Einführung: Navigieren auf dem globalen Markt für die Überprüfung eines Starters

Im Bereich der Kfz-Wartung ist es für einen effizienten Fahrzeugbetrieb und die Minimierung von Ausfallzeiten entscheidend zu wissen, wie man einen Anlasser überprüft. Für internationale B2B-Einkäufer, insbesondere in Afrika, Südamerika, dem Nahen Osten und Europa, kann die Beschaffung zuverlässiger Automobilkomponenten eine große Herausforderung darstellen. Dieser Leitfaden bietet einen umfassenden Überblick über die verschiedenen Arten von Startern, ihre Anwendungen und die wichtigsten Methoden zur Prüfung der Funktionalität. Er befasst sich auch mit den Prozessen der Lieferantenüberprüfung, Kostenüberlegungen und Techniken zur Fehlerbehebung.

Um die Komplexität des globalen Marktes für Kfz-Anlasser zu beherrschen, sind nicht nur Kenntnisse, sondern auch umsetzbare Erkenntnisse erforderlich. Käufer lernen, wie sie die Leistung von Anlassern effektiv bewerten können, damit sie fundierte Entscheidungen treffen können, die ihren betrieblichen Anforderungen entsprechen. Vom Verständnis der beteiligten elektrischen Systeme bis hin zur Erforschung der Feinheiten der Prüfstandsprüfung versetzt dieser Leitfaden Unternehmen in die Lage, gängige Probleme im Zusammenhang mit Anlassern mit Zuversicht anzugehen. Durch die Bereitstellung detaillierter Schritte und bewährter Praktiken möchten wir B2B-Einkäufern die notwendigen Werkzeuge an die Hand geben, um ihre Beschaffungsstrategien zu verbessern, betriebliche Risiken zu verringern und letztendlich einen größeren Wert für ihr Unternehmen zu schaffen. Ganz gleich, ob Sie Fuhrparkleiter in Nigeria oder Kfz-Teilehändler in Deutschland sind, dieser Leitfaden soll Sie auf dem Weg zur Optimierung der Anlasserleistung und zur Beschaffung von Qualitätskomponenten unterstützen.

Inhaltsverzeichnis

- Top 3 der Liste der Hersteller & Lieferanten von Anlasser prüfen

- Einführung: Navigieren auf dem globalen Markt für die Überprüfung eines Starters

- Wie man eine Vorspeise überprüft Typen und Variationen

- Wichtige industrielle Anwendungen für die Überprüfung eines Anlassers

- 3 Häufig auftretende Schmerzpunkte bei der Überprüfung eines Anlassers und ihre Lösungen

- Leitfaden zur strategischen Materialauswahl für die Überprüfung eines Starters

- Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für die Überprüfung eines Starters

- Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für die Überprüfung einer Vorspeise‘.’

- Umfassende Kosten- und Preisanalyse für die Überprüfung eines Sourcing-Startups

- Analyse der Alternativen: Vergleich der Überprüfung eines Starters mit anderen Lösungen

- Grundlegende technische Eigenschaften und Fachterminologie für die Überprüfung eines Anlassers

- Navigieren durch Marktdynamik und Beschaffungstrends im Sektor how to check a starter

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zur Überprüfung eines Starters

- Strategische Beschaffung Schlussfolgerung und Ausblick für die Prüfung einer Vorspeise

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Wie man eine Vorspeise überprüft Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Sichtprüfung | Schnelle Beurteilung von Terminals und Anschlüssen | Kfz-Werkstätten, Flottenwartung | Vorteile: Schnelle, kostengünstige Methode. Nachteile: Möglicherweise werden tiefere Probleme übersehen. |

| Elektrische Systemprüfung | Überprüft mit dem Multimeter die Batterie und die Magnetspule | Fahrzeugdiagnose, Kfz-Ausbildung | Vorteile: Genaue Messwerte, identifiziert spezifische Fehler. Nachteile: Erfordert technisches Wissen. |

| Ritzel Kontrolle | Beinhaltet die manuelle Überprüfung der Bewegung des Anlasserritzels | Kleine Werkstätten, DIY-Mechaniker | Vorteile: Einfach zu beheben, wenn es klemmt. Nachteile: Gilt nicht für alle Fahrzeuge. |

| Prüfstandstests | Umfassender Test der Funktionalität des Starters | Automobilzulieferer, Reparaturzentren | Vorteile: Bestätigt den Zustand des Starters. Nachteile: Zeitaufwendig, muss entfernt werden. |

| Schaltungsprüfung | Prüft den Stromfluss zu den Komponenten des Anlassers | Elektrische Reparaturen, Diagnose | Vorteile: Isoliert elektrische Probleme. Nachteile: Kompliziert für Nichtfachleute. |

Was sind die wichtigsten Merkmale der Sichtprüfung für Starter?

Die Sichtprüfung ist die einfachste Methode zur Überprüfung eines Anlassers. Dabei werden die Batteriepole und die Verkabelung auf Korrosion oder lockere Verbindungen untersucht, die häufig die Ursache für Anlasserausfälle sind. Diese Methode eignet sich besonders für Kfz-Werkstätten und Flottenwartungsdienste, bei denen eine schnelle Beurteilung Zeit sparen kann. Es ist zwar eine kostengünstige und schnelle Methode, doch werden dabei möglicherweise keine tiefer liegenden Probleme entdeckt, die eine eingehendere Prüfung erfordern.

Wie funktioniert die Prüfung des elektrischen Systems bei Startern?

Bei der Prüfung des elektrischen Systems werden Werkzeuge wie Multimeter eingesetzt, um die Batteriespannung zu messen und die Funktion der Magnetspule zu überprüfen. Diese Methode ist für die Fahrzeugdiagnose von entscheidender Bedeutung und wird häufig in der Kfz-Ausbildung eingesetzt. Sie gibt einen genauen Einblick in den elektrischen Zustand des Anlassersystems und hilft, bestimmte Fehler zu erkennen. Sie erfordert jedoch ein gewisses Maß an Fachwissen und Vertrautheit mit elektrischen Systemen.

Warum ist die Überprüfung des Ritzels für die Funktion des Anlassers wichtig?

Die Ritzelprüfung konzentriert sich auf die Fähigkeit des Anlasserritzels, ordnungsgemäß ein- und auszukuppeln. Diese Methode ist für kleine Werkstätten und Heimwerker von Vorteil, da sie bei einem klemmenden Ritzel oft schnell Abhilfe schaffen kann. Obwohl diese Technik eine einfache Lösung sein kann, ist sie nicht für alle Fahrzeugtypen geeignet, insbesondere nicht für solche ohne Schaltgetriebe.

Was beinhaltet der Prüfstandstest für Berufsanfänger?

Die Prüfung auf dem Prüfstand ist eine umfassende Methode, bei der der Anlasser aus dem Fahrzeug ausgebaut wird, um seine Funktionsfähigkeit außerhalb der eingebauten Umgebung zu beurteilen. Diese Technik ist für Automobilzulieferer und Reparaturwerkstätten, die eine genaue Beurteilung benötigen, unerlässlich. Sie bestätigt zwar den Betriebszustand des Anlassers, ist aber zeitaufwändig und erfordert technische Kenntnisse für den ordnungsgemäßen Aus- und Einbau.

Wie hilft die Schaltkreisprüfung bei der Diagnose von Anlasserproblemen?

Bei der Prüfung des Stromkreises wird der Stromfluss zu den Anlasserkomponenten überprüft, um sicherzustellen, dass die Magnetspule und der Anlasser mit Strom versorgt werden. Diese Methode ist für elektrische Reparaturen und Diagnosen von entscheidender Bedeutung, da sie es den Technikern ermöglicht, elektrische Probleme effektiv zu isolieren. Obwohl sie wertvolle Informationen über das elektrische System des Anlassers liefert, kann sie für Personen ohne elektrische Fachkenntnisse komplex und schwierig sein.

Wichtige industrielle Anwendungen für die Überprüfung eines Anlassers

| Branche/Sektor | Spezifische Anwendung der Überprüfung eines Anlassers | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Routine-Diagnose von Fahrzeugstartern | Reduziert Ausfallzeiten und Reparaturkosten für Kunden | Qualitätswerkzeuge, Kompatibilität mit verschiedenen Anlassertypen |

| Flottenmanagement | Präventive Wartungskontrollen von Flottenfahrzeugen | Erhöht die Zuverlässigkeit und die betriebliche Effizienz der Fahrzeuge | Großeinkaufsoptionen, langlebige Ausrüstungen |

| Baumaschinen | Prüfung von Startern an schweren Maschinen | Gewährleistet Betriebszeit und Sicherheit auf den Baustellen | Kompatibilität der Ausrüstung, lokale Verfügbarkeit von Teilen |

| Landwirtschaftliche Maschinen | Kontrolle von Startern in Traktoren und Erntemaschinen | Minimiert unerwartete Ausfälle während kritischer Jahreszeiten | Spezialwerkzeuge für Landmaschinen, Schulungen für das Personal |

| Marine Operationen | Prüfung von Startern in Booten und Schiffsausrüstung | Erhöht die Sicherheit und Zuverlässigkeit in Meeresumgebungen | Witterungsbeständige Werkzeuge, Fachwissen über Schiffssysteme |

Wie wird die Frage ‘Wie prüft man einen Anlasser?’ in der Kfz-Reparaturbranche verwendet?

In der Kfz-Reparaturbranche ist die Diagnose von Anlasserproblemen entscheidend für die Aufrechterhaltung der Fahrzeugleistung. Techniker überprüfen routinemäßig Anlasser, um Probleme wie ein defektes Ritzel oder elektrische Probleme zu erkennen. Dieser proaktive Ansatz trägt dazu bei, Ausfallzeiten und Reparaturkosten zu reduzieren und letztlich die Kundenzufriedenheit zu erhöhen. B2B-Einkäufer in diesem Sektor sollten der Beschaffung von hochwertigen Diagnosewerkzeugen, die mit verschiedenen Anlassertypen kompatibel sind, Priorität einräumen, um effiziente und genaue Reparaturen zu gewährleisten.

