Introduction: Navigating the Global Market for best car alternator brand

Navigating the global market for the best car alternator brands presents a unique challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The increasing demand for reliable automotive components necessitates informed sourcing decisions to ensure operational efficiency and customer satisfaction. This guide is meticulously crafted to provide a comprehensive overview of the best car alternator brands, addressing essential considerations such as types of alternators, their applications across various vehicle models, and the intricacies of supplier vetting.

Within these pages, you will find detailed insights into the performance characteristics of different alternator types, including high-output and remanufactured options, alongside practical advice on evaluating the reliability and compatibility of suppliers. We also delve into cost considerations, enabling you to strike a balance between quality and budget constraints.

By leveraging the information presented in this guide, international B2B buyers can make well-informed purchasing decisions that enhance their supply chains, reduce downtime, and ultimately contribute to the long-term success of their automotive operations. Whether you’re sourcing for a fleet in Nigeria, Brazil, or elsewhere, this guide equips you with the knowledge to navigate the complexities of the car alternator market with confidence.

Inhaltsverzeichnis

- Top 2 Best Car Alternator Brand Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best car alternator brand

- Understanding best car alternator brand Types and Variations

- Key Industrial Applications of best car alternator brand

- 3 Common User Pain Points for ‘best car alternator brand’ & Their Solutions

- Strategic Material Selection Guide for best car alternator brand

- In-depth Look: Manufacturing Processes and Quality Assurance for best car alternator brand

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best car alternator brand’

- Comprehensive Cost and Pricing Analysis for best car alternator brand Sourcing

- Alternatives Analysis: Comparing best car alternator brand With Other Solutions

- Essential Technical Properties and Trade Terminology for best car alternator brand

- Navigating Market Dynamics and Sourcing Trends in the best car alternator brand Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best car alternator brand

- Strategic Sourcing Conclusion and Outlook for best car alternator brand

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding best car alternator brand Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Hochleistungsgeneratoren | Produces up to 200 amps, brushless technology | High-performance vehicles, audio systems | Vorteile: Handles high electrical demands; durable. Nachteile: Höhere Kosten; kann Änderungen erfordern. |

| Normale Lichtmaschinen | Uses carbon brushes, standard amperage output | Most standard vehicles | Vorteile: Cost-effective; readily available. Nachteile: Shorter lifespan; lower output. |

| Überholte Lichtmaschinen | Inspected and rebuilt to meet OE specifications | Budget-conscious buyers, fleet services | Vorteile: Cost-efficient; reliable warranties. Nachteile: May not match new part performance. |

| Compact Alternators | Smaller size, efficient power generation | Smaller vehicles, urban applications | Vorteile: Space-saving; lightweight. Nachteile: Limited output; may not support heavy electrical loads. |

| Hochleistungsgeneratoren | Designed for commercial vehicles, high amperage output | Trucks, buses, construction vehicles | Vorteile: Robust; handles high loads. Nachteile: Bulkier; higher installation complexity. |

What Are High-Output Alternators and Their B2B Relevance?

High-output alternators are engineered to deliver substantial power, often exceeding 200 amps, making them ideal for high-performance vehicles and sophisticated audio systems. Their brushless technology enhances durability and reduces maintenance needs, which is particularly appealing for businesses in the automotive aftermarket and performance tuning sectors. B2B buyers should consider compatibility with existing electrical systems and potential modifications needed for installation.

How Do Regular Alternators Fit into the Market?

Regular alternators are the standard choice for most vehicles, utilizing carbon brushes to generate power. They are cost-effective and widely available, making them suitable for fleet services and everyday automotive repairs. However, their shorter lifespan and lower amperage output may not meet the needs of vehicles with high electrical demands. Buyers should evaluate the specific requirements of their vehicle models to ensure optimal performance.

Why Choose Remanufactured Alternators?

Remanufactured alternators offer a balance of quality and affordability, having undergone rigorous inspection and component replacement to meet original equipment (OE) specifications. This option is particularly attractive for budget-conscious businesses or those managing fleets. While they provide reliable performance comparable to new parts, buyers should verify warranty conditions and the reputation of the manufacturer to ensure satisfactory service.

What Are the Advantages of Compact Alternators?

Compact alternators are designed for smaller vehicles and urban applications where space is at a premium. Their lightweight design contributes to overall vehicle efficiency, making them appealing for manufacturers focusing on fuel efficiency and urban mobility. However, their limited output may restrict their use in vehicles with extensive electrical systems. B2B buyers should assess the electrical load requirements before opting for this type.

What Makes Heavy-Duty Alternators Essential?

Heavy-duty alternators are crucial for commercial vehicles, including trucks and buses, where high amperage output is necessary to support demanding electrical systems. These alternators are robustly built to withstand rigorous use, making them ideal for businesses in transportation and construction. However, their bulkier design can complicate installation, and buyers should ensure compatibility with vehicle specifications to avoid operational issues.

Key Industrial Applications of best car alternator brand

| Branche/Sektor | Specific Application of best car alternator brand | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Integration in electric vehicles (EVs) | Enhances vehicle performance and energy efficiency | Compliance with regional electrical standards and specs |

| Heavy-Duty Transportation | Powering fleet vehicles’ electrical systems | Improves reliability and reduces downtime | Durability and high output for demanding environments |

| Landwirtschaftliche Geräte | Supporting farm machinery and equipment | Ensures consistent operation of electrical components | Compatibility with various machinery models |

| Erneuerbare Energien | Used in hybrid systems for energy storage | Optimizes energy conversion and storage efficiency | Sourcing for high-output alternatives |

| Baumaschinen | Powering tools and machinery on job sites | Increases productivity and reduces operational costs | Focus on rugged design and reliability |

How is the best car alternator brand used in the automotive manufacturing sector?

In the automotive manufacturing sector, the best car alternator brands are crucial for integrating electrical systems in electric vehicles (EVs). These alternators convert mechanical energy into electrical power, supporting advanced electronic features such as regenerative braking and energy management systems. For international buyers, especially in Africa and South America, sourcing alternators that comply with local electrical standards is essential to ensure compatibility and performance. This focus on energy efficiency not only enhances vehicle performance but also meets the growing demand for sustainable transportation solutions.

