Introduction: Navigating the Global Market for alternator parts diagram

In the competitive landscape of the global automotive industry, sourcing high-quality alternator parts diagram can pose significant challenges for B2B buyers. With an array of components critical to the functioning of alternators—such as rotors, stators, rectifiers, and voltage regulators—understanding the intricate details of these parts is essential. This comprehensive guide aims to demystify alternator parts diagrams by providing in-depth insights into their types, applications, and the technical specifications that can influence purchasing decisions.

International buyers from regions like Africa, South America, the Middle East, and Europe face unique challenges, including varying standards, market volatility, and supplier reliability. This guide equips decision-makers with the necessary tools to navigate these complexities effectively. By exploring how to assess suppliers, evaluate costs, and understand the nuances of alternator components, B2B buyers can make informed purchasing choices that align with their operational needs.

Furthermore, we delve into the implications of advanced technologies in alternator design and performance, highlighting the importance of selecting parts that enhance efficiency and reliability. With actionable insights and expert recommendations, this guide empowers businesses to optimize their procurement strategies and secure superior alternator parts, ultimately driving value in their automotive operations.

Inhaltsverzeichnis

- Top 4 Alternator Parts Diagram Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator parts diagram

- Understanding alternator parts diagram Types and Variations

- Key Industrial Applications of alternator parts diagram

- 3 Common User Pain Points for ‘alternator parts diagram’ & Their Solutions

- Strategic Material Selection Guide for alternator parts diagram

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator parts diagram

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator parts diagram’

- Comprehensive Cost and Pricing Analysis for alternator parts diagram Sourcing

- Alternatives Analysis: Comparing alternator parts diagram With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator parts diagram

- Navigating Market Dynamics and Sourcing Trends in the alternator parts diagram Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator parts diagram

- Strategic Sourcing Conclusion and Outlook for alternator parts diagram

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding alternator parts diagram Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Alternator Diagram | Shows basic components like rotor, stator, rectifier, and regulator | Autowerkstätten, Teilelieferanten | Vorteile: Easy to understand; Nachteile: Lacks detail for advanced diagnostics. |

| Electrical Schematic Diagram | Detailed wiring connections and electrical flow | Electrical engineering firms, manufacturers | Vorteile: Umfassend; Nachteile: Can be complex for beginners. |

| 3D Alternator Model | Interactive, three-dimensional view of alternator components | Training institutions, technical workshops | Vorteile: Engaging; Nachteile: Requires advanced software to view. |

| Functional Flow Diagram | Illustrates operational stages (pre-excitation to voltage regulation) | Technical training, automotive education | Vorteile: Clarifies processes; Nachteile: May oversimplify complex systems. |

| Component Breakdown Diagram | Detailed views of individual components and assembly | Parts manufacturers, OEMs | Vorteile: In-depth knowledge; Nachteile: Not suitable for quick reference. |

What Are the Key Characteristics of a Standard Alternator Diagram?

