Introduction: Navigating the Global Market for como se arregla el motor de arranque

In the dynamic landscape of automotive repair, understanding how to effectively repair a starter motor—”como se arregla el motor de arranque”—is crucial for businesses seeking to minimize operational costs and enhance service offerings. Many B2B buyers face the challenge of sourcing reliable solutions that not only address immediate repair needs but also align with their budgetary constraints and operational timelines. This guide provides a comprehensive overview of the intricacies involved in starter motor repair, including various types, common applications, and essential maintenance practices.

Buyers will gain insights into the latest repair techniques, supplier vetting processes, and cost considerations, enabling them to make informed purchasing decisions. Whether you are in Nigeria, Germany, or any other market across Africa, South America, the Middle East, or Europe, this guide is tailored to address your specific needs. By empowering you with actionable knowledge, we aim to enhance your business’s repair capabilities and ultimately improve customer satisfaction.

Navigating the global market for starter motor repairs can be daunting; however, with the right information and resources, you can streamline your operations and ensure your vehicles are always ready to hit the road.

Inhaltsverzeichnis

- Top 3 Como Se Arregla El Motor De Arranque Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for como se arregla el motor de arranque

- Understanding como se arregla el motor de arranque Types and Variations

- Key Industrial Applications of como se arregla el motor de arranque

- 3 Common User Pain Points for ‘como se arregla el motor de arranque’ & Their Solutions

- Strategic Material Selection Guide for como se arregla el motor de arranque

- In-depth Look: Manufacturing Processes and Quality Assurance for como se arregla el motor de arranque

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘como se arregla el motor de arranque’

- Comprehensive Cost and Pricing Analysis for como se arregla el motor de arranque Sourcing

- Alternatives Analysis: Comparing como se arregla el motor de arranque With Other Solutions

- Essential Technical Properties and Trade Terminology for como se arregla el motor de arranque

- Navigating Market Dynamics and Sourcing Trends in the como se arregla el motor de arranque Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of como se arregla el motor de arranque

- Strategic Sourcing Conclusion and Outlook for como se arregla el motor de arranque

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding como se arregla el motor de arranque Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Basic Electrical Troubleshooting | Involves checking wiring, battery connections, and relays. | Kfz-Werkstätten, Flottenservices | Vorteile: Cost-effective, quick diagnosis. Nachteile: Limited to minor issues. |

| Component Replacement | Replacing worn parts like brushes or solenoids. | Auto parts distributors, repair facilities | Vorteile: Extends lifespan of the starter. Nachteile: Erfordert technische Fähigkeiten. |

| Complete Starter Overhaul | Full disassembly and refurbishment of the starter motor. | Industrial machinery, automotive sectors | Vorteile: Restores original performance, cost-effective. Nachteile: Zeitaufwendig. |

| Starter Motor Reconditioning | Refurbishing components instead of full replacement. | Remanufacturing businesses, workshops | Vorteile: Eco-friendly, reduces waste. Nachteile: May not be as reliable as new parts. |

| Professional Repair Services | Engaging specialized technicians for complex issues. | Automotive service centers, fleet operators | Vorteile: Expertise ensures high-quality repairs. Nachteile: Higher costs compared to DIY. |

What Are the Key Characteristics of Basic Electrical Troubleshooting for Starter Motors?

Basic electrical troubleshooting is essential for diagnosing common starter motor issues. This method focuses on inspecting wiring, battery connections, and relays to identify faults. It is particularly suitable for automotive repair shops and fleet services that require quick and cost-effective solutions. Buyers should consider the skill level of their technicians, as this approach often requires minimal tools and training, making it accessible for many service providers.

How Does Component Replacement Enhance Starter Motor Functionality?

Component replacement involves swapping out worn parts like brushes, solenoids, or gears within the starter motor. This method is ideal for auto parts distributors and repair facilities looking to extend the lifespan of starter motors without complete replacement. Buyers should weigh the benefits of this approach, as it can effectively restore functionality but requires a certain level of technical skill and understanding of motor assembly.

Why Choose a Complete Starter Overhaul?

A complete starter overhaul entails disassembling the starter motor to refurbish or replace all components. This comprehensive approach is beneficial for industrial machinery and automotive sectors where reliability is crucial. While it can restore the starter to its original performance, buyers must consider the time investment required for the process. This method is often more cost-effective than purchasing new starters, especially for businesses with tight budgets.

What Are the Benefits of Starter Motor Reconditioning?

Starter motor reconditioning focuses on refurbishing existing components rather than replacing them entirely. This eco-friendly approach is gaining traction among remanufacturing businesses and workshops. Buyers can appreciate the reduced waste and lower costs associated with reconditioning, but they should also consider the potential trade-off in reliability compared to new parts. This method is suitable for businesses looking to maintain sustainability while managing repair costs.

When Should Businesses Opt for Professional Repair Services?

Engaging professional repair services is advisable when facing complex issues that basic troubleshooting or component replacement cannot resolve. Automotive service centers and fleet operators often benefit from the expertise of specialized technicians who can ensure high-quality repairs. While this option may incur higher costs, the assurance of expert handling can mitigate risks of future failures, making it a worthwhile investment for businesses reliant on vehicle performance.