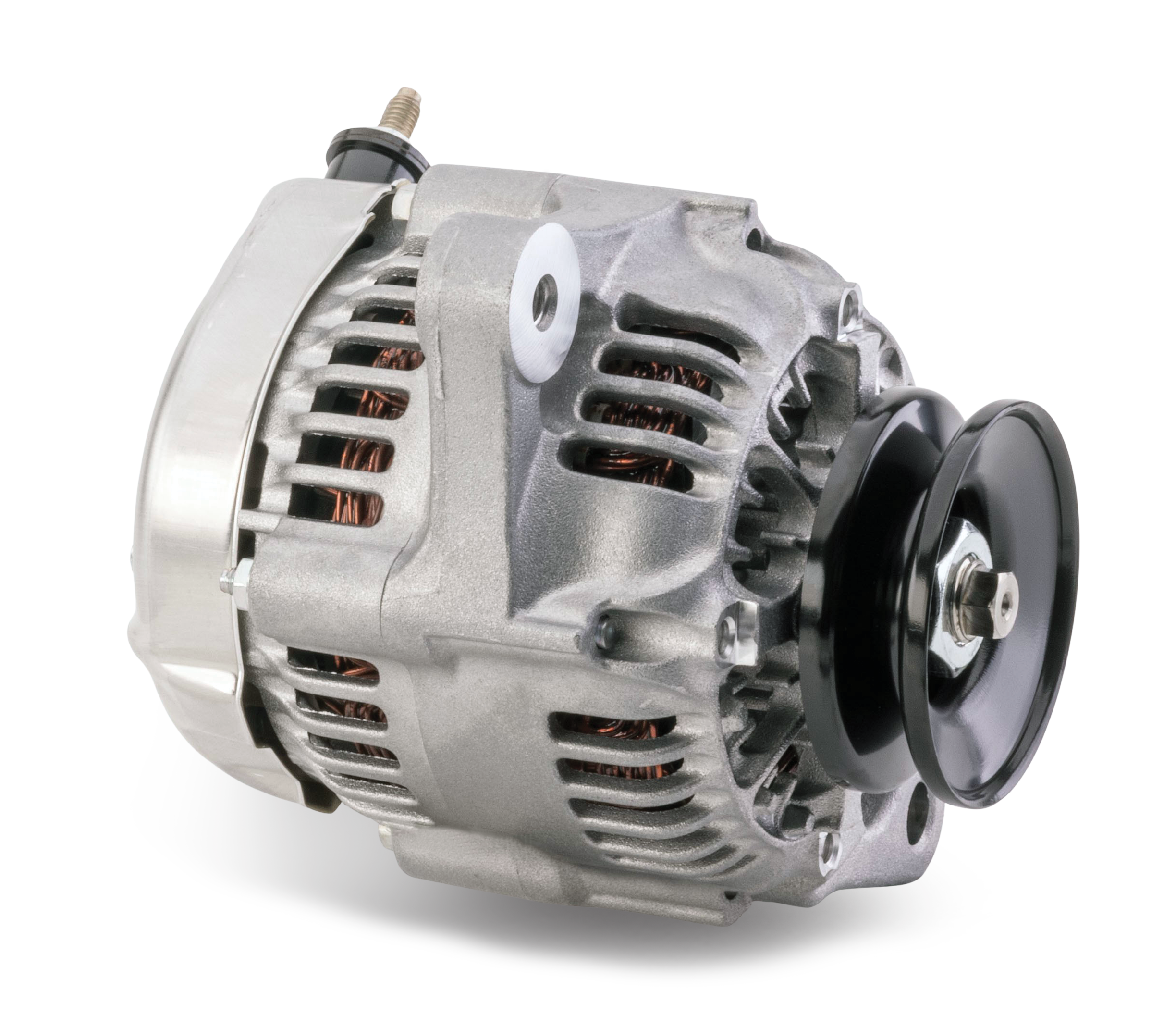

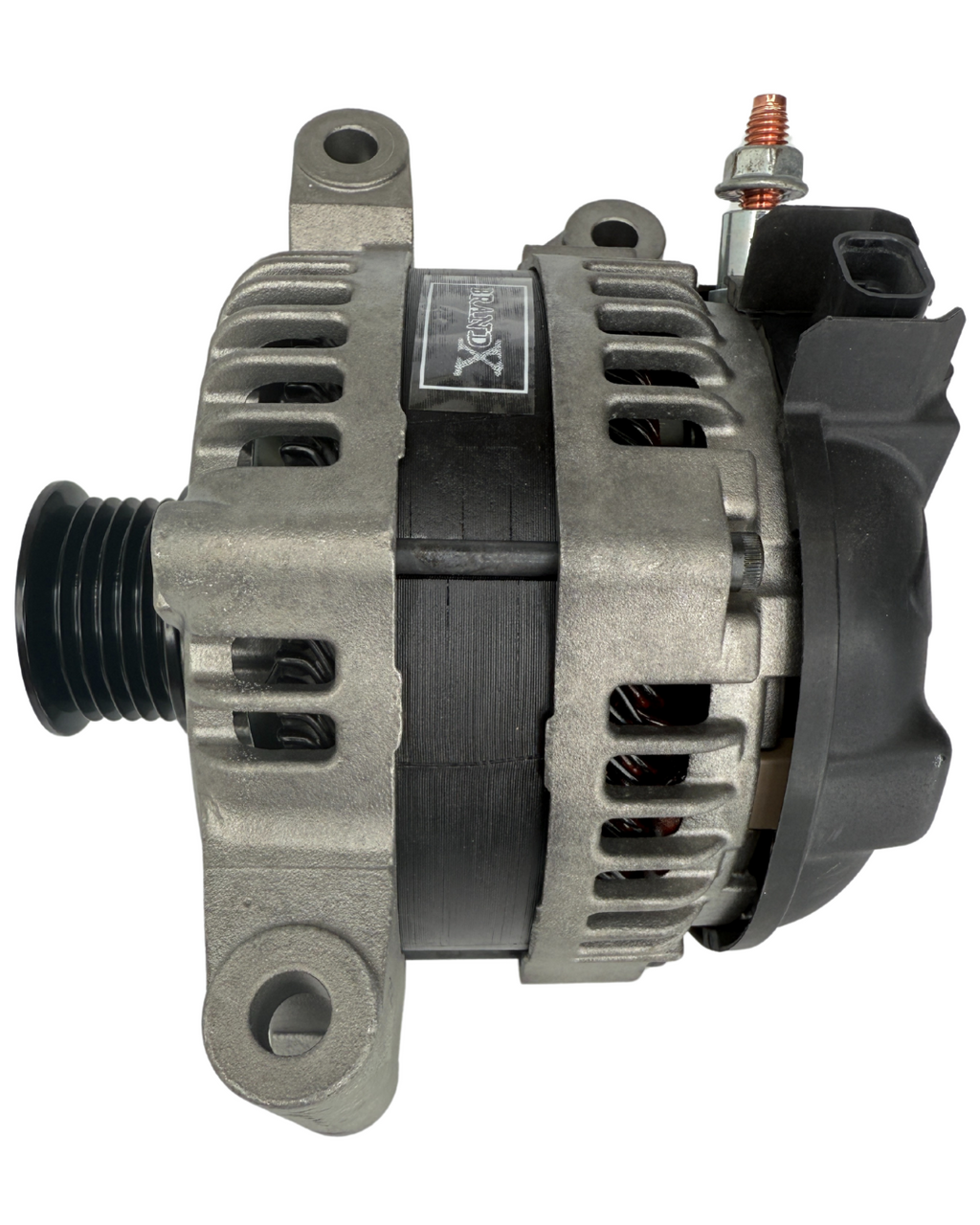

Illustrative image related to best car alternator brand

What role do alternators play in heavy-duty transportation applications?

In heavy-duty transportation, the best car alternator brands provide reliable power for fleet vehicles, ensuring that essential electrical systems, such as GPS, lighting, and communication devices, operate seamlessly. A high-output alternator reduces downtime by maintaining battery charge and supporting the operation of multiple electrical components. For buyers in the Middle East and Europe, selecting durable alternators that can withstand harsh operating conditions is vital. This reliability translates to increased operational efficiency and reduced maintenance costs, benefiting fleet management.

How are alternators applied in agricultural equipment?

Agricultural equipment heavily relies on the best car alternator brands to power machinery and ensure the functionality of electrical systems, such as irrigation controls and automated farming technologies. These alternators are essential for maintaining consistent operation in challenging conditions, which is particularly important for buyers in regions like Nigeria and Brazil, where agricultural productivity is critical. Compatibility with various machinery models is a key consideration for sourcing, as it affects the overall efficiency and reliability of farming operations.

In what ways do alternators support renewable energy initiatives?

The best car alternator brands are increasingly being utilized in renewable energy applications, particularly in hybrid systems where they play a vital role in energy storage and conversion. These alternators enhance the efficiency of energy management systems, allowing for better integration of renewable sources like solar and wind. For B2B buyers in emerging markets, sourcing high-output alternators that can handle variable loads and support energy storage solutions is essential. This capability not only optimizes energy use but also contributes to sustainability efforts in the energy sector.

How do alternators enhance productivity in construction equipment?

