Introduction: Navigating the Global Market for parts of the alternator

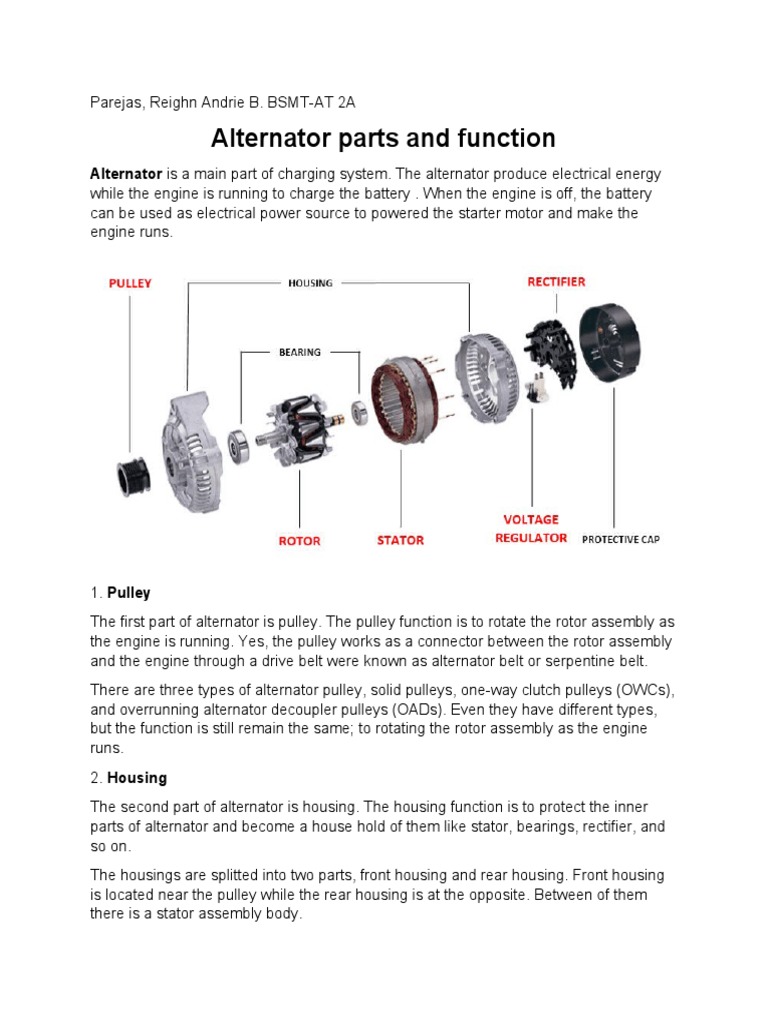

In the dynamic landscape of the global automotive industry, sourcing high-quality parts of the alternator is a critical challenge for B2B buyers. With a diverse range of applications across various vehicle types, understanding the essential components and their functions is vital for ensuring reliable performance and longevity. This comprehensive guide delves into the intricate world of alternator parts, covering key components such as rotors, stators, rectifiers, and voltage regulators, as well as their specific applications in different markets.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—face unique challenges in sourcing these critical components. This guide equips them with the knowledge to navigate supplier vetting processes effectively, evaluate pricing structures, and make informed purchasing decisions that align with their operational needs. By emphasizing quality assurance and offering insights into the latest industry trends, we aim to empower buyers to establish robust supply chains that enhance their competitiveness in the market.

In addition to outlining the types and functions of alternator parts, this guide also discusses best practices for supplier engagement and cost analysis. With actionable insights and expert advice, we aim to support your journey toward sourcing excellence in the alternator parts market.

Inhaltsverzeichnis

- Top 3 Parts Of The Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of the alternator

- Understanding parts of the alternator Types and Variations

- Key Industrial Applications of parts of the alternator

- 3 Common User Pain Points for ‘parts of the alternator’ & Their Solutions

- Strategic Material Selection Guide for parts of the alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of the alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of the alternator’

- Comprehensive Cost and Pricing Analysis for parts of the alternator Sourcing

- Alternatives Analysis: Comparing parts of the alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of the alternator

- Navigating Market Dynamics and Sourcing Trends in the parts of the alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of the alternator

- Strategic Sourcing Conclusion and Outlook for parts of the alternator

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding parts of the alternator Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Lichtmaschine | Commonly used in most vehicles; includes a rotor, stator, and voltage regulator. | Automobilherstellung, Reparaturwerkstätten | Vorteile: Weithin verfügbar, kostengünstig. Nachteile: May not meet high-performance demands. |

| Hochleistungs-Lichtmaschine | Designed for enhanced power generation; larger rotor and stator, often with upgraded cooling. | Hochleistungsfahrzeuge, Schwermaschinen | Vorteile: Higher power output, suitable for advanced electrical systems. Nachteile: Höhere Kosten, erfordert möglicherweise eine spezielle Installation. |

| Marine-Lichtmaschine | Corrosion-resistant materials; optimized for saltwater environments. | Marine vessels, offshore equipment | Vorteile: Durable in harsh conditions, reliable performance. Nachteile: Typically more expensive due to specialized materials. |

| Intelligenter Generator | Features integrated electronics for better efficiency and control; often includes advanced diagnostics. | Elektrofahrzeuge, Hybridsysteme | Vorteile: Improved fuel efficiency, real-time monitoring. Nachteile: Higher initial investment, complexity in integration. |

| Rebuilt Alternator | Refurbished units that meet OEM specifications; often more affordable than new units. | Automotive repair, fleet management | Vorteile: Kostengünstig und umweltfreundlich. Nachteile: Potential reliability concerns, shorter lifespan than new units. |

Was sind die wichtigsten Merkmale von Standard-Generatoren?

