Introduction: Navigating the Global Market for is it the battery or alternator

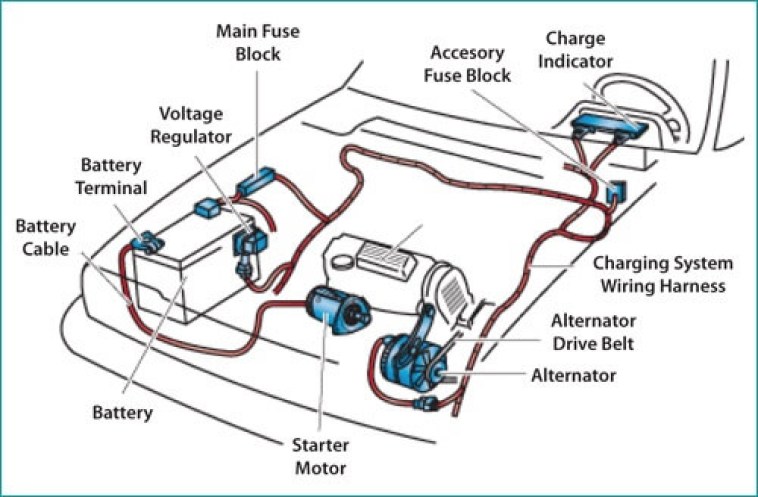

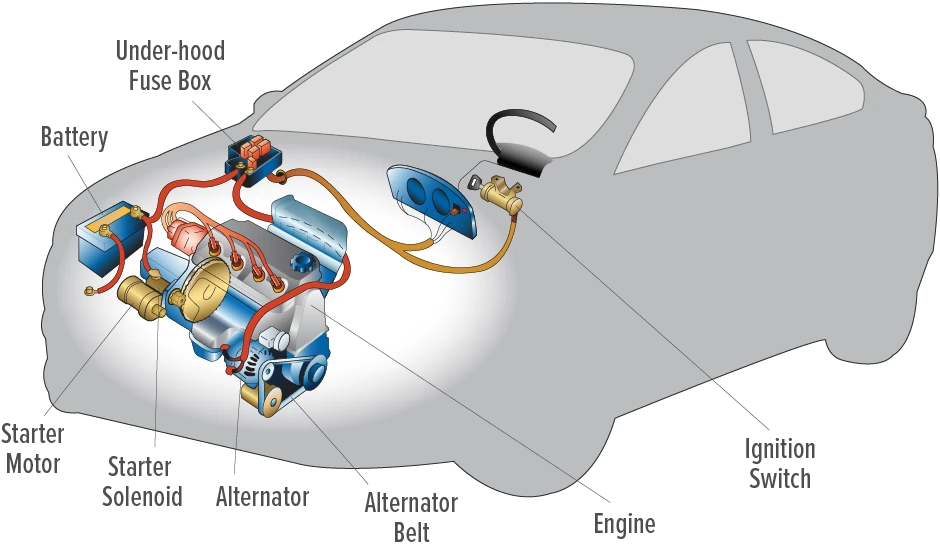

In today’s fast-paced automotive market, discerning whether the issue lies with the battery or alternator can be a significant challenge for international B2B buyers. This guide aims to streamline the decision-making process by providing an in-depth analysis of both components, their functions, and how they interact within the vehicle’s electrical system. Understanding the differences between a malfunctioning battery and a failing alternator is crucial for sourcing reliable parts and ensuring optimal vehicle performance.

The comprehensive scope of this guide includes detailed insights into the types of batteries and alternators available, their applications across various vehicle models, and best practices for supplier vetting. It also addresses cost considerations and provides actionable tips for diagnosing common issues, empowering buyers to make informed purchasing decisions. By focusing on the specific needs of international buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Vietnam—this guide seeks to bridge knowledge gaps and enhance procurement strategies.

Navigating the complexities of the automotive parts market can be daunting, but with the right information at your fingertips, you can confidently assess your options and select the best components for your business needs. Whether you are looking to improve vehicle reliability, reduce downtime, or enhance customer satisfaction, this guide serves as an essential resource for optimizing your supply chain in the automotive sector.

Inhaltsverzeichnis

- Top 2 Is It The Battery Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for is it the battery or alternator

- Understanding is it the battery or alternator Types and Variations

- Key Industrial Applications of is it the battery or alternator

- 3 Common User Pain Points for ‘is it the battery or alternator’ & Their Solutions

- Strategic Material Selection Guide for is it the battery or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for is it the battery or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘is it the battery or alternator’

- Comprehensive Cost and Pricing Analysis for is it the battery or alternator Sourcing

- Alternatives Analysis: Comparing is it the battery or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for is it the battery or alternator

- Navigating Market Dynamics and Sourcing Trends in the is it the battery or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of is it the battery or alternator

- Strategic Sourcing Conclusion and Outlook for is it the battery or alternator

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding is it the battery or alternator Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Blei-Säure-Batterie | Widely used, cost-effective, requires maintenance | Kraftfahrzeuge, Nutzfahrzeuge | Pros: Affordable, easy to source. Cons: Short lifespan, sensitive to temperature. |

| Absorbent Glass Mat (AGM) Battery | Sealed, maintenance-free, better performance in extreme conditions | High-end vehicles, luxury fleets | Pros: Longer lifespan, better deep cycle performance. Cons: Higher initial cost. |

| Lithium-Ionen-Akku | Lightweight, high energy density, longer lifespan | Elektrofahrzeuge, Systeme für erneuerbare Energien | Pros: Efficient, fast charging. Cons: Expensive, requires specialized handling. |

| Alternator with Integrated Voltage Regulator | Combines alternator and voltage regulator into one unit | Heavy-duty trucks, industrial applications | Pros: Space-saving, simplified installation. Cons: More complex repairs if failure occurs. |

| Hochleistungs-Lichtmaschine | Designed for high-demand electrical systems, higher amperage output | Performance vehicles, audio systems | Pros: Supports heavy electrical loads. Cons: Higher cost, may require upgrades to other components. |

What are the Key Features of Lead-Acid Batteries for B2B Buyers?