Welche Rolle spielt die Frage, wie man einen Anlasser überprüft, im Fuhrparkmanagement?

Das Flottenmanagement hängt stark von der Zuverlässigkeit der Fahrzeuge ab. Regelmäßige Kontrollen der Anlasser können unerwartete Ausfälle verhindern und so die betriebliche Effizienz steigern. Durch die Einführung eines systematischen Ansatzes zur Prüfung von Anlassern können Flottenmanager die Lebensdauer von Fahrzeugen verlängern und Wartungspläne optimieren. Käufer sollten die Möglichkeit des Großeinkaufs von Diagnosewerkzeugen und -geräten in Betracht ziehen, um sicherzustellen, dass diese langlebig und für verschiedene Flottenfahrzeuge geeignet sind.

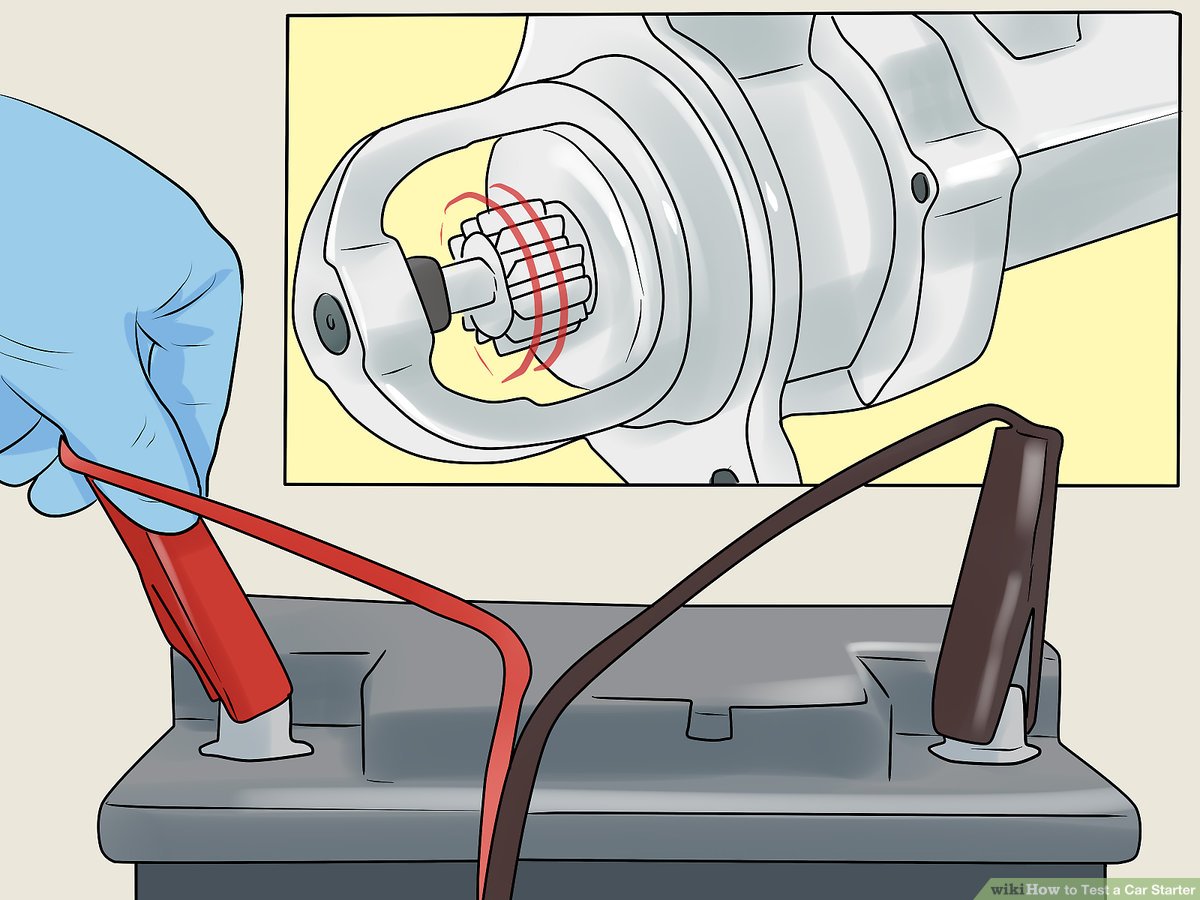

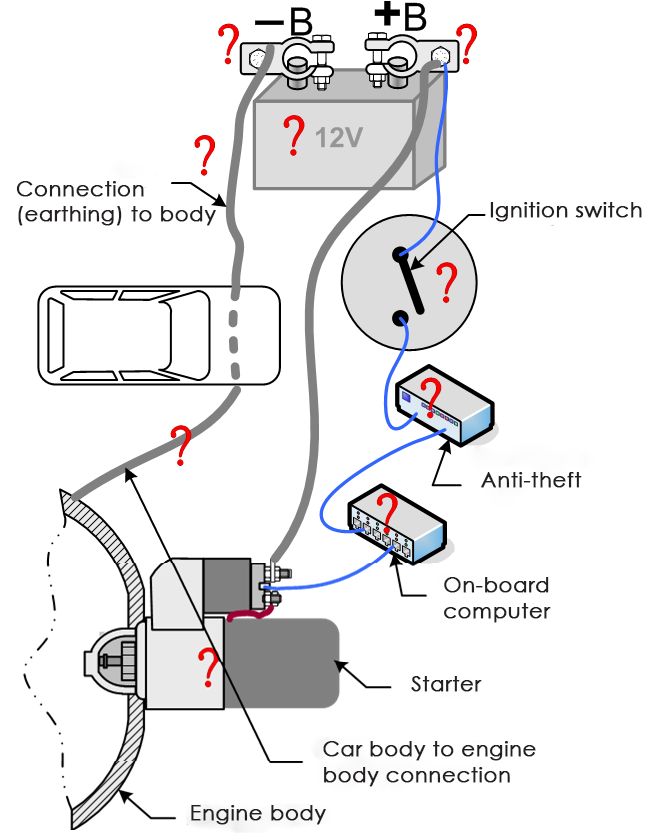

Anschauliches Bild zur Überprüfung eines Starters

Wie wird das Thema ‘Überprüfung eines Anlassers’ in der Baumaschinenindustrie angewendet?

Im Baugewerbe sind schwere Maschinen oft extremen Bedingungen ausgesetzt, so dass Startkontrollen für die Betriebssicherheit und Betriebszeit unerlässlich sind. Regelmäßige Diagnosen helfen, Geräteausfälle zu vermeiden, die Projekte zum Stillstand bringen und erhebliche Kosten verursachen könnten. Unternehmen in diesem Sektor sollten sich auf die Beschaffung von Geräten konzentrieren, die mit verschiedenen Arten von Schwermaschinen kompatibel sind, und gleichzeitig sicherstellen, dass die verwendeten Werkzeuge robust genug sind, um rauen Umgebungen standzuhalten.

Warum ist die Überprüfung eines Anlassers für landwirtschaftliche Maschinen wichtig?

Landmaschinen wie Traktoren und Erntemaschinen benötigen zuverlässige Starter, um während der kritischen Pflanz- und Erntezeiten effektiv zu arbeiten. Regelmäßige Kontrollen können das Risiko unerwarteter Ausfälle minimieren und sicherstellen, dass die Landwirte ihre Arbeit rechtzeitig erledigen können. B2B-Einkäufer sollten nach speziellen Diagnosewerkzeugen für Landmaschinen Ausschau halten und Schulungen für ihre Mitarbeiter in Erwägung ziehen, um deren technische Fähigkeiten in der Anlasserdiagnose zu verbessern.

Welchen Nutzen hat die Überprüfung eines Anlassers für den Schiffsbetrieb?

In der Schifffahrt ist die Zuverlässigkeit von Startern in Booten und Schiffsausrüstungen entscheidend für Sicherheit und Leistung. Routinediagnosen stellen sicher, dass Anlasser ordnungsgemäß funktionieren, und verringern das Risiko von Ausfällen, die zu gefährlichen Situationen auf See führen könnten. Käufer in diesem Sektor sollten der Beschaffung von witterungsbeständigen Werkzeugen und Geräten, die speziell für Schiffssysteme entwickelt wurden, Vorrang einräumen und sicherstellen, dass das Personal für die besonderen Anforderungen von Anlasserprüfungen auf See geschult ist.

3 Häufig auftretende Schmerzpunkte bei der Überprüfung eines Anlassers und ihre Lösungen

Szenario 1: Schwierige Diagnose von Anlasserproblemen bei Flottenfahrzeugen

Das Problem: B2B-Einkäufer, die Flottenfahrzeuge verwalten, stehen oft vor der Herausforderung, Anlasserprobleme effizient zu diagnostizieren. Wenn mehrere Fahrzeuge aufgrund von Anlasserproblemen außer Betrieb sind, kann dies zu erheblichen Ausfallzeiten und Umsatzeinbußen führen. Flottenmanager verfügen möglicherweise nicht über das technische Fachwissen, das erforderlich ist, um jeden Anlasser systematisch zu überprüfen, was zu einer verlängerten Fehlersuche und erhöhten Arbeitskosten führt. Außerdem kann die Inanspruchnahme externer Mechaniker die Reparaturen weiter verzögern und die Zeitplanung erschweren.

