoren beachten?

Logistics considerations include understanding shipping methods, costs, and timelines. Choose a reliable freight forwarder experienced in handling automotive parts to ensure compliance with customs regulations. Be aware of import duties and taxes that may apply, as these can significantly affect your total costs. Additionally, consider the supplier’s ability to provide necessary documentation, such as invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. -

Can I customize high-quality alternators to meet specific needs?

Yes, many suppliers offer customization options for high-quality alternators to meet specific applications, including voltage adjustments, amperage ratings, and physical dimensions. Discuss your requirements with the supplier to determine feasibility and any associated costs. Customization may involve longer lead times, so plan accordingly. Ensure that the supplier has the technical expertise and manufacturing capabilities to deliver products that meet your exact specifications.

Top 7 High Quality Alternators Manufacturers & Suppliers List

1. Mechman – High Output Alternators

Domäne: mechman.com

Registriert: 1996 (29 Jahre)

Einleitung: Mechman Alternators are U.S.A made high output alternators with options ranging from 150a to 370a. They offer a variety of products including 24 Volt and 48 Volt alternators, engine stands, bracket kits, pulleys, plugs and harnesses, and voltage control. The 48-Volt Elite Alternators are available for 2011 – 2024 Cummins 6.7L and Ford T-Mount Housing, both in AGM and LiFePO4 variants, priced at $1…

2. JS Alternators – High Output Alternators

Domäne: js-alternators.com

Registriert: 2017 (8 Jahre)

Einleitung: High Output Alternators built in the USA. Free shipping on all orders within the United States. Hassle-free returns with a 90-day return policy. Lifetime warranty on employee labor and a one-year warranty on parts. Various types of alternators available including Billet Alternators, Slingshot Alternators, and Universal Alternators. Big 3 Wiring Kits and accessories offered. Customer satisfaction r…

3. Nations Starter & High Amp Alternator – High-Quality Starters & Alternators

Domäne: nationsstarteralternator.com

Registriert: 2010 (15 Jahre)

Einleitung: Nations Starter & High Amp Alternator offers a variety of high-quality starters and alternators for automotive, farm, heavy-duty, and industrial applications. Key products include:

– Alternators: Automotive, Farm Tractor, Heavy Duty, High Amp Industrial, Isuzu, Mahle, RV & Work Vans.

– Starters: Diesel Starters, Farm Tractor, Heavy Duty High Torque, Industrial, Mahle, Marine, Motorcycle.

– Alte…

4. AC Delco – OEM Quality Replacement Parts

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, AC Delco – OEM Quality Replacement Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Quality Power Auto – High Output Alternators & Starters

Domäne: qualitypowerauto.com

Registriert: 2006 (19 Jahre)

Einleitung: High Output Alternators & High Torque Starters; Custom built high output alternators and starters; Suitable for street rods, off-road vehicles, and stereo systems; High amp alternators for stock, heavy-duty, and high performance; Custom solutions available for specific applications; Heavy-duty alternators designed for tough conditions; Extensive range of high output alternators; Free ground shippi…

6. SP Alternators – High-Quality USA-Made Alternators

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, SP Alternators – High-Quality USA-Made Alternators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Autotech Engineering – High Output Alternators

Domäne: autotechengineeringusa.com

Registered: 2018 (7 years)

Einleitung: High Output Alternators for Cars, Trucks, Marine, Racing, Offroad, Overlanding, SXS, and UTV. Amperage ratings range from 130 Amp to 500 Amp. Custom-built options available. Internal voltage regulators meet or exceed OEM specifications. Heavy-duty dual bridge rectifiers with Avalanche diodes for durability. Premium high-temperature bearings for long life. Testing includes computerized testing for …

Strategic Sourcing Conclusion and Outlook for high quality alternators

In the competitive landscape of high-quality alternators, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality, reliability, and customer support, companies can significantly enhance operational efficiency and reduce the risk of downtime. The advantages of sourcing from reputable manufacturers—such as those with proven track records in the USA—cannot be overstated. These suppliers not only provide durable products tailored to specific needs but also offer exceptional customer service that fosters long-term partnerships.

As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-output alternators is expected to rise. Buyers should leverage this opportunity by engaging with suppliers who understand regional requirements and can deliver customized solutions.

Illustrative image related to high quality alternators

Looking ahead, it is crucial for B2B buyers to stay informed about emerging trends and technological advancements in the alternator industry. By doing so, they can make informed decisions that will enhance their operational capabilities. Now is the time to connect with trusted manufacturers and explore the extensive range of high-quality alternators available. Invest in your power solutions today for a more sustainable and efficient tomorrow.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.