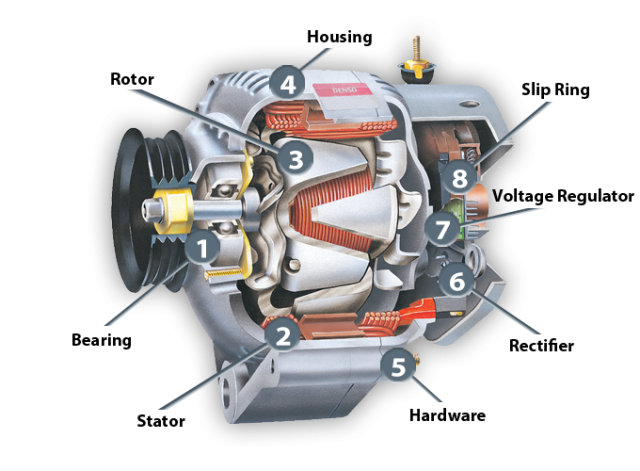

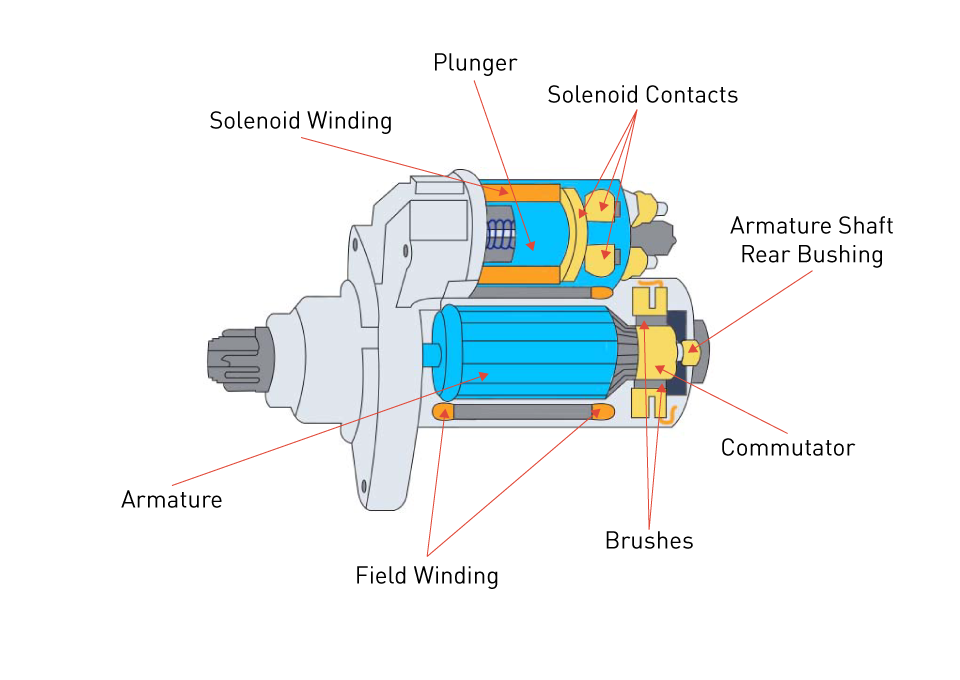

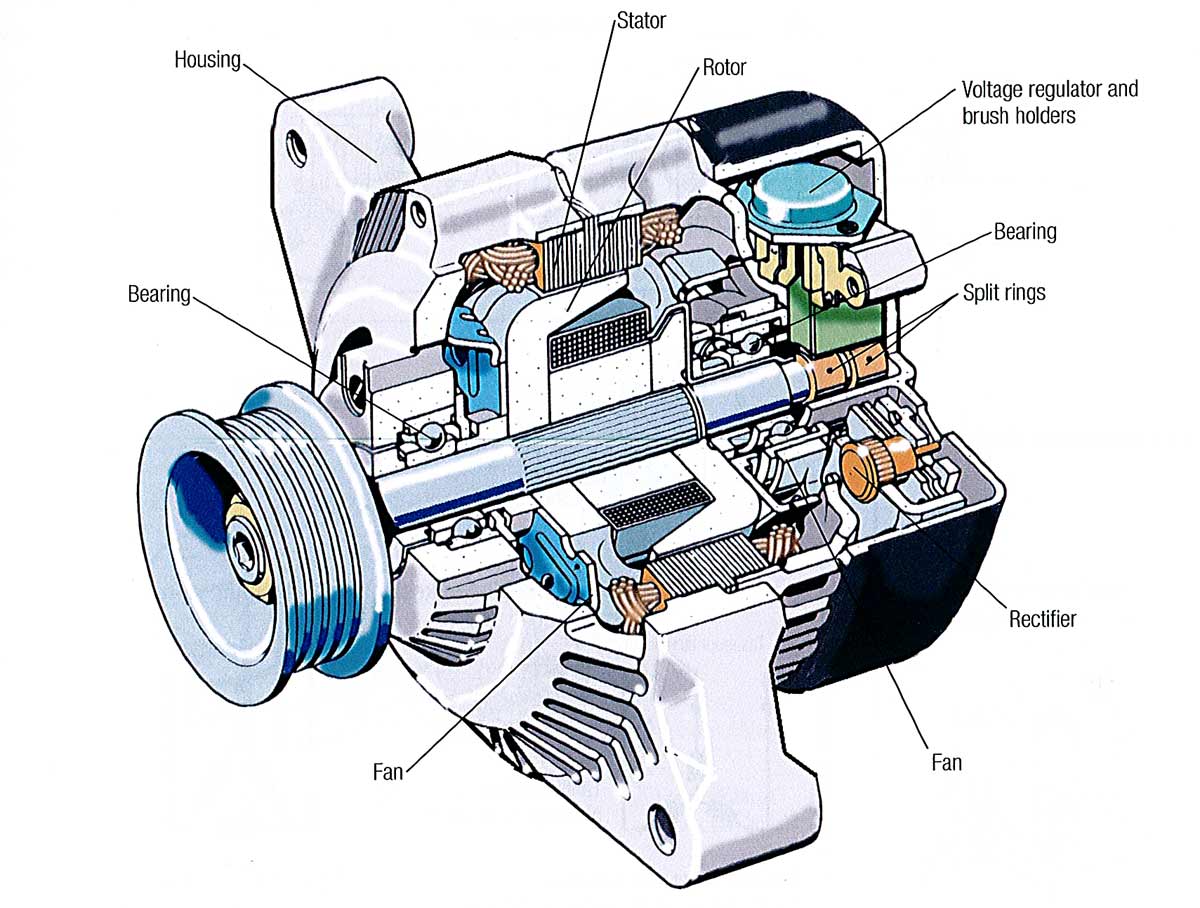

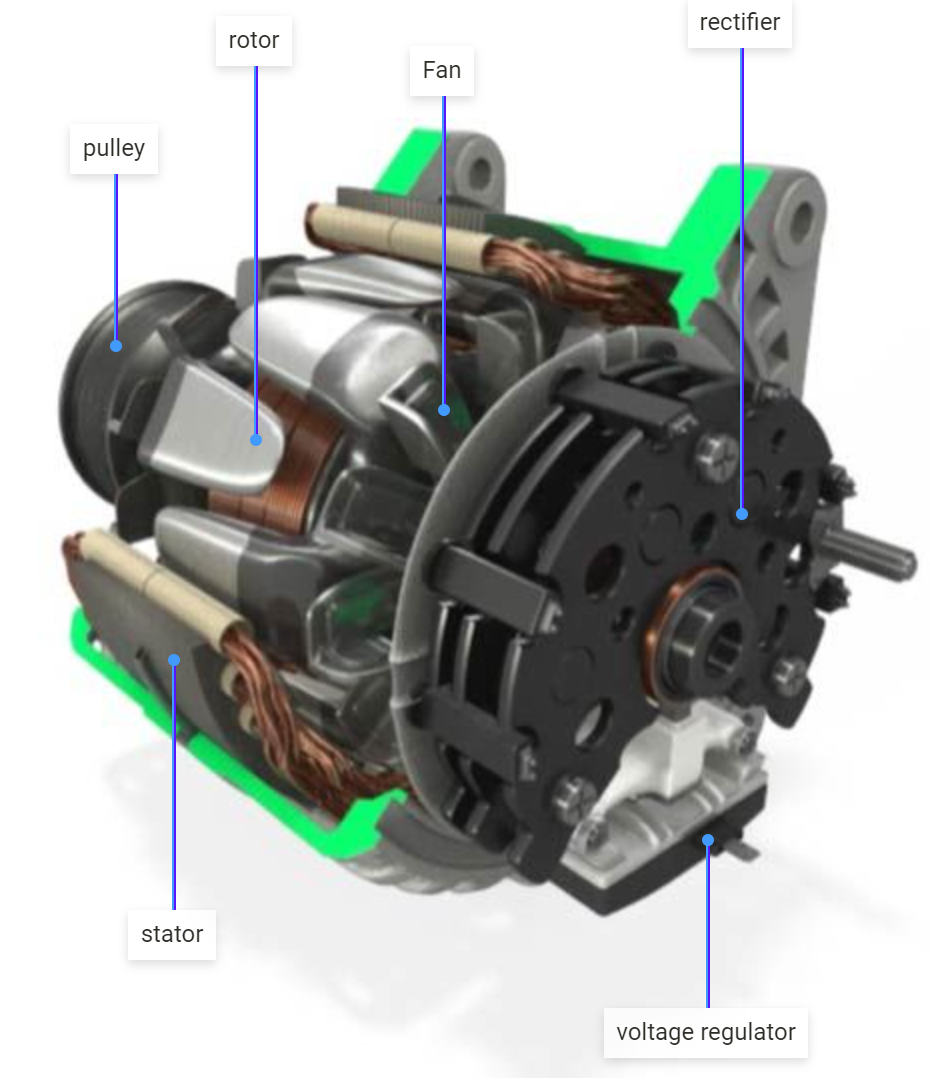

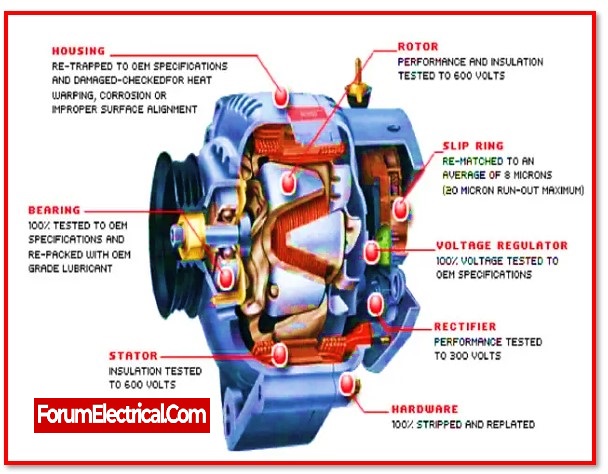

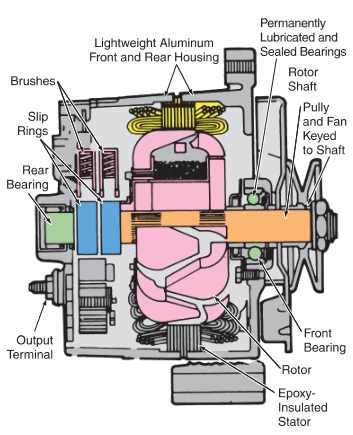

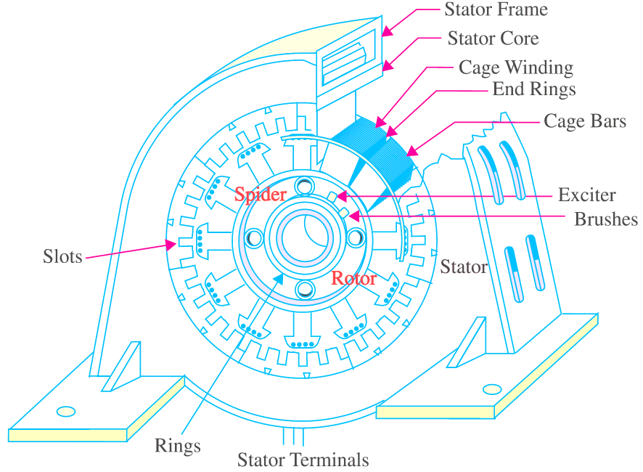

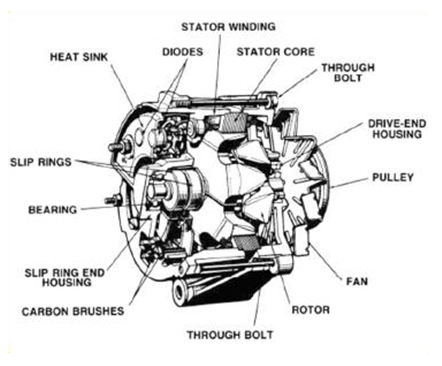

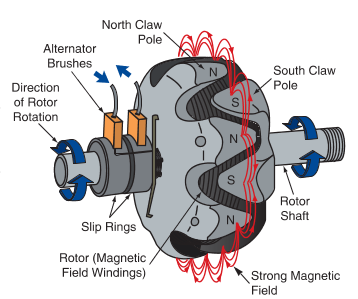

The standard alternator diagram is fundamental for understanding the basic components of an alternator, including the rotor, stator, rectifier, and voltage regulator. This type of diagram is primarily used in automotive repair shops and parts suppliers as a reference for maintenance and repairs. While it’s straightforward and easy to interpret, its simplicity may not provide enough detail for advanced diagnostics, making it less suitable for specialized technicians.

How Does an Electrical Schematic Diagram Enhance Understanding?

An electrical schematic diagram provides a detailed representation of the wiring connections and electrical flow within the alternator. This type is crucial for electrical engineering firms and manufacturers that need to understand the intricate electrical pathways and interconnections. While it offers comprehensive insights, the complexity of the diagram may pose a challenge for those without a solid background in electrical engineering.

Why Opt for a 3D Alternator Model in Training?

The 3D alternator model brings an interactive, three-dimensional view of alternator components, making it a powerful educational tool for training institutions and technical workshops. This model enhances engagement and facilitates a deeper understanding of how parts fit and function together. However, it may require advanced software to view, which can be a barrier for some users, especially in regions with limited access to technology.

What Insights Can a Functional Flow Diagram Provide?

A functional flow diagram illustrates the operational stages of an alternator, from pre-excitation to voltage regulation. It is particularly beneficial for technical training and automotive education, as it clarifies the processes involved in alternator operation. While it simplifies complex systems for easier comprehension, there is a risk that it may oversimplify certain aspects, potentially leading to misunderstandings in practical applications.

How Does a Component Breakdown Diagram Support Parts Manufacturers?

The component breakdown diagram offers a detailed view of individual alternator components and their assembly. This type of diagram is invaluable for parts manufacturers and OEMs as it provides in-depth knowledge of each component’s function and relationship within the system. However, its level of detail may not be suitable for quick reference, which could be a drawback for buyers seeking rapid insights.

Key Industrial Applications of alternator parts diagram