Key Industrial Applications of como se arregla el motor de arranque

| Branche/Sektor | Specific Application of como se arregla el motor de arranque | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Repairing starters in vehicles and machinery | Reduces operational downtime and maintenance costs | Availability of repair kits, quality of components, local expertise |

| Landwirtschaftliche Geräte | Servicing agricultural machinery starters | Ensures reliability of equipment during peak seasons | Access to durable parts, compatibility with various machinery types |

| Construction & Heavy Equipment | Overhauling starter motors in construction machinery | Minimizes equipment failure, enhancing project timelines | Sourcing from trusted suppliers, understanding machinery specifications |

| Transport & Logistik | Maintaining starters in fleet vehicles | Enhances fleet reliability and reduces breakdowns | Availability of timely service, understanding regional vehicle standards |

| Bergbauarbeiten | Repairing starter motors in mining equipment | Increases machinery uptime, critical for operational efficiency | Quality assurance of parts, local support for rapid repairs |

How Is ‘como se arregla el motor de arranque’ Applied in the Automotive Repair Sector?

In the automotive repair sector, the ability to repair starter motors is crucial for ensuring vehicles are operational. Businesses can save costs by opting for repairs instead of replacements, which can be significantly more expensive. Automotive repair shops often require access to specialized repair kits and components that suit various vehicle models. Buyers in this sector should prioritize suppliers who provide high-quality parts and offer training or resources for effective repairs.

What Role Does Starter Repair Play in Agriculture Equipment?

Agricultural machinery heavily relies on functional starter motors to ensure timely operations, especially during planting and harvesting seasons. The ability to repair rather than replace starter motors can lead to significant savings and increased productivity. For buyers in agriculture, sourcing durable and compatible components is essential, as machinery often varies widely in specifications. Understanding the specific needs of different equipment types is vital for successful maintenance.

How Is Starter Motor Repair Relevant in Construction and Heavy Equipment?

In the construction industry, heavy machinery is critical for project success, making the repair of starter motors a high-priority task. Efficient starter repair can minimize downtime, which is particularly valuable during tight project timelines. Buyers should consider suppliers that not only offer high-quality parts but also provide expertise on machinery specifications. Ensuring compatibility with various types of construction equipment is essential for seamless operations.

Why Is Fleet Vehicle Starter Repair Important in Transportation and Logistics?

For transportation and logistics companies, maintaining fleet vehicles is essential to ensure reliability and minimize disruptions. Repairing starter motors can significantly reduce breakdowns, enhancing overall fleet performance. When sourcing for this application, businesses should focus on suppliers who can provide timely service and understand the specific standards and requirements of regional vehicle models. This ensures that repairs are efficient and effective, contributing to operational success.

How Does Starter Repair Benefit Mining Operations?

In the mining sector, where equipment reliability is paramount, the ability to repair starter motors can dramatically impact productivity. Frequent breakdowns can lead to costly delays, making efficient repairs essential. Buyers in this industry should prioritize sourcing high-quality parts and services that ensure rapid turnaround times. Local support for repairs can also enhance operational efficiency, as it reduces the time machinery is out of service, ultimately supporting the mining operation’s bottom line.

