Introduction: Navigating the Global Market for cost to replace an alternator

Navigating the complexities of the global market for the cost to replace an alternator can be daunting for international B2B buyers. With variations in pricing, sourcing options, and labor costs across different regions—especially in Africa, South America, the Middle East, and Europe (including Germany and Saudi Arabia)—understanding these elements is crucial for making informed purchasing decisions. This guide delves into the essential factors influencing alternator replacement costs, including the types of alternators available, the applications suited for each type, and key considerations for vetting suppliers.

As B2B buyers, you face the challenge of balancing quality with cost-effectiveness in your procurement strategies. This comprehensive resource empowers you to navigate these challenges by providing insights into the distinctions between OEM, remanufactured, and aftermarket alternators. Furthermore, we explore the impact of vehicle make and model on pricing, labor complexities, and regional variations that can affect overall costs.

By leveraging the information presented in this guide, you will be equipped to make strategic decisions that enhance your operational efficiency while optimizing your budget. The ultimate goal is to foster a deeper understanding of the market dynamics surrounding alternator replacement, enabling you to source effectively and partner with reliable suppliers across diverse geographical landscapes.

Inhaltsverzeichnis

- Top 4 Cost To Replace An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cost to replace an alternator

- Understanding cost to replace an alternator Types and Variations

- Key Industrial Applications of cost to replace an alternator

- 3 Common User Pain Points for ‘cost to replace an alternator’ & Their Solutions

- Strategic Material Selection Guide for cost to replace an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for cost to replace an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost to replace an alternator’

- Comprehensive Cost and Pricing Analysis for cost to replace an alternator Sourcing

- Alternatives Analysis: Comparing cost to replace an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for cost to replace an alternator

- Navigating Market Dynamics and Sourcing Trends in the cost to replace an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cost to replace an alternator

- Strategic Sourcing Conclusion and Outlook for cost to replace an alternator

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding cost to replace an alternator Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| OEM-Lichtmaschinen | Manufactured by the vehicle’s original maker | Dealerships, fleet management | Vorteile: High reliability, warranty support. Nachteile: Higher cost, potential for longer lead times. |

| Ersatzteil-Lichtmaschinen | Produziert von Drittanbietern | Independent repair shops, retailers | Vorteile: Cost-effective, wide availability. Nachteile: Variable quality, limited warranty options. |

| Überholte Lichtmaschinen | Restored to factory standards after use | Auto parts suppliers, repair shops | Vorteile: Cheaper than new, reliable performance. Nachteile: Shorter lifespan than OEM, potential quality variations. |

| Salvage Yard Alternators | Used parts sourced from dismantled vehicles | Salvage yards, budget-focused repairs | Vorteile: Lowest cost, immediate availability. Nachteile: Ungewisse Zuverlässigkeit, keine Garantie. |

| DIY Replacement Kits | Kits with necessary components for self-installation | Heimwerker, kleine Reparaturwerkstätten | Vorteile: Cost savings on labor, hands-on experience. Nachteile: Requires mechanical skills, potential for errors. |

What are OEM Alternators and Their B2B Relevance?

OEM (Original Equipment Manufacturer) alternators are produced by the vehicle’s manufacturer. They are ideal for businesses looking for high reliability and warranty support, often used by dealerships and fleet management companies. The key consideration for B2B buyers is the higher cost associated with these parts, which can impact the overall maintenance budget. However, the assurance of quality and compatibility makes OEM parts a preferred choice for long-term fleet operations.

How Do Aftermarket Alternators Benefit B2B Buyers?

Aftermarket alternators are produced by third-party manufacturers and are widely available at competitive prices. They are commonly sourced by independent repair shops and retailers due to their affordability. B2B buyers should weigh the cost savings against potential quality variability, as not all aftermarket parts meet the same standards. However, established manufacturers often produce reliable options that can still provide good performance at a lower price point.

What Are the Advantages of Remanufactured Alternators?

Remanufactured alternators are used parts that have been restored to meet factory specifications. These are particularly appealing to auto parts suppliers and repair shops seeking a cost-effective alternative to new parts. While they are generally reliable and cheaper than OEM options, B2B buyers should consider the potential for shorter lifespans and variations in quality. Remanufactured parts often come with warranties, providing a balance between cost and assurance.