| Branche/Sektor | Specific Application of alternator parts diagram | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Understanding alternator functionality in vehicle design | Enhances vehicle reliability and performance | Quality of components, compatibility with vehicle models, local regulations |

| Erneuerbare Energien | Integration of alternators in wind and solar energy systems | Maximizes energy conversion efficiency | Durability under environmental conditions, certification standards |

| Marine | Use in onboard power generation systems for boats and ships | Ensures continuous power supply during operations | Marine-grade materials, resistance to corrosion, maintenance support |

| Baumaschinen | Alternators in heavy machinery for power generation | Verbessert die betriebliche Effizienz und reduziert Ausfallzeiten | Heavy-duty design, availability of spare parts, service agreements |

| Landwirtschaft | Use in agricultural machinery for reliable power supply | Enhances productivity and reduces equipment failure risk | Adaptability to various machinery types, local support services |

How is the Alternator Parts Diagram Used in the Automotive Industry?

In the automotive sector, the alternator parts diagram serves as a critical tool for engineers and technicians during vehicle design and maintenance. By understanding the components and their functions, such as the rotor, stator, and voltage regulator, manufacturers can optimize power generation and distribution. This helps in enhancing vehicle reliability and performance, which is paramount for international markets. Buyers from regions like Africa and South America often seek components that meet specific vehicle standards and local regulations, necessitating clear diagrams for compatibility checks.

What Role Does the Alternator Parts Diagram Play in Renewable Energy Applications?

In renewable energy applications, particularly wind and solar systems, the alternator parts diagram is essential for integrating these components into larger systems. The diagram helps engineers understand how to maximize energy conversion efficiency by ensuring the alternator is correctly configured. For international buyers, especially in the Middle East, sourcing durable alternators that can withstand harsh environmental conditions is crucial. Compliance with certification standards also becomes a key consideration, ensuring that the components meet local energy regulations.

How is the Alternator Parts Diagram Relevant to Marine Applications?

Marine applications rely heavily on alternators for onboard power generation. The alternator parts diagram aids in the design and troubleshooting of electrical systems within boats and ships, ensuring a continuous power supply during operations. The marine industry demands components that are resistant to corrosion and built with marine-grade materials. Buyers in this sector must consider the sourcing of high-quality alternators and the availability of maintenance support to prevent operational disruptions.

Why is the Alternator Parts Diagram Important for Construction Equipment?