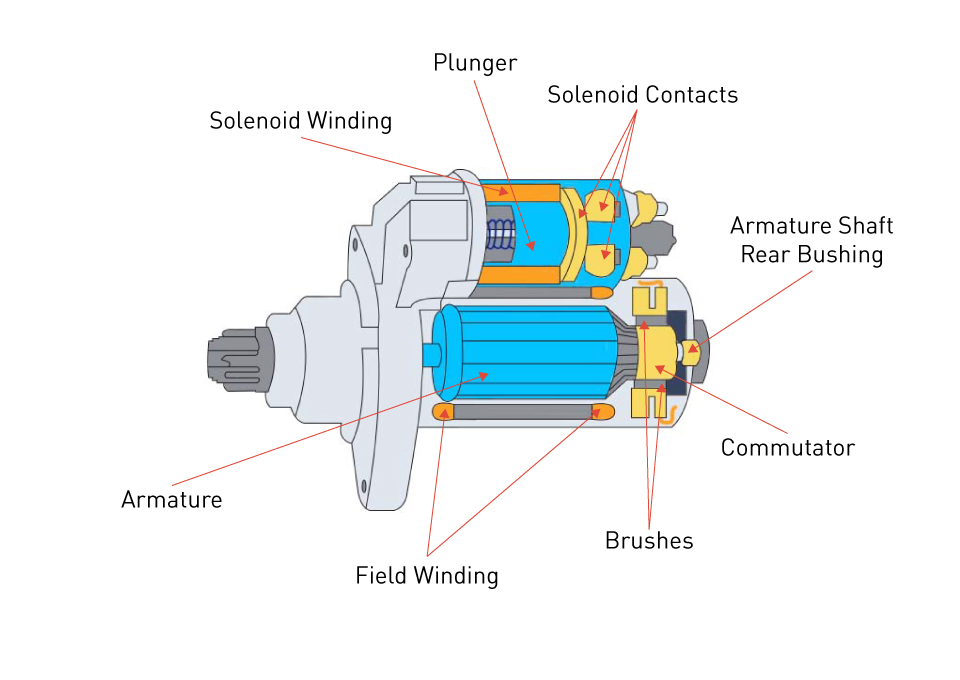

Die Lösung: Um dieses Problem anzugehen, sollten Fuhrparkmanager in Schulungen für ihre Wartungsteams investieren, in denen sie lernen, wie man Anlasserprüfungen durchführt. Dazu gehört das Verständnis der Schlüsselkomponenten von Anlassern, wie Ritzel und Magnetspule, und die Durchführung von Vorprüfungen wie die Überprüfung der Batteriespannung und der elektrischen Anschlüsse. Die Einführung einer standardisierten Checkliste für die Anlasserdiagnose kann den Prozess rationalisieren. Beispielsweise kann die Verwendung eines Multimeters zur Überprüfung der Batteriespannung Zeit und Ressourcen sparen, bevor man davon ausgeht, dass der Anlasser defekt ist. Wenn Wartungsteams mit grundlegenden Werkzeugen für die Prüfung von Anlassern ausgestattet werden, können sie Probleme vor Ort diagnostizieren und beheben, wodurch die Abhängigkeit von externen Diensten verringert wird.

Szenario 2: Beschaffung hochwertiger Ersatzstarter

Das Problem: B2B-Einkäufer tun sich oft schwer mit der Beschaffung zuverlässiger Ersatzanlasser für ihre Fahrzeuge. Der Markt wird von verschiedenen Anbietern überschwemmt, aber nicht alle bieten hochwertige Produkte an, die den spezifischen Anforderungen ihrer Flotten entsprechen. Dies kann dazu führen, dass minderwertige Anlasser gekauft werden, die vorzeitig ausfallen, was zu erhöhten Kosten für Ersatz und Reparaturen sowie zu potenziellen Sicherheitsrisiken im Straßenverkehr führt.

Die Lösung: Um dieses Risiko zu minimieren, sollten Käufer Beziehungen zu seriösen Lieferanten aufbauen, die sich auf Kfz-Teile, insbesondere Anlasser, spezialisiert haben. Eine gründliche Recherche und das Lesen von Kundenrezensionen können helfen, vertrauenswürdige Anbieter zu finden. Käufer sollten auch nach Lieferanten suchen, die Garantien und Gewährleistungen für ihre Produkte anbieten, um sicherzustellen, dass sie fehlerhafte Anlasser ohne zusätzliche Kosten zurückgeben oder umtauschen können. Darüber hinaus kann die Nutzung von Großeinkaufsvereinbarungen zu besseren Preisen und einer konstanten Produktverfügbarkeit führen. Indem sie der Qualität den Vorrang vor dem Preis einräumen, können B2B-Einkäufer sicherstellen, dass sie in langlebige Anlasser investieren, die die Zuverlässigkeit ihres Fuhrparks erhöhen.

Szenario 3: Mangel an geeigneten Werkzeugen und Ressourcen für Startertests

Das Problem: Viele Unternehmen verfügen nicht über die notwendigen Werkzeuge und Ressourcen, um Anlasser effektiv zu prüfen und zu testen, was zu Fehldiagnosen von Problemen und unsachgemäßen Reparaturen führen kann. Ohne Zugang zu Multimetern, Schaltkreistestern oder dem Wissen, wie man sie benutzt, können Wartungsteams nur schwer feststellen, ob ein Anlasser richtig funktioniert oder ob das Problem an einer anderen Stelle des elektrischen Systems liegt. Dieser Mangel an Fähigkeiten kann zu längeren Reparaturzeiten und höheren Kosten führen.

Anschauliches Bild zur Überprüfung eines Starters

Die Lösung: Um diese Herausforderung zu meistern, sollten Unternehmen in einen umfassenden Werkzeugsatz investieren, der speziell für die Kfz-Diagnose entwickelt wurde. Dieses Kit sollte wichtige Werkzeuge wie Multimeter, Schaltkreistester und Überbrückungskabel sowie benutzerfreundliche Anleitungen für die Prüfung von Anlassern enthalten. Darüber hinaus kann eine kontinuierliche Schulung der Techniker im effektiven Umgang mit diesen Werkzeugen ihre Diagnosefähigkeiten verbessern. Ein regelmäßiger Wartungsplan kann ebenfalls dazu beitragen, potenzielle Probleme mit dem Anlasser zu erkennen, bevor sie sich zu größeren Problemen entwickeln. Wenn Unternehmen ihre Teams mit den richtigen Werkzeugen und Kenntnissen ausstatten, können sie ihre betriebliche Effizienz verbessern und die Wahrscheinlichkeit kostspieliger Reparaturen verringern.

Leitfaden zur strategischen Materialauswahl für die Überprüfung eines Starters

Bei der Auswahl von Materialien für Komponenten, die bei der Überprüfung eines Starters zum Einsatz kommen, ist es wichtig, die Eigenschaften zu berücksichtigen, die eine optimale Leistung und Langlebigkeit gewährleisten. Im Folgenden analysieren wir vier gängige Materialien, die in diesem Zusammenhang verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vorteile, Nachteile und spezifischen Überlegungen für internationale B2B-Käufer.

Was sind die wichtigsten Eigenschaften von Stahl in Starterkomponenten?

Stahl ist ein weit verbreiteter Werkstoff für verschiedene Automobilkomponenten, darunter auch Anlasser. Er zeichnet sich durch eine hervorragende Festigkeit und Haltbarkeit aus und ist daher ideal, um den mechanischen Beanspruchungen während des Betriebs standzuhalten. Stahlkomponenten können in der Regel hohe Temperaturen und Drücke aushalten, was für Automobilanwendungen von entscheidender Bedeutung ist.

Vor- und Nachteile: Stahl ist relativ preiswert und weithin verfügbar, was ihn für die Hersteller zu einer kostengünstigen Wahl macht. Allerdings ist er korrosionsanfällig, wenn er nicht ordnungsgemäß behandelt wird, was in feuchten oder korrosiven Umgebungen zu einem vorzeitigen Ausfall führen kann. Außerdem kann die Herstellung aufgrund der erforderlichen Schutzbeschichtungen komplexer werden.

Auswirkungen auf die Anwendung: Aufgrund seiner Verträglichkeit mit verschiedenen Kfz-Medien, wie Ölen und Kraftstoffen, eignet sich Stahl für die Verwendung in Anlasserkomponenten. Der Käufer muss jedoch sicherstellen, dass die verwendete Stahlsorte für die vorgesehene Anwendung geeignet ist.

Überlegungen für internationale Käufer: Käufer aus Regionen wie Afrika und Südamerika sollten sich der lokalen Korrosionsprobleme bewusst sein, während Käufer in Europa möglicherweise die strengen EU-Normen in Bezug auf Emissionen und Materialsicherheit einhalten müssen.

Wie verhält sich Aluminium in Starteranwendungen?

Aluminium ist ein weiteres gängiges Material für Automobilkomponenten, insbesondere bei Leichtbauanwendungen. Es bietet ein günstiges Verhältnis von Festigkeit zu Gewicht und eine ausgezeichnete Korrosionsbeständigkeit, wodurch es sich für Anlassergehäuse und andere Komponenten eignet.

Vor- und Nachteile: Das geringe Gewicht von Aluminium kann die Effizienz und Leistung von Fahrzeugen verbessern. Allerdings ist es in der Regel teurer als Stahl und kann spezielle Herstellungsverfahren erfordern, was die Kosten weiter erhöhen kann.

Auswirkungen auf die Anwendung: Die Korrosionsbeständigkeit von Aluminium ist in Umgebungen mit hoher Luftfeuchtigkeit oder Streusalzeinwirkung, wie sie in vielen Regionen üblich sind, von Vorteil. Seine im Vergleich zu Stahl geringere Festigkeit kann jedoch seine Verwendung bei Anwendungen, die eine hohe mechanische Festigkeit erfordern, einschränken.

Überlegungen für internationale Käufer: In Regionen wie dem Nahen Osten, in denen hohe Temperaturen vorherrschen, können die thermischen Eigenschaften von Aluminium von Vorteil sein. Käufer sollten auch auf die Einhaltung internationaler Normen achten, wie z. B. der ASTM- oder JIS-Normen.

Welche Rolle spielt Kupfer bei den elektrischen Verbindungen von Startern?

Kupfer wird aufgrund seiner hervorragenden Leitfähigkeit hauptsächlich für elektrische Verbindungen in Anlassern verwendet. Es ist unerlässlich für eine effiziente Stromübertragung von der Batterie zum Anlasser.

Vor- und Nachteile: Kupfer hat eine hohe Leitfähigkeit, was die Leistung elektrischer Systeme erhöht. Es ist jedoch anfällig für Korrosion, insbesondere in feuchten Umgebungen, und kann teurer sein als andere leitfähige Materialien wie Aluminium.

