Introduction: Navigating the Global Market for what is the starter solenoid

The starter solenoid is a critical component in the automotive ignition system, acting as the gateway between the battery and the starter motor. For international B2B buyers navigating the complexities of sourcing automotive parts, understanding the intricacies of the starter solenoid can pose a significant challenge. This guide aims to demystify the starter solenoid, providing insights into its various types, applications across different vehicle models, and the essential factors to consider when vetting suppliers.

From identifying the warning signs of a failing solenoid to exploring cost-effective options, this comprehensive resource equips buyers with the knowledge needed to make informed purchasing decisions. The guide also emphasizes best practices for ensuring quality and reliability, which are paramount in markets across Africa, South America, the Middle East, and Europe, including countries like Brazil and Nigeria.

By detailing the specifications and operational characteristics of starter solenoids, alongside actionable tips for evaluating potential suppliers, this guide empowers B2B purchasers to confidently navigate the global market. As the demand for reliable automotive components continues to grow, understanding the significance of the starter solenoid will enable businesses to enhance their supply chain efficiency and ultimately support their operational goals.

Inhaltsverzeichnis

- Top 3 What Is The Starter Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is the starter solenoid

- Understanding what is the starter solenoid Types and Variations

- Key Industrial Applications of what is the starter solenoid

- 3 Common User Pain Points for ‘what is the starter solenoid’ & Their Solutions

- Strategic Material Selection Guide for what is the starter solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter solenoid’

- Comprehensive Cost and Pricing Analysis for what is the starter solenoid Sourcing

- Alternatives Analysis: Comparing what is the starter solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for what is the starter solenoid

- Navigating Market Dynamics and Sourcing Trends in the what is the starter solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter solenoid

- Strategic Sourcing Conclusion and Outlook for what is the starter solenoid

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding what is the starter solenoid Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Electromagnetic Solenoid | Operates using electromagnetic coils to create movement | Automobilindustrie, Schwermaschinen | Vorteile: Reliable and efficient. Nachteile: Can be sensitive to heat. |

| Permanent Magnet Solenoid | Utilizes permanent magnets for operation | Industrial Equipment, Robotics | Vorteile: Compact and lightweight. Nachteile: Limited power output. |

| Pull-in Solenoid | Designed for quick engagement and disengagement | Automotive, Marine Applications | Vorteile: Fast response time. Nachteile: May wear out quickly under heavy use. |

| Push-pull Solenoid | Functions by pushing and pulling in a linear motion | Automation Systems, Door Locks | Vorteile: Versatile in applications. Nachteile: Requires precise alignment. |

| Dual Voltage Solenoid | Operates on two different voltage levels | Agricultural Equipment, Construction | Vorteile: Flexible power options. Nachteile: Complexity in installation. |

What Are the Characteristics of Electromagnetic Solenoids?

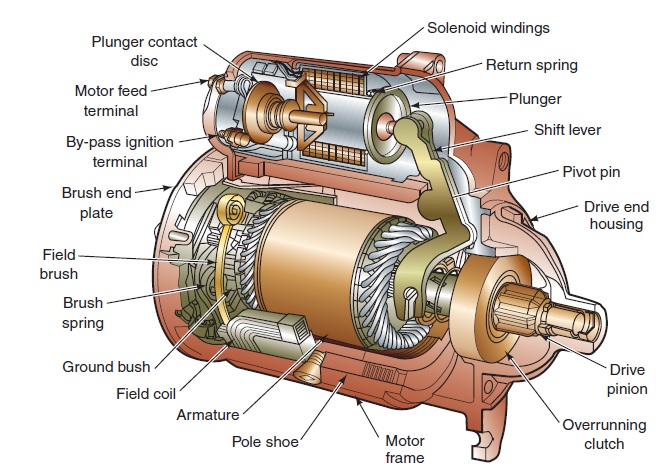

Electromagnetic solenoids are the most common type used in starter applications, where they utilize coils of wire to generate a magnetic field when electrical current flows through them. This magnetic field moves a plunger that engages the starter motor. B2B buyers should consider the reliability and efficiency of these solenoids, especially in automotive and heavy machinery applications where durability is critical. However, they may be sensitive to heat, which can lead to failure in high-temperature environments.

How Do Permanent Magnet Solenoids Differ?

Permanent magnet solenoids employ permanent magnets to create the necessary magnetic field for operation. This design makes them compact and lightweight, making them ideal for use in industrial equipment and robotic applications where space is limited. When purchasing, B2B buyers should evaluate their power output needs, as permanent magnet solenoids typically have limitations compared to electromagnetic types. Their lightweight nature can be advantageous in applications requiring mobility.

What Are the Benefits of Pull-in Solenoids?

Pull-in solenoids are engineered for rapid engagement and disengagement, making them particularly useful in automotive and marine applications. They provide quick response times, which is essential for systems requiring immediate action. However, B2B buyers should be aware that the fast operation can lead to faster wear and tear, especially under heavy use. Evaluating the operational environment and expected usage frequency can help in selecting the right solenoid.

Why Choose Push-pull Solenoids?

Push-pull solenoids operate by pushing and pulling in a linear motion, making them highly versatile for various applications, including automation systems and door locks. Their adaptability allows them to be used in diverse settings, but B2B buyers must ensure precise alignment during installation to avoid operational issues. The versatility of push-pull solenoids can be a significant advantage when integrating into existing systems.