In the construction industry, heavy machinery often utilizes alternators for power generation. The alternator parts diagram assists manufacturers and service providers in enhancing the operational efficiency of these machines. By ensuring the correct integration of alternators, businesses can minimize downtime and improve productivity. For international buyers, particularly in regions with rugged terrain, sourcing heavy-duty alternators that can withstand harsh working conditions is vital. Availability of spare parts and service agreements are critical sourcing considerations.

How Does the Alternator Parts Diagram Benefit Agricultural Machinery?

Agricultural machinery increasingly relies on alternators for a reliable power supply. The alternator parts diagram helps manufacturers and technicians understand how to implement these components effectively to enhance productivity. For buyers in the agriculture sector, the adaptability of alternators to various machinery types is essential. Additionally, local support services play a significant role in ensuring that equipment remains operational, thus reducing the risk of failure during critical agricultural cycles.

3 Common User Pain Points for ‘alternator parts diagram’ & Their Solutions

Scenario 1: Difficulty Understanding Alternator Components from Diagrams

Das Problem: B2B buyers often encounter detailed alternator parts diagrams that can be overwhelming due to their complexity. This is particularly true for buyers in regions with less access to technical training or resources, such as parts of Africa and South America. Many buyers may struggle to identify key components like the rotor, stator, and rectifier, leading to confusion about how these parts interact within the alternator system. This misunderstanding can result in poor purchasing decisions, incorrect installations, and ultimately, increased downtime for their operations.

Die Lösung: To effectively utilize alternator parts diagrams, buyers should invest in training sessions that break down these diagrams into manageable sections. Consider collaborating with suppliers or manufacturers who offer educational resources, including webinars or workshops focused on alternator mechanics. Additionally, using simplified diagrams that highlight only the essential components can facilitate better understanding. Buyers should also request annotated diagrams from suppliers that explain the function of each part, making it easier to visualize and comprehend the overall system. By equipping themselves with this knowledge, buyers can make informed decisions and ensure proper installation and maintenance of alternators, enhancing operational efficiency.

Scenario 2: Inconsistent Quality Across Suppliers

Das Problem: International B2B buyers often face the challenge of inconsistent quality in alternator parts sourced from different suppliers. This issue is exacerbated when parts diagrams do not accurately represent the specifications or quality standards needed for specific applications. For buyers in the Middle East or Europe, where high-performance standards are crucial, receiving subpar components can lead to operational failures and financial losses.

Die Lösung: To mitigate this risk, buyers should establish a robust supplier evaluation process that includes quality assessments based on the alternator parts diagrams. This process could involve requesting detailed specifications and quality certifications before placing orders. Buyers can also create a checklist derived from the diagrams that outlines the necessary standards each component must meet, ensuring they align with their operational requirements. Furthermore, forming partnerships with trusted suppliers who provide guarantees on their products can foster long-term relationships built on reliability. Conducting periodic audits of supplier performance can also help maintain quality standards, ensuring that all components meet the necessary specifications.

Szenario 3: Herausforderungen bei Installation und Wartung

Das Problem: Proper installation and maintenance of alternators can be a significant hurdle for B2B buyers, particularly in regions where technical expertise may be limited. Misinterpretation of the alternator parts diagrams can lead to installation errors, which can cause immediate failures or long-term inefficiencies. This is especially critical in sectors like transportation or heavy machinery, where reliable performance is non-negotiable.

Die Lösung: To address these installation challenges, buyers should prioritize sourcing detailed installation guides along with the alternator parts diagrams. These guides should include step-by-step instructions and troubleshooting tips tailored to the specific model of the alternator. It can be beneficial to arrange for hands-on training sessions with technical experts who can walk through the installation process. Additionally, creating a feedback loop where technicians can share their experiences and challenges with the diagrams can lead to improved clarity and usability. By enhancing their understanding of the installation process and promoting best practices, buyers can significantly reduce installation errors, leading to increased uptime and performance of their machinery.

Strategic Material Selection Guide for alternator parts diagram

What Are the Key Materials Used in Alternator Parts?

When selecting materials for alternator components, it is crucial to consider properties such as thermal conductivity, corrosion resistance, and mechanical strength. Here, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic. Each material has its unique advantages and disadvantages that can significantly impact performance and suitability for specific applications.

How Does Aluminum Perform in Alternator Components?

Aluminum is widely used in alternator housings and components due to its lightweight and excellent thermal conductivity. It has a high strength-to-weight ratio, making it ideal for automotive applications where reducing weight is essential for fuel efficiency. Aluminum also offers good corrosion resistance, particularly when anodized or coated.

Vorteile: Aluminum is relatively inexpensive and easy to manufacture, allowing for complex shapes and designs. Its lightweight nature reduces overall vehicle weight, contributing to better fuel efficiency.

Nachteile: While aluminum has good corrosion resistance, it can still be susceptible to galvanic corrosion when in contact with dissimilar metals. Additionally, it has lower fatigue strength compared to steel, which may limit its use in high-stress applications.

Auswirkungen auf die Anwendung: Aluminum’s thermal properties make it suitable for dissipating heat generated during alternator operation, ensuring efficient performance.

Überlegungen für internationale Käufer: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, for aluminum alloys. In Europe, adherence to EN standards is crucial, particularly regarding environmental regulations.

What Role Does Copper Play in Alternator Wiring?

Copper is the preferred material for electrical windings and connections within alternators due to its excellent electrical conductivity. This property allows for efficient energy transfer, which is vital for the performance of the alternator.

Vorteile: Copper’s high conductivity minimizes energy losses, ensuring that the alternator operates efficiently. It is also highly ductile, making it easy to work with during manufacturing.

Nachteile: Copper is heavier than aluminum and can be more expensive. Additionally, it is prone to oxidation, which can degrade its conductive properties over time unless properly treated.

Auswirkungen auf die Anwendung: Copper’s conductivity is critical for the rotor and stator windings, directly affecting the alternator’s output voltage and overall efficiency.

Überlegungen für internationale Käufer: In regions like the Middle East, where high temperatures can accelerate oxidation, buyers should consider copper with protective coatings. Compliance with JIS and other international standards is also essential.

Wie trägt Stahl zur Langlebigkeit von Lichtmaschinen bei?

Steel is commonly used in the structural components of alternators, such as the rotor shaft and housing. Its high tensile strength and durability make it suitable for parts that experience significant mechanical stress.

Vorteile: Steel’s strength ensures that components can withstand high rotational speeds and mechanical loads. It is also relatively inexpensive compared to other metals.

Nachteile: Steel is heavier than aluminum and can be prone to corrosion if not treated or coated. Its manufacturing processes can also be more complex, potentially increasing costs.

Illustrative image related to alternator parts diagram

Auswirkungen auf die Anwendung: The strength of steel is vital for maintaining the integrity of the alternator under operational stresses, ensuring long-term reliability.

Überlegungen für internationale Käufer: Buyers should be aware of regional standards for steel quality, such as ASTM or DIN, and consider corrosion-resistant coatings for applications in humid or coastal environments.