Auswirkungen auf die Anwendung: Die Kompatibilität von Kupfer mit verschiedenen elektrischen Systemen macht es zu einer bevorzugten Wahl für Verkabelung und Anschlüsse in Startern. Sein Gewicht kann jedoch bei leichten Fahrzeugkonstruktionen ein Problem darstellen.

Überlegungen für internationale Käufer: Die Käufer sollten sich über die örtlichen Vorschriften für die Verwendung von Kupfer informieren, insbesondere in Regionen mit strengen Recycling- und Umweltstandards. Entscheidend ist auch die Einhaltung der internationalen Normen für elektrische Geräte.

Warum wird Kunststoff in Starterkomponenten verwendet?

Kunststoffe, insbesondere technische Thermoplaste, werden häufig für die Isolierung von Bauteilen und Gehäusen in Startern verwendet. Sie bieten eine hervorragende elektrische Isolierung und können in komplexe Formen gegossen werden.

Anschauliches Bild zur Überprüfung eines Starters

Vor- und Nachteile: Kunststoffe sind leicht und korrosionsbeständig, was die Haltbarkeit von Starterkomponenten erhöhen kann. Allerdings halten sie hohen Temperaturen möglicherweise nicht so gut stand wie Metalle, was ihre Anwendung in bestimmten Bereichen einschränken könnte.

Auswirkungen auf die Anwendung: Die Verwendung von Kunststoffen kann die Gesamteffizienz von Anlassersystemen durch Gewichtsreduzierung verbessern. Die Käufer müssen jedoch sicherstellen, dass der verwendete Kunststoff mit den Flüssigkeiten im Fahrzeug und den Umgebungsbedingungen kompatibel ist.

Überlegungen für internationale Käufer: Käufer sollten auf die Verfügbarkeit bestimmter Kunststofftypen achten, die den internationalen Normen für Automobilanwendungen entsprechen, wie z. B. den DIN- oder ISO-Normen.

Übersichtstabelle zur Materialauswahl für Starterkomponenten

| Material | Typischer Anwendungsfall für die Überprüfung eines Starters | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Anlassergehäuse und mechanische Komponenten | Hohe Festigkeit und Haltbarkeit | Korrosionsanfällig | Niedrig |

| Aluminium | Leichte Startergehäuse | Hervorragende Korrosionsbeständigkeit | Höhere Kosten und komplexere Herstellung | Med |

| Kupfer | Elektrische Anschlüsse und Klemmen | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Kunststoff | Isolierte Bauteile und Gehäuse | Leicht und korrosionsbeständig | Begrenzte Hochtemperaturleistung | Med |

Diese Analyse bietet einen umfassenden Überblick über die Materialauswahl für Komponenten, die an der Überprüfung eines Starters beteiligt sind, zugeschnitten auf die Bedürfnisse internationaler B2B-Einkäufer. Das Verständnis dieser Faktoren kann dabei helfen, fundierte Kaufentscheidungen zu treffen, die mit den regionalen Anforderungen und Normen übereinstimmen.

Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für die Überprüfung eines Starters

Was sind die wichtigsten Schritte im Herstellungsprozess von Startern?

Die Herstellung von Anfängern umfasst mehrere kritische Phasen, die sicherstellen, dass das Endprodukt den betrieblichen Standards und Qualitätserwartungen entspricht. Zu den wichtigsten Phasen gehören die Materialvorbereitung, die Formgebung, die Montage und die Endbearbeitung.

-

Materialvorbereitung

Der Herstellungsprozess beginnt mit der Auswahl hochwertiger Rohstoffe, vor allem Metalle wie Aluminium und Kupfer, die für ihre Leitfähigkeit und Haltbarkeit bekannt sind. Diese Materialien werden einer gründlichen Prüfung unterzogen, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen. So werden beispielsweise Kupferdrähte auf ihre Leitfähigkeit und Aluminiumkomponenten auf ihre Zugfestigkeit geprüft. -

Formung

In dieser Phase werden die vorbereiteten Materialien zu Bauteilen geformt. Üblich sind Techniken wie Stanzen, Schmieden und spanende Bearbeitung. Beim Stanzen werden flache Bauteile aus Blech hergestellt, während beim Schmieden Metall durch Druckkräfte geformt wird. Bei der maschinellen Bearbeitung werden Teile wie das Anlassergehäuse und das Ritzel durch Präzisionsschneiden auf exakte Maße gebracht. -

Montage

Nach der Formgebung werden die Komponenten zum Startgerät zusammengebaut. Dieser Schritt erfordert viel Liebe zum Detail, da bei der Montage oft sowohl manuelle als auch automatische Verfahren zum Einsatz kommen. Komponenten wie die Magnetspule, der Anker und das Gehäuse werden sorgfältig zusammengefügt. Jede Montagestation ist mit Werkzeugen ausgestattet, die sicherstellen, dass die richtigen Drehmomentspezifikationen eingehalten werden, um zukünftige Ausfälle zu vermeiden. -

Endbearbeitung

In der letzten Phase werden die Oberflächen behandelt, um Haltbarkeit und Leistung zu verbessern. Verfahren wie Lackieren, Plattieren oder Beschichten werden zum Schutz vor Korrosion und Verschleiß angewendet. Außerdem wird jeder Anlasser vor Verlassen des Werks einer elektrischen Prüfung unterzogen, um sicherzustellen, dass er korrekt funktioniert.

Wie wird die Qualitätssicherung in der Starterproduktion umgesetzt?

Die Qualitätssicherung (QA) ist ein wesentlicher Bestandteil der Herstellung von Startern und stellt sicher, dass jedes Gerät die Industrienormen erfüllt oder übertrifft. Ein gut strukturierter QS-Prozess umfasst in der Regel die Einhaltung internationaler Normen wie ISO 9001 und branchenspezifische Zertifizierungen wie CE und API.

-

Einschlägige internationale Normen

ISO 9001 bietet einen Rahmen für Qualitätsmanagementsysteme, die auf Kundenzufriedenheit und kontinuierliche Verbesserung ausgerichtet sind. Die Einhaltung dieser Norm ist für Hersteller, die auf internationalen Märkten Fuß fassen wollen, von entscheidender Bedeutung. Die CE-Kennzeichnung zeigt die Konformität mit Gesundheits-, Sicherheits- und Umweltschutznormen an, was für in Europa vermarktete Produkte von entscheidender Bedeutung ist. -

Kontrollpunkte der Qualitätskontrolle

Der QA-Prozess umfasst mehrere Kontrollpunkte:

– Eingangsqualitätskontrolle (IQC): Bei dieser Erstkontrolle wird geprüft, ob die Rohmaterialien den Spezifikationen entsprechen.

– In-Process-Qualitätskontrolle (IPQC): Während der Herstellung werden regelmäßige Kontrollen durchgeführt, um die Prozesse zu überwachen und Fehler frühzeitig zu erkennen.

– Endkontrolle (FQC): Vor dem Verpacken wird jeder Starter umfassenden Tests unterzogen, um sicherzustellen, dass er die Betriebs- und Sicherheitsstandards erfüllt. -

Gängige Prüfmethoden

Um die Funktionsfähigkeit und Sicherheit von Startern zu überprüfen, werden verschiedene Prüfverfahren eingesetzt:

– Elektrische Prüfung: Dazu gehören Spannungs- und Stromprüfungen, um sicherzustellen, dass der Anlasser innerhalb der vorgegebenen Parameter arbeitet.

– Mechanische Prüfung: Um die Langlebigkeit der Produkte zu gewährleisten, werden sie auf ihre Haltbarkeit und Verschleißfestigkeit geprüft.

– Leistungsprüfung: Die Starter werden simulierten Betriebsbedingungen unterzogen, um die Leistung unter Last zu überprüfen.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

B2B-Einkäufer müssen sicherstellen, dass ihre Lieferanten strenge Qualitätskontrollstandards einhalten. Im Folgenden finden Sie praktische Schritte zur Überprüfung der Qualitätskontrollprozesse von Lieferanten:

-

Lieferantenaudits

Die Durchführung von Audits vor Ort ist eine wirksame Methode zur Bewertung der Qualitätskontrollverfahren eines Lieferanten. Während eines Audits können die Einkäufer die Produktionsumgebung bewerten, die Dokumentation überprüfen und die Qualitätskontrollverfahren in Aktion beobachten. -

Überprüfung der Qualitätssicherungsdokumentation

Verlangen Sie Unterlagen zur Qualitätssicherung, einschließlich Qualitätshandbüchern, Prüfberichten und Zertifizierungen. In diesen Unterlagen sollten die vom Lieferanten befolgten Verfahren und Standards detailliert aufgeführt sein. -

Inspektionen durch Dritte

Die Beauftragung von Inspektionsdiensten durch Dritte kann eine unvoreingenommene Bewertung der Qualitätskontrollverfahren des Lieferanten liefern. Diese Dienste können Stichprobenkontrollen durchführen und detaillierte Berichte über die Qualität der hergestellten Produkte erstellen. -

Überprüfung der Zertifizierung

Überprüfen Sie die Echtheit von Qualitätszertifizierungen wie ISO oder CE, indem Sie sich bei den entsprechenden Zertifizierungsstellen erkundigen. So kann sichergestellt werden, dass der Lieferant die internationalen Qualitätsstandards einhält.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

Internationale B2B-Einkäufer, insbesondere aus verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa, stehen vor besonderen Herausforderungen bei der Qualitätskontrolle:

-

Einhaltung gesetzlicher Vorschriften

Es ist wichtig, die rechtlichen Anforderungen in den verschiedenen Regionen zu kennen. Produkte, die in Europa verkauft werden, müssen beispielsweise den CE-Vorschriften entsprechen, während für bestimmte Märkte spezifische lokale Zertifizierungen erforderlich sein können. Käufer sollten sich mit diesen Vorschriften vertraut machen, um Konformitätsprobleme zu vermeiden. -

Kulturelle Unterschiede bei den Qualitätserwartungen

Die kulturellen Vorstellungen von Qualität können von Region zu Region sehr unterschiedlich sein. Einkäufer sollten mit ihren Lieferanten klar über ihre Qualitätserwartungen und -standards kommunizieren, um eine Angleichung sicherzustellen. -

Logistik und Lieferkette

Die Logistik des Transports von Vorspeisen kann sich auf die Qualität auswirken. Die Käufer müssen sicherstellen, dass die Lieferanten ordnungsgemäße Handhabungs- und Verpackungsverfahren anwenden, um Schäden während des Transports zu vermeiden. -

Überlegungen zu Support und Garantie nach dem Verkauf

Vergewissern Sie sich, dass die Lieferanten einen soliden Kundendienst und Garantieoptionen anbieten. Dies ist besonders für internationale Käufer wichtig, da es ihnen Sicherheit in Bezug auf Produktqualität und Leistung gibt.