What Are Dual Voltage Solenoids Best Suited For?

Dual voltage solenoids are designed to operate on two different voltage levels, providing flexibility in power options. This feature is particularly beneficial in agricultural and construction equipment, where varying power sources may be encountered. B2B buyers should consider the complexity of installation and ensure compatibility with existing systems when opting for dual voltage solenoids. Their adaptability can enhance operational efficiency in dynamic environments.

Key Industrial Applications of what is the starter solenoid

| Branche/Sektor | Specific Application of what is the starter solenoid | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Integration in vehicle assembly lines for starting systems | Enhances reliability of vehicle ignition systems, reducing downtime | High-quality components, compatibility with various vehicle models |

| Landwirtschaft | Use in agricultural machinery such as tractors and harvesters | Ensures efficient start-up of equipment, crucial for time-sensitive operations | Durability in harsh environments, availability of spare parts |

| Bauwesen | Deployment in heavy machinery like excavators and bulldozers | Erhöht die betriebliche Effizienz und reduziert die Wartungskosten | Resistance to extreme conditions, support for local suppliers |

| Schiffsindustrie | Implementation in marine engines for boats and vessels | Guarantees reliable engine start-up, essential for safety and operations | Corrosion resistance, compliance with maritime regulations |

| Transport & Logistik | Utilization in fleet vehicles for commercial transport | Minimizes vehicle downtime, improving logistics efficiency | Bulk purchasing options, warranty and service agreements |

How is the Starter Solenoid Used in Automotive Manufacturing?

In the automotive manufacturing sector, starter solenoids are integral to the assembly of vehicle ignition systems. They act as a switch that connects the battery to the starter motor, ensuring a reliable engine start. This reliability is crucial for maintaining production schedules and reducing downtime in manufacturing lines. Buyers in this industry must ensure that the solenoids meet specific quality standards and compatibility with various vehicle models to prevent production delays.

What Role Does the Starter Solenoid Play in Agriculture?

In agriculture, starter solenoids are employed in tractors and other essential machinery to facilitate quick and reliable engine starts. This capability is vital for farmers who operate under tight schedules, especially during planting and harvest seasons. The durability of these solenoids is particularly important, as agricultural equipment often operates in rugged conditions. Buyers need to consider sourcing solenoids that can withstand environmental stressors and provide easy access to spare parts for maintenance.

How is the Starter Solenoid Essential in Construction Equipment?

Heavy machinery in the construction industry, such as excavators and bulldozers, relies on starter solenoids to ensure efficient operation. A malfunctioning solenoid can lead to significant delays on construction sites, impacting project timelines and costs. Therefore, selecting solenoids that are resistant to extreme conditions, including dust and moisture, is critical. Buyers should prioritize suppliers that offer reliable products and robust after-sales support to minimize downtime.

Why is the Starter Solenoid Important in the Marine Industry?

In the marine industry, starter solenoids are crucial for the reliable operation of boat engines. They help ensure that engines start promptly, which is essential for safety and operational efficiency on the water. Given the corrosive nature of marine environments, solenoids must be made from materials that resist rust and corrosion. Buyers need to focus on sourcing products that comply with maritime regulations and offer warranties for long-term reliability.

What Benefits Does the Starter Solenoid Provide in Transportation and Logistics?

In the transportation and logistics sector, starter solenoids are used in fleet vehicles, ensuring quick engine starts to minimize downtime. This reliability is vital for meeting delivery schedules and maintaining customer satisfaction. When sourcing these components, businesses should look for bulk purchasing options and consider suppliers that offer warranties and service agreements to ensure ongoing support and reliability in their fleet operations.

3 Common User Pain Points for ‘what is the starter solenoid’ & Their Solutions

Scenario 1: Difficulty in Diagnosing Starter Solenoid Issues

Das Problem: B2B buyers often face challenges in accurately diagnosing problems related to starter solenoids, particularly in regions with varying electrical standards and vehicle types. Many buyers lack the technical expertise to pinpoint whether the issue stems from the solenoid itself or from connected components like the battery or ignition switch. This uncertainty can lead to unnecessary downtime for their fleet, increased repair costs, and frustration among technicians who may not have the right tools to test the solenoid effectively.

Die Lösung: To address this challenge, B2B buyers should invest in comprehensive diagnostic tools, such as multimeters and specialized automotive testers that can measure voltage and current flow through the starter solenoid. Furthermore, implementing a detailed checklist can streamline the diagnostic process. This checklist should include steps like checking battery voltage, inspecting for corrosion at terminal connections, and listening for clicking sounds when the ignition is engaged. By training technicians on these diagnostic techniques and the specific symptoms of a failing starter solenoid, businesses can reduce guesswork and improve repair turnaround times.

Scenario 2: Sourcing Quality Starter Solenoids for Diverse Applications

Das Problem: Sourcing high-quality starter solenoids that meet the diverse needs of different vehicle models and geographical markets can be daunting for B2B buyers. In regions like Africa and South America, where vehicles may be older or from various manufacturers, buyers struggle to find solenoids that are compatible and durable enough to withstand local conditions. Compromising on quality can lead to frequent replacements and increased costs.