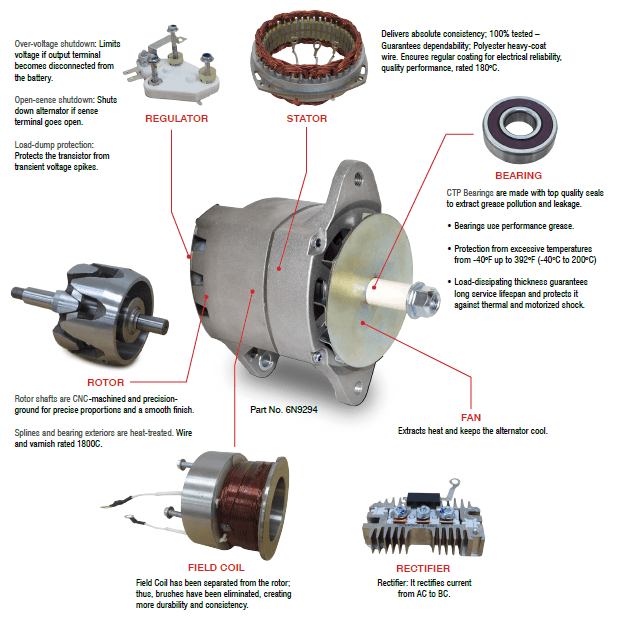

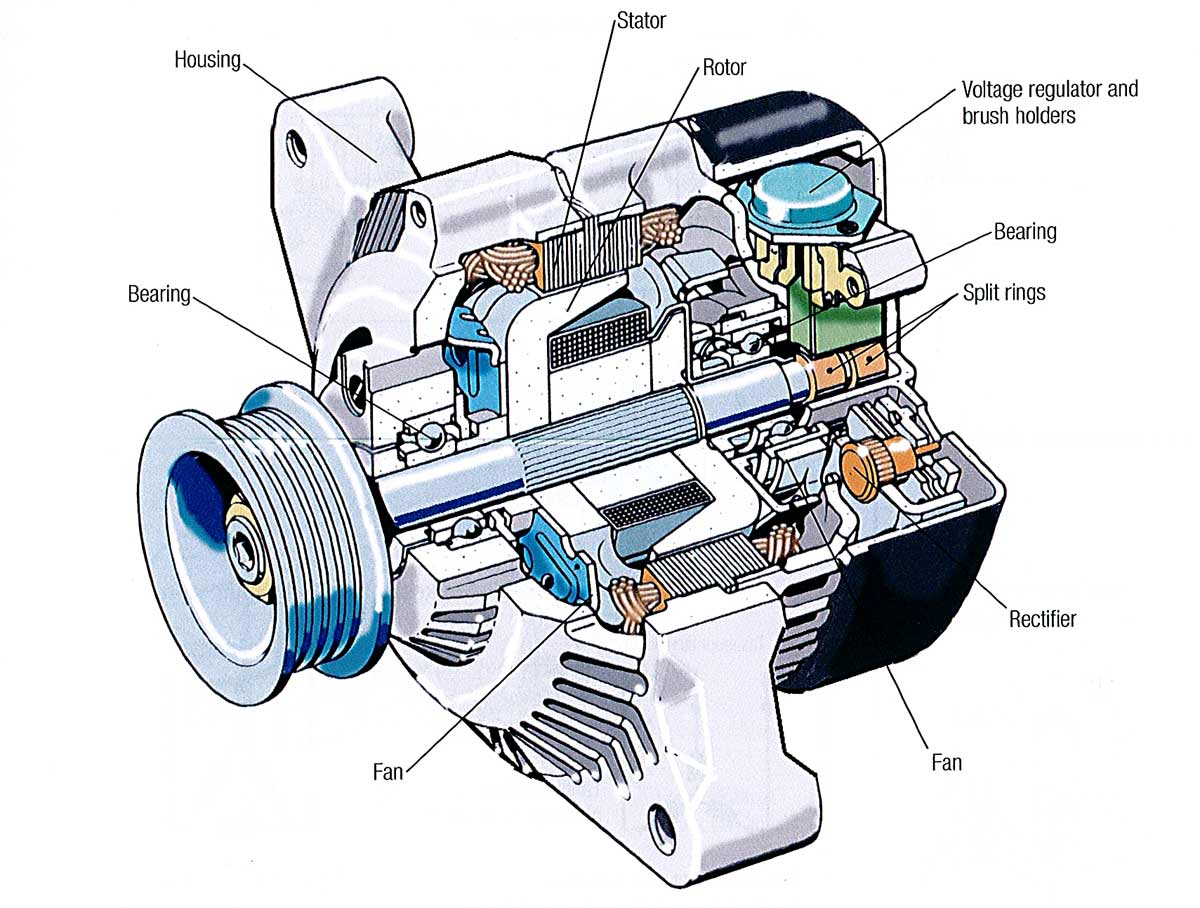

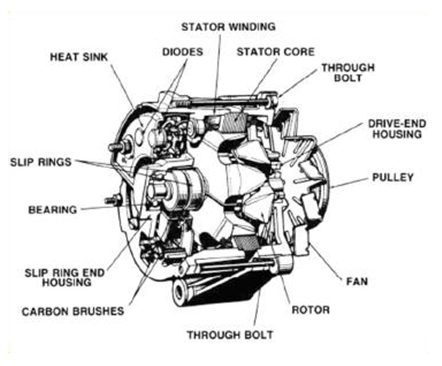

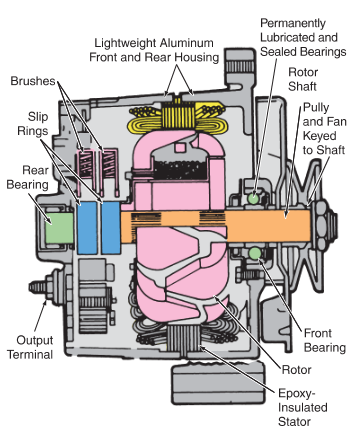

Standard alternators are the backbone of most automotive electrical systems. They typically consist of a rotor, stator, and voltage regulator, generating the necessary electrical power for vehicle accessories. They are widely used in automotive manufacturing and repair shops due to their availability and affordability. However, they may not satisfy the power demands of high-performance vehicles or specialized applications, making it essential for buyers to assess their specific needs.

Wie unterscheiden sich Lichtmaschinen mit hoher Leistung von Standardmodellen?

High-output alternators are engineered for enhanced performance, featuring larger rotors and stators that can generate more electricity. These units are particularly beneficial for performance vehicles or heavy machinery that require additional power for advanced electrical systems. While they provide significant advantages in terms of power output, buyers must consider the higher cost and potential installation requirements, which may necessitate modifications to existing systems.

Was macht Marine-Generatoren so einzigartig?

Marine alternators are specifically designed to withstand the harsh conditions of saltwater environments. They are built with corrosion-resistant materials and optimized for durability, making them ideal for marine vessels and offshore equipment. While their specialized construction ensures reliable performance in adverse conditions, the cost is typically higher than standard alternators, which is a critical consideration for businesses operating in marine sectors.