Welche Vorteile bietet Kunststoff bei der Konstruktion von Wechselstromgeneratoren?

Plastic materials are increasingly used in non-structural components of alternators, such as housings and insulating parts. They offer lightweight alternatives that can reduce overall costs.

Vorteile: Plastics are lightweight and can be molded into complex shapes, offering design flexibility. They also provide excellent electrical insulation properties.

Nachteile: Plastics may not withstand high temperatures as well as metals and can degrade over time under UV exposure. Their mechanical strength is generally lower than that of metals.

Auswirkungen auf die Anwendung: The insulating properties of plastic are crucial for preventing electrical shorts and ensuring safe operation of the alternator.

Überlegungen für internationale Käufer: Buyers must ensure that the plastics used meet relevant safety and performance standards, particularly in regions with stringent regulations like Europe.

Übersichtstabelle zur Materialauswahl für Generatorenteile

| Material | Typical Use Case for alternator parts diagram | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leichtes Gewicht und gute Wärmeleitfähigkeit | Susceptible to galvanic corrosion | Mittel |

| Kupfer | Elektrische Wicklungen und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Heavier and prone to oxidation | Hoch |

| Stahl | Rotor shafts and structural parts | Hohe Zugfestigkeit und Haltbarkeit | Schwerer und korrosionsanfällig | Niedrig |

| Kunststoff | Isolierte Bauteile und Gehäuse | Geringes Gewicht und Designflexibilität | Lower mechanical strength and heat resistance | Mittel |

This material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in alternator components. By understanding these factors, buyers can make informed decisions that align with their operational needs and regional compliance requirements.

Illustrative image related to alternator parts diagram

In-depth Look: Manufacturing Processes and Quality Assurance for alternator parts diagram

Was sind die wichtigsten Phasen im Herstellungsprozess von Generatorteilen?

The manufacturing process for alternator parts is multifaceted and involves several critical stages that ensure the quality and reliability of the final product. Each stage is designed to optimize efficiency while maintaining high standards of quality.

Materialvorbereitung: Welche Rohstoffe werden verwendet?

The first step in manufacturing alternator parts is material preparation. Common materials include aluminum for the housing due to its lightweight and heat-dissipating properties, copper for electrical components, and high-quality steel for the rotor and stator. Suppliers often source materials from reputable vendors to ensure consistency in quality. Prior to use, materials undergo inspections to check for defects, contaminants, and compliance with specifications.

How Are Alternator Parts Formed?

Once materials are prepared, the next stage is forming. This involves several techniques:

- Gießen: Aluminum housings and components may be produced through die casting, which provides precision and reduces waste.

- Bearbeitung: Components such as the rotor and stator are often machined to achieve specific tolerances and surface finishes.

- Wickeln: The stator coils are wound with copper wire, which is crucial for generating electricity. Automated winding machines ensure accuracy in the number of turns and wire placement.

What Is the Assembly Process for Alternator Parts?

After forming, the assembly process begins. This typically involves:

- Komponentenintegration: Parts like the rotor, stator, rectifier, and voltage regulator are brought together. This process may be manual or automated, depending on the scale of production.

- Verbindung: Electrical connections are made between components, including the attachment of brushes and slip rings.

- Qualitätskontrollen: At this stage, initial quality checks are conducted to ensure that components fit correctly and that electrical connections are secure.

How Are Finishing Processes Applied to Alternator Parts?

Finishing processes are essential for enhancing the durability and performance of alternator parts. Techniques include:

- Oberflächenbehandlung: Components may undergo anodizing or powder coating to prevent corrosion and enhance appearance.

- Ausgleichen: The rotor is dynamically balanced to reduce vibrations during operation, which can lead to longer life and better performance.

- Abschließende Inspektion: A thorough visual and functional inspection ensures that all parts meet the required specifications.

What Quality Assurance Measures Are Essential for Alternator Parts?

Quality assurance (QA) is critical in ensuring the reliability of alternator parts. Adhering to international standards and implementing robust quality control (QC) checkpoints is essential for manufacturers targeting B2B buyers globally.

Illustrative image related to alternator parts diagram

Welche internationalen Normen sollten befolgt werden?

For manufacturers, compliance with international standards such as ISO 9001 is crucial. This standard emphasizes a process-oriented approach to quality management, ensuring continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for automotive applications may be required.

Was sind die wichtigsten QC-Kontrollpunkte im Herstellungsprozess?

Quality control checkpoints are integrated at various stages of the manufacturing process:

- Eingangsqualitätskontrolle (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before they are used in production.

- In-Process-Qualitätskontrolle (IPQC): During production, ongoing checks are performed to monitor critical processes and detect any deviations from standards.

- Endkontrolle (FQC): After assembly, a comprehensive inspection and testing phase is conducted to verify that the finished alternator parts meet all specifications and performance criteria.

Welche gängigen Prüfverfahren werden zur Qualitätssicherung eingesetzt?

Testing methods used in quality assurance for alternator parts include:

- Elektrische Prüfung: This verifies the electrical performance of components, ensuring they function correctly under specified conditions.

- Thermische Prüfung: Assessing how components handle heat is critical, especially for parts like the rectifier and voltage regulator.

- Mechanische Prüfung: This may involve stress tests and fatigue tests to ensure components can withstand operational stresses.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, it is vital to verify the quality control practices of suppliers. Here are actionable steps buyers can take:

Welche Schritte können zur Durchführung von Lieferantenaudits unternommen werden?

- Lieferantenaudits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This helps identify potential issues before placing large orders.

- Anfordern von Dokumentation: Buyers should request quality management system documentation, including reports on IQC, IPQC, and FQC processes, to understand the supplier’s commitment to quality.

- Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Nuances of Quality Control for International Buyers?

International buyers should be aware of specific nuances that may affect quality control, including:

- Einhaltung gesetzlicher Vorschriften: Different regions may have unique regulatory requirements that affect the manufacturing and testing of alternator parts. Understanding these requirements is crucial for ensuring compliance.

- Kulturelle Erwägungen: Building strong relationships with suppliers can facilitate better communication and cooperation regarding quality expectations and standards.

By understanding the manufacturing processes and quality assurance measures for alternator parts, B2B buyers can make informed decisions and establish partnerships with reliable suppliers. This knowledge is crucial for ensuring the longevity and performance of the automotive systems that rely on these essential components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator parts diagram’

To assist B2B buyers in the procurement of alternator parts diagrams, this guide outlines a systematic approach to ensure effective sourcing. Understanding the components and functionality of alternators is crucial for making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing high-quality diagrams that can enhance your technical knowledge and operational efficiency.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Clearly outline the specifications required for the alternator parts diagram you need. Consider aspects such as the type of alternator, voltage requirements, and the specific components you want detailed in the diagram. This clarity will help you communicate effectively with suppliers and ensure you receive diagrams that meet your operational needs.