Die Lösung: To navigate these sourcing challenges, B2B buyers should establish relationships with reputable suppliers who specialize in automotive components and have a track record of quality assurance. Conducting thorough market research to identify suppliers that offer a wide range of solenoid models, including OEM and aftermarket options, can also be beneficial. Additionally, leveraging technology such as online procurement platforms can simplify the sourcing process by providing access to comprehensive product catalogs and user reviews. Buyers should also consider requesting samples or technical specifications to ensure compatibility with their specific applications before committing to larger orders.

Scenario 3: Managing Maintenance and Replacement Costs

Das Problem: Many B2B buyers experience unexpected costs associated with the maintenance and replacement of starter solenoids, especially in regions where service infrastructure may be lacking. The lack of regular maintenance can lead to premature solenoid failures, resulting in unplanned repairs that disrupt operations. This financial strain can be particularly challenging for businesses managing large fleets or multiple vehicle types.

Die Lösung: To mitigate maintenance costs, B2B buyers should implement a proactive maintenance program that includes regular inspections and performance checks of starter solenoids. This program can involve scheduled servicing, where technicians assess the solenoid’s condition, check for signs of wear or corrosion, and replace them as needed before they fail. Investing in training for technicians on the signs of solenoid wear—such as intermittent starting issues or unusual noises—can also prevent costly breakdowns. Furthermore, establishing a stock of commonly used starter solenoids can enable quick replacements, minimizing vehicle downtime and ensuring continuous operations.

Strategic Material Selection Guide for what is the starter solenoid

What Materials Are Commonly Used for Starter Solenoids?

When selecting materials for starter solenoids, it is crucial to consider properties that affect performance, durability, and overall functionality. Here, we analyze four common materials used in the construction of starter solenoids: copper, aluminum, stainless steel, and plastic composites.

How Does Copper Benefit Starter Solenoid Performance?

Copper is a widely used material in electrical components due to its excellent electrical conductivity. It typically has a temperature rating of around 200°C and can withstand significant electrical loads, making it ideal for the high-current applications found in starter solenoids.

Vorteile: Copper’s high conductivity ensures efficient power transfer, which is essential for the solenoid’s operation. It is also relatively easy to manufacture, allowing for intricate designs that can enhance performance.

Nachteile: However, copper is susceptible to corrosion, particularly in humid or saline environments, which can lead to electrical failures over time. Additionally, copper components can be more expensive than alternatives, impacting overall production costs.

Illustrative image related to what is the starter solenoid

Auswirkungen auf die Anwendung: Given its conductivity, copper is suitable for environments where high electrical performance is critical. However, international buyers in regions like Africa and South America should consider local climate conditions that may affect copper’s longevity.

What Advantages Does Aluminum Offer for Starter Solenoids?

Aluminum is another common material, known for its lightweight properties and good corrosion resistance. It can typically handle temperatures up to 150°C, making it suitable for automotive applications.

Vorteile: The primary advantage of aluminum is its weight, which can contribute to overall vehicle efficiency. It is also less expensive than copper, making it an attractive option for cost-sensitive projects.

Illustrative image related to what is the starter solenoid

Nachteile: While aluminum has decent electrical conductivity, it is not as efficient as copper. This can lead to performance issues in high-demand applications. Additionally, aluminum can be more challenging to machine, which may complicate manufacturing processes.

Auswirkungen auf die Anwendung: Aluminum is a good choice for vehicles operating in moderate climates. However, buyers in regions with extreme temperatures or high humidity should be cautious of potential performance limitations.

Why Choose Stainless Steel for Starter Solenoid Components?

Stainless steel is often used for solenoid housings and components due to its exceptional corrosion resistance and mechanical strength. It can withstand temperatures up to 300°C, making it suitable for high-heat environments.

Vorteile: The durability of stainless steel ensures a long lifespan, which is vital for components exposed to harsh conditions. It also provides excellent structural integrity, making it ideal for protective housings.

Nachteile: The downside of stainless steel is its higher cost and lower electrical conductivity compared to copper and aluminum. This can affect the overall efficiency of the solenoid.

Auswirkungen auf die Anwendung: Stainless steel is particularly beneficial in environments with high humidity or exposure to corrosive substances. Buyers from the Middle East, where heat and corrosion are prevalent, may find stainless steel to be a reliable choice.

How Do Plastic Composites Fit into Starter Solenoid Design?

Plastic composites are increasingly being used in starter solenoids for non-conductive components, such as housings or insulating parts. These materials can withstand temperatures up to 120°C and are generally lightweight.

Vorteile: The primary advantage of plastic composites is their resistance to corrosion and electrical insulation properties. They are also cost-effective and can be molded into complex shapes.

Nachteile: However, plastic composites typically have lower mechanical strength and thermal stability compared to metals. This can limit their use in high-stress applications.

Auswirkungen auf die Anwendung: Plastic composites are suitable for applications where weight reduction and corrosion resistance are priorities. However, buyers should be aware of the limitations in high-temperature environments, particularly in regions like Brazil where heat can be an issue.

Summary Table of Material Selection for Starter Solenoids

| Material | Typical Use Case for what is the starter solenoid | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Klemmen | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Aluminium | Strukturkomponenten und Gehäuse | Leicht und kostengünstig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Rostfreier Stahl | Protective housings and high-stress components | High durability and corrosion resistance | Higher cost and lower conductivity | Hoch |

| Kunststoffverbundwerkstoffe | Insulating parts and non-conductive components | Korrosionsbeständigkeit und geringes Gewicht | Geringere mechanische Festigkeit | Niedrig |

This table provides a concise overview for international B2B buyers, facilitating informed decision-making based on performance, cost, and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter solenoid

What Are the Main Stages of Manufacturing Starter Solenoids?