Why Consider Smart Alternators for Modern Applications?

Smart alternators incorporate advanced electronics that enhance efficiency and provide better control over the electrical system. These units are commonly found in electric vehicles and hybrid systems, offering features like real-time diagnostics and improved fuel efficiency. Although they represent a higher initial investment, the long-term savings from enhanced efficiency and reduced maintenance can make them a wise choice for businesses focusing on sustainability and innovation.

What Are the Advantages of Rebuilt Alternators?

Rebuilt alternators offer a cost-effective solution for businesses looking to save on automotive repairs. These refurbished units meet OEM specifications and are often more affordable than new alternatives, appealing to fleet management and automotive repair services. However, potential buyers should be cautious of the reliability concerns and shorter lifespan compared to new units, necessitating thorough inspections and warranties to ensure quality.

Key Industrial Applications of parts of the alternator

| Branche/Sektor | Specific Application of parts of the alternator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Use of rotor and stator in electric and hybrid vehicles | Enhances vehicle efficiency and reduces emissions | Quality certifications, compatibility with vehicle models, lead times. |

| Erneuerbare Energien | Components in wind turbine generators (rotors and rectifiers) | Converts mechanical energy into electrical power | Durability in harsh conditions, compliance with international standards. |

| Schwere Maschinen | Voltage regulators in construction and mining equipment | Ensures reliable power supply for equipment operation | Robustness, ability to handle high loads, after-sales support. |

| Schiffsindustrie | Alternator parts in ship engines for power generation | Provides essential power for navigation and systems | Corrosion resistance, compliance with marine regulations, maintenance support. |

| Landwirtschaftliche Geräte | Use of diodes and voltage regulators in farming machinery | Improves efficiency of machinery and reduces downtime | Sourcing from reliable suppliers, technical support, parts availability. |

How are Parts of the Alternator Used in Automotive Manufacturing?

In the automotive sector, the rotor and stator are vital components in both electric and hybrid vehicles. The rotor generates the electromagnetic field necessary for power generation, while the stator converts this energy into usable electrical power. This dual functionality enhances vehicle efficiency, reduces emissions, and supports the growing demand for sustainable transport solutions. For international buyers, sourcing high-quality alternator parts with appropriate certifications is crucial to ensure compatibility with various vehicle models and adherence to regional regulations.

What Role Do Alternator Parts Play in Renewable Energy Applications?

In renewable energy, particularly in wind turbine generators, the rotor and rectifier are essential for converting mechanical energy from wind into electrical energy. The rotor spins to create an electromagnetic field, while the rectifier ensures that the alternating current (AC) produced is converted into direct current (DC) for grid use. This application is critical for regions investing in renewable energy infrastructures. Buyers should consider the durability of components against harsh environmental conditions and ensure compliance with international energy standards.

How is the Voltage Regulator Essential in Heavy Machinery?

Voltage regulators are crucial in heavy machinery used in construction and mining. They maintain a consistent voltage supply to ensure that equipment operates efficiently and reliably, preventing power fluctuations that could lead to equipment failure. This reliability is particularly important in high-stakes environments where downtime can lead to significant financial losses. When sourcing these parts, businesses should prioritize robustness and the ability to handle high electrical loads, as well as after-sales support for maintenance.

Why are Alternator Parts Important in the Marine Industry?

In the marine industry, alternator components, especially those related to power generation in ship engines, are essential for the operation of navigation and onboard systems. The reliability of these parts ensures that vessels can operate safely and efficiently. Given the corrosive nature of marine environments, sourcing parts with high corrosion resistance is paramount. Additionally, compliance with marine regulations and the availability of maintenance support are key considerations for international buyers in this sector.

How Do Alternator Parts Enhance Agricultural Equipment Efficiency?

In agricultural machinery, components such as diodes and voltage regulators are vital for improving the efficiency and reliability of equipment. These parts help manage the electrical systems that power various functions, reducing downtime during critical farming operations. For buyers in the agricultural sector, sourcing from reliable suppliers who offer technical support and ensure parts availability is essential for maintaining operational efficiency throughout the farming season.

3 Common User Pain Points for ‘parts of the alternator’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Alternator Components

Das Problem:

B2B buyers often struggle to find reliable suppliers of alternator parts, particularly in regions with limited access to quality automotive components. This challenge is compounded by the prevalence of counterfeit or substandard parts that can lead to performance issues and safety risks. Buyers may face significant downtime if they source parts that fail to meet specifications or standards, leading to increased operational costs and customer dissatisfaction.

Die Lösung:

To effectively source high-quality alternator components, B2B buyers should prioritize establishing relationships with reputable suppliers who have a proven track record in the industry. This can be achieved by researching potential suppliers through industry networks, trade shows, and online platforms that focus on verified reviews and ratings. Buyers should also request samples or certifications that validate the quality of the parts, including compliance with international standards such as ISO or SAE. Leveraging local distributors who specialize in automotive parts can also help ensure faster delivery times and support. Additionally, engaging in contracts that include warranties or return policies can mitigate risks associated with quality assurance.

Scenario 2: Understanding the Technical Specifications of Alternator Parts

Das Problem:

Many B2B buyers encounter difficulties in understanding the intricate technical specifications of alternator parts, which can lead to purchasing the wrong components. For instance, a buyer may misinterpret the voltage requirements or the compatibility of specific parts like rectifiers and voltage regulators. This lack of clarity can result in costly errors, such as needing to return parts or redoing installations, which not only affects budget but also delays project timelines.

Die Lösung:

To navigate the complexities of alternator specifications, buyers should invest time in educating themselves about the components and their functions. This can involve consulting technical documentation from manufacturers, participating in training sessions, or accessing online resources that provide detailed insights into alternator technologies. Creating a checklist of essential specifications for each component, such as amperage ratings, dimensions, and compatibility with existing systems, can streamline the selection process. Furthermore, engaging with technical experts from suppliers can provide valuable guidance, ensuring that buyers make informed decisions tailored to their specific applications.

Scenario 3: Managing Supply Chain Disruptions for Alternator Parts

Das Problem:

Supply chain disruptions can significantly impact the availability of alternator parts, leaving B2B buyers vulnerable to delays that can halt operations. Factors such as geopolitical tensions, natural disasters, or fluctuating demand can lead to unexpected shortages or increased lead times. This situation is particularly challenging for buyers in emerging markets, where logistics infrastructure may not be as robust.