Wenn B2B-Einkäufer die Herstellungsverfahren und Qualitätssicherungsprotokolle kennen, können sie bei der Beschaffung von Vorspeisen fundierte Entscheidungen treffen und sicherstellen, dass sie zuverlässige Lieferanten auswählen, die hochwertige Produkte liefern.

Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für die Überprüfung einer Vorspeise‘.’

Einführung

Dieser praktische Leitfaden soll B2B-Einkäufern bei der effektiven Beschaffung der erforderlichen Komponenten und des Fachwissens für die Überprüfung von Automobilstartern helfen. Zu wissen, wie die Qualität und Zuverlässigkeit von Anlassersystemen zu bewerten ist, ist entscheidend für die Aufrechterhaltung der Fahrzeugleistung, insbesondere in verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa. Diese Checkliste enthält praktische Schritte, mit denen Sie sicherstellen können, dass Sie die richtigen Produkte und Dienstleistungen für Ihren Bedarf beschaffen.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Bevor Sie mit dem Beschaffungsprozess beginnen, sollten Sie die technischen Spezifikationen für die Anlassersysteme klar umreißen. Ermitteln Sie die spezifischen Fahrzeugmodelle, Motortypen und Anlassermerkmale, die für Ihren Betrieb wichtig sind.

– Warum das wichtig ist: Diese Klarheit hilft den Lieferanten, Ihre Anforderungen zu verstehen und gewährleistet die Kompatibilität mit Ihrem Fuhrpark.

– Worauf Sie achten sollten: Erstellen Sie eine Liste der wichtigsten Merkmale, wie z. B. Spannungswerte, Abmessungen und eventuelle Zertifizierungen, die für die Einhaltung der örtlichen Vorschriften erforderlich sind.

Schritt 2: Potenzielle Lieferanten recherchieren

Führen Sie gründliche Recherchen durch, um Lieferanten zu finden, die sich auf Kfz-Starter spezialisiert haben. Nutzen Sie Branchenverzeichnisse, Online-Plattformen und Fachmessen, um eine Liste potenzieller Partner zu erstellen.

– Warum das wichtig ist: Eine breite Lieferantenbasis erhöht Ihre Chancen, qualitativ hochwertige Produkte zu finden, die Ihren Anforderungen entsprechen.

– Worauf Sie achten sollten: Konzentrieren Sie sich auf Anbieter mit einer nachgewiesenen Erfolgsbilanz, positiven Kundenrezensionen und einer starken Präsenz in den Regionen Ihres Zielmarktes.

Schritt 3: Lieferantenzertifizierungen überprüfen

Vergewissern Sie sich, dass die von Ihnen in die engere Wahl gezogenen Lieferanten über einschlägige Zertifizierungen verfügen und die Branchenstandards einhalten. Zertifizierungen wie ISO, IATF 16949 oder lokale behördliche Zulassungen sind Indikatoren für Qualitätssicherung.

– Warum das wichtig ist: Die Zertifizierungen bestätigen, dass der Lieferant strenge Qualitätsmanagementpraktiken anwendet, was für die Zuverlässigkeit der Produkte entscheidend ist.

– Worauf Sie achten sollten: Fordern Sie Unterlagen an und überprüfen Sie die Echtheit der Bescheinigungen, um mögliche Fallstricke zu vermeiden.

Schritt 4: Bewertung von Produktqualität und Prüfverfahren

Beurteilen Sie die Qualitätskontrollmaßnahmen und Prüfverfahren, die die Lieferanten für ihre Anlassersysteme anwenden. Erkundigen Sie sich nach den Herstellungsprozessen und den verwendeten Materialien.

– Warum das wichtig ist: Hochwertige Komponenten verringern das Ausfallrisiko und verbessern die Gesamtleistung des Fahrzeugs.

– Worauf Sie achten sollten: Fragen Sie nach detaillierten Spezifikationen, Testprotokollen und Garantien, die die Haltbarkeit und Leistung der Starter belegen.

Schritt 5: Muster anfordern und Praxistests durchführen

Fordern Sie vor der endgültigen Auftragsvergabe Muster der Startersysteme zur Bewertung an. Führen Sie Tests auf dem Prüfstand durch, um ihre Funktionalität und Zuverlässigkeit unter realen Bedingungen zu überprüfen.

– Warum das wichtig ist: Durch das Testen von Mustern können Sie mögliche Probleme erkennen, bevor Sie sich zu einem größeren Kauf verpflichten.

– Worauf Sie achten sollten: Überwachen Sie während der Tests Leistungsdaten wie Startgeschwindigkeit, Stromaufnahme und Geräuschpegel.

Schritt 6: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Sobald Sie einen geeigneten Lieferanten gefunden haben, nehmen Sie Verhandlungen auf, um günstige Konditionen zu vereinbaren. Sprechen Sie über Preise, Liefertermine, Zahlungsbedingungen und Kundendienst.

– Warum das wichtig ist: Klare Vereinbarungen schützen Ihre Interessen und sorgen für einen reibungslosen Beschaffungsprozess.

– Worauf Sie achten sollten: Bemühen Sie sich um Transparenz bei allen Aspekten des Geschäfts, einschließlich Vertragsstrafen bei Lieferverzug oder Qualitätsproblemen.

Schritt 7: Aufbau einer langfristigen Beziehung

Erwägen Sie den Aufbau einer langfristigen Beziehung zu dem von Ihnen gewählten Anbieter. Regelmäßige Kommunikation und Zusammenarbeit können zu besseren Preisen, bevorzugtem Support und Zugang zu neuen Technologien führen.

– Warum das wichtig ist: Eine starke Partnerschaft kann Ihre betriebliche Effizienz und Wettbewerbsfähigkeit erheblich steigern.

– Worauf Sie achten sollten: Engagieren Sie Lieferanten, die sich für Kundenservice und Innovation einsetzen, und stellen Sie sicher, dass sie mit Ihren Unternehmenszielen übereinstimmen.

Anhand dieser Checkliste können B2B-Einkäufer die Komplexität der Beschaffung von Anlassersystemen effektiv bewältigen und so eine optimale Leistung und Zuverlässigkeit in ihrem Kfz-Betrieb sicherstellen.

Umfassende Kosten- und Preisanalyse für die Überprüfung eines Sourcing-Startups

Was sind die wichtigsten Kostenfaktoren für die Überprüfung eines Starters?

Bei der Bewertung der Kosten, die mit der Prüfung eines Starters verbunden sind, müssen mehrere Schlüsselkomponenten berücksichtigt werden. Dazu gehören Material, Arbeit, Fertigungsgemeinkosten, Werkzeuge, Qualitätskontrolle, Logistik und Gewinnspannen.

-

Materialien: Zu den wichtigsten Materialien, die für die Prüfung eines Anlassers benötigt werden, gehören Kabel, Steckverbinder und Prüfgeräte wie Multimeter und Schaltkreistester. Je nach Komplexität des Anlassersystems können zusätzliche Komponenten erforderlich sein, was sich auf die Gesamtmaterialkosten auswirken kann.

-

Arbeit: Die Arbeitskosten variieren erheblich, je nachdem, welche Fachkenntnisse für die Prüfung von Startern erforderlich sind. Für qualifizierte Techniker können höhere Löhne gezahlt werden, insbesondere in Regionen mit einer starken Kfz-Service-Industrie. Die Arbeitskosten sollten sowohl die direkte Arbeit (die Zeit, die für das Prüfen und Reparieren aufgewendet wird) als auch die indirekte Arbeit (Hilfspersonal, Verwaltungsaufgaben) umfassen.

-

Fertigungsgemeinkosten: Dazu gehören die Kosten für Einrichtungen, Versorgungsleistungen und die Wartung der Ausrüstung. Die Gemeinkosten können je nach Standort und Größe des Betriebs stark variieren. So kann eine Werkstatt in einem Ballungsgebiet höhere Gemeinkosten haben als eine Werkstatt in einer ländlichen Umgebung.

-

Werkzeuge: Spezialwerkzeuge, die für die Prüfung von Anlassern erforderlich sind, können die Anfangsinvestition erhöhen. Dazu gehört auch die Ausrüstung für die Prüfung von Startern auf dem Prüfstand, die erhebliche Vorlaufkosten verursachen kann, aber für eine genaue Diagnose entscheidend ist.

-

Qualitätskontrolle (QC): Es ist von entscheidender Bedeutung, dass der Prüfprozess den Industriestandards entspricht. Die Kosten für die Qualitätskontrolle können Inspektionen, Zertifizierungen und die Einhaltung lokaler Vorschriften umfassen, die in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa unterschiedlich sein können.

-

Logistik: Wenn Teile oder Komponenten von verschiedenen Standorten aus beschafft werden müssen, können die Logistikkosten ein wesentlicher Faktor werden. Dazu gehören Versand, Zollgebühren und Lagerhaltung, insbesondere für internationale Käufer.

-

Marge: Schließlich schlagen die Anbieter in der Regel eine Marge auf, um ihre Kosten zu decken und einen Gewinn zu erzielen. Diese Marge kann je nach Wettbewerb, Marktnachfrage und dem wahrgenommenen Wert der Dienstleistung variieren.

Was beeinflusst die Preisgestaltung auf dem Markt für Startertests?