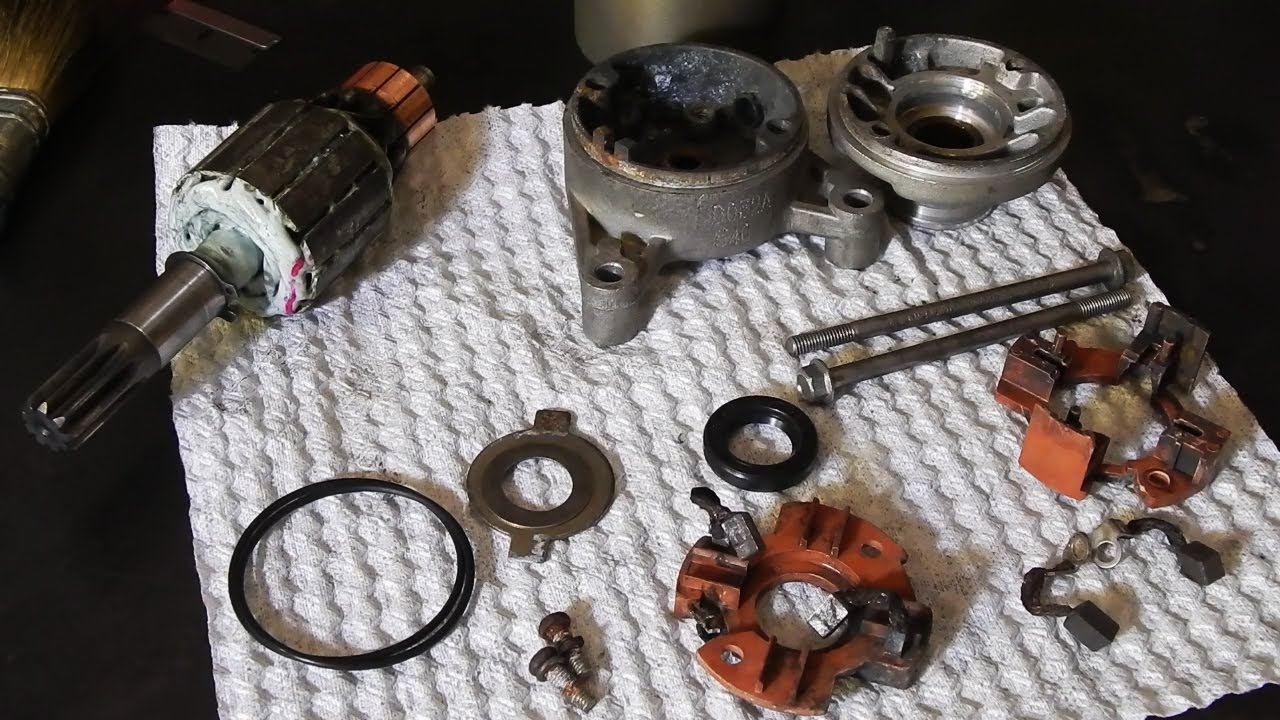

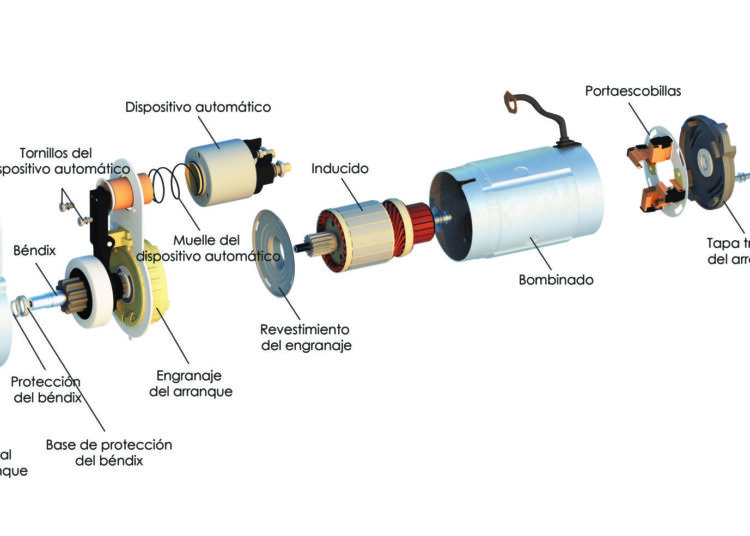

Illustrative image related to como se arregla el motor de arranque

3 Common User Pain Points for ‘como se arregla el motor de arranque’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Motor Issues

Das Problem: Many B2B buyers encounter challenges when diagnosing problems with starter motors, particularly in a fleet management context. A common issue is that vehicles may exhibit symptoms such as slow starts or clicking noises, leading to uncertainty about whether the starter motor is faulty or if other components, like the battery or ignition system, are the root cause. This uncertainty can result in unnecessary downtime, impacting operational efficiency and increasing maintenance costs.

Die Lösung: To effectively diagnose starter motor issues, it is critical to implement a systematic troubleshooting process. Begin by conducting a visual inspection of the starter motor, checking for loose connections and corrosion, which can impede electrical flow. Next, utilize a multimeter to measure voltage at the starter motor terminals. If the voltage is present but the motor does not engage, the issue may lie within the starter itself. In such cases, refer to the manufacturer’s specifications for testing and identifying specific components like the solenoid or brushes. Having a robust diagnostic toolkit and training personnel on troubleshooting techniques can significantly reduce downtime and ensure accurate repairs.

Scenario 2: High Costs of Starter Motor Replacement

Das Problem: B2B buyers often face substantial costs associated with replacing starter motors, especially when dealing with a large fleet of vehicles. The financial burden can be exacerbated by the need to source new parts from various suppliers, which may lead to delays and inflated costs due to shipping and handling. Additionally, the complexity of some vehicles may require specialized knowledge or tools for proper installation, further complicating the replacement process.

Illustrative image related to como se arregla el motor de arranque

Die Lösung: To mitigate replacement costs, consider implementing a preventive maintenance program that includes regular inspections of the starter motor and associated components. This proactive approach allows for early identification of wear and tear, enabling repairs rather than full replacements. For example, sourcing starter motor repair kits can be a cost-effective alternative to complete motor replacements. These kits often include brushes, solenoids, and other essential components, allowing in-house technicians to perform repairs efficiently. Establishing relationships with reliable suppliers who offer competitive pricing and bulk purchasing options can also help reduce costs. Training staff on these repair techniques can further enhance your in-house capabilities, leading to significant savings over time.

Szenario 3: Uneinheitliche Qualität von Aftermarket-Anlassern

Das Problem: Another prevalent issue for B2B buyers is the inconsistent quality of aftermarket starter motors. When sourcing replacement parts, many buyers have reported receiving components that do not meet the necessary specifications, leading to premature failures and increased warranty claims. This inconsistency can erode trust with clients and lead to significant operational disruptions as vehicles remain inoperable for extended periods.

Die Lösung: To ensure high-quality replacements, it is essential to develop a rigorous supplier evaluation process. Prioritize suppliers who provide detailed product specifications and have a strong reputation for quality assurance. Implementing a standardized testing protocol for incoming parts can help identify defective components before they are installed in vehicles. Additionally, consider establishing partnerships with reputable manufacturers who offer warranties and guarantees on their products. This practice not only enhances the reliability of the parts used but also builds a safety net for your operations, ensuring that any faulty components are promptly addressed without incurring additional costs. Regularly reviewing supplier performance and customer feedback can help maintain high standards and foster long-term relationships with dependable partners.

Strategic Material Selection Guide for como se arregla el motor de arranque

What are the Common Materials Used in Repairing a Starter Motor?

When considering the repair of starter motors, selecting the appropriate materials is crucial for ensuring durability and performance. Here, we analyze four common materials used in starter motor repairs, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Kupfer

Wichtige Eigenschaften:

Copper is known for its excellent electrical conductivity and thermal properties. It can withstand high temperatures, making it suitable for components that experience significant heat during operation.

Vor- und Nachteile:

Copper’s high conductivity ensures efficient electrical performance, which is critical for starter motors. However, it is prone to corrosion, especially in humid environments, which can affect its longevity. The cost of copper is relatively high compared to other materials, and its manufacturing complexity can increase the overall repair costs.