Die Lösung:

To mitigate the risks associated with supply chain disruptions, B2B buyers should adopt a proactive approach to inventory management. This includes maintaining a buffer stock of critical alternator components that are most prone to shortages, thereby allowing for continued operations during supply delays. Establishing relationships with multiple suppliers can also diversify sourcing options and reduce dependency on a single source. Implementing a just-in-time inventory system can optimize stock levels while minimizing excess, thus reducing costs. Additionally, utilizing advanced analytics to forecast demand trends can help buyers anticipate shortages and adjust their purchasing strategies accordingly, ensuring a steady supply of necessary parts.

Strategic Material Selection Guide for parts of the alternator

When selecting materials for alternator components, it is crucial to consider their properties, advantages, disadvantages, and the specific needs of international B2B buyers. This analysis will focus on four common materials used in alternators: aluminum, copper, steel, and composites. Each material has unique characteristics that influence performance and suitability for various applications.

What Are the Key Properties of Aluminum in Alternator Parts?

Aluminum is widely used for the outer housing of alternators due to its lightweight and non-magnetizing properties. It has excellent thermal conductivity, allowing for efficient heat dissipation, which is essential for maintaining performance under high operational temperatures. Aluminum also exhibits good corrosion resistance, particularly when anodized, which enhances its durability in diverse environments.

Vor- und Nachteile: The primary advantage of aluminum is its low weight, which contributes to overall vehicle efficiency. However, it can be more expensive than steel and may require more complex manufacturing processes, such as die-casting or extrusion, which can increase production costs.

Auswirkungen auf die Anwendung: Aluminum’s compatibility with various media makes it suitable for automotive applications, where exposure to fuel, oil, and other chemicals is common.

Überlegungen für internationale Käufer: Buyers in regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM and DIN for aluminum grades used in automotive applications.

How Does Copper Perform in Alternator Components?

Copper is primarily used in the windings of the rotor and stator due to its exceptional electrical conductivity. This property is crucial for efficient power generation and transmission within the alternator. Copper also has a high melting point, which contributes to its performance under high-temperature conditions.

Vor- und Nachteile: The major advantage of copper is its superior conductivity, which enhances the alternator’s efficiency. However, copper is relatively expensive compared to aluminum and is subject to corrosion, which can necessitate protective coatings or treatments.

Auswirkungen auf die Anwendung: Copper’s high conductivity makes it ideal for applications where electrical performance is critical, such as in the rotor and stator windings of alternators.

Überlegungen für internationale Käufer: Buyers should be aware of fluctuating copper prices and the importance of sourcing from reliable suppliers who adhere to international standards for electrical components.

Welche Rolle spielt Stahl bei der Herstellung von Lichtmaschinen?

Steel is often used for internal components like the rotor shaft and housing due to its strength and durability. It can withstand high mechanical stresses and is less prone to deformation under load, making it a reliable choice for structural components.

Vor- und Nachteile: Steel’s primary advantage is its strength and lower cost compared to aluminum and copper. However, it is heavier, which can negatively impact vehicle efficiency. Additionally, steel is susceptible to corrosion unless treated or coated.

Auswirkungen auf die Anwendung: Steel is suitable for components that require high strength and durability, particularly in heavy-duty applications.

Überlegungen für internationale Käufer: Buyers should consider the specific grades of steel that meet local and international standards, such as JIS and ASTM, particularly in regions with high humidity or corrosive environments.

How Are Composites Revolutionizing Alternator Design?

Composites, such as carbon fiber or reinforced plastics, are increasingly being used in alternator components due to their lightweight and high-strength properties. These materials can be engineered to provide specific performance characteristics, such as enhanced thermal stability and resistance to environmental factors.

Vor- und Nachteile: The key advantage of composites is their weight-saving potential, which can significantly improve vehicle efficiency. However, they often come with higher manufacturing costs and require specialized processes for production.

Auswirkungen auf die Anwendung: Composites are particularly beneficial in applications where weight reduction is critical, such as in electric vehicles.

Überlegungen für internationale Käufer: Buyers should ensure that composite materials meet the necessary performance standards and are sourced from manufacturers with experience in automotive applications.

Übersichtstabelle zur Materialauswahl für Generatorenteile

| Material | Typical Use Case for parts of the alternator | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Outer housing and structural components | Lightweight with good heat dissipation | Higher cost than steel | Mittel |

| Kupfer | Rotor- und Statorwicklungen | Hervorragende elektrische Leitfähigkeit | Teuer und korrosionsanfällig | Hoch |

| Stahl | Rotor shaft and internal structural parts | Hohe Festigkeit und Haltbarkeit | Heavier and corrosion susceptibility | Niedrig |

| Verbundwerkstoffe | Leichte Strukturkomponenten | Significant weight reduction | Höhere Fertigungskomplexität | Hoch |

This strategic material selection guide provides valuable insights for international B2B buyers in the automotive sector, helping them make informed decisions about the materials used in alternator components based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of the alternator

What Are the Key Manufacturing Processes for Alternator Parts?

The manufacturing of alternator parts involves several critical stages, each designed to ensure precision and durability. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Alternator Components?

The first step in manufacturing alternator parts is material preparation. High-quality materials are essential for performance and longevity. For instance, aluminum is commonly used for the housing due to its lightweight and non-magnetizing properties. Steel or copper is often selected for the rotor and stator components because of their superior conductivity and magnetic properties.

Material preparation involves sourcing raw materials from reputable suppliers, followed by thorough inspections to ensure compliance with international standards. Buyers should inquire about the material certifications and traceability to verify the authenticity and quality of the materials used.

What Forming Techniques Are Utilized in Alternator Manufacturing?

Once materials are prepared, the next stage is forming, which shapes the raw materials into specific components. Key techniques include:

-

Gießen: This is often used for the housing and complex shapes of components like the rotor. Aluminum is melted and poured into molds to create the desired shapes.

-

Bearbeitung: Precision machining is employed for components that require tight tolerances, such as the slip rings and rectifiers. CNC (Computer Numerical Control) machines ensure high accuracy in dimensions.

-

Stamping and Forging: These techniques are used for producing the stator laminations and other flat components. Stamping involves pressing sheets of metal into shapes, while forging uses compressive forces to shape materials.