Mehrere Faktoren können die Preise für Dienstleistungen im Zusammenhang mit der Überprüfung eines Starters beeinflussen. Die Kenntnis dieser Faktoren kann den Käufern helfen, bessere Bedingungen auszuhandeln und Kosteneffizienz zu gewährleisten.

-

Menge/Mindestbestellmenge: Der Einkauf in großen Mengen kann oft zu erheblichen Rabatten führen. Einkäufer sollten ihren Bedarf prüfen und überlegen, ob sie sich auf Mindestbestellmengen festlegen können, um bessere Preise zu erzielen.

-

Spezifikationen/Anpassung: Maßgeschneiderte Lösungen können höhere Kosten verursachen. Käufer sollten ihre spezifischen Bedürfnisse im Vorfeld klären, um unerwartete Ausgaben im späteren Verlauf des Beschaffungsprozesses zu vermeiden.

-

Materialien und Qualitätszertifizierungen: Die Qualität der verwendeten Materialien kann den Preis erheblich beeinflussen. Lieferanten, die zertifizierte Produkte anbieten, verlangen möglicherweise einen Aufpreis, der sich jedoch häufig in einer höheren Zuverlässigkeit und Leistung niederschlägt.

-

Lieferantenfaktoren: Der Ruf des Lieferanten, seine Zuverlässigkeit und sein Kundenservice können den Preis beeinflussen. Etablierte Lieferanten können aufgrund ihrer nachgewiesenen Erfolgsbilanz höhere Preise verlangen, während neue Marktteilnehmer niedrigere Preise anbieten könnten, um Marktanteile zu gewinnen.

-

Incoterms: Das Verständnis der internationalen Versandbedingungen ist für Käufer von entscheidender Bedeutung, da diese die Gesamtkosten beeinflussen können. Unterschiedliche Incoterms (wie FOB, CIF usw.) bestimmen, wer die Versandkosten und -risiken trägt, was sich auf den Endpreis auswirkt.

Welche Tipps können Käufern helfen, bessere Preise zu verhandeln?

Für internationale B2B-Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, können verschiedene Strategien die Verhandlungsergebnisse verbessern:

-

Führen Sie Marktforschung durch: Die Kenntnis der Marktlandschaft und der Vergleich von Preisen mehrerer Anbieter können Einkäufer in die Lage versetzen, effektiv zu verhandeln.

-

Fokus auf Gesamtbetriebskosten (TCO): Betonen Sie die langfristigen Einsparungen durch Qualitätsprodukte und nicht nur die anfänglichen Kosten. Dieser Ansatz kann höhere Anfangsinvestitionen rechtfertigen, wenn er zu niedrigeren Wartungskosten führt.

-

Beziehungen aufbauen: Der Aufbau eines guten Verhältnisses zu den Lieferanten kann zu besseren Konditionen führen. Langfristige Beziehungen können zu Treuerabatten und Vorzugsbehandlung führen.

-

Seien Sie transparent in Bezug auf Ihre Bedürfnisse: Teilen Sie Ihre Anforderungen klar und deutlich mit, um Missverständnisse zu vermeiden, die zu zusätzlichen Kosten führen könnten. Transparenz trägt zur Vertrauensbildung bei und kann Lieferanten dazu bewegen, wettbewerbsfähigere Preise anzubieten.

Schlussfolgerung

Während Richtpreise stark variieren können, ist das Verständnis der Kostenstruktur und der Preiseinflüsse für eine effektive Beschaffung auf dem Markt für Startertests unerlässlich. Durch die Nutzung dieser Erkenntnisse können B2B-Einkäufer fundierte Entscheidungen treffen, die mit ihren betrieblichen Anforderungen und Budgetvorgaben übereinstimmen.

Analyse der Alternativen: Vergleich der Überprüfung eines Starters mit anderen Lösungen

Erkundung alternativer Methoden für Startertests

Wenn ein Fahrzeug nicht anspringt, kann das Wissen um die verschiedenen Methoden zur Überprüfung eines Anlassers B2B-Käufer in die Lage versetzen, fundierte Entscheidungen zu treffen. Während der herkömmliche Ansatz eine manuelle Prüfung beinhaltet, können alternative Lösungen, die Technologie nutzen, Effizienz und Präzision bieten. Im Folgenden vergleichen wir die herkömmliche Methode zur Überprüfung eines Anlassers mit zwei Alternativen: der Verwendung eines Diagnosegeräts und der Inanspruchnahme eines mobilen Mechanikerdienstes.

Anschauliches Bild zur Überprüfung eines Starters

Vergleichstabelle

| Vergleichsaspekt | Überprüfung eines Anlassers | Diagnosewerkzeug | Mobiler Mechanikerdienst |

|---|---|---|---|

| Leistung | Zuverlässig, aber arbeitsintensiv | Hohe Genauigkeit, schnelle Ergebnisse | Variabel je nach Techniker |

| Kosten | Niedrig (meist DIY) | Mäßig (Werkzeugkauf) | Hoch (Servicegebühr) |

| Einfache Implementierung | Erfordert mechanische Kenntnisse | Benutzerfreundlich, minimale Schulung erforderlich | Bequem, kein Werkzeug erforderlich |

| Wartung | Gering (gelegentliche Inspektionen) | Mittel (Software-Aktualisierungen) | Keine (Dienst auf Abruf) |

| Bester Anwendungsfall | Heimwerker, Basisdiagnostik | Schnelle Diagnose in Geschäften | Wenn professionelle Hilfe benötigt wird |

Eingehende Analyse von Alternativen

Diagnosewerkzeug

Die Verwendung eines Diagnosewerkzeugs ist eine effiziente Methode zur Beurteilung von Anlasserproblemen. Diese Geräte werden an das On-Board-Diagnosesystem (OBD) eines Fahrzeugs angeschlossen und können Probleme durch das Lesen von Fehlercodes schnell identifizieren. Der Hauptvorteil liegt in der Schnelligkeit und Genauigkeit der Diagnose, die die Ausfallzeiten erheblich reduzieren kann. Die Erstinvestition in ein hochwertiges Diagnosewerkzeug kann jedoch moderat ausfallen, und die Benutzer benötigen möglicherweise eine gewisse Schulung, um die Ergebnisse effektiv zu interpretieren. Für Unternehmen mit einer Fahrzeugflotte kann diese Methode die Wartung rationalisieren und die Zuverlässigkeit gewährleisten.

Mobiler Mechanikerdienst

Die Beauftragung eines mobilen Mechanikerdienstes bietet Komfort und Fachwissen, ohne dass der Käufer in Werkzeuge oder mechanische Kenntnisse investieren muss. Die Techniker kommen zum Standort des Fahrzeugs, diagnostizieren das Problem und führen die Reparatur oft vor Ort durch. Diese Lösung ist besonders für Unternehmen von Vorteil, die sich keine Ausfallzeiten aufgrund von Fahrzeugproblemen leisten können. Allerdings können die Kosten je nach Dienstleister und Komplexität des Problems hoch sein. Auch die unterschiedlichen Qualifikationen der Techniker können zu uneinheitlichen Ergebnissen führen, weshalb es wichtig ist, einen seriösen Dienst zu wählen.

Die richtige Wahl für Ihre Geschäftsbedürfnisse

Die Wahl der richtigen Methode zur Überprüfung eines Anlassers hängt von verschiedenen Faktoren ab, darunter Budget, Fachwissen und Dringlichkeit der Situation. Für Unternehmen, die über qualifiziertes Personal und ein knappes Budget verfügen, kann die traditionelle Methode zur Überprüfung des Anlassers ausreichen. Für Unternehmen, die Wert auf Effizienz und schnelle Durchlaufzeiten legen, kann die Investition in ein Diagnosewerkzeug dagegen von Vorteil sein. Für diejenigen schließlich, die Bequemlichkeit und professionelle Aufsicht bevorzugen, könnte ein mobiler Mechanikerdienst die ideale Lösung sein. Letzten Endes wird das Verständnis der spezifischen Anforderungen Ihres Betriebs Sie zu der am besten geeigneten Wahl für Ihre Fahrzeugwartungsanforderungen führen.

Grundlegende technische Eigenschaften und Fachterminologie für die Überprüfung eines Anlassers

Was sind die wichtigsten technischen Eigenschaften, die bei der Prüfung eines Anlassers zu beachten sind?

Bei der Bewertung eines Starters nach Leistung und Zuverlässigkeit müssen mehrere kritische technische Eigenschaften berücksichtigt werden. Diese Spezifikationen beeinflussen nicht nur die Funktionalität des Anlassers, sondern wirken sich auch auf die Beschaffungsentscheidungen von B2B-Käufern aus.

-

Werkstoffgüte

Die Qualität der in einem Anlasser verwendeten Materialien wirkt sich erheblich auf seine Haltbarkeit und Leistung aus. Zu den gängigen Materialien gehören Edelstahl für das Gehäuse und Kupfer für die Wicklungen. Bei B2B-Geschäften stellt die Kenntnis der Materialqualität sicher, dass Sie Anlasser beschaffen, die rauen Bedingungen standhalten, insbesondere in Regionen mit extremen Klimabedingungen. -

Toleranzwerte

Die Toleranz bezieht sich auf die zulässige Abweichung der Abmessungen während der Herstellung. Hohe Toleranzwerte sind entscheidend für Komponenten wie das Ritzel, das genau auf das Schwungrad des Motors abgestimmt sein muss. Für die Käufer ist es für die Kompatibilität und Leistung von entscheidender Bedeutung, dass die Hersteller strenge Toleranzwerte einhalten, um das Risiko von Frühausfällen zu verringern. -

Nennspannung

Anlasser arbeiten in der Regel mit bestimmten Spannungen, in der Regel 12 V oder 24 V in Kraftfahrzeugen. Die Kenntnis der Nennspannung ist für die Kompatibilität mit dem elektrischen System des Fahrzeugs entscheidend. B2B-Käufer müssen sicherstellen, dass die Anlasser die Spannungsanforderungen erfüllen, um Leistungsprobleme oder elektrische Ausfälle zu vermeiden. -

Drehmoment-Spezifikationen

Die Drehmomentangaben geben die Drehkraft an, die der Anlasser zum Anlassen des Motors aufbringen kann. Für größere Motoren oder solche mit höherem Verdichtungsverhältnis sind höhere Drehmomentwerte erforderlich. Für internationale Käufer ist die Kenntnis der Drehmomentspezifikationen entscheidend für die Auswahl des richtigen Anlassers für verschiedene Fahrzeugtypen, insbesondere in Märkten mit unterschiedlichen Motorkonstruktionen. -

Stromaufnahme

Die Stromaufnahme bezieht sich auf die Menge des elektrischen Stroms, den der Anlasser während des Betriebs verbraucht. Diese Eigenschaft ist wichtig für die Beurteilung der Effizienz des Anlassers und seiner Auswirkungen auf die Lebensdauer der Fahrzeugbatterie. Käufer müssen die Stromaufnahme berücksichtigen, um sicherzustellen, dass der Anlasser die Batterie nicht überlastet, insbesondere in Regionen, in denen die Verfügbarkeit der Batterie ein Problem darstellen kann.