Why Consider Salvage Yard Alternators?

Salvage yard alternators are sourced from dismantled vehicles and offer the lowest cost option for repairs. They are suitable for budget-focused repairs in salvage yards and among small repair shops. However, the major downside is the uncertainty regarding reliability and the lack of warranty coverage. B2B buyers should approach salvage parts with caution, ensuring thorough inspections before purchase to mitigate risks.

How Do DIY Replacement Kits Cater to Specific B2B Needs?

DIY replacement kits come with all necessary components for self-installation and are ideal for DIY enthusiasts and small repair shops. They provide significant cost savings on labor but require mechanical skills and tools. B2B buyers considering this option should assess their workforce’s capabilities and the potential for errors during installation. While DIY kits can enhance profitability, they also introduce risks if not handled properly.

Key Industrial Applications of cost to replace an alternator

| Branche/Sektor | Specific Application of cost to replace an alternator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Flottenwartung für Nutzfahrzeuge | Reduces downtime and maintenance costs for operational fleets | Consider OEM vs. aftermarket parts and labor costs |

| Transport | Logistics companies maintaining delivery vehicles | Ensures reliability in transportation and timely deliveries | Evaluate part availability and sourcing options |

| Landwirtschaft | Agricultural machinery requiring regular electrical maintenance | Increases productivity and reduces unexpected equipment failures | Assess local parts suppliers and warranty options |

| Bauwesen | Heavy machinery and equipment in construction sites | Minimizes project delays and maintains operational efficiency | Look for specialized parts and service providers |

| Fertigung | Production machinery reliant on electrical systems | Enhances productivity and ensures uninterrupted production flow | Focus on sourcing reliable parts with quick delivery options |

How is the cost to replace an alternator applied in the automotive repair industry?

In the automotive repair sector, particularly for fleet maintenance, understanding the cost to replace an alternator is crucial. Commercial vehicles often operate under high demand and need reliable electrical systems to function efficiently. By budgeting for alternator replacements, fleet operators can avoid unexpected breakdowns, ensuring their vehicles remain operational and minimizing downtime. When sourcing parts, businesses should weigh the benefits of OEM parts against aftermarket options, as well as consider the cost implications of labor in different regions.

What are the implications of alternator replacement costs for transportation logistics?

For logistics companies, the reliability of delivery vehicles is paramount. The cost to replace an alternator can directly affect operational efficiency and service reliability. A malfunctioning alternator can lead to delays, impacting customer satisfaction and operational costs. By proactively managing maintenance budgets that include alternator replacements, logistics managers can maintain fleet reliability. Key considerations include sourcing high-quality parts and ensuring that labor costs are factored into the overall budget, particularly in regions with varying labor rates.

Why is understanding alternator replacement costs important in agriculture?

In agriculture, machinery reliability is critical for productivity during peak seasons. The cost to replace an alternator in agricultural equipment can be significant, but understanding this cost enables farmers to plan maintenance schedules effectively. Unexpected equipment failures due to alternator issues can lead to severe productivity losses. Therefore, agricultural businesses must seek reliable suppliers for alternators and consider the potential impact of sourcing delays on their operations, especially in remote areas.

How does the cost of alternator replacement affect construction projects?

In the construction industry, heavy machinery is essential for project completion. The cost to replace an alternator can influence project budgets and timelines. Equipment failures can cause significant delays, leading to increased labor costs and project overruns. Construction managers should prioritize sourcing high-quality alternators and establishing relationships with reliable service providers to ensure quick turnaround times for repairs. This proactive approach minimizes downtime and keeps projects on track.

What role does alternator replacement cost play in manufacturing efficiency?

Manufacturing operations rely heavily on electrical systems to maintain productivity. The cost to replace an alternator in production machinery can impact overall operational efficiency. Understanding these costs allows manufacturing managers to budget effectively and minimize disruptions caused by equipment failures. When sourcing alternators, businesses should consider not only the price but also the reliability of suppliers and the speed of delivery, ensuring that production lines remain uninterrupted.