These processes significantly impact the performance and reliability of the alternator. Buyers should consider suppliers who utilize advanced forming techniques that align with best practices in the industry.

How Are Alternator Parts Assembled?

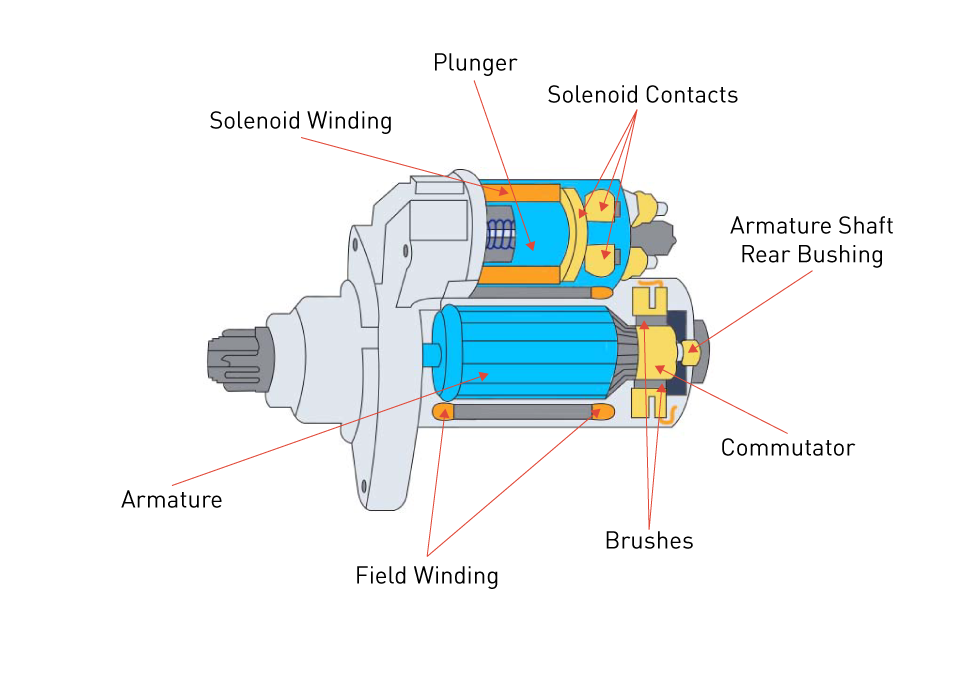

The assembly of alternator parts is a critical phase that ensures all components work harmoniously. Typically, the assembly process includes:

-

Unterbaugruppe: Components like the rotor and stator are first assembled separately. Bearings are fitted, and slip rings are attached to the rotor.

-

Hauptmontage: The rotor is then inserted into the stator, and rectifiers, voltage regulators, and other electrical components are added.

-

Qualitätskontrollen: Each assembly stage includes quality checks to ensure components meet specifications. This is crucial for ensuring the alternator performs reliably under operational conditions.

B2B buyers should assess the assembly line practices of potential suppliers, particularly looking for automation and skilled labor that enhance the precision of the assembly process.

What Finishing Techniques Are Important for Alternator Components?

Finishing processes are essential to enhance the durability and aesthetic appeal of alternator components. Common finishing techniques include:

-

Oberflächenbehandlung: Processes such as anodizing for aluminum housings and galvanizing for steel components protect against corrosion and wear.

-

Beschichtung: Application of protective coatings can enhance electrical insulation and thermal resistance.

-

Polieren: This is applied to various components to improve surface smoothness, which can reduce friction and wear during operation.

Buyers should ensure that suppliers follow appropriate finishing techniques that comply with international standards, as these can significantly affect the performance and lifespan of alternator parts.

Welche Qualitätssicherungsmaßnahmen werden durchgeführt?

Quality assurance is vital in the manufacturing of alternator components to ensure that they meet both regulatory and customer specifications.

Which International Standards Should Buyers Be Aware Of?

For manufacturing processes, compliance with international standards such as ISO 9001 is crucial. ISO 9001 outlines a framework for quality management systems, ensuring consistent quality in production. Additionally, industry-specific certifications like CE mark for European markets, and API standards for automotive parts can be significant indicators of quality.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

Quality control (QC) is typically integrated at various stages of the manufacturing process. Key checkpoints include:

Illustrative image related to parts of the alternator

-

Eingangsqualitätskontrolle (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is the first line of defense against defects.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, regular inspections are conducted to monitor compliance with design specifications. This can include dimensional checks and functional tests of assemblies.

-

Endkontrolle (FQC): Once the alternator is fully assembled, a final inspection is performed. This may involve functional testing, electrical testing, and thermal cycling to ensure the alternator performs under expected conditions.

B2B buyers should request detailed QC reports and documentation from suppliers to verify that these checkpoints are actively monitored and maintained.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

To ensure reliable sourcing, B2B buyers should consider several approaches:

-

Lieferantenaudits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality management systems.

-

Qualitätsberichte: Requesting detailed quality reports, including data from IQC, IPQC, and FQC, can help buyers assess the reliability of the supplier’s products.

-

Inspektionen durch Dritte: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. This is particularly important for international buyers, as it helps mitigate risks associated with sourcing from different regions.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific challenges related to quality control. These include:

-

Einhaltung gesetzlicher Vorschriften: Different regions have varying regulations concerning automotive parts. Understanding local compliance requirements is crucial for avoiding legal issues and ensuring product acceptance in the market.

-

Kulturelle Unterschiede: Quality perceptions can vary significantly across cultures. It is vital to establish clear communication with suppliers to ensure that quality expectations are aligned.

-

Logistik und Lieferkettenmanagement: International shipping can introduce risks such as damage or delays. Buyers should work with suppliers that have robust logistics practices and can demonstrate effective supply chain management.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing alternator parts, ensuring they receive high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of the alternator’

This guide serves as a practical sourcing checklist for B2B buyers looking to procure parts of the alternator. As the alternator plays a critical role in generating electrical energy from mechanical energy, understanding the components and ensuring quality sourcing is essential for operational efficiency and reliability. Below are the steps to follow to ensure a successful procurement process.

Illustrative image related to parts of the alternator

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the sourcing process, it’s crucial to outline your specific technical requirements. Determine the type of alternator parts needed, such as rotors, stators, rectifiers, and voltage regulators, based on the applications they will serve.