Auswirkungen auf die Anwendung:

Copper is primarily used in electrical connections and windings within the starter motor. Its compatibility with various electrical media makes it a preferred choice for high-performance applications.

Überlegungen für internationale Käufer:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire and consider local corrosion resistance requirements, especially in regions with high humidity, such as parts of Africa and South America.

2. Stahl

Wichtige Eigenschaften:

Steel offers high tensile strength and durability, making it suitable for structural components of the starter motor. It can withstand significant mechanical stress and is generally more resistant to wear than softer metals.

Vor- und Nachteile:

The primary advantage of steel is its strength and cost-effectiveness. However, it has lower electrical conductivity compared to copper, which can limit its use in electrical components. Steel is also susceptible to rust and corrosion if not properly treated or coated.

Auswirkungen auf die Anwendung:

Steel is often used for the casing and structural components of the starter motor, where strength is paramount. Its mechanical properties make it suitable for high-torque applications.

Überlegungen für internationale Käufer:

Buyers should look for compliance with standards such as ASTM A36 for structural steel. In regions like Europe, buyers might prefer galvanized steel to prevent corrosion, especially in coastal areas.

3. Aluminium

Wichtige Eigenschaften:

Aluminum is lightweight and has good corrosion resistance. It also has decent thermal and electrical conductivity, making it a versatile material for various applications.

Illustrative image related to como se arregla el motor de arranque

Vor- und Nachteile:

The lightweight nature of aluminum makes it easier to handle and install, which can reduce labor costs. However, it is less durable than steel and can deform under high stress, limiting its use in certain structural applications. The cost of aluminum is generally moderate, making it an attractive option for many manufacturers.

Auswirkungen auf die Anwendung:

Aluminum is often used in components that require a balance of weight and strength, such as housings and brackets in starter motors.

Überlegungen für internationale Käufer:

International buyers should ensure that aluminum components meet standards like ASTM B221 for extruded aluminum. In regions with high temperatures, such as the Middle East, considerations for thermal expansion and conductivity are essential.

4. Kunststoffverbundwerkstoffe

Wichtige Eigenschaften:

Plastic composites are lightweight and can be engineered for specific thermal and mechanical properties. They often exhibit excellent corrosion resistance and can be molded into complex shapes.

Vor- und Nachteile:

The primary advantage of plastic composites is their versatility and low weight, which can lead to reduced manufacturing costs. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their application in high-performance starter motors.

Auswirkungen auf die Anwendung:

These materials are commonly used for non-load-bearing components, such as covers and insulators, where weight savings and corrosion resistance are more critical than strength.

Überlegungen für internationale Käufer:

Buyers should verify that plastic composites comply with relevant standards, such as ISO 9001 for quality management. In regions with varying temperatures, such as Europe and Africa, thermal stability and UV resistance are important factors to consider.

Zusammenfassende Tabelle

| Material | Typical Use Case for como se arregla el motor de arranque | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Wicklungen | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Stahl | Strukturelle Komponenten | Hohe Zugfestigkeit | Geringere elektrische Leitfähigkeit | Niedrig |

| Aluminium | Gehäuse und Halterungen | Leicht und korrosionsbeständig | Weniger haltbar unter hoher Belastung | Med |

| Kunststoffverbundwerkstoffe | Abdeckungen und Isolatoren | Versatile and low weight | May not withstand high temperatures | Niedrig |

This guide provides a comprehensive overview of materials used in starter motor repairs, equipping international B2B buyers with the insights needed to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for como se arregla el motor de arranque

What Are the Main Stages of Manufacturing Processes for Starter Motor Repairs?

The manufacturing process for starter motor repairs involves several critical stages, ensuring that the parts are prepared, formed, assembled, and finished to meet high standards.

-

Materialvorbereitung: The process begins with sourcing high-quality raw materials, including copper for windings, steel for housings, and various alloys for gears and brushes. Suppliers must adhere to stringent quality standards to ensure that materials can withstand the operational demands of starter motors.

-

Formung: This stage involves shaping the raw materials into the required components. Techniques such as die casting for the housing and stamping for metal parts are common. Precision is paramount, as any deviation can affect the performance and longevity of the starter motor.

-

Montage: During assembly, individual components like the armature, brushes, and solenoid are put together. Automated assembly lines often enhance efficiency, but manual checks remain crucial to ensure proper fit and function. Skilled technicians may perform this step, especially for complex assemblies that require precise alignment.

-

Endbearbeitung: The final stage includes surface treatments to enhance durability, such as coating to prevent corrosion and polishing to ensure smooth operation. Quality control measures are implemented throughout to catch any defects before the product reaches the market.

Which Key Techniques Are Used in the Manufacturing of Starter Motors?

In the manufacturing of starter motors, several techniques are integral to achieving quality and reliability:

- CNC Machining: This technology allows for precise cutting and shaping of components, ensuring tight tolerances that are critical for performance.

- Welding and Soldering: These methods are employed to join various parts of the starter motor, such as the electrical connections, ensuring a robust and reliable assembly.

- Wärmebehandlung: Components often undergo heat treatment to enhance their mechanical properties, improving strength and resistance to wear.

- Testing and Calibration: Before leaving the production line, motors are tested for electrical continuity, torque, and functionality to ensure they meet specifications.

Wie wird die Qualitätssicherung bei der Herstellung von Anlassern umgesetzt?

Quality assurance in starter motor manufacturing is vital for ensuring that products meet international standards and customer expectations.

-

Internationale Normen: Compliance with ISO 9001 is essential, as it sets the framework for quality management systems. This ensures that processes are documented, monitored, and continuously improved.