3 Common User Pain Points for ‘cost to replace an alternator’ & Their Solutions

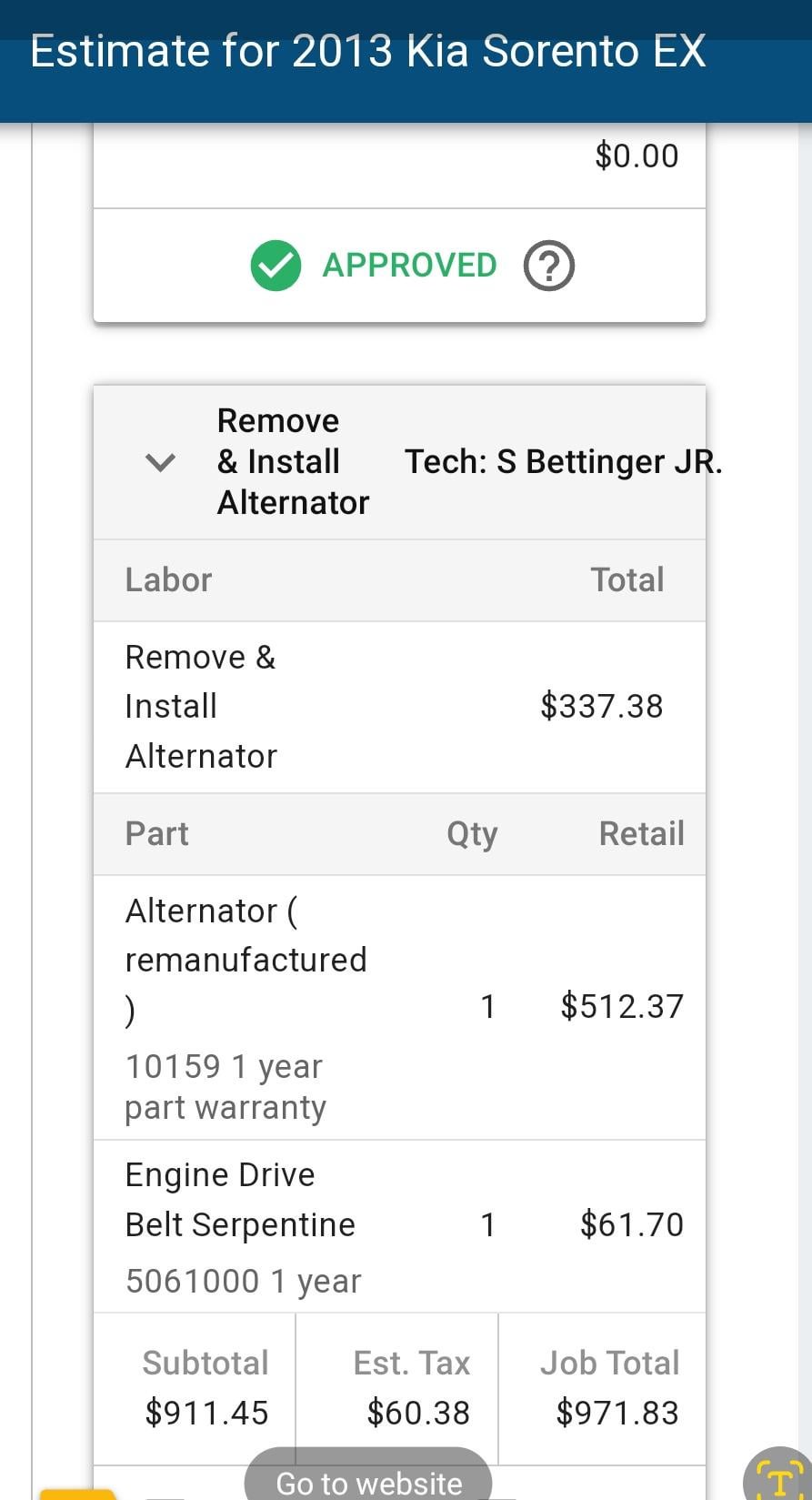

Scenario 1: Navigating the Cost Variability for Different Vehicle Models

Das Problem: B2B buyers often operate fleets that include a diverse range of vehicle makes and models. This diversity creates a significant challenge when it comes to the cost of replacing alternators. For example, an aftermarket alternator for a standard vehicle like a Honda Civic may cost around $450, while an OEM alternator for a luxury vehicle like a BMW 740i could exceed $2,200. The disparity in costs can lead to budget overruns and complicate procurement strategies, especially when buyers are trying to standardize maintenance costs across their fleet.