Lead-acid batteries are the most common type in automotive applications, known for their affordability and availability. They are typically used in a variety of commercial vehicles, including trucks and buses. However, these batteries require regular maintenance and have a shorter lifespan compared to newer technologies. B2B buyers should consider the cost-effectiveness of lead-acid batteries against their operational longevity and maintenance requirements.

How Do AGM Batteries Stand Out in the Market?

Absorbent Glass Mat (AGM) batteries offer a maintenance-free alternative with superior performance in extreme temperatures and deep cycle applications. They are commonly used in high-end vehicles and fleets requiring reliable power. While AGM batteries come with a higher upfront cost, their longevity and efficiency make them a worthwhile investment for businesses prioritizing reliability and performance.

Why Choose Lithium-Ion Batteries for Advanced Applications?

Lithium-ion batteries are gaining traction in the B2B sector, particularly for electric vehicles and renewable energy systems. Their lightweight design and high energy density make them ideal for applications requiring quick charging and long service life. However, the higher initial investment and need for specialized handling may deter some buyers. Companies should evaluate their long-term energy needs to determine if the benefits justify the cost.

What are the Advantages of Alternators with Integrated Voltage Regulators?

Alternators with integrated voltage regulators streamline the electrical system in vehicles, particularly in heavy-duty trucks and industrial applications. This combination reduces the number of components, simplifying installation and maintenance. However, if these units fail, repairs can be more complex and costly. B2B buyers should weigh the benefits of reduced space and installation time against potential repair challenges.

When Should You Consider High-Output Alternators?

High-output alternators are designed for vehicles with significant electrical demands, such as those equipped with advanced audio systems or additional lighting. These alternators provide higher amperage output, ensuring that all electrical components function optimally. While they are more expensive than standard alternators, businesses that require robust electrical systems will find them invaluable. Buyers should also assess compatibility with existing vehicle systems to avoid additional upgrades.

Key Industrial Applications of is it the battery or alternator

| Branche/Sektor | Specific Application of is it the battery or alternator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Power supply for assembly line robots | Ensures uninterrupted production and operational efficiency | Reliability of components, compatibility with existing systems, and local availability of parts. |

| Erneuerbare Energien | Energy storage systems for solar or wind farms | Enhances energy reliability and storage capabilities | Durability in harsh environments, scalability options, and compliance with international standards. |

| Transport & Logistik | Fleet vehicle maintenance and management | Reduziert Ausfallzeiten und Wartungskosten | Availability of diagnostic tools, service agreements, and access to local repair facilities. |

| Telekommunikation | Backup power for cell towers and data centers | Guarantees continuous operation and service availability | Compatibility with existing infrastructure, energy efficiency, and local support for installation and maintenance. |

| Landwirtschaft | Powering irrigation systems and agricultural machinery | Increases productivity and operational reliability | Resistance to environmental conditions, battery life, and local sourcing of replacement parts. |

How is the Battery or Alternator Used in Automotive Manufacturing?

In the automotive manufacturing sector, the battery and alternator play crucial roles in powering assembly line robots and other automated systems. These components ensure that machines operate efficiently without interruptions, which is vital for maintaining production schedules. For international buyers, particularly in regions like Africa and South America, sourcing reliable batteries and alternators that meet local voltage and amperage requirements is essential. Additionally, businesses must consider the availability of compatible parts to facilitate quick repairs and minimize downtime.

What is the Role of Batteries and Alternators in Renewable Energy?

In renewable energy applications, particularly solar and wind farms, batteries are essential for storing energy generated during peak production times for use during low production periods. Alternators are used in hybrid systems to convert mechanical energy into electrical energy. For B2B buyers in regions like the Middle East and Europe, it’s important to source batteries that can withstand extreme weather conditions and have a long life cycle. Buyers should also consider the scalability of energy storage solutions to accommodate future growth.

How Do Batteries and Alternators Impact Transportation & Logistics?

In the transportation and logistics industry, the reliability of fleet vehicles is paramount. Batteries and alternators are critical for maintaining the operational efficiency of vehicles, ensuring they start reliably and are equipped to handle various electrical loads. This is especially important in regions with challenging driving conditions, such as Nigeria and Vietnam. Buyers should prioritize sourcing high-quality components that offer excellent performance and longevity, as well as ensuring access to local repair services to minimize vehicle downtime.

What is the Importance of Backup Power in Telecommunications?

Telecommunications companies rely on batteries and alternators to provide backup power for cell towers and data centers, ensuring uninterrupted service. These components are vital for maintaining operational integrity during power outages. For international buyers, it’s crucial to source equipment that meets local energy regulations and can operate efficiently in diverse climates. Additionally, businesses should look for suppliers that offer robust support and maintenance services to ensure continuous operation.

How Do Batteries and Alternators Enhance Agricultural Operations?

In agriculture, batteries and alternators power irrigation systems and agricultural machinery, significantly improving productivity. Reliable power sources are essential for ensuring that irrigation systems function optimally, especially in areas where water availability is critical. B2B buyers in regions like Africa and South America should focus on sourcing durable components that can withstand harsh environmental conditions and offer long operational life. Furthermore, having access to local suppliers for quick replacement parts is vital for maintaining operational efficiency.

3 Common User Pain Points for ‘is it the battery or alternator’ & Their Solutions

Scenario 1: Diagnosing Electrical System Failures in Fleet Vehicles

Das Problem: Fleet managers often face challenges when their vehicles experience electrical issues, particularly when determining whether the problem lies with the battery or the alternator. These situations can lead to unexpected downtime, impacting service delivery and operational efficiency. For example, a delivery truck might fail to start, leaving packages undelivered and creating a ripple effect on logistics and customer satisfaction. Fleet managers may struggle to pinpoint the issue quickly, leading to costly repairs and extended vehicle inactivity.