-

Branchenspezifische Zertifizierungen: Depending on the market, additional certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for certain applications may be required. These certifications indicate compliance with safety and quality regulations.

-

Kontrollpunkte der Qualitätskontrolle:

– Eingangsqualitätskontrolle (IQC): This step checks the quality of raw materials and components as they arrive at the facility.

– In-Process-Qualitätskontrolle (IPQC): During manufacturing, operators conduct checks to ensure that processes are being followed correctly and that products meet quality standards.

– Endkontrolle (FQC): Finished products undergo comprehensive testing to verify that they function correctly and meet all specifications before shipment.

What Common Testing Methods Are Used in Quality Assurance for Starter Motors?

Testing is a critical component of quality assurance, helping to identify defects and ensure reliability:

- Elektrische Prüfung: This includes continuity checks, insulation resistance tests, and performance evaluations to ensure that the motor operates efficiently under load.

- Mechanische Prüfung: Torque tests and endurance tests simulate real-world conditions to evaluate the durability and performance of the starter motor.

- Schwingungsprüfung: This assesses how the motor performs under various operational vibrations, helping to predict potential failures in service.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

For B2B buyers, especially those in diverse markets like Africa, South America, the Middle East, and Europe, ensuring the reliability of suppliers is essential. Here are actionable steps:

-

Lieferantenaudits: Conduct regular audits of potential suppliers to evaluate their manufacturing processes, quality control measures, and adherence to international standards. This can help identify any gaps in their quality management systems.

-

Qualitätsberichte anfordern: Suppliers should provide documentation, including inspection reports, test results, and certifications. This transparency allows buyers to assess the quality of the products before purchasing.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. This is particularly valuable when sourcing from regions with varying levels of quality assurance practices.

Was sind die Feinheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International B2B buyers must navigate various quality control and certification nuances:

- Regionale Übereinstimmung: Different regions have specific regulations and standards that must be met. Buyers should familiarize themselves with these requirements to avoid compliance issues.

- Kulturelle Unterschiede: Understanding the cultural context of suppliers can aid in communication and negotiation, ensuring that quality expectations are clearly articulated.

- Logistik und Lieferkettenmanagement: Quality assurance does not end at manufacturing; it extends to logistics and delivery. Buyers should ensure that their suppliers have robust processes for handling products during transit to prevent damage.

In summary, a thorough understanding of manufacturing processes and quality assurance in starter motor repairs is crucial for B2B buyers. By focusing on these aspects, businesses can ensure they are sourcing high-quality products that meet their operational needs while adhering to international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘como se arregla el motor de arranque’

To successfully source components and services for repairing a starter motor, it’s essential to follow a structured approach. This guide outlines a step-by-step checklist designed for B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding the exact requirements for your starter motor repair is crucial. Specify the type of vehicles or equipment the starter motor will be used for, including make, model, and year. This information helps ensure compatibility with replacement parts and repair services.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify suppliers that specialize in starter motor components and repair services. Look for companies with a proven track record in your region. Utilize online platforms, trade shows, and industry directories to gather a list of potential suppliers.

- Wichtige Überlegungen:

- Supplier reputation within the industry.

- Feedback from other businesses in similar sectors.

Schritt 3: Lieferantenzertifizierungen bewerten

Before proceeding, verify that suppliers hold relevant certifications and comply with international standards. Certifications such as ISO 9001 for quality management systems can indicate a commitment to quality and reliability.

- Wichtigkeit:

- Ensures the parts and services meet industry standards.

- Reduces the risk of defective components affecting your operations.

Schritt 4: Muster oder Demonstrationen anfordern

Ask suppliers for samples or demonstrations of their starter motor repair kits or components. This hands-on approach allows you to assess the quality and performance of their offerings before making a bulk purchase.

- What to Observe:

- Material quality and durability.

- Ease of installation and compatibility with existing systems.

Schritt 5: Bewertung von Preisgestaltung und Zahlungsbedingungen

Compare pricing structures among different suppliers while considering the total cost of ownership, including shipping and potential tariffs. Understanding payment terms is equally important; look for suppliers offering flexible payment options that align with your financial strategies.

- Tips:

- Negotiate bulk purchase discounts.

- Evaluate the cost against quality to ensure value.

Schritt 6: Check After-Sales Support and Warranty

After-sales support is vital for addressing any issues that may arise post-purchase. Inquire about warranty terms and the availability of customer support for troubleshooting or additional guidance on repairs.

- Warum das wichtig ist:

- Provides peace of mind knowing assistance is readily available.

- A robust warranty can protect your investment against defects.

Schritt 7: Finalize the Procurement Process

Once you’ve evaluated all aspects, finalize your procurement process by placing an order. Ensure that all agreements, including delivery timelines and return policies, are documented clearly to avoid future disputes.

- Final Checklist:

- Confirm order details with the supplier.

- Ensure all logistics, including shipping and handling, are clearly outlined.

By following this practical sourcing guide, B2B buyers can streamline the process of procuring necessary components for starter motor repairs, enhancing operational efficiency and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for como se arregla el motor de arranque Sourcing

When analyzing the cost and pricing structure for sourcing components or services related to “como se arregla el motor de arranque” (how to repair a starter motor), several key components and influencers must be considered. Understanding these factors can significantly enhance the purchasing strategy for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Main Cost Components in Starter Motor Repairs?

-

Materialien: The cost of raw materials is a significant factor in the overall pricing structure. This includes components like brushes, armatures, solenoids, and gears. The quality of materials directly impacts durability and performance, which can lead to cost variations.