Was sind gängige Handelsbegriffe bei der Beschaffung von Start-ups?

Das Verständnis der branchenspezifischen Terminologie ist entscheidend für eine effektive Kommunikation und Entscheidungsfindung bei B2B-Transaktionen im Zusammenhang mit Anfängern. Hier sind die wichtigsten Begriffe, mit denen Käufer vertraut sein sollten:

Anschauliches Bild zur Überprüfung eines Starters

-

OEM (Originalgerätehersteller)

OEM-Teile sind Komponenten, die vom Fahrzeughersteller hergestellt werden. Für die Käufer bedeutet die Beschaffung von OEM-Anlassern oft Kompatibilität und Zuverlässigkeit, da diese Teile den Spezifikationen des Herstellers entsprechen. Das Verständnis von OEM-Produkten kann bei Kaufentscheidungen helfen und das Vertrauen in die Produktqualität stärken. -

MOQ (Mindestbestellmenge)

MOQ bezieht sich auf die kleinste Menge eines Produkts, die ein Lieferant zu verkaufen bereit ist. Dieser Begriff ist für B2B-Einkäufer von wesentlicher Bedeutung, da er sich auf die Bestandsverwaltung und den Cashflow auswirken kann. Die Kenntnis der MOQ hilft Einkäufern, ihre Beschaffungsstrategien effektiv zu planen, insbesondere in Regionen, in denen Großeinkäufe üblich sind. -

RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preise und Bedingungen für eine bestimmte Menge von Waren anzufordern. Dieser Prozess ist für B2B-Einkäufer unerlässlich, um Angebote zu vergleichen und bessere Angebote auszuhandeln. Die Vertrautheit mit Ausschreibungen stellt sicher, dass Einkäufer ihre Bedürfnisse effektiv kommunizieren und wettbewerbsfähige Preise erzielen können. -

Incoterms (Internationale Handelsklauseln)

Incoterms sind eine Reihe von Regeln, die die Verantwortlichkeiten von Käufern und Verkäufern bei internationalen Transaktionen festlegen. Diese Bedingungen klären, wer für Versand, Versicherung und Zölle verantwortlich ist. Die Kenntnis der Incoterms ist für B2B-Einkäufer von entscheidender Bedeutung, insbesondere wenn sie Vorprodukte von internationalen Lieferanten beziehen, da sie dazu beitragen, Risiken und Missverständnisse in der Logistik zu minimieren. -

Garantiezeitraum

Die Garantiezeit ist der Zeitraum, in dem ein Hersteller die Leistung des Anlassers garantiert. Dieser Begriff ist für Käufer entscheidend, da er das Vertrauen des Herstellers in sein Produkt ausdrückt. Eine längere Garantiezeit deutet oft auf eine höhere Qualität und Zuverlässigkeit hin, was für Unternehmen, die auf die Betriebszeit ihrer Fahrzeuge angewiesen sind, von entscheidender Bedeutung ist.

Wenn B2B-Einkäufer diese technischen Eigenschaften und Handelsbegriffe kennen, können sie bei der Beschaffung von Vorspeisen fundierte Entscheidungen treffen und sicherstellen, dass sie Produkte auswählen, die ihren betrieblichen Anforderungen und Standards entsprechen.

Navigieren durch Marktdynamik und Beschaffungstrends im Sektor how to check a starter

Was sind die aktuelle Marktdynamik und die Beschaffungstrends im Starter-Sektor?

Der Weltmarkt für Automobilstarter wird von mehreren Schlüsselfaktoren beeinflusst, insbesondere da sich die Branche in Richtung Elektrifizierung und fortschrittliche Fahrzeugtechnologien bewegt. In Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa steigt die Nachfrage nach zuverlässigen Startersystemen, angetrieben durch den wachsenden Fahrzeugbestand und das zunehmende Bewusstsein für die Fahrzeugwartung. Internationale B2B-Einkäufer konzentrieren sich jetzt auf die Beschaffung hochwertiger Komponenten, die nicht nur die Leistungsstandards erfüllen, sondern auch mit den sich entwickelnden Automobiltechnologien übereinstimmen.

Ein aufkommender Trend ist die Integration intelligenter Technologien in Starter, einschließlich Diagnosefunktionen, die es dem Benutzer ermöglichen, Probleme aus der Ferne zu beheben. Dies ist besonders wertvoll für Käufer in Regionen, in denen das technische Fachwissen begrenzt sein kann. Darüber hinaus hat das Aufkommen von E-Commerce-Plattformen die Beschaffungspraktiken verändert und ermöglicht es Einkäufern aus verschiedenen geografischen Regionen, auf eine breitere Palette von Lieferanten und Produkten zuzugreifen. Mit der zunehmenden Verbreitung digitaler Tools wird von B2B-Einkäufern erwartet, dass sie die Datenanalyse für eine bessere Lieferantenbewertung und Bestandsverwaltung nutzen.

Darüber hinaus wird die Nachhaltigkeit zu einem entscheidenden Kriterium bei Beschaffungsentscheidungen. Einkäufer suchen zunehmend nach Lieferanten, die umweltfreundliche Praktiken nachweisen können, wie z. B. die Verwendung von recycelbaren Materialien oder die Einführung energieeffizienter Fertigungsverfahren. Dieser Trend ist in Europa besonders ausgeprägt, wo die gesetzlichen Rahmenbedingungen die Nachhaltigkeit in der Automobilherstellung fördern.

Welchen Einfluss hat die Nachhaltigkeit auf die Beschaffung in der Starterbranche?

Das Thema Nachhaltigkeit gewinnt in der Automobilindustrie zunehmend an Bedeutung, zumal die Verbraucher umweltfreundlichere Produkte fordern. Für B2B-Einkäufer in der Einstiegsbranche ist das Verständnis der Umweltauswirkungen von Beschaffungsentscheidungen von entscheidender Bedeutung. Die Automobilindustrie trägt erheblich zu den Kohlendioxidemissionen bei, was zu einer Verlagerung hin zu nachhaltigeren Praktiken in der gesamten Lieferkette geführt hat.

Die ethische Beschaffung wird zunehmend als entscheidende Komponente der Unternehmensverantwortung anerkannt. Einkäufer werden ermutigt, Lieferanten zu suchen, die Umweltstandards einhalten und Zertifizierungen vorweisen können, die ihr Engagement für Nachhaltigkeit belegen. Dazu gehören die Einhaltung der ISO 14001-Normen für das Umweltmanagement und die Beschaffung von Materialien, die als ‘grün’ oder ‘umweltfreundlich’ zertifiziert sind.

Darüber hinaus gewinnt die Verwendung von recycelten Materialien bei der Herstellung von Startern an Bedeutung. Käufer sollten nach Herstellern Ausschau halten, die recycelte Metalle und andere Komponenten verwenden, da dies nicht nur den Abfall reduziert, sondern auch den mit der Produktion verbundenen CO2-Fußabdruck minimiert. Im Zuge der Marktentwicklung werden Unternehmen, die bei ihren Beschaffungsstrategien der Nachhaltigkeit Priorität einräumen, wahrscheinlich einen Wettbewerbsvorteil erlangen und umweltbewusste Verbraucher und Partner gleichermaßen ansprechen.

Was ist der historische Kontext der Startertechnologien und ihrer Entwicklung?

Der Anlasser hat seit seinen Anfängen im frühen 20. Jahrhundert erhebliche Fortschritte gemacht. Ursprünglich als einfacher Elektromotor konzipiert, hat sich die Technologie weiterentwickelt und umfasst heute hochentwickelte Funktionen wie Magnetspulen und integrierte elektronische Steuereinheiten. Diese Entwicklung wurde durch den Bedarf an höherer Zuverlässigkeit und Effizienz in Automobilsystemen vorangetrieben.

In der Vergangenheit war das manuelle Anlassen die Standardmethode zum Starten von Motoren, aber die Einführung elektrischer Anlasser hat den Fahrzeugbetrieb revolutioniert. Im Laufe der Jahrzehnte haben Verbesserungen bei Materialien und Herstellungsverfahren zu leichteren, kompakteren Konstruktionen geführt, die die Gesamtleistung des Fahrzeugs verbessern. Das Aufkommen von Hybrid- und Elektrofahrzeugen hat ebenfalls zu Innovationen in der Anlassertechnologie geführt, was die Entwicklung fortschrittlicher Anlassersysteme zur Folge hatte, die für den Betrieb moderner Automobilantriebe unerlässlich sind.

Anschauliches Bild zur Überprüfung eines Starters

Das Verständnis dieses historischen Kontextes ist für B2B-Einkäufer von entscheidender Bedeutung, da es ihnen bei ihren Beschaffungsentscheidungen hilft. Wenn Einkäufer die Entwicklung der Startertechnologie kennen, können sie die Fähigkeiten aktueller Lieferanten besser einschätzen und künftige Trends vorhersehen, die sich auf die Automobilbranche auswirken könnten.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zur Überprüfung eines Starters

-

Wie kann ich einen Anlasser lösen, der nicht einrastet?