Die Lösung: To effectively navigate these cost variations, B2B buyers should implement a systematic approach to sourcing alternators. Start by conducting a thorough analysis of the fleet to categorize vehicles by make and model. Create a comprehensive database that includes the average cost for alternator replacements for each category. Leverage relationships with multiple suppliers to negotiate bulk purchase agreements, which can significantly reduce costs. Additionally, consider establishing partnerships with specialized repair shops that understand the intricacies of different vehicle types and can provide competitive pricing based on volume. This proactive strategy will not only streamline the procurement process but also facilitate better budget management.

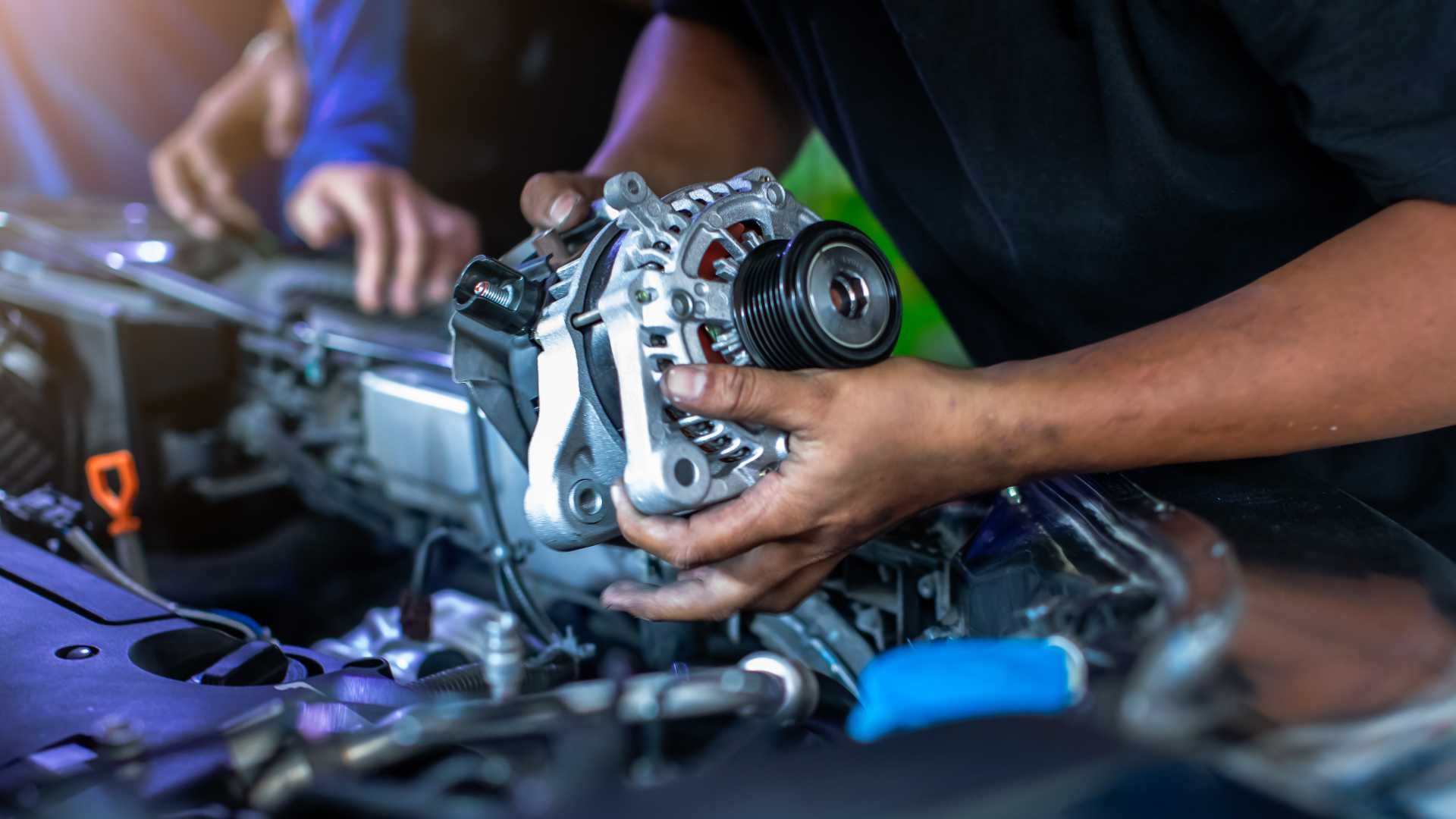

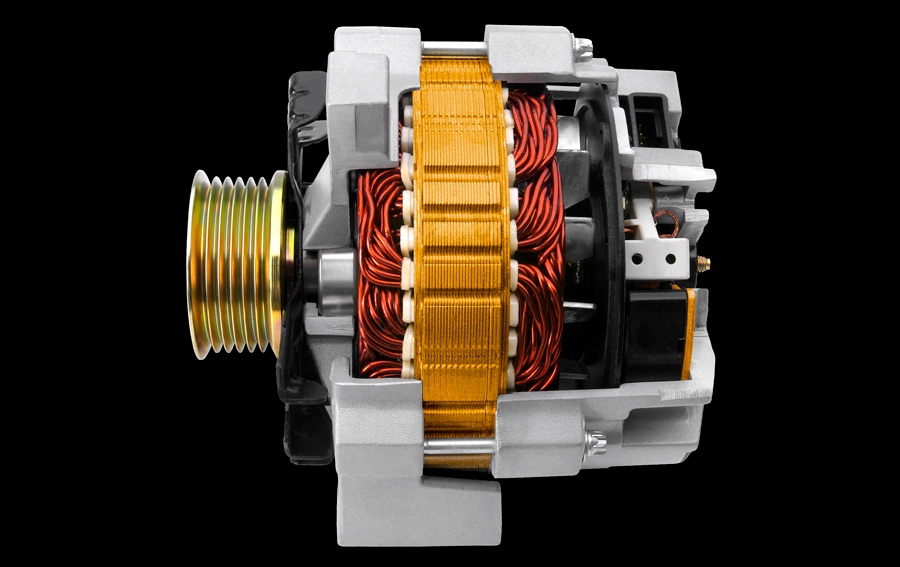

Illustrative image related to cost to replace an alternator

Scenario 2: Understanding the Impact of Labor Costs on Total Replacement Expenses

Das Problem: Labor costs associated with alternator replacements can vary widely based on the complexity of the installation. For instance, some vehicles may allow for quick access to the alternator, resulting in lower labor costs, while others may require extensive disassembly of the engine compartment, leading to higher labor charges. B2B buyers may find it challenging to predict the total cost of replacement, complicating budgeting and financial planning.

Die Lösung: To gain better control over labor costs, B2B buyers should proactively communicate with their mechanics and repair shops before any replacement work begins. Request detailed estimates that break down both parts and labor costs, and ask for insights into the expected labor hours based on the specific vehicle model. Additionally, consider investing in training