– Überlegungen: Include factors such as size, material specifications, and voltage ratings. This clarity will guide you in selecting the right suppliers who can meet your precise needs.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Look for companies with a proven track record and expertise in the automotive industry.

– Aktionspunkte: Utilize online directories, trade shows, and industry publications to compile a list of candidates. Pay attention to their market presence and reputation in your specific regions, such as Africa, South America, the Middle East, and Europe.

Schritt 3: Lieferantenzertifizierungen bewerten

Before finalizing any supplier, verify their certifications and compliance with international quality standards. This step is vital to ensure that the parts meet safety and quality benchmarks.

– Was zu überprüfen ist: Look for ISO certifications and other relevant quality assurance marks. Certifications indicate that the supplier adheres to industry best practices and can provide reliable components.

Schritt 4: Detaillierte Produktspezifikationen anfordern

Engage with shortlisted suppliers to request comprehensive product specifications and samples of the alternator parts. This helps in assessing quality and compatibility.

– Key Aspects to Consider: Pay attention to material properties, manufacturing processes, and warranty terms. Ensure that the products meet your defined technical specifications.

Schritt 5: Bewertung von Preisgestaltung und Zahlungsbedingungen

Once you have gathered product information, compare pricing structures among suppliers. While cost is an important factor, it should not compromise quality.

– Verhandlungstipps: Discuss payment terms, bulk order discounts, and delivery timelines. Understanding the total cost of ownership, including shipping and potential tariffs, will aid in making an informed decision.

Schritt 6: Verify Supply Chain Reliability

Assess the supplier’s ability to deliver consistently and on time. A reliable supply chain is crucial for maintaining your production schedules and minimizing downtime.

– Zu stellende Fragen: Inquire about their inventory management practices, lead times, and contingency plans for unforeseen disruptions.

Illustrative image related to parts of the alternator

Schritt 7: Establish Communication Protocols

Maintain open lines of communication with your chosen supplier to facilitate a smooth procurement process. Clear communication helps in addressing any issues promptly.

– Best Practices: Set regular check-ins and establish a point of contact for inquiries. This proactive approach can foster a stronger partnership and enhance collaboration.

Following this checklist will empower B2B buyers to make informed decisions when sourcing alternator parts, ensuring quality, reliability, and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for parts of the alternator Sourcing

What Are the Key Cost Components in Sourcing Alternator Parts?

When sourcing parts of an alternator, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to parts of the alternator

-

Materialien: The cost of raw materials like aluminum for the housing, copper for windings, and silicon for rectifiers significantly influences pricing. Sourcing high-quality materials can increase upfront costs but may lead to longer-lasting components, ultimately lowering the total cost of ownership.

-

Arbeit: Labor costs vary by region and can impact the overall price of alternator components. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Fertigungsgemeinkosten: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, allowing suppliers to offer more competitive prices.

-

Werkzeuge: The initial investment in tooling for specific parts can be significant, especially for custom orders. Buyers should be aware that the tooling cost is often amortized over larger production runs, making it more economical for high-volume orders.

-

Qualitätskontrolle (QC): Implementing rigorous QC processes adds to costs but ensures that the parts meet specifications and standards. Certifications such as ISO can also influence pricing, as they often require additional investment in quality systems.

-

Logistik: Shipping costs, which can vary based on distance and method (air vs. sea), play a critical role in pricing, especially for international buyers. Incoterms will dictate who bears the cost and risk during transportation, impacting the final price.

-

Rand: Suppliers typically include a profit margin that reflects their operational costs and market conditions. Understanding typical margins in specific markets can aid in negotiations.

How Do Price Influencers Affect Alternator Parts Sourcing?

Several factors influence the pricing of alternator parts, making it essential for buyers to be informed:

-

Menge/Mindestbestellmenge: Minimum order quantities (MOQ) can significantly affect unit prices. Suppliers often offer discounts for larger orders, making bulk purchasing a viable strategy for cost savings.

-

Specifications/Customization: Custom components tailored to specific requirements may come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Materials and Quality: Higher-quality materials and components often command higher prices. Buyers should assess their quality requirements to ensure they are not overpaying for unnecessary features.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but offer peace of mind.

-

Incoterms: Different Incoterms can alter the total cost of purchasing alternator parts. Understanding these terms helps buyers calculate the true cost of procurement, including shipping and handling.

What Tips Can Help Buyers Negotiate Better Prices for Alternator Parts?

Negotiating the best possible price for alternator parts requires strategic thinking:

-

Understand Total Cost of Ownership: Beyond the initial purchase price, consider maintenance, replacement frequency, and operational efficiency. A higher upfront cost might be justified by lower long-term expenses.

-

Leverage Volume Discounts: As mentioned, purchasing in bulk can lead to significant savings. Discussing future orders with suppliers may incentivize them to offer better pricing for initial orders.

-

Explore Multiple Suppliers: Gathering quotes from various suppliers can provide leverage in negotiations. It’s essential to compare not only prices but also delivery times and quality standards.

-

Be Clear About Specifications: Providing detailed specifications and quality requirements upfront can help avoid misunderstandings that may lead to increased costs later.

-

Stay Informed About Market Trends: Keep abreast of changes in material costs, labor rates, and global supply chain issues that could affect pricing. This knowledge can empower you during negotiations.

Schlussfolgerung

Understanding the cost and pricing dynamics of alternator parts is essential for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. By being informed about cost components, price influencers, and negotiation strategies, buyers can make smarter sourcing decisions that align with their operational needs and budget constraints. Keep in mind that prices may vary based on regional factors, and always request indicative prices to ensure accurate budgeting.

Alternatives Analysis: Comparing parts of the alternator With Other Solutions

Alternatives to traditional alternator components are essential to consider for businesses seeking efficient energy generation solutions. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs, budget constraints, and maintenance capabilities. This analysis compares the parts of an alternator against two alternative technologies: generator systems und battery energy storage systems (BESS).