The manufacturing process of starter solenoids involves several critical stages, each designed to ensure that the final product meets the necessary performance and durability standards. Understanding these stages can help B2B buyers make informed decisions when sourcing components.

How Is Material Prepared for Starter Solenoid Production?

The first step in the manufacturing process is material preparation. High-quality raw materials, such as copper for electrical components and durable plastics or metals for housings, are essential. Suppliers typically procure materials that meet specific mechanical and electrical properties, ensuring they can withstand operational stresses.

Illustrative image related to what is the starter solenoid

Materials are inspected upon arrival to ensure they conform to specifications. This initial quality check (Incoming Quality Control – IQC) is crucial, as substandard materials can lead to failures in the finished product.

What Techniques Are Used in the Forming Stage of Starter Solenoid Manufacturing?

Once materials are prepared, they undergo various forming techniques. These techniques may include:

-

Stempeln: This process shapes metal components into required forms, such as terminals and housings, using high-pressure presses. Precision stamping ensures that parts are uniform, which is vital for effective assembly and operation.

-

Coiling: Copper wire is often coiled to create solenoid windings. The coiling process must be tightly controlled to ensure the proper number of turns and tension, which directly affects the solenoid’s magnetic field strength.

-

Spritzgießen: For plastic components, injection molding is commonly used. This method allows for complex shapes and tight tolerances, essential for the solenoid’s housing and insulators.

How Is Assembly of Starter Solenoids Conducted?

After forming, the components are assembled. This stage involves:

-

Komponentenintegration: The various parts, including the solenoid coil, housing, and terminals, are assembled using automated machinery or manual labor, depending on the complexity and volume of production.

-

Elektrische Anschlüsse: Proper soldering or crimping techniques are employed to ensure reliable electrical connections. Any faults in this stage can lead to performance issues in the final product.

-

Quality Checks During Assembly (In-Process Quality Control – IPQC): Throughout the assembly process, quality checks are conducted to ensure parts fit correctly and that there are no defects. This can include visual inspections and functionality tests.

What Finishing Processes Are Important for Starter Solenoids?

Once assembled, starter solenoids undergo finishing processes to enhance durability and performance. Common finishing techniques include:

-

Beschichtung: Components may be coated to prevent corrosion and enhance electrical insulation. This is particularly important for terminals and metal housings exposed to harsh environments.

-

Prüfung: Each solenoid is subjected to rigorous testing, including electrical testing to ensure proper functionality and performance under load conditions.

-

Endkontrolle (FQC): Before products leave the facility, they undergo a final quality inspection. This includes checking for proper assembly, functionality, and compliance with specifications.

Welche Qualitätssicherungsstandards sollten B2B-Käufer berücksichtigen?

For B2B buyers, understanding the quality assurance processes that manufacturers implement is essential for ensuring product reliability. Various international and industry-specific standards guide quality assurance in starter solenoid manufacturing.

Which International Standards Are Relevant for Starter Solenoid Quality Assurance?

ISO 9001 is a widely recognized standard that focuses on quality management systems. Companies adhering to ISO 9001 demonstrate their commitment to quality and continuous improvement. B2B buyers should look for suppliers who are certified to this standard, as it indicates robust quality control processes.

What Industry-Specific Standards Should Be Considered?

In addition to ISO standards, several industry-specific certifications may apply, such as:

-

CE-Kennzeichnung: This indicates compliance with European safety, health, and environmental protection standards, which is crucial for buyers in Europe.

-

API-Standards: For solenoids used in automotive applications, adherence to American Petroleum Institute (API) standards may be necessary, especially for products used in extreme conditions.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Verifying a supplier’s quality control processes is vital for ensuring that the products meet industry standards and requirements. Here are some effective methods for B2B buyers:

Was sind die besten Vorgehensweisen für die Durchführung von Lieferantenaudits?

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. During these audits, buyers should:

- Review documentation related to quality control procedures and certifications.

- Observe manufacturing processes to ensure adherence to standards.

- Assess the handling of non-conforming products and corrective actions taken.

Wie können Käufer Berichte und Inspektionen durch Dritte nutzen?

Buyers should request quality control reports from suppliers, detailing inspection results and compliance with standards. Additionally, third-party inspections can provide an unbiased assessment of a supplier’s capabilities. Engaging a third-party testing agency can ensure that products meet necessary specifications before they are shipped.

Welche Feinheiten sollten internationale B2B-Einkäufer beachten?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding regional nuances in quality assurance is essential.

How Do Regional Regulations Impact Quality Control?

Different regions may have varying regulations and standards that affect product compliance. For instance, buyers in Europe must be particularly mindful of CE marking and RoHS compliance for electronic components. Understanding local regulations can help buyers avoid costly compliance issues.

What Considerations Are There for Supply Chain Transparency?