In the construction industry, the best car alternator brands are integral to powering tools and machinery on job sites, ensuring that equipment operates effectively without interruptions. A robust alternator can withstand the rigors of construction environments, leading to increased productivity and reduced operational costs. Buyers should focus on sourcing rugged designs that offer reliability in demanding conditions, particularly in regions where construction activities are expanding rapidly. This reliability ensures that projects stay on schedule and within budget, providing a competitive edge in the market.

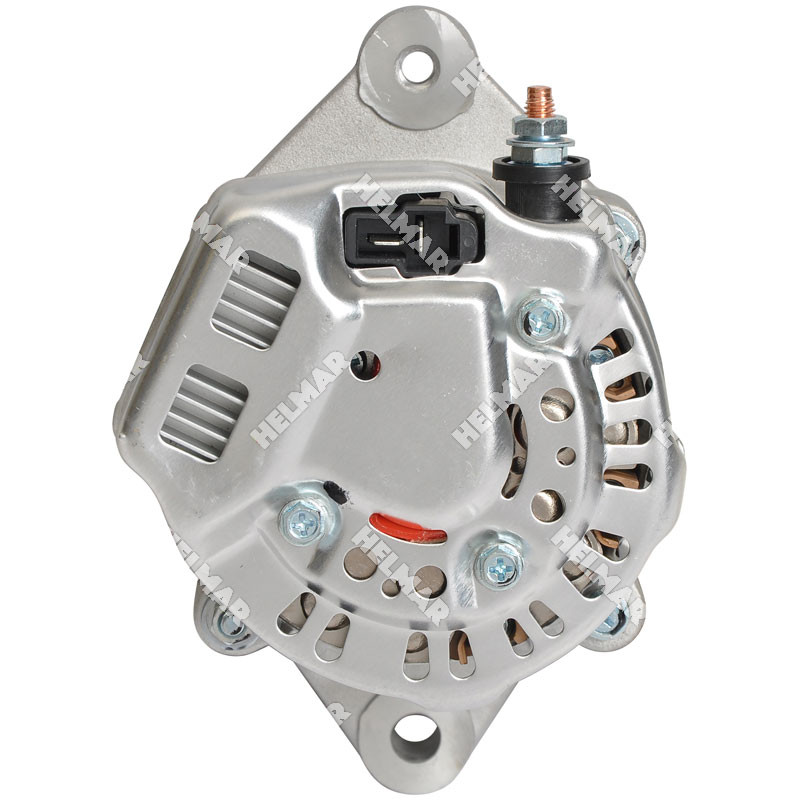

Illustrative image related to best car alternator brand

3 Common User Pain Points for ‘best car alternator brand’ & Their Solutions

Scenario 1: Inconsistent Quality of Alternators Leads to Operational Downtime

Das Problem: B2B buyers, particularly those sourcing alternators for fleets or repair shops, often face the issue of inconsistent quality among various brands. This inconsistency can lead to frequent failures, resulting in operational downtime and increased maintenance costs. Buyers may invest in a reputed brand, only to discover that the alternators do not perform as expected, affecting the reliability of their vehicles and ultimately their bottom line. This issue is compounded in regions where access to reliable service and replacement parts is limited, making it critical to choose the right alternator brand from the outset.

Die Lösung: To mitigate quality inconsistencies, buyers should conduct thorough research and select brands that have a proven track record of reliability and customer satisfaction. Look for brands that offer warranties and have established reputations in the market, such as Wilson or Denso. Additionally, consider sourcing alternators from authorized distributors who can provide insights into the latest models and performance metrics. Conducting a pilot test by purchasing a small batch can also help evaluate the performance of the alternators before committing to larger orders. Establishing a relationship with the manufacturer for ongoing support and feedback can further enhance the quality assurance process.