-

Arbeit: Labor costs can vary greatly depending on the region and skill level required. Regions with higher labor costs may impact the overall pricing. Skilled technicians are crucial for repair services, and their wages should be factored into the pricing model.

-

Fertigungsgemeinkosten: This includes costs associated with facilities, utilities, and administrative expenses. For suppliers, understanding their overhead can provide insight into their pricing structures.

-

Werkzeuge: The cost of specialized tools and equipment necessary for the repair process also plays a role. These tools can be a one-time investment for suppliers but may affect pricing if they are frequently updated or replaced.

-

Qualitätskontrolle (QC): Implementing stringent QC measures ensures that repaired components meet industry standards. The costs associated with these processes should be included in the pricing.

-

Logistik: Transportation and shipping costs can vary significantly based on distance and shipping methods. Buyers should consider these costs, especially when sourcing from international suppliers.

-

Marge: Suppliers typically include a profit margin, which can vary based on competition, market demand, and the perceived value of the service.

How Do Price Influencers Affect Starter Motor Repair Costs?

-

Volumen/MOQ (Mindestbestellmenge): Larger orders often come with bulk pricing advantages. Buyers looking to source multiple units should negotiate for better pricing based on their purchasing volume.

-

Spezifikationen und Anpassung: Customized repairs or specific component requirements can lead to higher costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Qualität der Materialien und Zertifizierungen: Higher-quality materials or those that meet specific certifications will typically cost more. Buyers should evaluate the long-term benefits of investing in higher-quality components against initial costs.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium due to their proven track record, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding the Incoterms associated with international shipping can impact total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the transportation costs and risks.

Welche Tipps können Käufern helfen, bessere Preise zu verhandeln?

-

Effektiv verhandeln: Buyers should be prepared to negotiate based on volume, potential future orders, and long-term relationships. Establishing a rapport with suppliers can lead to better pricing and terms.

-

Fokus auf Kosteneffizienz: Evaluate the total cost of ownership rather than just the upfront costs. This includes considering the longevity and performance of components, which can lead to savings in the long run.

-

Lokale Lieferanten in Betracht ziehen: For buyers in regions like Africa and South America, local suppliers may offer lower logistics costs and faster turnaround times, despite potentially higher material costs.

-

Preisdifferenzen verstehen: Buyers should familiarize themselves with local market conditions and currency fluctuations, as these can significantly impact pricing, especially in volatile regions.

-

Detaillierte Angebote anfordern: When seeking quotes, request itemized breakdowns to understand where costs are allocated. This transparency can aid in negotiations and comparisons.

Haftungsausschluss zu Preisen

It’s important to note that the prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough market research and supplier evaluations to obtain the most accurate and relevant pricing information for your sourcing needs.

Alternatives Analysis: Comparing como se arregla el motor de arranque With Other Solutions

In the automotive industry, the need to address starter motor issues efficiently is paramount, especially for businesses involved in vehicle maintenance and repair. While “como se arregla el motor de arranque” offers a practical approach to troubleshooting and repairing starter motors, there are alternative solutions that might better suit specific operational needs. This section will compare traditional repair methods with alternative solutions, helping B2B buyers make informed decisions.

| Vergleichsaspekt | Como Se Arregla El Motor De Arranque | Reconditioning Starter Motors | Austausch des Anlassers |

|---|---|---|---|

| Leistung | Effective for minor issues | Restores to near-original performance | New performance guaranteed |

| Kosten | Low-cost DIY repairs | Moderate cost (less than new) | Höhere Anfangskosten |

| Einfache Implementierung | Requires technical knowledge | Requires specialized tools and knowledge | Simple, straightforward installation |

| Wartung | Regelmäßige Kontrollen erforderlich | Minimal maintenance if done correctly | Requires full replacement after failure |

| Bester Anwendungsfall | Quick fixes for minor malfunctions | Businesses with frequent starter issues | When repair is not feasible |

What Are the Benefits and Drawbacks of Reconditioning Starter Motors?

Reconditioning starter motors involves refurbishing existing units to restore functionality. This method can be cost-effective for businesses that frequently deal with starter motor failures. The primary advantage is that it can save money compared to purchasing new units, while also reducing waste. However, the process can be labor-intensive and may require specialized training or tools, which could be a drawback for companies without a dedicated workshop or technical staff.

How Does Starter Motor Replacement Compare to Repairs?

Starter motor replacement is often considered the most straightforward solution, especially when the existing unit is beyond repair. This method guarantees new performance levels and reliability, making it ideal for businesses that prioritize uptime and efficiency. However, the initial investment is higher than repair or reconditioning methods. Companies with limited budgets or those aiming to maintain older vehicle fleets may find this option less attractive.

Illustrative image related to como se arregla el motor de arranque

Conclusion: Which Solution is Right for Your Business Needs?

Choosing the right solution for starter motor issues largely depends on your operational needs, budget, and technical capabilities. If your business frequently encounters minor problems with starter motors, learning “como se arregla el motor de arranque” can be a cost-effective approach. For companies looking to balance cost and reliability, reconditioning offers a middle ground. Conversely, if your priority is immediate and guaranteed performance, particularly in high-demand scenarios, investing in new starter motors may be the best route. Each solution has its unique advantages and disadvantages, so a thorough assessment of your specific context will guide you toward the most effective decision.

Essential Technical Properties and Trade Terminology for como se arregla el motor de arranque

Was sind die wichtigsten technischen Eigenschaften eines Anlassers?