Illustrative image related to parts of the alternator

| Vergleichsaspekt | Parts of the Alternator | Generator Systems | Battery Energy Storage Systems (BESS) |

|---|---|---|---|

| Leistung | High efficiency in converting mechanical energy to electrical energy; reliable for automotive applications. | Versatile power output; can generate high wattage for extended periods. | Instantaneous power delivery; excellent for load balancing and peak shaving. |

| Kosten | Generally low initial cost; ongoing maintenance required. | Higher upfront costs, but long-term savings on fuel and maintenance. | Initial investment can be high; potential for cost savings through energy arbitrage. |

| Einfache Implementierung | Simple integration into existing automotive systems; minimal training required. | Requires more extensive setup and integration, especially in mobile applications. | Installation can be complex; requires skilled labor for integration with existing systems. |

| Wartung | Regular checks on brushes, slip rings, and voltage regulators; moderate upkeep needed. | Requires routine maintenance; fuel management and mechanical parts need attention. | Low maintenance compared to mechanical systems; periodic battery health checks necessary. |

| Bester Anwendungsfall | Ideal for automotive applications and smaller machinery where mechanical energy is readily available. | Best for off-grid applications and backup power needs; suitable for construction sites. | Excellent for renewable energy integration and applications needing rapid power adjustments. |

What Are the Benefits and Drawbacks of Generator Systems Compared to Alternators?

Generator systems provide a versatile power solution, often capable of generating high wattage for extended durations. They excel in off-grid applications, such as construction sites or remote locations. However, their higher initial costs and ongoing fuel expenses can be a deterrent for some businesses. Additionally, they require more maintenance than alternators, as mechanical components can wear out over time and fuel management is necessary.

How Do Battery Energy Storage Systems (BESS) Compare to Traditional Alternators?

Battery energy storage systems (BESS) offer instantaneous power delivery and are particularly effective for load balancing and managing peak energy demands. They integrate well with renewable energy sources, allowing businesses to utilize stored energy when needed. However, the high upfront costs and complexity of installation can be significant drawbacks. While BESS requires less maintenance than traditional mechanical systems, businesses must still monitor battery health regularly to ensure optimal performance.

How Should B2B Buyers Choose Between These Solutions?

When selecting the right energy generation solution, B2B buyers must consider their specific operational requirements, budget constraints, and long-term goals. For automotive applications, the parts of an alternator remain a reliable choice due to their efficiency and ease of integration. However, businesses looking for versatility and higher power output might find generator systems more suitable. Conversely, those focused on sustainability and energy management may lean towards battery energy storage systems, despite their higher initial investment. Ultimately, a thorough evaluation of each option’s performance, cost, and maintenance requirements will guide buyers to the solution that best fits their needs.

Essential Technical Properties and Trade Terminology for parts of the alternator

Was sind die wichtigsten technischen Eigenschaften von Generatorteilen?

In the realm of alternators, understanding specific technical properties is crucial for B2B buyers, especially when sourcing components for automotive applications. Here are some essential specifications:

Illustrative image related to parts of the alternator

1. Werkstoffgüte

The outer housing of an alternator is typically made from aluminum due to its lightweight and non-magnetic properties. This material aids in heat dissipation, which is vital for maintaining performance. For buyers, knowing the material grade ensures compatibility with environmental conditions and longevity of the parts.

2. Toleranzwerte

Tolerance refers to the permissible limit of variation in a physical dimension. For alternator components like the rotor and stator, precise tolerances are critical to prevent mechanical failure during operation. Understanding these specifications helps buyers assess the quality and reliability of the components.

3. Elektrischer Widerstand

This property is vital for components like slip rings and brushes, which conduct electricity. Low electrical resistance minimizes energy loss and enhances efficiency. Buyers should ensure that the electrical resistance values meet industry standards to avoid performance issues in their applications.

4. Spannungswerte

Alternators operate at specific voltage levels, typically around 12V or 24V for automotive applications. Voltage ratings are essential for ensuring that the alternator can adequately power the vehicle’s electrical system without causing damage. Buyers must match voltage ratings with their vehicle specifications.

5. Effizienz der Kühlung

Effective cooling mechanisms, such as internal fans or heat sinks, are essential for maintaining optimal performance. Components that dissipate heat efficiently prolong the life of the alternator. Buyers should inquire about cooling designs to ensure they meet the operational demands of their applications.

What Are Common Trade Terms Used in Alternator Parts Procurement?

Navigating the procurement landscape requires familiarity with key industry terms. Here are several commonly used trade terms relevant to alternator parts:

1. OEM (Originalgerätehersteller)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles. For B2B buyers, sourcing OEM parts ensures compatibility and quality, as these components meet the exact specifications set by vehicle manufacturers.

2. MOQ (Mindestbestellmenge)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand as it affects inventory levels and overall purchasing costs. Knowing the MOQ helps businesses plan their orders strategically.

Illustrative image related to parts of the alternator

3. RFQ (Angebotsanfrage)

An RFQ is a document sent by buyers to suppliers requesting price quotes for specific products. This process is essential for comparing pricing, terms, and conditions across multiple suppliers, enabling informed purchasing decisions.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and delivery responsibilities effectively, reducing risks in cross-border trade.

5. Vorlaufzeit

Lead time refers to the time taken from placing an order to receiving the product. This term is critical for buyers in planning inventory and ensuring that production schedules are met. Buyers should always inquire about lead times to avoid operational delays.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies for alternator parts, ensuring they make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the parts of the alternator Sector

What Are the Current Market Dynamics and Key Trends in the Parts of the Alternator Sector?

The global alternator parts market is witnessing a transformative phase driven by increasing demand for automotive electrification and advancements in technology. Key trends include the rising adoption of electric vehicles (EVs) and hybrid models, which are reshaping the requirements for alternator components. This shift is particularly evident in regions such as Europe and the Middle East, where stringent emissions regulations are propelling manufacturers to innovate and enhance efficiency. Additionally, advancements in materials science are leading to lighter and more durable components, such as aluminum housings, which improve performance and longevity.

International B2B buyers must also navigate the complexities of supply chain dynamics, particularly in sourcing critical parts like rotor assemblies, voltage regulators, and rectifiers. The ongoing geopolitical tensions and disruptions caused by the COVID-19 pandemic have emphasized the need for diversified sourcing strategies. Buyers from Africa and South America are increasingly looking to establish local partnerships to mitigate risks associated with long supply chains and to ensure timely deliveries. Moreover, the integration of digital technologies such as IoT and AI in manufacturing processes is enabling better quality control and predictive maintenance, thereby enhancing the overall reliability of alternator components.

How Is Sustainability and Ethical Sourcing Shaping the Alternator Parts Market?