Scenario 2: Difficulty in Matching Alternators with Specific Vehicle Requirements

Das Problem: Another common pain point for B2B buyers is the challenge of matching alternators to specific vehicle models and their unique electrical requirements. Different vehicles demand varying amperage outputs based on their electrical loads, which can complicate the selection process. Buyers may face issues such as underperformance if the wrong alternator is chosen, leading to battery drain and electrical system failures. This challenge is particularly acute in markets with a diverse range of vehicle makes and models, where universal solutions often fall short.

Die Lösung: To address this issue, it is essential for buyers to invest time in understanding the electrical specifications of the vehicles they service. Use resources like manufacturer specifications, and consider consulting with automotive experts or engineers who can help identify the correct alternator type and amperage. When selecting alternators, prioritize brands that provide detailed product information, including compatibility charts and performance ratings. Utilizing software tools or databases that track vehicle specifications can streamline the selection process. Additionally, consider building partnerships with reputable alternator manufacturers that offer customization options, allowing you to meet unique customer needs more effectively.

Illustrative image related to best car alternator brand

Scenario 3: High Costs Associated with Premium Alternator Brands

Das Problem: B2B buyers often grapple with the perception that premium alternator brands, while known for reliability, come at a significantly higher cost. This can be especially challenging for businesses operating on tight budgets or those looking to maximize profitability. The initial investment in high-quality alternators may deter some buyers, leading them to opt for cheaper alternatives that could result in higher long-term costs due to frequent replacements and repairs.

Die Lösung: To make informed purchasing decisions, buyers should conduct a total cost of ownership analysis, comparing the long-term benefits of premium brands against their upfront costs. Emphasize the importance of reliability and performance in reducing maintenance and replacement costs over time. Buyers can also explore bulk purchasing options or negotiate pricing with manufacturers to secure better rates on high-quality alternators. Furthermore, consider implementing a structured maintenance program that includes regular inspections and servicing of alternators, which can prolong their lifespan and enhance overall vehicle performance. By viewing alternators as an investment rather than just an expense, buyers can better align their purchasing strategies with their operational goals.

Strategic Material Selection Guide for best car alternator brand

What Are the Common Materials Used in Car Alternators?

When selecting the best car alternator brands, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic.

How Does Aluminum Impact Car Alternator Performance?

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent thermal conductivity. The key properties of aluminum include a temperature rating of around 150°C and good corrosion resistance, especially when anodized.

Vorteile: Aluminum’s lightweight characteristic reduces overall vehicle weight, enhancing fuel efficiency. It is also relatively inexpensive and easy to manufacture, which can lower production costs for manufacturers.

Nachteile: While aluminum is resistant to corrosion, it can be less durable than steel under high-stress conditions. Its mechanical strength is lower, making it less suitable for heavy-duty applications.

Auswirkungen auf die Anwendung: Aluminum is ideal for standard and light-duty vehicles where weight savings are essential, but it may not be the best choice for high-performance or heavy-duty alternators.

Überlegungen für internationale Käufer: B2B buyers in regions like Africa and South America should ensure that aluminum components meet local corrosion resistance standards, especially in humid or coastal environments.

Illustrative image related to best car alternator brand

What Role Does Copper Play in Electrical Conductivity?

Copper is primarily used in the windings of alternators due to its superior electrical conductivity, which is crucial for efficient power generation. It can handle high temperatures and has a melting point of approximately 1,085°C.

Vorteile: Copper’s high conductivity ensures minimal energy loss, making it an excellent choice for high-output alternators. It is also highly durable and resistant to fatigue.

Nachteile: The main drawback of copper is its cost, which is significantly higher than aluminum. Additionally, copper is heavier, which can affect overall vehicle weight.

Auswirkungen auf die Anwendung: Copper is essential in performance-oriented vehicles where high electrical output is required, making it suitable for aftermarket upgrades.

Illustrative image related to best car alternator brand

Überlegungen für internationale Käufer: Buyers should be aware of the fluctuating copper prices and consider sourcing from regions with stable supply chains to mitigate costs.

Why is Steel Used in Car Alternators?

Steel is often used for structural components of alternators, such as the frame and rotor. Its properties include high tensile strength and resistance to deformation under load.

Vorteile: Steel provides excellent durability and strength, making it suitable for heavy-duty applications. It can withstand high mechanical stress and is generally more resistant to wear and tear.

Nachteile: The main disadvantage is that steel is heavier than aluminum and can lead to increased vehicle weight. It is also more prone to corrosion unless properly treated.

Auswirkungen auf die Anwendung: Steel is ideal for heavy-duty and commercial vehicles where durability is paramount, but it may not be suitable for performance vehicles where weight is a concern.

Überlegungen für internationale Käufer: Compliance with local standards for steel quality, such as ASTM or DIN, is essential, especially in regions with strict regulations.

Welchen Beitrag leistet Kunststoff bei der Konstruktion von Wechselstromgeneratoren?

Plastic is commonly used for non-structural components, such as covers and insulators. Its properties include lightweight, corrosion resistance, and the ability to withstand moderate temperatures.

Vorteile: Plastic reduces the overall weight of the alternator and is resistant to corrosion, making it suitable for various environments. It can also be molded into complex shapes, allowing for innovative designs.

Nachteile: Plastic is generally less durable than metal and can degrade over time, especially under high temperatures or exposure to UV light.

Auswirkungen auf die Anwendung: Plastic is suitable for standard vehicles where weight savings are essential, but it may not be ideal for high-performance applications that require robust components.

Überlegungen für internationale Käufer: Buyers should ensure that the plastics used comply with local environmental regulations, especially in regions with strict waste management policies.

Übersichtstabelle zur Materialauswahl für Kfz-Generatoren

| Material | Typical Use Case for best car alternator brand | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Leichtbaukomponenten | Leichtes Gewicht und gute Wärmeleitfähigkeit | Geringere mechanische Festigkeit | Mittel |

| Kupfer | Windings for electrical components | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Stahl | Structural components for heavy-duty alternators | Hohe Haltbarkeit und Festigkeit | Schwerer und anfällig für Korrosion | Mittel |

| Kunststoff | Nicht-strukturelle Komponenten wie Abdeckungen | Leicht und korrosionsbeständig | Weniger haltbar bei Belastung | Niedrig |

Understanding the properties and applications of these materials will help international B2B buyers make informed decisions when selecting the best car alternator brands for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for best car alternator brand

What Are the Key Stages in the Manufacturing Process of High-Quality Car Alternators?