Die Lösung: To address this challenge, fleet managers should implement a systematic approach to diagnosing electrical issues. Start by training maintenance personnel to use a multimeter for testing battery voltage and alternator output. A healthy battery should read around 12.6 volts when the engine is off and between 13 to 14.5 volts when the engine is running. Regularly scheduled maintenance checks can include these tests to preemptively identify potential failures. Additionally, keeping spare batteries and alternators on hand can significantly reduce downtime. Establish relationships with reliable suppliers for quick access to replacement parts, ensuring that any electrical issues can be resolved rapidly.

Scenario 2: Educating Employees on Battery and Alternator Maintenance

Das Problem: Many organizations overlook the importance of educating employees about the differences between battery and alternator issues. This lack of knowledge can lead to misdiagnoses, where employees assume a battery is the problem when it may actually be the alternator, or vice versa. For businesses that rely on vehicles, this can result in unnecessary repairs, increased costs, and extended vehicle downtime. Employees may also feel frustrated and confused, leading to decreased morale and productivity.

Die Lösung: To mitigate this issue, businesses should invest in comprehensive training programs that cover the fundamentals of vehicle electrical systems. Workshops or online training modules can help employees understand how to identify symptoms of battery and alternator failures. For instance, teaching them that dimming lights and a clicking sound during startup often indicate a battery issue, while fluctuating voltage readings may point to alternator problems. Providing clear guidelines on when to seek professional assistance can empower employees to make informed decisions, ultimately leading to better maintenance practices and reduced operational costs.

Scenario 3: Managing Supply Chain Challenges for Replacement Parts

Das Problem: B2B buyers in regions such as Africa and South America often encounter supply chain challenges when sourcing replacement batteries and alternators. Fluctuations in availability, shipping delays, and inconsistent quality can hinder timely repairs, especially in industries where vehicle uptime is critical. Buyers may find themselves facing inflated costs or receiving subpar products, leading to further complications in vehicle performance and reliability.

Die Lösung: To navigate these supply chain challenges, businesses should establish partnerships with multiple suppliers to diversify their sources of batteries and alternators. By evaluating suppliers based on their reliability, quality of products, and delivery times, companies can build a more resilient supply chain. Utilizing technology, such as inventory management systems, can also help track usage and predict future needs, ensuring that replacement parts are ordered well in advance. Additionally, developing relationships with local manufacturers can enhance responsiveness and reduce lead times. By proactively managing their supply chain, B2B buyers can minimize the impact of delays and ensure that their vehicles remain operational.

Strategic Material Selection Guide for is it the battery or alternator

What Materials Are Commonly Used in Batteries and Alternators?

When considering the materials used in batteries and alternators, it’s essential to analyze their properties, advantages, disadvantages, and implications for international B2B buyers. The following materials are commonly utilized in these automotive components: lead, lithium, aluminum, and copper.

How Does Lead Impact Battery Performance?

Lead is the traditional material used in lead-acid batteries, which are prevalent in automotive applications.

- Wichtige Eigenschaften: Lead has excellent electrochemical properties and is capable of sustaining high discharge rates, making it ideal for starting applications. It also has a good temperature tolerance, functioning effectively in various climates.

- Vor- und Nachteile: Lead-acid batteries are relatively inexpensive and easy to manufacture. However, they are heavy and have a limited lifespan compared to newer technologies. Additionally, they require regular maintenance to ensure longevity.

- Auswirkungen auf die Anwendung: Lead-acid batteries are suitable for vehicles requiring high current for starting. However, they are less effective in extreme temperatures, which can be a concern in regions with significant climate variations.

- Überlegungen für internationale Käufer: Compliance with environmental regulations regarding lead disposal is crucial. Buyers in regions like Africa and South America should be aware of local laws governing lead usage and recycling.

What Role Does Lithium Play in Battery Technology?

Lithium has gained popularity in recent years, particularly in electric vehicles and advanced automotive applications.

- Wichtige Eigenschaften: Lithium batteries offer high energy density and a longer cycle life. They perform well in a wide temperature range and have low self-discharge rates.

- Vor- und Nachteile: The primary advantage of lithium batteries is their lightweight nature and efficiency. However, they are more expensive to produce and can pose safety risks if not managed properly.

- Auswirkungen auf die Anwendung: Lithium batteries are ideal for applications requiring lightweight and high-performance energy storage, such as electric vehicles. However, they may not be the best choice for traditional combustion engine vehicles.

- Überlegungen für internationale Käufer: Buyers should consider the availability of lithium and the regulatory frameworks surrounding its use. Compliance with standards such as UN 38.3 for lithium battery transport is essential, especially in regions like the Middle East and Europe.

How Is Aluminum Used in Alternator Construction?

Aluminum is commonly used in the construction of alternator housings and components.

- Wichtige Eigenschaften: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it suitable for automotive applications.

- Vor- und Nachteile: The lightweight nature of aluminum contributes to overall vehicle efficiency. However, it is less durable than steel and may not withstand high-stress applications as effectively.

- Auswirkungen auf die Anwendung: Aluminum components can improve the overall performance of alternators by reducing weight, which is critical for fuel efficiency. However, they may require protective coatings to enhance durability.

- Überlegungen für internationale Käufer: Buyers should be aware of the differences in aluminum grades and their compliance with international standards such as ASTM and DIN, particularly in regions with varying industrial regulations.

Why Is Copper Essential in Electrical Connections?

Copper is a critical material for electrical connections in both batteries and alternators.

- Wichtige Eigenschaften: Copper has excellent electrical conductivity, making it ideal for minimizing energy loss in electrical systems. It also has good corrosion resistance when properly treated.

- Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which enhances performance. However, copper is relatively expensive, and its weight can be a drawback in applications where weight savings are critical.

- Auswirkungen auf die Anwendung: Copper connections ensure efficient power transfer between the battery and alternator. Inadequate connections can lead to performance issues, particularly in high-demand applications.