Schritt 2: Recherche über seriöse Anbieter

Conduct thorough research to identify suppliers that specialize in automotive components and technical diagrams. Look for companies with a solid reputation in the industry, evidenced by customer reviews and case studies. Prioritize suppliers who have experience with the specific types of alternators relevant to your market, as they will better understand your requirements.

Illustrative image related to alternator parts diagram

Schritt 3: Lieferantenzertifizierungen bewerten

Before finalizing a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management and consistent production processes. Additionally, check if they adhere to any regional standards relevant to your target markets, which may vary across Africa, South America, the Middle East, and Europe.

Schritt 4: Request Sample Diagrams

Ask potential suppliers for sample alternator parts diagrams to assess the quality and clarity of their work. A well-constructed diagram should be detailed and easy to understand, reflecting accurate representations of components like the rotor, stator, rectifier, and voltage regulator. Reviewing samples allows you to gauge the supplier’s ability to meet your specifications.

Schritt 5: Inquire About Customization Options

Discuss any customization options available for the diagrams. Depending on your specific needs, you may require alterations in detail or format. Ensure the supplier is flexible and willing to accommodate your requests, as this can significantly enhance the utility of the diagrams for your technical team.

Illustrative image related to alternator parts diagram

Schritt 6: Assess Technical Support and Resources

Evaluate the level of technical support offered by the supplier. A reliable supplier should provide additional resources, such as installation guides, troubleshooting tips, and access to technical expertise. This support can be invaluable, especially if your team lacks in-depth knowledge about alternators.

Schritt 7: Verhandeln Sie Bedingungen und Preise

Finally, engage in negotiations regarding pricing and delivery terms. Ensure you understand the total cost, including any additional fees for customization or expedited shipping. Aim to establish clear terms that protect your interests while fostering a long-term relationship with the supplier.

By following this checklist, you can streamline the procurement process for alternator parts diagrams and ensure you partner with suppliers that meet your business’s technical and operational needs.

Comprehensive Cost and Pricing Analysis for alternator parts diagram Sourcing

What Are the Key Cost Components in Sourcing Alternator Parts Diagrams?

When considering the sourcing of alternator parts diagrams, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materialien: The quality and type of materials used in the manufacturing of alternator parts significantly influence costs. For instance, aluminum is commonly used for its lightweight properties and heat dissipation capabilities. Higher-grade materials may increase durability but also raise prices.

-

Arbeit: Labor costs vary by region and are influenced by local wage standards and the skill level required for manufacturing. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality.

-

Fertigungsgemeinkosten: This includes costs associated with the production facility, equipment maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, ultimately affecting the final price of alternator parts diagrams.

-

Werkzeuge: The cost of tools and machinery necessary for production can be substantial, especially for custom parts. This upfront investment is often amortized over the production run, impacting per-unit costs.

-

Qualitätskontrolle (QC): Implementing stringent QC processes ensures that parts meet the required specifications and certifications. While this adds to costs, it is crucial for maintaining quality, particularly in industries with strict regulatory standards.

-

Logistik: Transportation and shipping costs can vary widely based on distance, mode of transport, and fuel prices. International shipping can be particularly costly and may involve customs duties and tariffs.

-

Marge: Suppliers typically add a margin to cover their costs and generate profit. Understanding the typical margins within the industry can help buyers negotiate better pricing.

How Do Volume and Specifications Influence Pricing?

Volume and minimum order quantities (MOQs) play a critical role in pricing. Larger orders generally lead to lower per-unit costs due to economies of scale. Conversely, smaller orders may incur higher costs due to the lack of bulk pricing benefits.

Customization also affects pricing. Unique specifications or modifications to standard designs can lead to increased costs due to additional labor and tooling requirements. Buyers should weigh the need for customization against the potential price increase.

What External Factors Impact Pricing for Alternator Parts Diagrams?

Several external factors can influence pricing, including:

-

Material Availability: Fluctuations in the availability and cost of raw materials can lead to price changes. For instance, aluminum prices can vary based on market demand and supply chain disruptions.

-

Qualitätszertifizierungen: Products that meet specific industry standards or certifications often command higher prices due to the assurance of quality and reliability.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality and service may charge a premium.

-

Incoterms: The chosen Incoterms affect shipping costs and responsibilities between buyers and suppliers. Understanding these terms is crucial for calculating the total landed cost.

What Negotiation Strategies Can B2B Buyers Use?

Effective negotiation is key to achieving cost efficiency in sourcing alternator parts diagrams. Here are some tips for buyers:

-

Bulk Purchasing: Leverage bulk purchasing to negotiate better rates. Suppliers are often willing to offer discounts for larger orders.

-

Beziehungen zu den Lieferanten: Building strong relationships with suppliers can lead to better pricing and terms over time. Trust and communication can facilitate more favorable negotiations.

-

Gesamtbetriebskosten (TCO): Consider the total cost of ownership rather than just the upfront price. Factors such as durability, maintenance, and efficiency can influence long-term costs.

-

Marktforschung: Stay informed about market trends and competitor pricing to strengthen negotiation positions. Knowledge of industry standards can help in discussions.

-

Flexibility on Specifications: Be open to slightly altering specifications if it can lead to significant cost savings without compromising quality.

What Should International Buyers Keep in Mind?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of pricing nuances. Currency fluctuations can affect costs, and understanding local market conditions is essential for effective budgeting. Additionally, import duties and taxes should be factored into the overall cost analysis to avoid unexpected expenses.

Haftungsausschluss: Prices can vary widely based on the factors discussed and should be considered indicative. Always consult multiple suppliers and conduct thorough market research before finalizing purchases.

Illustrative image related to alternator parts diagram

Alternatives Analysis: Comparing alternator parts diagram With Other Solutions

Exploring Alternatives for Understanding Alternator Components

In the realm of automotive components, the alternator parts diagram serves as a vital tool for understanding the intricate workings of an alternator. However, various alternatives exist that can provide similar insights and functionality, catering to different needs and preferences of international B2B buyers. This section will delve into a comparative analysis of the alternator parts diagram against two other viable solutions: 3D modeling software and augmented reality (AR) applications.

Vergleichstabelle

| Vergleichsaspekt | Alternator Parts Diagram | 3D Modeling Software | Augmented Reality (AR) Applications |

|---|---|---|---|

| Leistung | Provides clear, static visuals of components. | Offers dynamic and interactive representations. | Delivers immersive experiences with real-time interaction. |

| Kosten | Generally low-cost or free resources. | Can be expensive depending on software complexity. | Varies significantly based on the application and device used. |

| Einfache Implementierung | Easy to create and distribute. | Requires technical skills to design and manipulate models. | May need specialized hardware and software setup. |

| Wartung | Minimal; static content does not require updates. | Requires regular updates and maintenance of models. | Maintenance needed for software updates and device compatibility. |

| Bester Anwendungsfall | Ideal for educational purposes and basic understanding. | Best for detailed design and engineering analysis. | Suitable for hands-on training and real-time simulations. |

Eingehende Analyse von Alternativen

3D Modeling Software

3D modeling software such as Autodesk Inventor or SolidWorks offers a sophisticated alternative to traditional diagrams. Users can create detailed models of alternator components, allowing for manipulation and examination from various angles. The primary advantage is the ability to visualize how parts interact in a real-world context, enhancing understanding for engineers and designers. However, the complexity of these tools may necessitate training, which could pose a barrier for some users. Additionally, the cost of licensing can be prohibitive, particularly for smaller businesses.