Transparency in the supply chain is becoming increasingly important. Buyers should inquire about traceability practices to ensure that all materials used in starter solenoids are sourced responsibly and meet quality standards. This not only enhances product quality but also aligns with ethical sourcing practices.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance measures involved in the production of starter solenoids is crucial for B2B buyers. By being informed about material preparation, forming techniques, assembly, finishing processes, and quality assurance standards, buyers can make educated decisions and establish partnerships with reliable suppliers. This knowledge not only enhances the quality of the products sourced but also contributes to the overall success of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter solenoid’

In the context of sourcing starter solenoids, understanding their functionality and specifications is crucial for making informed procurement decisions. This guide provides a clear checklist to streamline the sourcing process for B2B buyers, ensuring that they acquire high-quality components that meet their operational needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Clearly outline the requirements for the starter solenoid. Determine the voltage, current ratings, and specific dimensions required for your application. Understanding these specifications is essential, as it will help you avoid compatibility issues and ensure optimal performance in your machinery or vehicles.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in starter solenoid technology. Regularly review industry publications and attend trade shows to learn about new features, materials, and manufacturing techniques. This knowledge will not only help you find the best products but also give you leverage in negotiations with suppliers.

Schritt 3: Bewertung potenzieller Lieferanten

Thoroughly assess suppliers before making a commitment. Request detailed company profiles, product catalogs, and case studies that demonstrate their expertise in manufacturing starter solenoids. Pay attention to reviews and references from businesses in your region or industry to gauge reliability and service quality.

- Zertifizierungen überprüfen: Ensure suppliers have relevant certifications (e.g., ISO, CE) that indicate compliance with international standards.

- Investigate Production Capacity: Assess whether suppliers can meet your volume requirements consistently.

Step 4: Verify Quality Assurance Processes

Inquire about the quality control measures implemented by potential suppliers. Reliable manufacturers will have robust QA processes to ensure each starter solenoid meets the required specifications. Ask for documentation of testing procedures, including any certifications for testing and inspection.

- Qualitätsprüfung: Look for details on the types of tests conducted (e.g., electrical, thermal) and the frequency of these tests.

- Fehlerquoten: Request information on historical defect rates and how the supplier addresses quality issues.

Schritt 5: Aushandeln von Bedingungen und Konditionen

Engage in discussions about pricing, delivery timelines, and payment terms. Ensure that you are clear on all aspects of the agreement, including warranties and return policies. A well-structured contract protects both parties and clarifies expectations.

- Mengenrabatte: Ask about pricing flexibility for larger orders to maximize cost savings.

- Vorlaufzeiten: Confirm lead times for production and shipping to align with your project schedules.

Schritt 6: Erstellen Sie einen Kommunikationsplan

Set up clear communication channels with your chosen supplier. Define points of contact for both parties and establish regular check-ins to discuss order status, potential issues, and feedback. Effective communication fosters a strong supplier relationship, which can lead to better service and support.

Step 7: Plan for Ongoing Maintenance and Support

Consider the long-term relationship with your supplier. Ensure they offer ongoing support, including technical assistance and replacement parts. Understanding the supplier’s capabilities for after-sales service can help you maintain the performance of your starter solenoids over time.

By following this checklist, B2B buyers can streamline their sourcing process for starter solenoids, ensuring they acquire components that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for what is the starter solenoid Sourcing

What Are the Key Cost Components in Sourcing Starter Solenoids?

When sourcing starter solenoids, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materialien: The quality of materials directly impacts the solenoid’s performance and longevity. Common materials include copper for wiring and various metals for the housing. Prices can fluctuate based on global commodity markets, which means buyers should be aware of current trends.

-

Arbeit: Labor costs can vary significantly based on the manufacturing location. For instance, labor costs in regions like South America or Africa may be lower than in Europe, affecting the overall pricing structure.

-

Fertigungsgemeinkosten: This encompasses costs related to factory maintenance, utilities, and indirect labor. Efficient manufacturing processes can help minimize these costs, which can be a negotiating point for buyers.

-

Werkzeuge: The initial investment in tooling for custom solenoids can be substantial. Buyers should assess whether the tooling costs are amortized over larger production runs, as this can significantly affect unit pricing.

-

Qualitätskontrolle: Ensuring that the solenoids meet specified standards incurs costs, but it is essential for minimizing returns and warranty claims. Certifications such as ISO can also add to costs but may enhance trust and credibility with buyers.

-

Logistik: Transportation and shipping costs vary by region and can be influenced by the chosen Incoterms. For instance, CIF (Cost, Insurance, and Freight) terms might lead to higher upfront costs but ensure that the buyer is not surprised by additional shipping charges.

-

Marge: Supplier margins typically range from 10% to 30%, depending on the supplier’s market position and the complexity of the solenoid.

What Influences Pricing for Starter Solenoids?

Several factors can influence the pricing of starter solenoids, including volume, specifications, materials, quality certifications, supplier reputation, and the chosen Incoterms.

Illustrative image related to what is the starter solenoid

-

Volumen/MOQ (Mindestbestellmenge): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQs that align with their projected needs to optimize cost savings.

-

Spezifikationen/Anpassung: Custom solenoids tailored for specific applications can drive up costs. Buyers should balance the need for customization with budget constraints.

-

Materialien: The choice of materials not only affects performance but also cost. High-quality materials may increase the price but result in lower failure rates and extended lifespans.

-

Qualität/Zertifizierungen: Products with recognized certifications may come at a premium, but they can reduce the risk of failures and warranty claims. International buyers should consider the implications of certifications in their local markets.