The manufacturing process for car alternators involves multiple stages, each critical to ensuring the final product meets the required performance standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Car Alternator Production?

Material preparation is the foundational stage where raw materials such as aluminum, copper, and steel are sourced. High-quality alternators typically use high-grade materials to enhance durability and performance. Copper is essential for wiring and windings, while aluminum is commonly used for the housing due to its lightweight and corrosion resistance. Suppliers must demonstrate compliance with international material standards, ensuring they provide materials that meet the specifications of the automotive industry.

What Forming Techniques Are Utilized in Car Alternator Manufacturing?

Forming is where the raw materials undergo various processes to create the individual components of the alternator. Techniques such as die-casting for aluminum housings and stamping for metal parts are prevalent. Advanced manufacturing technologies, including CNC machining, allow for precise shaping of components, which is crucial for achieving the tight tolerances required in automotive applications. B2B buyers should inquire about the specific forming techniques used by suppliers to understand their capabilities and reliability.

How Are Car Alternators Assembled and What Quality Checks Are Conducted?

The assembly stage involves integrating the components into a complete alternator. This typically includes the rotor, stator, diode rectifier, voltage regulator, and cooling fan. Automated assembly lines are common, enhancing efficiency and consistency. During this phase, various quality control checkpoints are established. Incoming Quality Control (IQC) checks the quality of materials received, In-Process Quality Control (IPQC) monitors the assembly process for defects, and Final Quality Control (FQC) ensures the assembled alternators meet all specifications before they are shipped.

What Quality Assurance Standards Should B2B Buyers Look For in Car Alternators?

Quality assurance is paramount in the automotive industry, where safety and reliability are critical. International standards such as ISO 9001 provide a framework for quality management systems, ensuring manufacturers maintain consistent quality throughout their processes. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil-related components are vital. B2B buyers should verify that their suppliers hold these certifications, which indicate compliance with strict quality and safety standards.

What Are the Common Testing Methods Employed in Car Alternator Quality Control?

Testing methods play a crucial role in the quality assurance process. Common tests include electrical performance tests to measure output voltage and current, thermal cycling tests to assess durability under varying temperatures, and vibration tests to simulate real-world operating conditions. Suppliers may also conduct visual inspections for physical defects and use advanced equipment for non-destructive testing to identify internal flaws without damaging the components.

Illustrative image related to best car alternator brand

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

To ensure the reliability of their suppliers, B2B buyers should conduct thorough audits of the manufacturing facilities. This includes reviewing quality control documentation, process flow charts, and test reports. Regular audits help verify that suppliers adhere to the established quality standards and continuously improve their processes. Additionally, buyers can request third-party inspections, which provide an unbiased assessment of the supplier’s quality control measures.

Was sind die Besonderheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various certification requirements. Different markets may have specific regulations that dictate the standards alternators must meet. For example, European buyers must ensure compliance with the EU’s stringent environmental and safety regulations, while buyers in Africa might face different local standards. Understanding these nuances is essential for ensuring that the purchased products are compliant and safe for use in their respective markets.

How Do International Standards Impact the Quality of Car Alternators?

International standards not only enhance product quality but also facilitate trade between countries. Compliance with recognized standards can significantly increase a product’s marketability and acceptance in various regions. For instance, an alternator that meets ISO 9001 standards will likely be more trusted by B2B buyers looking for reliable suppliers. Additionally, products with CE markings are often viewed as safer and more reliable in European markets, giving suppliers an edge in competitive landscapes.

What Should B2B Buyers Consider Regarding After-Sales Support and Warranty?

After-sales support is a critical aspect of the purchasing decision for B2B buyers. Quality manufacturers often provide comprehensive warranty programs that cover defects and performance issues. Buyers should inquire about the warranty terms, including the duration and what is covered. Effective after-sales support, including access to technical assistance and replacement parts, is essential for minimizing downtime and ensuring the longevity of the alternators in use.

Conclusion: Why Understanding Manufacturing Processes and Quality Assurance Is Essential for B2B Buyers

For B2B buyers, particularly those in international markets, understanding the manufacturing processes and quality assurance measures of car alternators is essential for making informed purchasing decisions. By focusing on the detailed manufacturing stages, international standards, and verification methods, buyers can ensure that they source high-quality alternators that meet their operational needs and regulatory requirements. This knowledge not only aids in selecting reliable suppliers but also strengthens partnerships based on quality and trust.

Illustrative image related to best car alternator brand

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best car alternator brand’

Einführung

This guide provides a systematic approach for B2B buyers seeking to procure the best car alternator brands. Given the critical role alternators play in vehicle performance and electrical system management, selecting the right supplier and product is essential. This checklist will help you navigate the complexities of sourcing quality alternators tailored to your specific needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Start by identifying the specific requirements for the alternators you need. Consider factors such as electrical output, compatibility with vehicle models, and whether you need new or remanufactured units. This clarity will guide your supplier discussions and ensure you procure alternators that meet your operational demands.

- Electrical Output: Determine the required amperage based on the vehicle’s electrical load.

- Kompatibilität: Verify fitment with vehicle specifications to avoid installation issues.

Schritt 2: Recherche zu seriösen Marken

Conduct thorough research to identify leading alternator brands known for reliability and performance. Look for brands with a proven track record, positive customer reviews, and industry certifications. This knowledge will help narrow your options and focus on quality suppliers.

Illustrative image related to best car alternator brand

- Ruf der Marke: Check online reviews and industry rankings.

- Longevity in the Market: Consider brands with a history of innovation and customer trust.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, product catalogs, and case studies showcasing their work with clients in similar industries or regions. This due diligence will help ensure you partner with a reputable supplier.

- Referenzen anfordern: Ask for contacts from previous clients to gauge satisfaction.

- Assess Communication: Evaluate responsiveness and willingness to provide detailed information.

Schritt 4: Lieferantenzertifizierungen überprüfen

Ensure that potential suppliers have the necessary certifications and compliance with international quality standards. This verification process is crucial for ensuring product quality and reliability, especially when sourcing from different regions.

- ISO-Zertifizierungen: Look for suppliers with ISO 9001 or equivalent certifications.

- Lokale Compliance: Check for adherence to regional regulations, especially in automotive standards.