- Überlegungen für internationale Käufer: Buyers should ensure compliance with electrical standards and consider the sourcing of copper, as geopolitical factors can affect availability and pricing, especially in regions like Africa and South America.

Summary Table of Material Selection for Batteries and Alternators

| Material | Typical Use Case for is it the battery or alternator | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Blei | Lead-acid batteries for starting vehicles | Cost-effective and widely available | Schwer und begrenzte Lebensdauer | Niedrig |

| Lithium | Batteries for electric vehicles and advanced applications | High energy density and lightweight | Expensive and safety risks | Hoch |

| Aluminium | Alternator housings and components | Leicht und korrosionsbeständig | Weniger haltbar als Stahl | Mittel |

| Kupfer | Electrical connections in batteries and alternators | Hervorragende elektrische Leitfähigkeit | Relatively expensive and heavy | Mittel |

This analysis provides a comprehensive overview of the materials used in batteries and alternators, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers. By understanding these factors, buyers can make informed decisions that align with their specific application needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for is it the battery or alternator

What Are the Key Stages in the Manufacturing Process of Batteries and Alternators?

The manufacturing processes for batteries and alternators encompass several critical stages, each designed to ensure high-quality end products. Understanding these stages is essential for B2B buyers who want to ensure they source reliable components.

Material Preparation: What Materials Are Used in Batteries and Alternators?

The first step in manufacturing involves sourcing and preparing raw materials. For batteries, this typically includes lead, sulfuric acid, and various additives that enhance performance. In contrast, alternators primarily consist of copper wire, steel, aluminum, and a variety of electronic components. These materials must meet specific standards to ensure performance and safety.

During this phase, suppliers should conduct rigorous testing to verify that materials comply with relevant international standards, such as ISO 9001. This ensures that the materials used are not only high quality but also sustainable and environmentally friendly, which is increasingly important in today’s market.

How Are Batteries and Alternators Formed and Assembled?

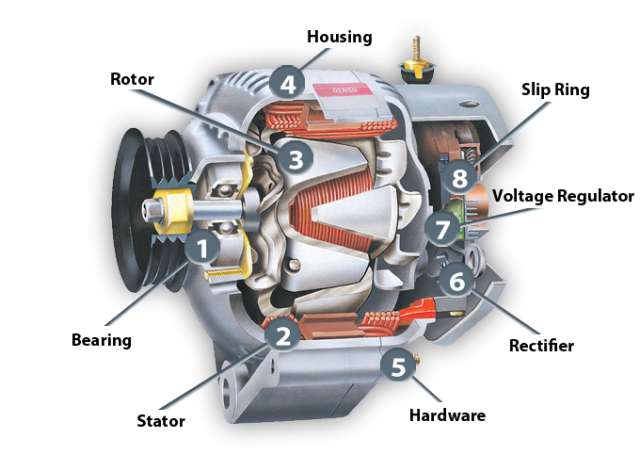

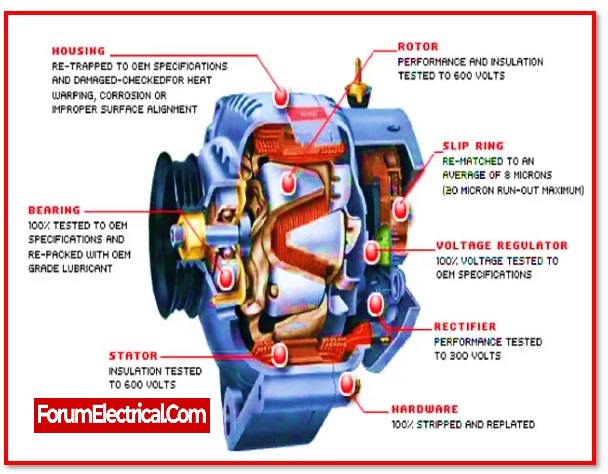

The forming stage involves shaping the raw materials into usable parts. For batteries, this might include the formation of lead plates and the creation of the battery casing. Alternators undergo a similar process where the stator and rotor are assembled. Techniques such as die-casting for aluminum parts and winding for copper coils are commonly employed.

Assembly lines are then utilized to combine these components into finished products. Automation plays a significant role in enhancing efficiency and consistency. However, human oversight remains crucial, particularly for quality-critical assemblies, such as connecting electrical components in alternators.

What Finishing Processes Are Applied to Ensure Quality?

Finishing processes involve applying protective coatings and conducting final inspections. Batteries may undergo acid washing and terminal coating to prevent corrosion, while alternators might receive treatments to enhance durability and resistance to environmental factors.

This stage is crucial for enhancing product longevity and performance. For instance, a well-finished alternator will better withstand heat and vibration, leading to improved reliability.

What Quality Control Measures Are Implemented in Battery and Alternator Manufacturing?

Quality control (QC) is a cornerstone of manufacturing, particularly for components critical to vehicle operation. B2B buyers must understand the various QC checkpoints and international standards that govern these processes.

What International Standards Should Be Considered for Battery and Alternator QC?

ISO 9001 is a widely recognized standard that outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has processes in place to ensure continuous improvement and customer satisfaction. For battery manufacturers, adherence to CE (Conformité Européenne) standards is also vital, particularly for those exporting to European markets.

Additionally, automotive components may need to meet specific industry standards such as API (American Petroleum Institute) for lubricants used within alternators. Understanding these standards can help B2B buyers evaluate potential suppliers more effectively.

Was sind die wichtigsten QC-Kontrollpunkte in der Fertigung?

Quality control is typically segmented into three main checkpoints:

- Eingangsqualitätskontrolle (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process-Qualitätskontrolle (IPQC): During manufacturing, random samples are tested to ensure adherence to quality specifications. This can include visual inspections and functional testing.

- Endkontrolle (FQC): Before products leave the factory, they undergo comprehensive testing to ensure they meet performance standards. This includes electrical testing for alternators and capacity testing for batteries.

These checkpoints help identify defects early in the production process, minimizing waste and ensuring only quality products reach the market.