-

Lieferantenfaktoren: Building relationships with reliable suppliers can lead to better pricing and terms. Assessing a supplier’s track record can provide insights into their pricing structure and reliability.

-

Incoterms: Understanding shipping terms is essential for cost management. Incoterms such as FOB (Free on Board) or DDP (Delivered Duty Paid) can significantly impact the total landed cost of solenoids.

What Are the Best Practices for Negotiating Starter Solenoid Prices?

B2B buyers can adopt several strategies to enhance their negotiation outcomes when sourcing starter solenoids.

-

Hebelwirkung auf die Gesamtbetriebskosten (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and potential failure costs. This approach can justify higher upfront costs for better-quality components.

-

Führen Sie Marktforschung durch: Understanding the market landscape can provide leverage in negotiations. Knowing competitor pricing and market trends can help in discussions with suppliers.

-

Langfristige Beziehungen aufbauen: Establishing a strong relationship with suppliers can lead to favorable terms and pricing over time. Consistent orders may encourage suppliers to offer better prices.

-

Be Clear on Requirements: Clearly communicate specifications and requirements to avoid misunderstandings that could lead to increased costs.

-

Explore Regional Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce logistics costs and lead times, making negotiations more favorable.

Schlussfolgerung

Sourcing starter solenoids involves a complex interplay of cost components and pricing influences. By understanding these factors and employing strategic negotiation practices, B2B buyers can secure favorable terms and ensure they are getting value for their investment. Always remain aware that prices can fluctuate, and maintaining flexibility in sourcing strategies is essential for long-term success.

Alternatives Analysis: Comparing what is the starter solenoid With Other Solutions

Exploring Alternatives to the Starter Solenoid

In the automotive and machinery sectors, the starter solenoid is a crucial component, acting as a switch that allows current to flow from the battery to the starter motor. However, several alternative solutions and technologies can serve similar functions or enhance the starting process. This section evaluates the starter solenoid against two viable alternatives: the starter relay and push-button ignition systems.

Illustrative image related to what is the starter solenoid

Vergleichstabelle

| Vergleichsaspekt | What Is The Starter Solenoid | Starter Relay | Druckknopf-Zündsystem |

|---|---|---|---|

| Leistung | Reliable, quick activation | Simple operation, less robust | Fast start, modern technology |

| Kosten | Mäßige Kosten | Geringe Kosten | Höhere Erstinvestition |

| Einfache Implementierung | Moderate complexity | Easy to install | Requires more integration |

| Wartung | Regelmäßige Kontrollen erforderlich | Minimale Wartung erforderlich | Low maintenance with proper setup |

| Bester Anwendungsfall | Traditional ignition systems | Budget-friendly vehicles | High-end or modern vehicles |

Detaillierte Aufschlüsselung der Alternativen

1. Starter Relay

The starter relay is a compact device that acts as an intermediary between the ignition switch and the starter solenoid. Its primary role is to facilitate the low-voltage signal from the ignition switch to the solenoid, thereby allowing the high current from the battery to flow to the starter motor.

Vorteile:

– Cost-effective, making it an ideal choice for budget-conscious buyers.

– Simplifies the wiring in the starting system, reducing potential points of failure.

Nachteile:

– Less robust than a dedicated starter solenoid, which may lead to reliability issues in higher-performance applications.

– May not provide the same level of power management as a solenoid, potentially leading to quicker wear.

2. Push-Button Ignition System

Push-button ignition systems represent a modern approach to starting vehicles, replacing traditional keys and solenoids with a simple button. These systems utilize advanced technology to enhance user convenience and streamline the starting process.

Vorteile:

– Provides faster and more convenient engine starting with a single button press.

– Often integrates additional features such as keyless entry, improving user experience.

Nachteile:

– Higher initial costs for installation and components, making it less accessible for budget-focused buyers.

– Requires more complex wiring and electronic integration, which can lead to higher maintenance demands.

Illustrative image related to what is the starter solenoid

Schlussfolgerung

When selecting the right starting solution for a vehicle or machinery, B2B buyers should carefully consider their specific needs, including budget, performance requirements, and ease of installation. The starter solenoid remains a reliable choice for traditional systems, while the starter relay offers a cost-effective alternative for simpler applications. For those seeking modern features and convenience, push-button ignition systems present an appealing option, albeit at a higher cost and complexity. Ultimately, understanding these alternatives will empower buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for what is the starter solenoid

What Are the Key Technical Properties of a Starter Solenoid?

When sourcing starter solenoids for automotive or machinery applications, understanding the essential technical properties is crucial for ensuring compatibility and reliability. Here are some key specifications to consider:

1. Werkstoffgüte

The material used in starter solenoids typically includes high-grade steel and copper. High-grade steel ensures durability and resistance to corrosion, while copper is essential for efficient electrical conductivity. For B2B buyers, selecting solenoids made from these materials can minimize the risk of failure, ensuring longevity and reduced maintenance costs.

2. Betriebsspannung

Most starter solenoids operate at either 12V or 24V, depending on the vehicle or machinery. This specification is critical for compatibility with the electrical systems of the equipment. Incorrect voltage ratings can lead to solenoid failure or even electrical damage to the system, which is why verifying this specification is essential for B2B procurement.