Schritt 5: Muster anfordern und Tests durchführen

Always request samples of the alternators before making a bulk purchase. Testing samples for compatibility, performance, and durability will help ensure they meet your specifications and expectations.

- Leistungstests: Evaluate the alternator under different loads to ensure it meets your requirements.

- Fitment Tests: Install samples in vehicles to confirm compatibility and ease of installation.

Schritt 6: Verhandeln Sie Bedingungen und Preise

Once you’ve identified a suitable supplier, engage in negotiations to finalize pricing, payment terms, and delivery schedules. Ensure that you discuss warranty terms and after-sales support, as these factors can significantly impact your overall experience.

Illustrative image related to best car alternator brand

- Price Comparisons: Compare quotes from multiple suppliers to ensure competitive pricing.

- Warranty Coverage: Understand the warranty terms to safeguard your investment.

Schritt 7: Eine langfristige Beziehung aufbauen

After the initial purchase, focus on building a long-term relationship with your supplier. This can lead to better pricing, improved service, and access to new products as they become available.

- Regelmäßige Kommunikation: Halten Sie die Kommunikationswege offen, um Probleme umgehend anzugehen.

- Feedback-Mechanismus: Provide feedback on product performance to foster mutual growth.

By following these steps, B2B buyers can streamline their sourcing process for car alternators, ensuring they select the best brands and suppliers for their business needs.

Comprehensive Cost and Pricing Analysis for best car alternator brand Sourcing

When sourcing car alternators, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section will explore the various cost components, price influencers, and provide actionable tips for negotiating the best deals.

What Are the Key Cost Components in Car Alternator Manufacturing?

-

Materialien: The cost of raw materials such as copper, aluminum, and steel constitutes a significant portion of the overall cost. High-quality materials ensure better performance and longevity, which can justify higher prices. Buyers should consider the balance between material quality and cost-effectiveness.

-

Arbeit: Labor costs can vary significantly by region. In areas with lower labor costs, such as parts of Africa and South America, manufacturers may offer more competitive pricing. However, this can sometimes compromise quality. It’s essential to evaluate labor standards and the skills of the workforce when assessing potential suppliers.

-

Fertigungsgemeinkosten: This includes costs associated with factory operations, such as utilities and maintenance. Efficient production processes can reduce overhead costs, allowing manufacturers to offer more competitive pricing.

-

Werkzeuge: Custom tooling for specific alternator designs can be a significant initial expense. Buyers should consider whether the supplier has the necessary tooling already in place or if additional costs will be incurred for custom designs.

-

Qualitätskontrolle (QC): Rigorous quality control processes ensure that alternators meet performance standards and certifications. While QC adds to manufacturing costs, it is a crucial factor for reliability, especially in markets where vehicle performance is paramount.

-

Logistik: Shipping and handling costs can greatly affect the final price. For international buyers, understanding logistics costs, including customs duties and freight charges, is vital. Incoterms can influence who bears these costs, thus impacting pricing negotiations.

-

Marge: The manufacturer’s margin will also play a role in the final price. Higher quality brands may command higher margins due to their reputation and product reliability.

What Factors Influence the Pricing of Car Alternators?

-

Volumen und Mindestbestellmenge (MOQ): Ordering in bulk can significantly reduce per-unit costs. Suppliers often have tiered pricing structures, so understanding MOQ can lead to better pricing.

-

Spezifikationen und Anpassung: Custom alternators tailored for specific vehicle models or requirements can incur additional costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Qualitätszertifizierungen: Alternators that meet international quality standards may come at a premium. Certifications can be a valuable selling point, especially for buyers in regions demanding high reliability.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more, but they often offer peace of mind regarding product performance.

-

Incoterms: Understanding the chosen Incoterms is essential for international transactions. They dictate the responsibilities of buyers and sellers, impacting the overall cost structure.

Welche Tipps können Käufern helfen, bessere Preise für Kfz-Generatoren auszuhandeln?

-

Do Your Research: Understanding the market price range for different alternator brands can empower buyers during negotiations. Use industry reports and competitor pricing as benchmarks.

-

Negotiate Based on Total Cost of Ownership (TCO): Emphasize the long-term savings that come from investing in high-quality alternators. While the upfront cost may be higher, the reduced failure rates and longer lifespan can lead to significant savings.

-

Erkunden Sie mehrere Anbieter: Engage with multiple suppliers to compare offers. This not only helps in negotiating better prices but also allows buyers to evaluate different quality levels.

-

Lokale Lieferanten in Betracht ziehen: For buyers in regions like Africa and South America, local suppliers may reduce logistics costs and provide faster delivery times, enhancing overall value.

-

Preisdifferenzen verstehen: Be aware of seasonal price fluctuations and market trends that may affect pricing. For instance, prices may rise during peak manufacturing seasons or when raw material costs increase.

Haftungsausschluss zu Preisen

Prices for car alternators can vary widely based on factors such as brand, specifications, and market conditions. The information provided here serves as a general guideline and should be verified with specific suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing best car alternator brand With Other Solutions

Understanding Alternatives in Automotive Power Solutions

In the automotive industry, selecting the right alternator is crucial for ensuring optimal vehicle performance and reliability. While the ‘best car alternator brand’ offers proven benefits, B2B buyers should also consider alternative solutions that might better suit their specific needs. This analysis will explore various options, comparing their performance, cost, ease of implementation, maintenance requirements, and ideal use cases.

Vergleichstabelle

| Vergleichsaspekt | Best Car Alternator Brand | Hochleistungsgeneratoren | Überholte Lichtmaschinen |

|---|---|---|---|

| Leistung | High efficiency and reliability; supports standard electrical loads effectively. | Superior performance for high-demand applications; can handle up to 350 amps. | Comparable performance to new units; reliability can vary based on remanufacturing quality. |

| Kosten | Generally higher initial investment but long-term value. | Higher price point due to advanced technology and materials. | More affordable; cost-effective for budget-conscious buyers. |

| Einfache Implementierung | Direct replacement with minimal modifications; widely compatible. | May require additional modifications to the vehicle’s wiring and electrical system. | Simple installation if compatible; potential concerns with varying quality. |

| Wartung | Low maintenance; built to last with regular use. | Can require more frequent maintenance due to higher operational loads. | Maintenance depends on the quality of the remanufacturing process; may need more frequent checks. |

| Bester Anwendungsfall | Ideal for standard vehicles and daily drivers. | Best suited for high-performance vehicles, off-road applications, and heavy-duty use. | Suitable for budget vehicles and older models where new units are prohibitively expensive. |

Detaillierte Aufschlüsselung der Alternativen

Hochleistungsgeneratoren

High-output alternators are specifically designed to cater to vehicles with high electrical demands, such as those equipped with advanced audio systems or numerous electronic accessories. These alternators can produce significantly higher amperage, often exceeding 200 amps. While they provide exceptional performance and reliability, they come at a higher price point and may necessitate modifications to the vehicle’s wiring system to handle the increased load. Buyers should consider these factors when evaluating whether the benefits outweigh the costs.