What Common Testing Methods Are Used for Batteries and Alternators?

Testing methods vary but often include:

- Elektrische Prüfung: For batteries, this involves measuring voltage, capacity, and internal resistance. For alternators, tests typically measure output voltage and current under load.

- Umweltprüfungen: Products may be subjected to temperature and humidity tests to ensure they can withstand extreme conditions.

- Mechanische Prüfung: This includes vibration and shock tests to simulate real-world usage and ensure durability.

B2B buyers should inquire about specific testing methods employed by manufacturers to gain confidence in product reliability.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Verifying supplier quality control is essential for B2B buyers, especially those operating in international markets. Here are some actionable strategies:

What Audit Processes Can Buyers Implement?

Buyers should conduct audits of potential suppliers to assess their manufacturing processes and quality control systems. This can involve:

- Audits vor Ort: Visiting the manufacturing facility to observe processes firsthand and review quality documentation.

- Inspektionen durch Dritte: Engaging independent inspectors to evaluate compliance with international standards and assess product quality.

How Can Buyers Request Quality Reports and Certifications?

Requesting detailed quality reports and certifications can provide insights into a supplier’s commitment to quality. Buyers should ask for documentation related to:

- ISO-Zertifizierungen: Confirming compliance with quality management standards.

- Test Reports: Detailing the outcomes of various tests conducted on products.

- Supplier Quality Assurance (SQA) Documents: Outlining the supplier’s processes for maintaining quality standards.

Was sind die besonderen QC-Erwägungen für internationale Einkäufer?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider additional QC nuances.

Wie wirken sich regionale Standards auf die Qualitätssicherung aus?

Different regions may have specific regulations governing product safety and performance. For instance, the European Union has stringent regulations regarding environmental impact and product safety, which can affect battery and alternator imports. Buyers should familiarize themselves with local regulations to ensure compliance.

What Role Does Cultural Context Play in Quality Expectations?

Cultural differences can influence expectations around quality and service. For example, certain regions may prioritize speed over thoroughness, leading to potential discrepancies in product quality. Establishing clear communication regarding quality expectations can help mitigate these issues.

Illustrative image related to is it the battery or alternator

In summary, understanding the manufacturing processes and quality assurance mechanisms for batteries and alternators is vital for B2B buyers. By focusing on the key stages of production, relevant international standards, and effective verification strategies, buyers can make informed decisions that enhance their supply chain and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is it the battery or alternator’

Einführung

This practical sourcing guide aims to assist B2B buyers in effectively determining whether an issue lies with a vehicle’s battery or alternator. Understanding the distinction is vital for making informed purchasing decisions regarding replacement parts or services. By following this checklist, buyers can navigate the complexities of automotive electrical systems and ensure they procure the right solutions for their needs.

Schritt 1: Identify Your Needs

Before sourcing, clarify whether you require batteries, alternators, or both. This step is critical as it shapes your procurement strategy. Consider factors such as vehicle type, usage patterns, and specific performance requirements.

- Fahrzeugtyp: Different vehicles, from passenger cars to commercial trucks, may require specialized batteries or alternators.

- Usage Patterns: Frequent short trips may lead to battery depletion, influencing your choice of products.

Schritt 2: Definieren Sie Ihre technischen Spezifikationen

Establish clear technical specifications for the products you need. This includes voltage requirements, amperage ratings, and physical dimensions. Accurate specifications ensure compatibility and optimal performance.

Illustrative image related to is it the battery or alternator

- Voltage and Amperage: Ensure your selections meet the voltage output (typically between 12V and 14.5V) and amperage requirements specific to your vehicle.

- Physical Dimensions: Measure available space for installation to avoid compatibility issues.

Schritt 3: Recherche Lieferantennachweise

Conduct thorough research on potential suppliers to verify their credibility. This step is essential to ensure quality and reliability in your purchases.

- Zertifizierungen: Look for suppliers with industry certifications, such as ISO or local standards, which indicate adherence to quality control practices.

- Reputation: Check online reviews and testimonials from other B2B buyers in your region.

Schritt 4: Produktmuster anfordern

Before making bulk purchases, request samples of the batteries or alternators. Testing samples allows you to evaluate quality and performance firsthand.

- Qualitätssicherung: Assess the build quality and performance metrics of the samples to ensure they meet your expectations.

- Compatibility Testing: Verify that the samples work with your vehicles to prevent costly returns or replacements.

Schritt 5: Bewerten Sie Garantie- und Supportoptionen

Examine the warranty terms and after-sales support offered by potential suppliers. A solid warranty can protect your investment and reduce long-term costs.

- Garantiedauer: Look for warranties that cover a reasonable period, typically 1-3 years, which indicates manufacturer confidence in their products.

- Support-Dienstleistungen: Ensure the supplier provides accessible customer support for troubleshooting and claims.

Schritt 6: Preise und Zahlungsbedingungen vergleichen

Gather price quotes from multiple suppliers to compare costs and payment terms. This step is vital for budgeting and ensuring you get the best value for your investment.

- Total Cost of Ownership: Consider not just the initial price but also potential shipping, handling, and installation costs.

- Flexibilität bei der Zahlung: Evaluate payment options that suit your cash flow, such as net terms or installment plans.

Schritt 7: Schließen Sie Ihren Kaufvertrag ab

Once you’ve completed your evaluations, finalize your purchase agreement with the selected supplier. Ensure all terms are clear to avoid misunderstandings.

- Contract Details: Include all specifications, pricing, delivery timelines, and warranty conditions in the agreement.

- Juristische Überprüfung: If necessary, have the contract reviewed by legal counsel to safeguard your interests.

Following this step-by-step checklist will empower B2B buyers to make informed decisions when sourcing batteries and alternators, ultimately leading to improved vehicle performance and reliability.

Comprehensive Cost and Pricing Analysis for is it the battery or alternator Sourcing

What Are the Key Cost Components for Battery and Alternator Sourcing?