3. Aktuelle Bewertung

The current rating, often measured in amperes (A), indicates the maximum current the solenoid can handle without overheating. A solenoid must match or exceed the current requirements of the starter motor it serves. For buyers, understanding this property helps in selecting a solenoid that can reliably initiate engine cranking without risking overheating or damage.

4. Toleranzwerte

Tolerance refers to the acceptable range of variation in the dimensions of the solenoid components. This is particularly important for ensuring that the solenoid fits properly within the designated space in the vehicle or machinery. High tolerance levels reduce the likelihood of operational failures due to improper fit, which is vital for maintaining operational efficiency.

5. Reaktionszeit

Response time indicates how quickly the solenoid can engage and disengage. A faster response time is critical in high-performance applications where timing is essential. For B2B buyers, this specification can impact the overall performance of the vehicle or machinery, particularly in demanding environments.

6. Temperaturbereich

The temperature rating specifies the range of temperatures within which the solenoid can operate effectively. Extreme temperatures can affect performance and longevity. For international buyers, particularly in regions with varying climates, selecting solenoids with appropriate temperature ratings ensures reliable operation under different environmental conditions.

What Are Common Trade Terms Related to Starter Solenoids?

Understanding trade terminology is equally important when purchasing starter solenoids. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Originalgerätehersteller)

OEM refers to parts made by the original manufacturer of the vehicle or machinery. These parts are typically designed to meet the exact specifications of the original components. Purchasing OEM starter solenoids can ensure compatibility and reliability, which is a priority for many buyers.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost calculations. Buyers should negotiate MOQs to align with their purchasing needs without overcommitting resources.

3. RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. For B2B buyers, issuing an RFQ for starter solenoids can help in comparing offers and securing favorable terms, ensuring a cost-effective procurement process.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for international buyers to clarify shipping costs and responsibilities, thereby avoiding unexpected expenses.

5. Vorlaufzeit

Lead time refers to the amount of time it takes from placing an order to receiving the products. This is crucial for inventory planning and ensuring that operations are not disrupted. Buyers should inquire about lead times when sourcing starter solenoids to align with their operational timelines.

6. Garantiezeitraum

The warranty period is the time frame during which the manufacturer guarantees the product against defects. A longer warranty period can provide peace of mind for buyers, indicating confidence in the product’s durability and reliability. Understanding warranty terms is essential for risk management in procurement decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter solenoids, ensuring they choose components that meet their operational needs while optimizing costs.

Navigating Market Dynamics and Sourcing Trends in the what is the starter solenoid Sector

Understanding the Global Market Dynamics for Starter Solenoids

The starter solenoid market is experiencing robust growth, driven by the increasing demand for automotive components and advancements in technology. Key market drivers include the rising vehicle production rates, particularly in emerging economies in Africa and South America, where automotive manufacturing is gaining momentum. As these regions expand their automotive industries, there is a heightened need for reliable components like starter solenoids, which are crucial for engine ignition systems.

In addition to traditional automotive applications, the market is seeing a shift towards electric and hybrid vehicles, influencing sourcing trends. These vehicles often utilize more sophisticated starter systems, prompting manufacturers to innovate and adapt their solenoid designs accordingly. The integration of smart technology, such as IoT-enabled components for predictive maintenance, is becoming increasingly relevant, particularly for B2B buyers looking to enhance operational efficiency.

International buyers, particularly those from Brazil and Nigeria, are focusing on quality and reliability, leading to a demand for manufacturers that can provide consistent performance and durability. This trend emphasizes the importance of establishing long-term partnerships with suppliers who can demonstrate quality control measures and adherence to industry standards.

How Are Sustainability and Ethical Sourcing Impacting the Starter Solenoid Market?

Sustainability is becoming a pivotal concern for B2B buyers in the automotive sector. The environmental impact of manufacturing processes, including the sourcing of materials for starter solenoids, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recyclable materials and minimizing waste during production.

Ethical sourcing is equally important, as buyers aim to ensure that their supply chains do not contribute to environmental degradation or human rights violations. Certifications like ISO 14001 for environmental management and adherence to ethical labor practices are becoming prerequisites for many international buyers. Companies that can showcase their commitment to sustainability through transparent supply chains and environmentally friendly materials are likely to gain a competitive edge in the market.

The trend towards greener products is also shaping the development of starter solenoids. Manufacturers are exploring alternative materials and production methods that reduce carbon footprints. B2B buyers should actively seek partnerships with suppliers who prioritize sustainability, as this aligns with the growing consumer demand for eco-conscious products.

What Is the Evolution of Starter Solenoid Technology?

The starter solenoid has evolved significantly since its inception in the early 20th century. Originally designed as simple electromechanical switches, modern starter solenoids incorporate advanced materials and technologies to enhance efficiency and reliability. The transition from mechanical to electronic ignition systems necessitated improvements in solenoid design, leading to the development of more compact and durable components.

Today, starter solenoids are engineered to withstand higher electrical loads and extreme environmental conditions, making them suitable for a wide range of applications beyond traditional vehicles, including commercial fleets and heavy machinery. As the automotive industry moves towards electrification, the evolution of starter solenoid technology will continue to play a crucial role in ensuring the performance and longevity of modern engines.

By understanding these market dynamics, sustainability trends, and the historical context of starter solenoids, international B2B buyers can make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter solenoid

-

How do I identify a faulty starter solenoid?