Sustainability is becoming a pivotal concern in the alternator parts market, influencing both sourcing strategies and consumer preferences. As global awareness of environmental issues grows, international B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are environmentally friendly, such as recyclable aluminum and low-impact plastics, which not only reduce the carbon footprint but also comply with emerging regulations in various markets.

Ethical supply chains are equally critical. Buyers are urged to conduct due diligence on their suppliers to ensure that they adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for evaluating suppliers’ commitment to sustainability. Implementing a ‘green’ procurement policy not only enhances brand reputation but also aligns with the growing consumer demand for sustainable products. This strategic approach can lead to long-term partnerships with suppliers who are equally invested in ethical practices, thereby fostering innovation and shared values.

Illustrative image related to parts of the alternator

What Has Been the Evolution of the Alternator Parts Market?

The evolution of the alternator parts market can be traced back to the early 20th century when the first alternators were introduced as a means of generating electricity for automotive applications. Initially, these devices were rudimentary, but advancements in technology led to significant improvements in efficiency and reliability. By the 1960s, the introduction of the transistorized voltage regulator marked a pivotal moment, allowing for better control of voltage output and enhancing the overall performance of alternators.

As automotive technology continued to evolve, the demand for more compact and efficient alternator designs surged, leading to innovations such as the incorporation of lightweight materials and advanced cooling systems. Today, the focus is on integrating smart technologies that enable real-time monitoring and predictive maintenance, ensuring that alternator parts can meet the rigorous demands of modern vehicles. This historical context underscores the importance of continuous innovation and adaptability in the alternator parts market, which remains crucial for meeting the dynamic needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of the alternator

-

How do I troubleshoot common alternator problems?

Troubleshooting alternator issues typically involves checking for symptoms such as dimming headlights, electrical failures, or a battery warning light. Start by testing the voltage output; a healthy alternator should produce between 13.8 to 14.5 volts. Inspect the connections for corrosion or loose wires, and examine the belt for wear or slippage. If these checks do not resolve the issue, consider testing individual components like the rectifier and voltage regulator, as they are common failure points. -

What are the key components of an alternator that I should source?

When sourcing alternator parts, focus on critical components such as the rotor, stator, rectifier, voltage regulator, slip rings, and bearings. Each part plays a vital role in the alternator’s efficiency and reliability. Ensure that the parts meet industry standards for quality and compatibility with the vehicles they will be used in. Additionally, consider sourcing OEM or equivalent parts to maintain performance and longevity. -

What factors should I consider when selecting a supplier for alternator parts?

Selecting a supplier requires evaluating several factors, including their experience in the automotive parts sector, quality certifications (like ISO), and customer reviews. Verify their ability to provide consistent quality and timely deliveries. It’s also beneficial to assess their capacity for customization, response times for inquiries, and willingness to accommodate minimum order quantities (MOQ). Establishing a relationship with a reliable supplier is crucial for long-term success. -

How can I ensure the quality of alternator parts from international suppliers?

To ensure quality, request certifications and documentation for each component, such as compliance with international automotive standards. Conduct factory audits if possible, or use third-party inspection services to verify quality before shipment. Additionally, consider implementing a sample approval process where you test a small batch of parts before committing to larger orders. Regular communication with your supplier can also help maintain quality assurance. -

What are the typical payment terms when sourcing alternator parts internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, letters of credit, or net 30-60 days after delivery. Always clarify payment terms before finalizing contracts to avoid misunderstandings. Consider using escrow services for large transactions to protect both parties. Understanding the currency exchange implications and potential tariffs is also essential for budgeting your costs. -

What is the minimum order quantity (MOQ) for alternator parts?

MOQs can differ based on the supplier and the specific parts you are ordering. Typically, they can range from 50 to several hundred units, depending on the type of component and the supplier’s production capabilities. When negotiating, express your requirements and see if the supplier can accommodate smaller orders for initial testing or pilot projects. Building a long-term relationship may also allow for more flexible MOQs over time. -

How can I manage logistics when importing alternator parts?

Effective logistics management involves selecting reliable freight forwarders who specialize in automotive parts. Research shipping options that balance cost and delivery speed, such as air freight for urgent needs or sea freight for larger shipments. Ensure that all customs documentation is prepared in advance to prevent delays at the border. It’s also wise to track shipments closely and establish contingency plans for unexpected delays. -

What customization options are available for alternator parts?

Many suppliers offer customization options such as specific voltage ratings, sizes, or materials to meet unique requirements. Discuss your specifications with potential suppliers to determine their capabilities. Customization may also include branding with your logo or packaging requirements. Be mindful that custom orders can affect lead times and pricing, so plan accordingly to align with your project timelines.

Top 3 Parts Of The Alternator Manufacturers & Suppliers List

1. HowStuffWorks – Alternators

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation and non-magnetization. Key components include:

– Drive pulley attached to the rotor shaft, which converts mechanical energy to electrical power.

– Several terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L termin…

2. AutoElectro – Alternators

Domäne: autoelectro.de

Registriert: 1999 (26 Jahre)

Einleitung: Alternator: Generates energy to feed the electrical system and charge the battery. Works with the battery to supply power for vehicle electrical components. Outputs direct current (DC). Converts alternating current (AC) to DC via a rectifier. Components include: Regulator (controls power distribution), Rectifier (converts AC to DC), Rotor (spinning mass acting as an electromagnet), Slip Rings (pro…

3. Facebook – Parts of Alternator

Strategic Sourcing Conclusion and Outlook for parts of the alternator

In the evolving landscape of automotive components, the strategic sourcing of alternator parts presents a unique opportunity for international B2B buyers. Understanding the intricate functionalities of components like rotors, stators, rectifiers, and voltage regulators is crucial for making informed purchasing decisions. As industries across Africa, South America, the Middle East, and Europe seek to enhance operational efficiency, leveraging high-quality alternator parts can drive significant improvements in vehicle performance and reliability.

Investing in robust sourcing strategies allows buyers to tap into global supply chains, ensuring access to innovative technologies and competitive pricing. Building relationships with reputable suppliers not only guarantees the quality of parts but also fosters collaboration that can lead to tailored solutions for specific market needs.

Looking ahead, businesses should prioritize agility in their sourcing strategies to adapt to changing market demands and technological advancements. By focusing on sustainable practices and fostering partnerships with suppliers who share similar values, buyers can position themselves for long-term success. Engage with leading manufacturers today to secure the essential alternator components that will power your operations into the future.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.

Illustrative image related to parts of the alternator