Understanding the cost structure for sourcing batteries and alternators is essential for B2B buyers to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materialien: The cost of raw materials significantly influences the overall price. For batteries, lead, sulfuric acid, and plastic are key components, while alternators primarily use copper, aluminum, and steel. Fluctuations in the prices of these materials can lead to variations in sourcing costs.

-

Arbeit: Labor costs vary by region and can be a significant factor in the total cost of production. In regions with higher wage standards, such as Europe, labor costs will likely be higher compared to regions in Africa or South America where labor may be more economical.

-

Fertigungsgemeinkosten: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs, impacting the final pricing of the product.

-

Werkzeuge: Customization of batteries and alternators may require specialized tooling, which can increase initial costs. Buyers should consider whether they need standardized products or if they require bespoke solutions, as this will affect the tooling investment.

-

Qualitätskontrolle (QC): Ensuring that products meet specific quality standards can add to the cost. Batteries and alternators often require rigorous testing to ensure reliability, particularly in demanding environments. Certifications can also influence pricing, as products that meet international quality standards may come at a premium.

-

Logistik: Shipping and handling costs can vary dramatically based on the location of suppliers and buyers. International shipping can add significant costs, particularly for large orders or bulky items like batteries and alternators.

-

Marge: Suppliers will typically add a markup to cover their costs and ensure profitability. This margin can vary based on market competition and the perceived value of the product.

What Factors Influence Pricing in Battery and Alternator Sourcing?

Several factors can influence the pricing of batteries and alternators, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Menge/Mindestbestellmenge: Purchasing in bulk can often lead to significant cost savings. Suppliers may offer discounts for larger orders, so understanding minimum order quantities (MOQ) is crucial for B2B buyers.

-

Spezifikationen und Anpassung: Customized products often come at a premium compared to standard offerings. Buyers should assess their specific needs to balance customization with cost-effectiveness.

-

Materialien und Qualität: The choice of materials directly impacts the durability and performance of batteries and alternators. Higher-quality materials typically lead to higher costs but may offer better long-term value.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to perceived quality, while emerging suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of trade is vital for pricing. Incoterms determine the responsibilities of buyers and sellers in shipping, which can significantly influence total costs.

What Tips Can B2B Buyers Utilize for Cost-Efficiency?

B2B buyers can adopt several strategies to enhance cost-efficiency and negotiate better deals when sourcing batteries and alternators.

Illustrative image related to is it the battery or alternator

-

Verhandlung: Engage in active negotiations with suppliers. Understand the market rates and be prepared to discuss pricing based on volume and long-term partnerships.

-

Gesamtbetriebskosten (TCO): Consider the total cost of ownership, not just the upfront price. A cheaper product may incur higher maintenance or replacement costs, so evaluating the long-term implications is essential.

-

Preisgestaltung für internationale Käufer: International buyers should be aware of additional costs, such as tariffs, taxes, and customs duties, that can affect the overall price. Understanding local regulations and potential trade agreements can lead to better pricing strategies.

-

Vielfalt der Lieferanten: Cultivating relationships with multiple suppliers can provide leverage in negotiations and ensure competitive pricing. This approach can also mitigate risks associated with supply chain disruptions.

-

Marktforschung: Stay informed about market trends and material costs to anticipate pricing changes. This knowledge allows for more strategic purchasing decisions.

In conclusion, a comprehensive understanding of the cost structure and pricing influences related to battery and alternator sourcing can empower B2B buyers to make strategic, informed decisions that optimize their procurement processes.

Alternatives Analysis: Comparing is it the battery or alternator With Other Solutions

Exploring Alternatives to Diagnosing Electrical Issues in Vehicles

In the realm of automotive diagnostics, determining whether the issue lies with the battery or the alternator is a common challenge faced by many vehicle owners and fleet managers. However, there are alternative diagnostic methods and solutions that can provide valuable insights into electrical system failures. This section will compare the traditional approach of diagnosing battery versus alternator issues with two viable alternatives: advanced diagnostic tools and professional automotive services.

Vergleichstabelle

| Vergleichsaspekt | Is It The Battery Or Alternator | Erweiterte Diagnosetools | Professional Automotive Services |

|---|---|---|---|

| Leistung | Effective for basic diagnosis | High accuracy, detailed data | Comprehensive assessment and repair |

| Kosten | Gering bis mäßig | Moderate to high | Hoch |

| Einfache Implementierung | Simple tests with multimeter | Requires some training to use | Minimal effort from the user |

| Wartung | Minimal | Software-Updates erforderlich | Ongoing service costs |

| Bester Anwendungsfall | Quick troubleshooting | Eingehende Analyse für komplexe Themen | Complete diagnostics and repairs |

Detaillierte Aufschlüsselung der Alternativen

Erweiterte Diagnosetools

Advanced diagnostic tools, such as onboard diagnostics (OBD) scanners and multimeters, offer a precise way to assess the vehicle’s electrical system. These tools provide detailed data on various parameters, enabling users to identify faults more effectively than basic tests. While they require an upfront investment and some training to operate, their accuracy can significantly reduce the time spent troubleshooting. However, they may not cover all potential issues, particularly if there are underlying problems not detected by the tool.

Professional Automotive Services

Engaging professional automotive services is another alternative for diagnosing battery or alternator issues. Mechanics have access to sophisticated diagnostic equipment and extensive experience, allowing them to provide a comprehensive assessment of the vehicle. This approach is ideal for complex electrical issues that may not be easily identifiable through standard testing. However, the cost can be significantly higher than self-diagnosis methods, and it requires the vehicle to be brought to a service center, which may not be feasible for all fleet operations.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

When deciding between diagnosing whether the issue is with the battery or alternator versus utilizing alternative solutions, B2B buyers must consider their specific needs and resources. For quick troubleshooting, the traditional method is effective and cost-efficient. However, for more complex issues, investing in advanced diagnostic tools or seeking professional services may yield better long-term results. Ultimately, understanding the operational demands and budget constraints will guide buyers toward the most suitable solution for maintaining their vehicle fleet’s reliability.