Understanding the technical specifications of a starter motor is essential for any business involved in automotive repair or manufacturing. Here are some critical properties to consider:

1. Werkstoffgüte

The materials used in starter motors, such as copper for windings and high-grade steel for the casing, are crucial for performance. High-quality materials ensure durability and resistance to wear, which is vital for longevity. Businesses must source starter motors made from reliable materials to minimize replacements and reduce downtime.

2. Drehmoment

Torque rating indicates the amount of rotational force the starter motor can produce. This specification is vital for ensuring that the motor can effectively turn the engine over, especially in larger vehicles or those with high compression engines. A high torque rating is essential for B2B buyers looking to enhance vehicle performance and reliability.

3. Spannung und Stromstärke

Most starter motors operate on 12V or 24V systems, and the amperage can vary significantly. Understanding these ratings is crucial for compatibility with vehicle electrical systems. For B2B buyers, sourcing starter motors that match the voltage and amperage requirements of specific vehicles can enhance operational efficiency and safety.

4. Toleranzwerte

Tolerance refers to the acceptable limits of variation in the starter motor’s dimensions and performance. High tolerance levels ensure that components fit correctly and function efficiently, reducing the likelihood of mechanical failure. Businesses must be aware of these tolerances to ensure proper installation and operation in various applications.

5. Isolationsklasse

The insulation class of a starter motor determines its ability to withstand temperature extremes. Classes like B, F, and H indicate different temperature limits. For B2B buyers, selecting motors with appropriate insulation is crucial for applications in harsh environments, ensuring reliable operation without overheating.

What Are Common Trade Terminology and Their Importance in Starter Motor Repair?

Familiarity with industry jargon can streamline communications and negotiations in the starter motor market. Here are some essential terms:

1. OEM (Originalgerätehersteller)

OEM refers to parts made by the original manufacturer of the vehicle. For B2B buyers, OEM parts often guarantee compatibility and reliability, making them a preferred choice for repairs. Sourcing OEM starter motors can enhance customer trust and satisfaction.

2. MOQ (Mindestbestellmenge)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for businesses to ensure they can meet demand without overstocking. This term helps in negotiating better pricing and managing inventory efficiently.

3. RFQ (Angebotsanfrage)

An RFQ is a formal request to suppliers to provide pricing for specific products or services. In the context of starter motors, issuing an RFQ can help businesses compare prices and terms from different suppliers, facilitating informed purchasing decisions.

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is vital for B2B transactions involving starter motors, as they clarify who is responsible for shipping costs, insurance, and risk during transit.

5. Ersatzteile

Aftermarket parts are manufactured by companies other than the original manufacturer. While often less expensive, they may vary in quality. B2B buyers should carefully evaluate aftermarket starter motors to balance cost savings with reliability.

By grasping these technical properties and terminology, businesses can make informed decisions regarding starter motor repairs and sourcing, ultimately enhancing operational efficiency and customer satisfaction.

Illustrative image related to como se arregla el motor de arranque

Navigating Market Dynamics and Sourcing Trends in the como se arregla el motor de arranque Sector

What Are the Current Market Dynamics and Key Trends Affecting the ‘como se arregla el motor de arranque’ Sector?

The global market for starter motor repair services and components is shaped by several key drivers. Increasing vehicle ownership in developing regions like Africa and South America is leading to a surge in demand for repair services. In addition, the rising cost of new vehicles prompts many owners to seek cost-effective repair solutions, thereby driving the starter motor repair market. Technological advancements are also influencing the sector, with innovations such as smart diagnostic tools and automated repair processes becoming more prevalent.

For international B2B buyers, particularly those from regions like Nigeria and Germany, understanding local market dynamics is crucial. Buyers should be aware of the varying levels of access to repair technologies and skilled labor across different regions. In Europe, for instance, the focus is shifting towards high-quality components that ensure long-term reliability, whereas in emerging markets, affordability and availability remain primary concerns. Additionally, the trend towards e-commerce has made it easier for B2B buyers to source parts directly from manufacturers, reducing reliance on local distributors.

How Are Sustainability and Ethical Sourcing Shaping the ‘como se arregla el motor de arranque’ Market?

Environmental considerations are becoming increasingly important in the ‘como se arregla el motor de arranque’ sector. As the automotive industry faces pressure to reduce its carbon footprint, repair services must also adapt. This includes utilizing sustainable materials in the manufacturing of starter motor components and adopting practices that minimize waste.

Ethical sourcing is gaining traction, with B2B buyers prioritizing suppliers who adhere to responsible labor practices and environmental regulations. Green certifications, such as ISO 14001 for environmental management systems, are becoming essential for suppliers looking to establish credibility in the market. Buyers should seek partnerships with companies that demonstrate a commitment to sustainability, as these relationships can enhance their own brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context Behind the ‘como se arregla el motor de arranque’ Sector?

The evolution of starter motor repair can be traced back to the early 20th century when automobiles first became widely accessible. Initially, repair techniques were rudimentary, relying on manual labor and basic tools. As technology advanced, the introduction of electric starters revolutionized the industry, making repairs more complex but also more efficient.

The 1980s and 1990s saw significant innovations in starter motor design, including the use of more durable materials and improved electrical components. This period also marked the beginning of professional training programs for automotive technicians, emphasizing the importance of skilled labor in the repair process. Today, the integration of technology in diagnostics and repair is reshaping the sector, making it imperative for B2B buyers to stay informed about ongoing changes and advancements.

In summary, navigating the complexities of the ‘como se arregla el motor de arranque’ sector requires an understanding of market dynamics, a commitment to sustainability, and an awareness of historical context. By leveraging these insights, international B2B buyers can make informed decisions that align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of como se arregla el motor de arranque

-

How do I solve a slow-starting engine problem?