Augmented Reality (AR) Applications

AR applications provide an innovative approach by overlaying digital information onto the physical world, allowing users to visualize alternator parts in real-time. This immersive technology can enhance training sessions, providing hands-on experience without the need for physical components. The interactive nature of AR can significantly improve engagement and retention of information. However, the cost of AR technology can vary greatly, and the necessity for compatible devices may limit accessibility for some users. Furthermore, creating AR content can require specialized skills and resources.

Die richtige Wahl für Ihre Geschäftsbedürfnisse

When selecting the most suitable solution for understanding alternator components, B2B buyers should consider their specific requirements, budget constraints, and the technical capabilities of their teams. For educational purposes or quick reference, the alternator parts diagram remains a straightforward and cost-effective choice. In contrast, businesses seeking in-depth analysis and design capabilities may find 3D modeling software more beneficial. Finally, companies focused on training and interactive learning may leverage AR applications to create engaging experiences. Each alternative presents unique advantages and challenges, making it essential for buyers to align their choice with their operational goals and resources.

Essential Technical Properties and Trade Terminology for alternator parts diagram

Was sind die wichtigsten technischen Eigenschaften von Generatorteilen?

Understanding the technical properties of alternator parts is essential for B2B buyers involved in the automotive industry. Here are some critical specifications that should be considered:

1. Material Klasse

The outer casing of an alternator is typically made from aluminum, which is lightweight and resistant to corrosion. This material choice is crucial for durability and efficient heat dissipation, ensuring that the alternator functions optimally over time. B2B buyers should consider material grades that comply with industry standards to guarantee quality and performance.

2. Toleranzschwellen

Tolerance refers to the allowable deviation in the dimensions of alternator components, such as the rotor and stator. High tolerance levels are vital for ensuring that parts fit together correctly, which is essential for the efficient operation of the alternator. Buyers should seek components with precise tolerances to avoid performance issues and increase the longevity of the alternator.

3. Electrical Output Rating

This specification measures the amount of electrical current an alternator can produce, typically expressed in amperes (A). Understanding electrical output ratings is crucial for ensuring that the alternator can meet the power demands of various automotive systems. B2B buyers should match these ratings with the requirements of their specific applications to avoid underperformance.

4. Cooling Efficiency

Alternators generate significant heat during operation, making cooling efficiency a critical property. Components like internal cooling fans are designed to dissipate this heat effectively. Buyers should prioritize alternators with advanced cooling mechanisms, as this can enhance performance and reduce the risk of overheating, leading to failures.

5. Voltage Regulation

The voltage regulator is a key component that ensures the alternator maintains a consistent voltage output. This specification is essential for protecting the vehicle’s electrical system from voltage spikes. B2B buyers must consider the reliability of voltage regulation when selecting alternators, as poor regulation can lead to damage and increased maintenance costs.

What Are Common Trade Terms Related to Alternator Parts?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should know:

Illustrative image related to alternator parts diagram

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures products that are sold under another company’s brand name. In the context of alternators, OEM parts are typically designed to meet the original specifications of the vehicle manufacturer. Choosing OEM parts can ensure compatibility and reliability, making them a preferred option for many buyers.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can affect inventory levels and cash flow. Buyers should negotiate MOQs that align with their purchasing needs to optimize costs and manage stock effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing information from suppliers for specific quantities of products. This term is essential for B2B transactions, as it allows buyers to compare prices and terms from different suppliers, facilitating informed purchasing decisions.

Illustrative image related to alternator parts diagram

4. Incoterms (Internationale Handelsklauseln)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is vital for B2B buyers, as they outline who is responsible for shipping, insurance, and tariffs. Proper knowledge of Incoterms can help avoid misunderstandings and ensure smooth international transactions.

5. Gewährleistungsbedingungen

Warranty terms specify the conditions under which a supplier will repair or replace defective products. For alternator parts, warranty details can significantly influence buyer decisions. B2B buyers should carefully review warranty terms to ensure adequate protection against defects and to understand their rights in case of product failure.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing alternator parts, ultimately leading to better product performance and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the alternator parts diagram Sector

What Are the Current Market Dynamics for Alternator Parts Diagram in Global B2B Transactions?

The alternator parts diagram market is experiencing significant growth driven by the increasing demand for efficient automotive components across various global regions, particularly in Africa, South America, the Middle East, and Europe. Key drivers include the rising number of vehicles on the road, advancements in automotive technology, and a shift towards electric vehicles (EVs). As countries in these regions modernize their transportation systems, the need for reliable alternator parts becomes critical, prompting international buyers to seek out suppliers who can provide high-quality components.

Emerging B2B technology trends such as digital platforms for sourcing and automated supply chain management are reshaping the market landscape. Companies are increasingly adopting e-commerce solutions to streamline procurement processes, allowing for quicker access to alternator parts and diagrams. Moreover, the integration of advanced analytics and artificial intelligence in supply chain operations is enabling businesses to predict market fluctuations and optimize inventory management effectively.

International B2B buyers are also navigating challenges such as fluctuating raw material prices and regulatory changes, particularly in regions like the EU, where environmental standards are stringent. As a result, sourcing strategies are evolving, with an emphasis on finding suppliers who can offer not only competitive pricing but also compliance with local regulations and sustainability practices.

How Are Sustainability and Ethical Sourcing Influencing the Alternator Parts Diagram Market?

Sustainability is becoming a pivotal focus for international buyers of alternator parts. The environmental impact of automotive manufacturing is under scrutiny, with increasing pressure on suppliers to adopt green practices. This includes reducing carbon footprints in production processes and utilizing sustainable materials. For B2B buyers, sourcing from manufacturers that prioritize eco-friendly practices is not just a trend; it’s a commitment to corporate social responsibility.

Ethical sourcing is equally critical, as businesses aim to ensure that their supply chains are free from exploitative labor practices and environmental degradation. Buyers are increasingly favoring suppliers who can provide transparency in their sourcing processes, along with certifications that validate their commitment to sustainability. Green certifications such as ISO 14001 for environmental management and materials that are recyclable or derived from sustainable sources are becoming essential criteria in supplier selection.

The emphasis on sustainability is further supported by consumer demand for greener products. As automotive manufacturers strive to meet these expectations, the alternator parts diagram sector must adapt, ensuring that their components contribute to the overall sustainability of the vehicles they power.

What Is the Historical Context of Alternator Parts and Their Evolution in B2B Markets?