Essential Technical Properties and Trade Terminology for is it the battery or alternator

What Are the Key Technical Properties of Batteries and Alternators?

Understanding the essential technical properties of batteries and alternators is crucial for B2B buyers who want to ensure optimal performance and longevity in their applications. Here are several critical specifications to consider:

-

Spannung Ausgang

– Definition: The voltage output of a battery or alternator indicates its ability to provide electrical power. Standard automotive batteries typically have a nominal voltage of 12 volts, while alternators usually output between 13 and 14.5 volts while the engine is running.

– Bedeutung: Inconsistent voltage can lead to poor performance of electrical components, affecting everything from ignition to accessory operation. Ensuring the right voltage output is essential for operational efficiency. -

Kaltstart-Ampere (CCA)

– Definition: CCA measures a battery’s ability to start an engine in cold temperatures. It indicates how many amps a battery can deliver at 0°F for 30 seconds while maintaining at least 7.2 volts.

– Bedeutung: For regions with colder climates, selecting a battery with a higher CCA rating is vital. This specification directly impacts a vehicle’s reliability and performance in adverse weather conditions. -

Nennstromstärke

– Definition: This indicates the maximum current output of an alternator, often ranging from 130 to 400 amps depending on the application.

– Bedeutung: A higher ampere rating allows for more electrical accessories to be powered simultaneously, which is particularly crucial in commercial vehicles that may have additional equipment. -

Zyklus Leben

– Definition: Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity significantly declines.

– Bedeutung: Understanding cycle life helps businesses assess the long-term value of a battery, ensuring that they select products that align with their operational needs and usage patterns. -

Internal Resistance

– Definition: Internal resistance is the opposition to the flow of current within the battery or alternator. Lower resistance typically indicates better performance.

– Bedeutung: High internal resistance can lead to energy loss and inefficient operation. Selecting components with optimal internal resistance can improve overall system efficiency.

What Are Common Trade Terms Used in Battery and Alternator Procurement?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the procurement of batteries and alternators. Here are some common terms:

-

OEM (Originalgerätehersteller)

– Definition: OEM refers to products made by the original manufacturer of the vehicle or equipment, ensuring compatibility and quality.

– Bedeutung: B2B buyers often prefer OEM parts due to their reliability and warranty coverage, which can reduce long-term operational costs. -

MOQ (Mindestbestellmenge)

– Definition: MOQ indicates the smallest quantity of a product that a supplier is willing to sell.

– Bedeutung: Understanding MOQ is crucial for budget planning and inventory management, allowing buyers to avoid excess inventory or stockouts. -

RFQ (Angebotsanfrage)

– Definition: An RFQ is a document sent to suppliers requesting a price quote for specific goods or services.

– Bedeutung: Issuing an RFQ can help B2B buyers obtain competitive pricing and terms, facilitating better purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the transportation and delivery of goods.

– Bedeutung: Familiarity with Incoterms is essential for international transactions, as they clarify shipping costs, risk, and liability, ensuring smoother logistics. -

Vorlaufzeit

– Definition: Lead time is the amount of time it takes from placing an order to receiving the product.

– Bedeutung: Understanding lead times helps businesses plan their inventory and production schedules effectively, minimizing disruptions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding battery and alternator procurement, ultimately enhancing operational efficiency and reducing costs.

Illustrative image related to is it the battery or alternator

Navigating Market Dynamics and Sourcing Trends in the is it the battery or alternator Sector

What Are the Current Market Dynamics and Key Trends in the Battery and Alternator Sector?

The global battery and alternator market is currently influenced by several key drivers, including the increasing demand for electric vehicles (EVs), advancements in automotive technology, and a growing emphasis on energy efficiency. As countries across Africa, South America, the Middle East, and Europe push for greener transportation solutions, the demand for high-performance batteries and efficient alternators is surging. This trend is particularly pronounced in regions like Nigeria and Vietnam, where automotive electrification is gaining momentum.

Emerging B2B tech trends include the adoption of smart battery management systems (BMS) that optimize battery performance and lifespan. This technology is critical for industries that rely on batteries for uninterrupted power supply, from automotive to renewable energy sectors. Additionally, advancements in manufacturing processes, such as the use of lightweight materials and innovative design techniques, are enhancing the efficiency and cost-effectiveness of both batteries and alternators.

International B2B buyers must also be aware of the supply chain dynamics in this sector. Global supply chain disruptions have highlighted the importance of diversifying sourcing strategies to mitigate risks. Buyers are increasingly looking for suppliers who can provide reliable, high-quality products while maintaining flexibility in production and delivery timelines. This adaptability is crucial in a market characterized by rapid technological advancements and shifting consumer preferences.

How Is Sustainability and Ethical Sourcing Addressed in the Battery and Alternator Sector?

Sustainability is becoming a central focus in the battery and alternator sector, driven by the need to minimize environmental impact. The production of batteries, particularly lithium-ion batteries, raises concerns about resource extraction and waste management. Ethical sourcing of raw materials, such as lithium, cobalt, and nickel, is paramount to ensure that supply chains do not contribute to social or environmental degradation. B2B buyers are increasingly demanding transparency from suppliers regarding their sourcing practices and the environmental footprint of their products.

In response, many manufacturers are pursuing ‘green’ certifications and utilizing sustainable materials in their production processes. This includes developing batteries that are easier to recycle and using renewable energy sources for manufacturing. Buyers can leverage these certifications as part of their procurement strategy, ensuring that they not only meet regulatory requirements but also align with their corporate sustainability goals.

Illustrative image related to is it the battery or alternator

Furthermore, the circular economy is gaining traction within the sector. Companies are exploring ways to refurbish and recycle batteries and alternators to extend their lifecycle and reduce waste. Engaging with suppliers who prioritize sustainable practices can enhance a buyer’s brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution and History of the Battery and Alternator Sector?