Identifying a faulty starter solenoid typically involves observing certain symptoms. Common indicators include a single or repeated clicking sound when turning the ignition key, a complete lack of response, intermittent starting issues, or the engine failing to crank. To diagnose, check the battery voltage, inspect all electrical connections for corrosion or looseness, and use a multimeter to verify proper voltage at the solenoid terminals. Prompt identification can save time and costs associated with further mechanical failures. -

What are the key components of a starter solenoid?

A starter solenoid consists of three primary terminals: the battery terminal, starter terminal, and ignition terminal. The battery terminal connects to the positive battery post, supplying power. The starter terminal links to the starter motor, while the ignition terminal connects to the ignition switch. Understanding these components is crucial for effective troubleshooting and replacement, ensuring that the starter system functions optimally. -

What should I consider when sourcing starter solenoids internationally?

When sourcing starter solenoids internationally, consider factors such as supplier reputation, product quality, and compliance with international standards. Verify the supplier’s certifications and request samples to assess quality. Pay attention to lead times and shipping logistics, especially for regions with complex customs processes. Establish clear communication channels to discuss specifications, pricing, and terms of service, ensuring a smooth procurement process. -

What is the minimum order quantity (MOQ) for starter solenoids?

Minimum order quantities (MOQ) for starter solenoids can vary significantly among suppliers. Some manufacturers may have an MOQ of 100 units, while others might offer lower MOQs for initial orders. It’s beneficial to negotiate MOQs based on your purchasing needs and market demand. Understanding your inventory turnover can also help you determine the right quantity to order, balancing cost-effectiveness with supply chain efficiency. -

How can I ensure the quality of starter solenoids from suppliers?

To ensure the quality of starter solenoids, conduct thorough vetting of suppliers by reviewing their quality assurance processes and certifications, such as ISO standards. Request documentation for previous quality control tests and consider third-party inspections before shipment. Establish a clear return policy for defective units and maintain open lines of communication with your supplier to address any quality concerns promptly. -

What payment terms are common for international purchases of starter solenoids?

Common payment terms for international purchases often include options like Letter of Credit (LC), Telegraphic Transfer (TT), or PayPal for smaller transactions. Payment terms may vary based on the supplier’s policies and the buyer’s negotiation leverage. It’s advisable to discuss and agree on payment terms upfront, including deposits and final payments, to avoid misunderstandings and ensure a smooth transaction process. -

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Anlassermagneten anstellen?

When importing starter solenoids, consider shipping methods, delivery timelines, and customs regulations in your region. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency. Ensure that the supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. Being proactive about logistics can mitigate delays and additional costs upon arrival. -

Can I customize starter solenoids for specific applications?

Yes, many manufacturers offer customization options for starter solenoids to meet specific applications or industry standards. Discuss your requirements with potential suppliers, including voltage specifications, terminal configurations, and design modifications. Customization can enhance compatibility with your machinery and improve performance, but be sure to confirm any implications for lead times and costs associated with custom orders.

Top 3 What Is The Starter Solenoid Manufacturers & Suppliers List

1. Edmunds – Starter Solenoids

Domäne: edmunds.com

Registriert: 1996 (29 Jahre)

Einleitung: Starter solenoids carry current between the car’s ignition system and the starter motor. They act as a switch that closes the circuit between the battery and starter motor when the ignition key is turned. Common components include three terminals: battery terminal (connected to the positive battery side), starter terminal (connected to the starter motor), and ignition terminal (linked to the ignit…

2. Reddit – Starter Solenoid Insights

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: The starter solenoid in a car is responsible for moving the starter gear to mesh with the flywheel, allowing the engine to start. It uses a small amperage input (e.g., 10 amps) to switch a large amperage output (e.g., 200 amps) to the starter, enabling a small current to control a circuit that outputs a large current. Essentially, it kicks the starter gear into place and completes the large electr…

3. Tracy’s Tire Pros – Starter Solenoid

Domäne: tracystirepros.com

Registriert: 2011 (14 Jahre)

Einleitung: Starter solenoid is a crucial component of the vehicle’s starting system, engaging the starter motor to turn over the engine. It is typically mounted on the starter motor or in the engine bay. Signs of a faulty starter solenoid include clicking sounds, no sound when starting, intermittent starting issues, starter staying engaged, and no crank despite a charged battery. Diagnostic tests include che…

Strategic Sourcing Conclusion and Outlook for what is the starter solenoid

In conclusion, understanding the function and significance of the starter solenoid is crucial for businesses involved in automotive maintenance and manufacturing. This component serves as a critical link between the ignition system and the starter motor, ensuring efficient engine starts and preventing potential damage to sensitive electrical systems. By recognizing the signs of solenoid failure—such as clicking sounds or intermittent starting—B2B buyers can preemptively address issues, minimizing downtime and repair costs.

Strategic sourcing of high-quality starter solenoids can enhance operational efficiency and customer satisfaction. Buyers should prioritize partnerships with reputable suppliers who offer durable products and comprehensive support. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, establishing strong supplier relationships will be essential for securing reliable components.

Looking forward, the automotive industry is poised for innovation, with advancements in technology likely to impact starter solenoid designs and functionalities. International B2B buyers are encouraged to stay informed and agile, adapting their sourcing strategies to leverage these developments. Investing in quality parts today will ensure a competitive edge in tomorrow’s market.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.