To address a slow-starting engine, first inspect the battery connections and ensure they are clean and secure. Next, check the starter motor for any signs of wear or damage. Performing a voltage test on the starter can also help identify issues. If the starter is functioning but still slow, consider cleaning or replacing the brushes and inspecting the solenoid for proper operation. If these steps do not resolve the issue, professional assistance may be required to further diagnose the problem. -

What is the best method for troubleshooting a starter motor?

The best method for troubleshooting a starter motor involves a systematic approach. Begin with a visual inspection to identify any obvious damage or loose connections. Use a multimeter to check for voltage at the starter terminals when the ignition is turned on. If voltage is present but the starter does not engage, perform tests on the solenoid and motor windings. If problems persist after these checks, it may be time to consult a professional or consider a replacement. -

How can I find reliable suppliers for starter motor repair parts?

To find reliable suppliers for starter motor repair parts, start by researching manufacturers with good reputations in your region. Utilize trade platforms like Alibaba or global sourcing sites to view supplier ratings and reviews. Attend industry trade shows and networking events to meet suppliers and evaluate their products firsthand. Additionally, request samples and check for certifications to ensure quality compliance. Establishing relationships with multiple suppliers can also provide leverage in negotiations. -

What customization options are available for starter motor components?

Customization options for starter motor components often include variations in size, voltage ratings, and material specifications based on application needs. Many suppliers offer tailored solutions to meet specific requirements, such as different gear ratios or enhanced performance features for specialized vehicles or machinery. Discuss your needs with suppliers directly to explore available options and ensure that the customized parts comply with industry standards. -

What is the minimum order quantity (MOQ) for starter motor repair kits?

Minimum order quantities (MOQs) for starter motor repair kits can vary significantly between suppliers. Typically, MOQs can range from as low as 10 units to hundreds, depending on the manufacturer and the type of components requested. When sourcing, inquire about flexible order quantities, especially if you are testing a new supplier or product line. Some suppliers may accommodate lower MOQs for first-time buyers or bulk orders. -

What payment terms should I negotiate with suppliers for starter motor parts?

When negotiating payment terms with suppliers for starter motor parts, consider options like net 30, 60, or even 90 days for payment after delivery. Additionally, explore the possibility of partial upfront payments, especially for larger orders. It’s crucial to balance favorable terms with the supplier’s need for security. Always ensure that payment methods are secure, and consider using letters of credit for international transactions to mitigate risks. -

How do I ensure quality assurance when sourcing starter motor components?

To ensure quality assurance when sourcing starter motor components, request detailed product specifications and certifications from suppliers. Implement a thorough inspection process, including testing samples before placing bulk orders. Utilize third-party quality assurance services to conduct factory audits and inspections. Establish clear communication regarding quality standards and return policies to safeguard against defects or non-compliance. -

What logistics considerations should I keep in mind when importing starter motor parts?

When importing starter motor parts, logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with the regulations of your destination country. Ensure that all documentation, such as invoices and packing lists, is accurate to avoid delays at customs. Additionally, plan for lead times, and consider inventory management strategies to maintain stock levels while awaiting shipments.

Top 3 Como Se Arregla El Motor De Arranque Manufacturers & Suppliers List

1. Starter Solenoid – 12V & 24V Solutions

Domäne: startersolenoid.net

Registriert: 2017 (8 Jahre)

Einleitung: Solenoide de arranque de 12 V, solenoide de arranque de 24 V, solenoide de arranque marino, solenoide de arranque de alta resistencia, solenoide de arranque del tractor, solenoide de arranque para motocicletas, solenoide de arranque universal, fabricantes como Bosch, Delco, Denso, Ford, Hitachi, Lucas, Mitsubishi, Nikko, interruptor electromagnético, relé de arranque, kit de reparación del motor d…

2. Comercial Garrido – Reparación de Motores de Arranque

Domäne: comercialgarrido.es

Einleitung: El motor de arranque es un componente esencial para el funcionamiento de un coche, encargado de iniciar el motor principal. Puede fallar por desgaste natural, problemas eléctricos o mecánicos. En Comercial Garrido, ofrecemos servicios de reparación especializados, con un costo promedio entre 300 y 600 euros, dependiendo del modelo y la gravedad del problema. Nuestro equipo está capacitado para tra…

3. ScrapingDog – Instagram Scraping Services

Domäne: instagram.com

Registriert: 2004 (21 Jahre)

Einleitung: Contact us at info@scrapingdog.com for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for como se arregla el motor de arranque

In the realm of automotive maintenance, particularly concerning the repair of starter motors, strategic sourcing plays a pivotal role in ensuring efficiency and cost-effectiveness. By identifying reliable suppliers of high-quality components and repair kits, businesses can significantly reduce operational costs while maintaining the integrity of their services. The ability to conduct thorough troubleshooting and maintenance not only extends the lifespan of starter motors but also enhances customer satisfaction by minimizing downtime.

Illustrative image related to como se arregla el motor de arranque

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, embracing a proactive sourcing strategy is essential. This approach allows companies to leverage local expertise, understand market dynamics, and build strong relationships with suppliers. Investing in training for technicians and utilizing advanced diagnostic tools can further streamline the repair process, ensuring that businesses remain competitive.

As the automotive sector continues to evolve, staying ahead of trends and innovations will be critical. By prioritizing strategic sourcing and fostering collaboration across borders, businesses can position themselves for sustained growth and success in the global market. Now is the time to take action—evaluate your sourcing strategies, connect with trusted suppliers, and ensure your operations are optimized for the future.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.