Um einen Anlasser zu reparieren, der nicht anspringt, überprüfen Sie zunächst die Batteriespannung mit einem Multimeter. Ein Wert unter 12 V weist auf eine schwache Batterie hin. Untersuchen Sie die Batteriepole auf Korrosion und stellen Sie sicher, dass alle Anschlüsse sicher sind. Wenn die Batterie funktioniert, prüfen Sie die Magnetspule und die Verkabelung auf lose Verbindungen. Wenn diese Komponenten intakt sind, müssen Sie den Anlasser eventuell auf dem Prüfstand testen, um festzustellen, ob er ausgetauscht werden muss. Regelmäßige Wartungsprüfungen können helfen, solche Probleme zu vermeiden und einen reibungslosen Betrieb zu gewährleisten. -

Wie testet man einen Autoanlasser am besten?

Der beste Weg, einen Autoanlasser zu testen, umfasst mehrere Schritte. Vergewissern Sie sich zunächst, dass die Batterie vollständig geladen ist und die Pole sauber sind. Führen Sie als Nächstes eine Sichtprüfung der Magnetspule und der Anschlüsse des Anlassers durch. Bei anhaltenden Problemen bauen Sie den Anlasser aus und führen einen Prüfstandstest durch, indem Sie Überbrückungskabel an eine Batterie anschließen. Beobachten Sie, ob das Ritzel einrastet; wenn nicht, muss der Anlasser wahrscheinlich ausgetauscht werden. Diese systematische Vorgehensweise hilft Ihnen, Probleme mit dem Anlasser genau zu diagnostizieren. -

Was sollte ich bei der internationalen Beschaffung von Vorspeisen beachten?

Achten Sie bei der internationalen Beschaffung von Vorspeisen auf den Ruf und die Zuverlässigkeit des Lieferanten. Überprüfen Sie Zertifizierungen und die Einhaltung von Industrienormen, um die Qualität sicherzustellen. Prüfen Sie, ob der Lieferant in der Lage ist, Ihre spezifischen Anforderungen zu erfüllen, einschließlich der Kompatibilität mit verschiedenen Fahrzeugmodellen. Beurteilen Sie außerdem die logistischen Möglichkeiten des Anbieters, einschließlich der Versandzeiten und -kosten, um unerwartete Verzögerungen zu vermeiden. Eine klare Kommunikation bezüglich der Spezifikationen und Erwartungen ist für eine erfolgreiche Transaktion entscheidend. -

Wie überprüfe ich Lieferanten für Kfz-Teile wie Anlasser?

Um Zulieferer für Kfz-Teile zu überprüfen, sollten Sie zunächst ihre Branchenerfahrung und Kundenreferenzen einsehen. Fordern Sie Referenzen an und führen Sie Hintergrundprüfungen durch, um ihre Glaubwürdigkeit zu beurteilen. Beurteilen Sie die Produktionskapazitäten, die Qualitätssicherungsprozesse und die Einhaltung internationaler Normen. Erkundigen Sie sich auch nach den Rückgabe- und Garantiebedingungen des Unternehmens. Eine direkte Kommunikation kann alle Zweifel ausräumen und zum Aufbau einer vertrauensvollen Beziehung beitragen. -

Was sind übliche Mindestbestellmengen (MOQs) für Vorspeisen?

Die Mindestbestellmengen (MOQs) für Vorspeisen können je nach Lieferant und Region erheblich variieren. In der Regel liegen die MOQs zwischen 50 und 500 Stück, je nach Produktionskapazität des Herstellers und Marktnachfrage. Berücksichtigen Sie bei den Verhandlungen Ihren Bedarf an Lagerbeständen und die Flexibilität des Lieferanten, kleinere Bestellungen zu erfüllen. Einige Lieferanten bieten niedrigere Mindestbestellmengen für Erstkäufer oder während Aktionszeiträumen an, so dass es sich lohnt, Ihre Anforderungen im Vorfeld zu besprechen. -

Welche Zahlungsbedingungen sind bei internationalen Geschäften üblich?

Zu den Standardzahlungsbedingungen für internationale Transaktionen gehören häufig Optionen wie Vorauszahlung, Akkreditive oder Zahlung bei Lieferung. Viele Lieferanten verlangen eine Anzahlung von 30-50% im Voraus, wobei der Restbetrag vor dem Versand oder bei Erhalt der Ware fällig wird. Wenn Sie die Zahlungsbedingungen im Voraus besprechen, können Sie Missverständnisse vermeiden. Ziehen Sie außerdem die Verwendung sicherer Zahlungsmethoden in Betracht, um Ihre Finanztransaktionen zu schützen und die Einhaltung internationaler Handelsbestimmungen zu gewährleisten. -

Wie kann ich die Qualitätssicherung (QA) für ausgelagerte Berufsanfänger sicherstellen?

Legen Sie mit Ihrem Lieferanten klare Spezifikationen und Standards fest, um die Qualitätssicherung für zugekaufte Vorspeisen zu gewährleisten. Fordern Sie Muster an, um die Qualität zu beurteilen, bevor Sie größere Bestellungen aufgeben. Führen Sie in verschiedenen Phasen von der Produktion bis zur Auslieferung Prüfprotokolle ein, um etwaige Mängel frühzeitig zu erkennen. Die Zusammenarbeit mit externen Inspektionsdiensten kann eine zusätzliche Garantie für die Produktqualität bieten. Eine regelmäßige Kommunikation mit Ihrem Lieferanten über Qualitätssicherungsmaßnahmen kann eine Kultur der Verantwortlichkeit fördern. -

Welche logistischen Aspekte sollte ich bei der Einfuhr von Vorspeisen beachten?

Bei der Einfuhr von Anfängern müssen logistische Aspekte wie Versandmethoden, Kosten und Lieferfristen berücksichtigt werden. Wählen Sie einen zuverlässigen Spediteur mit Erfahrung im Bereich Kfz-Teile, um den Prozess zu optimieren. Achten Sie auf Einfuhrzölle, Steuern und Zollbestimmungen, die sich auf die Gesamtkosten auswirken können. Stellen Sie sicher, dass die Verpackung angemessen ist, um Schäden während des Transports zu vermeiden. Und schließlich kann eine offene Kommunikation mit Ihrem Lieferanten und Logistikdienstleister dazu beitragen, mögliche Probleme umgehend zu lösen.

Top 3 der Liste der Hersteller & Lieferanten von Anlasser prüfen

1. Reddit - Tipps zur Fehlerbehebung beim Anlasser

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Um zu prüfen, ob der Anlasser Ihres Fahrzeugs richtig funktioniert, können Sie ein Multimeter zur Diagnose von elektrischen Problemen verwenden. Alternativ können Sie auch mit einem kleinen Vorschlaghammer auf den Anlasser klopfen, während ein Freund den Zündschlüssel dreht. Wenn sich der Anlasser durch das Klopfen durchdrehen lässt, muss er möglicherweise ausgetauscht werden. Für einen gründlicheren Test können Sie den Anlasser auf dem Prüfstand testen, indem Sie ihn aus dem Auto ausbauen und Starthilfekabel verwenden...

2. Elevate Auto - Lösungen zum Testen von Anlassern

Domäne: elevateauto.com.au

Einleitung: Dieses Unternehmen, Elevate Auto - Starter Motor Testing Solutions, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

3. WikiHow - Anleitung zum Testen des Autostarters

Domäne: wikihow.com

Registriert: 2004 (21 Jahre)

Einleitung: Der Artikel bietet eine umfassende Anleitung zum Testen eines Autoanlassers, die drei Hauptteile umfasst: Prüfen des Ritzels, Testen des elektrischen Systems und Testen des Anlassers auf dem Prüfstand. Er umfasst Schritte wie das Einschalten der Scheinwerfer, um Probleme zu diagnostizieren, die visuelle Inspektion der Batteriepole und des Solenoids, das Prüfen der Batteriespannung mit einem Multimeter und die Verwendung eines Stromkreisprüfgeräts, um die Stromstärke zu...

Strategische Beschaffung Schlussfolgerung und Ausblick für die Prüfung einer Vorspeise

Zusammenfassend lässt sich sagen, dass es für B2B-Einkäufer, die in der Automobilindustrie tätig sind, von entscheidender Bedeutung ist, zu wissen, wie man einen Anlasser effektiv überprüft. Durch Befolgung der beschriebenen Schritte - Prüfung des Ritzels, Prüfung des elektrischen Systems und Prüfung des Anlassers auf dem Prüfstand - können Unternehmen Anlasserprobleme genau diagnostizieren und so Ausfallzeiten und Reparaturkosten minimieren. Strategische Beschaffung spielt eine entscheidende Rolle, wenn es darum geht, den Zugang zu Qualitätskomponenten und zuverlässigen Dienstleistern zu gewährleisten, so dass Unternehmen ihre betriebliche Effizienz und Kundenzufriedenheit steigern können.

Da internationale Einkäufer aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa versuchen, ihre Aktivitäten im Automobilbereich zu optimieren, sind Investitionen in solide Beschaffungsstrategien unerlässlich. Die Bevorzugung von Partnerschaften mit renommierten Zulieferern gewährleistet nicht nur die Verfügbarkeit von hochwertigen Starterkomponenten, sondern fördert auch langfristige Geschäftsbeziehungen, die zu Wettbewerbsvorteilen führen können.

Mit Blick auf die Zukunft möchten wir Sie ermutigen, diese Erkenntnisse zu nutzen, um Ihre Beschaffungspraktiken zu verfeinern. Auf diese Weise können Sie Ihr Unternehmen in die Lage versetzen, schnell auf die Marktanforderungen zu reagieren und sich im Automobilsektor zu behaupten. Machen Sie den nächsten Schritt zur Verbesserung Ihrer operativen Fähigkeiten, indem Sie Partnerschaften erkunden, die mit Ihren strategischen Zielen übereinstimmen.

Anschauliches Bild zur Überprüfung eines Starters

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.