The evolution of alternator parts can be traced back to the early 20th century when the first alternators were developed for automotive use. Initially, these components were bulky and less efficient, primarily designed to power basic electrical systems. However, as automotive technology advanced, so did the design and functionality of alternators. The transition from mechanical generators to modern alternators marked a significant milestone, offering improved reliability and efficiency.

Over the decades, the introduction of electronic voltage regulation and high-efficiency designs has transformed alternators into compact, lightweight units capable of meeting the growing electrical demands of modern vehicles. This evolution has led to a diversification of the alternator parts market, with specialized components designed for various applications, including hybrid and electric vehicles.

In the B2B context, understanding this historical evolution is essential for buyers as it provides insights into the technological advancements and the competitive landscape of the alternator parts market. As the industry continues to evolve, international buyers must stay informed about the latest trends and innovations to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator parts diagram

1. How do I identify the correct alternator parts diagram for my vehicle?

To identify the correct alternator parts diagram for your vehicle, start by gathering your vehicle’s make, model, and year. Most manufacturers provide detailed diagrams in their service manuals, which can often be accessed online or through authorized dealers. Additionally, consider reaching out to suppliers or manufacturers who specialize in alternator components; they typically have access to comprehensive technical resources. Ensure that the diagram aligns with the specifications of your vehicle to avoid compatibility issues.

Illustrative image related to alternator parts diagram

2. What is the best way to source quality alternator parts diagrams?

The best way to source quality alternator parts diagrams is to collaborate with reputable suppliers who specialize in automotive components. Look for suppliers with a proven track record in your region, particularly those who can provide OEM (Original Equipment Manufacturer) diagrams. Online marketplaces and industry-specific platforms can also be useful, but always verify the credibility of the seller and check for customer reviews. Establishing a relationship with a reliable distributor can ensure access to accurate and up-to-date diagrams.

3. How can I ensure the accuracy of an alternator parts diagram?

To ensure the accuracy of an alternator parts diagram, verify it against multiple sources. Cross-reference the diagram with the manufacturer’s specifications and consult technical manuals. If possible, request confirmation from the supplier regarding the diagram’s authenticity and applicability to your vehicle model. Additionally, seek feedback from technical experts or mechanics who have experience with similar models to validate the diagram’s accuracy.

4. What are the common customization options for alternator parts?

Customization options for alternator parts can vary by supplier but often include modifications to dimensions, electrical specifications, and mounting configurations. When working with manufacturers, specify your requirements regarding voltage ratings, amperage, and connector types. Some suppliers may also offer custom finishes or materials for durability in harsh environments. Ensure clear communication about your customization needs to avoid delays and ensure product compatibility.

5. What are the typical minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) for alternator parts can range significantly based on the supplier and product type. Generally, MOQs can be as low as 50 pieces for standard components but may increase for specialized or custom parts. It’s advisable to discuss your requirements directly with potential suppliers to negotiate MOQs that align with your purchasing capabilities. Some suppliers may offer flexible terms for first-time orders or ongoing partnerships.

6. What payment terms are commonly offered for B2B purchases of alternator parts?

Common payment terms for B2B purchases of alternator parts typically include options like net 30, net 60, or net 90 days, depending on the supplier’s policies and your business relationship. Some suppliers may require a deposit upfront, especially for custom orders. It’s essential to discuss payment terms during negotiations and ensure they are documented in your purchase agreement. Exploring various payment methods, including letters of credit for international transactions, can also provide added security.

7. How can I effectively vet suppliers for alternator parts?

Effectively vetting suppliers for alternator parts involves several steps. Start by researching their business history, reputation, and customer reviews. Check for certifications and compliance with industry standards, as this indicates reliability and quality assurance. Request samples of their products and examine their technical documentation. Building a rapport with potential suppliers through direct communication can also provide insights into their customer service and responsiveness.

8. What logistics considerations should I keep in mind when sourcing alternator parts internationally?

When sourcing alternator parts internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate the reliability of shipping partners and their ability to handle automotive components. Understand import duties and taxes that may apply to your orders, as these can affect overall costs. Establish clear timelines with your supplier to ensure timely delivery and maintain open communication throughout the shipping process to address any potential issues promptly.

Top 4 Alternator Parts Diagram Manufacturers & Suppliers List

1. Electude – Alternator

Domäne: electude.com

Registriert: 2005 (20 Jahre)

Einleitung: Eine Lichtmaschine ist ein wichtiges Bauteil in einem Kraftfahrzeug, das mechanische Energie in elektrische Energie umwandelt und so Strom für die elektrischen Verbraucher und die Batterie des Fahrzeugs erzeugt. Zu den wichtigsten Komponenten gehören:

- Riemenscheibe: Überträgt mechanische Energie vom Motor.

- Rotor: Erzeugt das Magnetfeld zur Erzeugung des Wechselstroms.

- Stator: Der statische Teil, in dem die Spannung erzeugt wird.

- Gleichrichter: ...

2. HowStuffWorks – Alternators Explained

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation. Key components include: 1. Drive pulley attached to the rotor shaft, which converts mechanical energy into electrical power. 2. Terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warnin…

3. Pinterest – Exploded View of an Alternator

Domäne: pinterest.com

Registriert: 2009 (16 Jahre)

Einleitung: Explosionszeichnung einer Lichtmaschine

4. Scribd – Automotive Alternator Components

Domäne: scribd.com

Registriert: 2006 (19 Jahre)

Einleitung: The document discusses the main parts and functions of an automotive alternator, describing 8 key parts: 1) Pulley – rotates the rotor assembly via the engine belt, 2) Housing – protects internal components, 3) Bearings – allow the rotor to spin freely, 4) Rotor Assembly – generates a magnetic field, 5) Stator Assembly – uses the magnetic field to generate electricity, 6) Rectifier – converts alte…

Strategic Sourcing Conclusion and Outlook for alternator parts diagram

The strategic sourcing of alternator parts is crucial for optimizing supply chains and ensuring the reliability of automotive systems in various markets, including Africa, South America, the Middle East, and Europe. By understanding the key components of alternators—such as the rotor, stator, rectifier, and voltage regulator—international B2B buyers can make informed decisions when sourcing quality parts. This knowledge not only aids in selecting suppliers who provide robust and efficient alternators but also enhances the overall performance of vehicles.

Investing in strategic sourcing can lead to improved cost efficiency, reduced lead times, and enhanced product quality. Buyers should prioritize partnerships with manufacturers that offer transparency and compliance with international standards. Additionally, leveraging local suppliers can help navigate regional regulations and minimize shipping costs.

As the automotive industry continues to evolve, staying ahead of trends such as electric vehicle technology and smart alternators will be essential. B2B buyers are encouraged to engage with innovative suppliers who can offer cutting-edge solutions. By doing so, companies can position themselves for long-term success in a competitive landscape. Embrace the future of automotive sourcing today, and ensure your business thrives in this dynamic market.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.