for in-house mechanics to handle common alternator replacements, especially for frequently used vehicle models. This not only reduces dependency on external service providers but also allows for more predictable maintenance costs. Establishing a robust maintenance schedule can help identify potential alternator issues early, minimizing emergency repairs that often come with inflated labor rates.

Scenario 3: Evaluating Options Between OEM, Aftermarket, and Remanufactured Alternators

Das Problem: B2B buyers frequently face the dilemma of choosing between OEM, aftermarket, and remanufactured alternators. Each option has its pros and cons regarding price, reliability, and warranty coverage. For instance, while OEM parts are generally more reliable, they can strain budgets, particularly for companies managing large fleets. Conversely, aftermarket or remanufactured parts may offer savings but come with variable quality and reliability, leading to potential longer-term costs due to failures.

Die Lösung: To make informed decisions, B2B buyers should develop a framework for evaluating alternator options based on specific criteria. Start by assessing the reliability and warranty terms of different suppliers for aftermarket and remanufactured parts. Request performance data and customer reviews to gauge reliability. Additionally, consider the total cost of ownership, which includes the purchase price, expected lifespan, and warranty coverage. For critical vehicles that demand high reliability, investing in OEM parts may be justified. For less critical vehicles or those with a higher turnover, remanufactured or reputable aftermarket options could be more cost-effective. Implementing a standardized evaluation process will help buyers make consistent and informed decisions, balancing cost with performance needs.