Überholte Lichtmaschinen

Remanufactured alternators are an economical choice for businesses operating on tight budgets. These units have been refurbished to meet original equipment specifications, making them a cost-effective alternative to new units. However, the reliability of remanufactured alternators can vary significantly based on the quality of the remanufacturing process. While they can offer comparable performance to new alternators, buyers need to ensure they source from reputable suppliers to mitigate risks associated with potential failures.

Schlussfolgerung: Die Wahl der richtigen Generatorlösung

When selecting an alternator, B2B buyers should carefully assess their specific needs, including vehicle type, electrical load requirements, and budget constraints. While the ‘best car alternator brand’ may provide reliability and performance, alternatives such as high-output and remanufactured options can also offer viable solutions depending on the application. By weighing the pros and cons of each option, buyers can make informed decisions that align with their operational goals and enhance vehicle performance.

Essential Technical Properties and Trade Terminology for best car alternator brand

When evaluating the best car alternator brands, understanding essential technical properties and industry terminology is crucial for informed purchasing decisions. This section outlines key specifications that impact performance and durability, along with common trade terms used in the automotive industry.

What Key Technical Properties Should B2B Buyers Consider for Car Alternators?

1. Werkstoffgüte

The materials used in alternator construction, such as copper for windings and aluminum for housings, significantly influence performance. High-grade materials offer better conductivity, durability, and heat resistance. For B2B buyers, selecting alternators made from superior materials ensures longevity and reliability, reducing the frequency of replacements and maintenance.

2. Electrical Output (Amperage)

Measured in amperes (amps), electrical output is a critical specification that determines how much power the alternator can provide to the vehicle’s electrical systems. High-output alternators can deliver between 130 to 350 amps, suitable for vehicles with extensive electrical demands, such as those with advanced audio systems or additional lighting. Understanding the required amperage ensures compatibility with the vehicle’s needs, preventing potential electrical failures.

3. Spannungsregelung

Voltage regulation is vital for maintaining a consistent voltage output, typically between 13 to 14.8 volts. An efficient voltage regulator prevents overcharging, which can damage the battery and electrical components. B2B buyers should prioritize alternators with high-quality voltage regulators to enhance battery life and system reliability.

4. Mechanismus der Kühlung

Alternators generate heat during operation, and effective cooling mechanisms (like built-in fans or external cooling systems) help maintain optimal performance. A well-cooled alternator operates more efficiently and has a longer lifespan. Buyers should assess cooling features, especially for high-output applications that generate more heat.

5. Size and Fitment

The physical dimensions and design of the alternator must align with the vehicle’s engine compartment. Compatibility issues can lead to installation challenges and operational inefficiencies. B2B buyers should verify the specifications for size and mounting locations to ensure a proper fit for the intended application.

Illustrative image related to best car alternator brand

Welche gängigen Handelsbegriffe sollten B2B-Einkäufer auf dem Markt für Wechselstromgeneratoren kennen?

1. OEM (Originalgerätehersteller)

OEM refers to parts made by the original manufacturer of the vehicle. These components are designed to meet specific performance standards and are often preferred for their reliability. Understanding OEM specifications is essential for B2B buyers seeking quality parts that match the original design.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B transactions, as it impacts inventory management and procurement strategies. Buyers should clarify MOQ terms to optimize their purchasing processes and ensure they meet supply needs without overcommitting.

3. RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is a vital part of the procurement process, allowing B2B buyers to compare offers and negotiate better deals. Clear RFQs can lead to more accurate quotes and foster strong supplier relationships.

Illustrative image related to best car alternator brand

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international shipping, including costs, risks, and delivery obligations. Familiarity with these terms helps B2B buyers understand shipping agreements and manage logistical challenges effectively.

5. Ersatzteile

Aftermarket parts are components made by companies other than the original manufacturer. While they can offer cost savings, quality may vary. Buyers should evaluate aftermarket options carefully, ensuring they meet performance and durability standards suitable for their applications.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting the best car alternator brands, ensuring they choose reliable components that meet their operational needs.

Illustrative image related to best car alternator brand

Navigating Market Dynamics and Sourcing Trends in the best car alternator brand Sector

What Are the Current Market Dynamics and Key Trends Affecting the Best Car Alternator Brands?

The automotive alternator market is currently witnessing significant shifts driven by technological advancements and changing consumer demands. Globally, the push for electric and hybrid vehicles is reshaping the alternator landscape. Manufacturers are increasingly focusing on high-output alternators that can support the growing electrical loads required by modern vehicles, such as advanced infotainment systems and electric power steering. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where the automotive market is rapidly evolving.

Emerging technologies, such as smart alternators equipped with integrated charging management systems, are gaining traction. These innovations not only improve vehicle efficiency but also enhance battery life, thereby offering a competitive edge to manufacturers who adopt them. Additionally, a rise in remanufactured alternators is noted, as buyers seek cost-effective solutions without compromising quality. This trend is particularly appealing to budget-conscious markets, such as Nigeria and Brazil, where price sensitivity plays a crucial role in purchasing decisions.

Furthermore, digitalization in the sourcing process is transforming how international buyers interact with suppliers. E-commerce platforms and B2B marketplaces are streamlining procurement, enabling buyers to compare product specifications, prices, and reviews seamlessly. As a result, international buyers can make informed decisions, ensuring they source from reputable brands that align with their specific needs.

How Are Sustainability and Ethical Sourcing Influencing the Car Alternator Market?

Sustainability has become a pivotal concern in the automotive sector, influencing sourcing decisions for car alternators. The environmental impact of manufacturing processes, particularly regarding waste and emissions, has led to increased scrutiny from both consumers and regulatory bodies. For B2B buyers, selecting brands that prioritize sustainability is no longer optional but a necessity. This includes sourcing from manufacturers that utilize eco-friendly materials and production techniques.