The evolution of the battery and alternator sector has been marked by significant technological advancements. Initially, lead-acid batteries dominated the market due to their low cost and reliability. However, as the automotive industry shifted towards more efficient and environmentally friendly solutions, lithium-ion batteries emerged as a game-changer. This transition was largely driven by the growing demand for electric vehicles, which require batteries that can deliver higher energy densities and longer lifespans.

Similarly, alternators have evolved from simple mechanical devices to sophisticated electronic systems capable of regulating power output more effectively. Modern alternators are designed to support a wide range of automotive accessories while maximizing energy efficiency. This evolution reflects the broader trends in the automotive sector, where performance and sustainability are increasingly prioritized.

For international B2B buyers, understanding this historical context can provide insights into product development trends and the competitive landscape, aiding in more informed purchasing decisions. As the market continues to evolve, staying abreast of technological advancements will be crucial for those looking to invest in reliable battery and alternator solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of is it the battery or alternator

-

How do I determine whether the problem is with the battery or the alternator?

To diagnose whether the issue lies with the battery or alternator, start by checking the battery voltage using a multimeter. A healthy battery should read around 12.6 volts when fully charged. If the vehicle starts but dies shortly after, it may indicate a failing alternator, as it’s not recharging the battery. Additionally, observe the dashboard warning lights; a battery warning light can signal issues with either component. Testing both components at a local automotive store can provide further clarity. -

What are the common signs of a failing battery?

Common indicators of a failing battery include difficulty starting the vehicle, a clicking sound when turning the key, and dimming headlights or interior lights. If the battery struggles to provide enough power for accessories, it may need replacement. Frequent jump starts can also signal a battery issue, especially if it fails to hold a charge after being charged. Regular maintenance and testing can help prevent unexpected failures. -

What are the key symptoms of a faulty alternator?

Symptoms of a faulty alternator include flickering or dimming lights, especially when the vehicle is idling. If electrical components malfunction or the vehicle exhibits stalling, these could also point to alternator issues. A consistent battery warning light on the dashboard is another critical sign. Testing the alternator’s output voltage—ideally between 13-14.5 volts—can help determine its functionality. -

How can I ensure reliable suppliers for batteries and alternators in international markets?

When sourcing batteries and alternators from international suppliers, prioritize vetting their credentials and certifications. Look for suppliers with a proven track record and positive reviews. Utilize trade platforms and industry networks to gather insights and feedback on potential partners. It’s also beneficial to request samples and conduct quality checks before committing to larger orders, ensuring that the products meet your standards. -

What are typical minimum order quantities (MOQs) for batteries and alternators?

Minimum order quantities (MOQs) can vary significantly among suppliers based on factors such as product type, manufacturer, and shipping considerations. Generally, MOQs for automotive batteries and alternators range from 50 to several hundred units. When negotiating, express your expected volume and inquire about flexible options, especially if you are entering a new market or establishing a partnership. -

What payment terms should I expect when purchasing batteries and alternators internationally?

Payment terms for international purchases typically vary by supplier and region but often include options such as advance payment, letters of credit, or payment upon delivery. It’s essential to clarify these terms upfront and consider using secure payment methods that provide buyer protection. Discussing payment terms early in negotiations can help avoid misunderstandings and ensure a smoother transaction process. -

How can I manage logistics effectively when importing batteries and alternators?

Effective logistics management for importing batteries and alternators involves thorough planning and coordination with freight forwarders. Ensure compliance with international shipping regulations, particularly for hazardous materials like batteries. Choose reliable shipping partners that offer tracking and timely delivery. Additionally, consider warehousing options to reduce lead times and facilitate distribution in your target market. -

What quality assurance measures should I implement when sourcing automotive parts?

Implementing quality assurance measures is crucial when sourcing automotive parts like batteries and alternators. Start by defining clear quality standards that products must meet. Utilize third-party inspections to verify product quality before shipment. Regularly review supplier performance and establish a feedback loop to address any quality issues promptly. Investing in quality assurance can lead to reduced returns and improved customer satisfaction.

Top 2 Is It The Battery Or Alternator Manufacturers & Suppliers List

1. Protyre – Tyres & Battery Services

Domäne: protyre.co.uk

Registriert: 1999 (26 Jahre)

Einleitung: Protyre offers a range of services including battery checks and replacements, with the ability to book appointments online. They provide premium tyres from brands like Michelin, Pirelli, Goodyear, and Bridgestone, as well as mid-range and economy options. Protyre garages also offer MOTs, servicing, vehicle repairs, and free safety checks. Customers can search for local garages and book services by…

2. Alternator Testing – Risks and Techniques

Domäne: mechanics.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It highlights that this method is not recommended as it can damage the vehicle’s electronics and the alternator itself. The alternator is internally regulated, and disconnecting the battery can lead to voltage spikes that may harm sensitive components. Instead, using a multimeter to ch…

Strategic Sourcing Conclusion and Outlook for is it the battery or alternator

In evaluating whether the issue lies with the battery or alternator, B2B buyers must focus on strategic sourcing of quality components to minimize downtime and operational costs. Understanding the distinct functions of these components is crucial; the battery provides the initial power to start the vehicle while the alternator maintains electrical supply and recharges the battery. By implementing regular maintenance checks and utilizing diagnostic tools, businesses can preemptively address issues, ensuring that both batteries and alternators operate efficiently.

Moreover, sourcing from reputable suppliers who offer warranties and reliable customer support can enhance operational reliability across various markets, including Africa, South America, the Middle East, and Europe. Given the diverse climatic and driving conditions in these regions, selecting the right products tailored to local needs can significantly impact vehicle performance and longevity.

As the automotive landscape continues to evolve, staying informed about advancements in battery and alternator technologies will empower businesses to make strategic purchasing decisions. Prioritizing quality and reliability in sourcing will not only reduce repair costs but also enhance overall fleet performance. Engage with trusted suppliers today to secure components that meet your specific operational requirements and drive your business forward.

Illustrative image related to is it the battery or alternator

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.