Strategic Material Selection Guide for cost to replace an alternator

What Are the Common Materials Used in Alternator Replacement?

When considering the cost to replace an alternator, the choice of materials plays a critical role in determining performance, longevity, and overall value. Here, we analyze four common materials used in alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Impact Alternator Performance?

Aluminum is a prevalent material for alternator housings and components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of around 150°C and offers good corrosion resistance, making it suitable for various environments.

Vorteile: Aluminum’s lightweight nature reduces the overall weight of the alternator, which can improve fuel efficiency in vehicles. It is also relatively inexpensive and easy to manufacture, allowing for cost-effective production.

Illustrative image related to cost to replace an alternator

Nachteile: While aluminum is durable, it may not withstand extreme conditions as well as other metals, such as steel. Additionally, its susceptibility to corrosion in highly saline environments can be a concern for buyers in coastal regions.

Auswirkungen auf die Anwendung: Aluminum components are compatible with most automotive fluids and can effectively handle the electrical demands of standard vehicles.

Überlegungen für internationale Käufer: Buyers in regions like Europe and the Middle East should ensure compliance with local standards such as DIN and ASTM for aluminum alloys. Additionally, understanding the environmental regulations regarding aluminum recycling is essential.

Welche Rolle spielt Kupfer bei der Funktion von Lichtmaschinen?

Copper is primarily used in the windings of alternators due to its excellent electrical conductivity, which is crucial for efficient power generation. It can handle high temperatures, typically rated up to 200°C.

Vorteile: The high conductivity of copper allows for efficient energy transfer, reducing energy loss and improving overall performance. Its durability also ensures a longer lifespan for the electrical components.

Illustrative image related to cost to replace an alternator

Nachteile: Copper is more expensive than aluminum, which can increase the overall cost of the alternator. Additionally, it is heavier, which may impact vehicle weight and fuel efficiency.

Auswirkungen auf die Anwendung: Copper is compatible with various automotive fluids and electrical systems, making it a standard choice for high-performance vehicles.

Überlegungen für internationale Käufer: Buyers should be aware of the fluctuating copper prices and potential supply chain issues. Compliance with international standards for electrical components is also critical, particularly in regions with strict regulations.

How Does Steel Affect Alternator Durability?

Steel is often used in the construction of alternator brackets and other structural components due to its high strength and durability. It typically has a temperature rating of around 250°C and offers excellent resistance to mechanical stress.

Vorteile: Steel’s strength makes it ideal for components that require structural integrity, ensuring that the alternator can withstand vibrations and impacts during vehicle operation. It is also widely available and relatively low-cost.

Illustrative image related to cost to replace an alternator

Nachteile: Steel is heavier than aluminum and may contribute to increased vehicle weight. It is also prone to rust if not properly coated or treated, which can be a concern in humid or coastal environments.

Auswirkungen auf die Anwendung: Steel components are compatible with various automotive systems but may require additional coatings to prevent corrosion.

Überlegungen für internationale Käufer: Buyers should consider the availability of high-quality steel that meets local standards, such as ASTM or JIS. Additionally, understanding the local market for treated versus untreated steel can influence purchasing decisions.

Illustrative image related to cost to replace an alternator

What Are the Benefits of Using Composite Materials in Alternators?

Composite materials, often used in advanced alternator designs, combine various materials to optimize performance. These materials can have varying temperature ratings depending on their composition.

Vorteile: Composites can be engineered for specific applications, offering lightweight solutions with excellent resistance to heat and corrosion. They can also reduce noise and vibration, enhancing overall vehicle performance.

Nachteile: The manufacturing complexity of composite materials can lead to higher costs. Additionally, their long-term durability under extreme conditions is still being evaluated compared to traditional materials.

Auswirkungen auf die Anwendung: Composites can be tailored for specific automotive applications, making them suitable for high-performance or specialized vehicles.

Überlegungen für internationale Käufer: Buyers should ensure that composite materials meet local compliance standards and are sourced from reputable manufacturers. Understanding the lifecycle and recyclability of composites is also crucial for sustainability considerations.