Ethical supply chains are gaining importance, particularly in regions where labor practices may be questioned. Buyers are increasingly seeking suppliers who demonstrate commitment to fair labor practices and transparency throughout their supply chain. Brands that achieve certifications such as ISO 14001 (Environmental Management) or ISO 26000 (Social Responsibility) not only enhance their reputation but also provide assurance to international buyers regarding their commitment to ethical practices.

Moreover, the demand for ‘green’ materials in the production of alternators is on the rise. This encompasses the use of recyclable components and reduced use of hazardous substances. As the automotive industry shifts toward electrification, the need for sustainable solutions is set to intensify. B2B buyers who prioritize sustainability will likely find it easier to forge strong relationships with manufacturers that share their values, ultimately leading to enhanced brand loyalty and market competitiveness.

What Historical Developments Have Shaped the Current Car Alternator Market?

The evolution of the car alternator can be traced back to the early 20th century when the first electric vehicles emerged. Initially, generators were used to power electrical systems in automobiles, but they were soon replaced by alternators due to their superior efficiency and output capabilities. The transition from generators to alternators marked a significant turning point, allowing vehicles to support more complex electrical systems.

Throughout the decades, advancements in materials and manufacturing processes have led to the development of high-output and compact alternators. The rise of digital technology in the late 20th century further transformed the alternator market, paving the way for smart alternators that integrate seamlessly with modern vehicle systems. This historical context is vital for B2B buyers as it highlights the ongoing innovation in the sector and the importance of partnering with manufacturers who are at the forefront of these developments. Understanding this evolution can guide buyers in making informed decisions that align with current market trends and technological advancements.

Illustrative image related to best car alternator brand

Frequently Asked Questions (FAQs) for B2B Buyers of best car alternator brand

1. How do I select the right alternator for my vehicle fleet?

Selecting the right alternator for your vehicle fleet involves assessing the specific electrical load requirements of each vehicle model. Consider the total amperage needed for all electrical components, especially in high-demand situations like idling or during peak usage. It’s also essential to ensure compatibility with the vehicle’s engine model and layout. By choosing alternators with a higher output than the required load, you can extend their lifespan and maintain optimal vehicle performance.

2. What are the top brands of alternators for B2B purchasing?

Top brands for alternators include Wilson, Remy, Denso, and Armature DNS. These brands are recognized for their quality, durability, and adherence to OEM specifications. When sourcing alternators, consider brands that offer remanufactured options, as they can provide cost-effective solutions without compromising on performance. Researching these brands’ reputations and customer reviews can help ensure you choose a reliable supplier.

3. How do I vet a supplier for car alternators in international markets?

Vetting a supplier for car alternators involves several steps. Start by researching their reputation through online reviews and industry feedback. Request references from other B2B buyers, and verify their experience in exporting to your region. Assess their compliance with international quality standards and certifications. Additionally, inquire about their warranty policies, return procedures, and after-sales support to ensure a reliable partnership.

4. What minimum order quantities (MOQs) should I expect when sourcing alternators?

Minimum order quantities (MOQs) for car alternators can vary significantly between suppliers. Many manufacturers set MOQs based on production costs and inventory capabilities, typically ranging from 50 to 500 units. It’s advisable to discuss your specific needs with potential suppliers and negotiate terms that align with your purchasing strategy. Some suppliers may offer flexibility on MOQs for new customers or bulk purchases.

5. What payment terms are commonly offered for international B2B transactions on alternators?

Payment terms for international B2B transactions on alternators often include options such as Letters of Credit (LC), telegraphic transfers (T/T), or payment upon delivery. Some suppliers may also accept partial payments upfront with the balance due upon shipping. It’s crucial to clarify payment terms before finalizing any agreements to avoid misunderstandings. Ensure that the terms are aligned with your cash flow management and financial capabilities.

6. How can I ensure quality assurance (QA) for alternators sourced internationally?

To ensure quality assurance (QA) for internationally sourced alternators, request detailed product specifications and certifications from suppliers. Conduct inspections at various production stages, if possible, or employ third-party inspection services. Establish clear quality standards and testing protocols to be followed before shipment. Regular communication with the supplier during the production process can also help address any issues proactively.

Illustrative image related to best car alternator brand

7. What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider logistics factors such as shipping methods, costs, and transit times. Choose a reliable freight forwarder experienced in handling automotive parts to navigate customs regulations and documentation. Be aware of duties and taxes applicable to your region, and plan for potential delays in customs clearance. Establishing a clear logistics timeline with your supplier can help ensure timely delivery and inventory management.

8. Can I customize alternators for specific vehicle requirements?

Yes, many manufacturers offer customization options for alternators to meet specific vehicle requirements. Customizations may include adjustments in amperage output, mounting configurations, or additional features like integrated cooling systems. When discussing custom options, provide detailed specifications and requirements to the supplier. Keep in mind that custom orders may involve higher MOQs and longer lead times, so plan accordingly.

Top 2 Best Car Alternator Brand Manufacturers & Suppliers List

1. Denso – Quality Automotive Parts

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Denso – Quality Automotive Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Cadillac – DHS, DTS, Deville Alternators

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Cadillac DHS, DTS, Deville; alternator brands: AC Delco, Duralast

Strategic Sourcing Conclusion and Outlook for best car alternator brand

In conclusion, the landscape of automotive alternators presents a wealth of opportunities for B2B buyers looking to enhance their supply chain. Strategic sourcing is crucial, as it allows businesses to select high-quality alternators that not only meet compatibility and electrical load requirements but also align with their operational goals. Key players such as Wilson, Remy, and Denso offer reliable options that cater to diverse market needs, ensuring durability and performance.

Illustrative image related to best car alternator brand

As international buyers from regions like Africa, South America, the Middle East, and Europe navigate this market, it is essential to prioritize suppliers who offer both innovative products and comprehensive support services. By leveraging insights from this guide, businesses can make informed decisions that drive efficiency and reliability in their automotive operations.

Looking ahead, fostering relationships with reputable alternator brands will be vital in adapting to evolving automotive technologies and increasing electrical demands. We encourage you to explore partnerships with established manufacturers to secure a competitive edge in your market. Take the next step in optimizing your procurement strategy today and position your business for success in the dynamic automotive sector.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.