Summary Table of Material Selection for Alternator Replacement

| Material | Typical Use Case for cost to replace an alternator | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und kostengünstig | Korrosionsanfällig | Mittel |

| Kupfer | Elektrische Wicklungen | Ausgezeichnete Leitfähigkeit und Haltbarkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Stahl | Brackets and structural components | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Niedrig |

| Komposit | Advanced designs for high-performance vehicles | Tailored properties and lightweight | Höhere Fertigungskomplexität | Hoch |

This analysis provides a comprehensive overview of the materials used in alternator replacements, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cost to replace an alternator

Was sind die wichtigsten Schritte bei der Herstellung eines Generators?

The manufacturing of an alternator involves several critical stages that ensure the final product meets performance and reliability standards. Understanding these stages can help B2B buyers assess supplier capabilities and quality.

Materialvorbereitung

The manufacturing process begins with the selection and preparation of raw materials. Key materials used in alternator production include:

Illustrative image related to cost to replace an alternator

- Kupferdraht: Essential for windings due to its excellent electrical conductivity.

- Stahl und Aluminium: Used for the casing and rotor components, providing strength and durability.

- Plastic and Composites: Often used for insulating parts and housings to prevent electrical shorts.

During this phase, materials undergo rigorous testing to ensure they meet specified standards. B2B buyers should inquire about the sources of these materials and their compliance with international standards such as ISO 9001, which ensures quality management throughout the supply chain.

Umformtechniken

Forming is a crucial step where raw materials are shaped into functional components. Common techniques include:

- Stanzen: Used to create metal parts such as the stator and rotor from sheets of metal.

- Druckguss: Often employed for aluminum components, this technique allows for high precision and complex geometries.

- Wickeln: Copper wire is wound around the core to create the stator and rotor windings. The quality of the winding process directly affects electrical efficiency and performance.

Each technique requires specialized machinery and skilled labor to ensure precision and consistency. For B2B buyers, understanding the forming capabilities of a supplier can help evaluate their ability to produce high-quality alternators.

Assembly Process

The assembly process integrates all the individual components into a complete alternator. Key steps include:

- Komponentenintegration: The stator, rotor, and housing are assembled with careful attention to alignment and fit.

- Elektrische Anschlüsse: Wiring is connected, and terminals are crimped to ensure reliable electrical contact.

- Testing Before Final Assembly: Some manufacturers conduct preliminary tests on individual components to identify defects early in the process.

This stage is critical for ensuring that the alternator operates effectively. B2B buyers should ask about the assembly process and any automation technologies used, as these can significantly affect production efficiency and consistency.

Finishing Touches

After assembly, the alternator undergoes finishing processes that may include:

- Beschichtung: Protective coatings are applied to prevent corrosion and enhance durability.

- Kennzeichnung: Clear labeling helps in identifying specifications and compliance with regulations.

- Abschließende Inspektion: Before packaging, a final quality check is conducted to ensure the alternator meets all functional and safety standards.

Buyers should consider the supplier’s capabilities in finishing processes, as these can influence the longevity and reliability of the alternators.

What Are the Key Quality Assurance Practices in Alternator Manufacturing?

Quality assurance (QA) is a vital aspect of alternator manufacturing, ensuring that each unit produced meets stringent performance standards.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

B2B buyers should familiarize themselves with various international quality standards that govern manufacturing processes:

- ISO 9001: This standard outlines the requirements for a quality management system and is crucial for ensuring consistent quality in manufacturing.

- CE-Kennzeichnung: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API-Standards: While more common in the oil and gas sector, API standards may apply to specific automotive components.

Understanding these certifications can provide insight into a supplier’s commitment to quality and reliability.

What Are the Common Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Common QC stages include:

Illustrative image related to cost to replace an alternator

- Eingangsqualitätskontrolle (IQC): Materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process-Qualitätskontrolle (IPQC): Continuous monitoring during manufacturing helps identify defects early. This can involve process audits and sampling inspections.

- Endkontrolle (FQC): The completed alternator is tested to ensure it meets performance standards. This may include electrical testing, noise level checks, and vibration analysis.

For B2B buyers, these checkpoints are critical indicators of a supplier’s quality management practices.

Welche Prüfmethoden werden üblicherweise verwendet?

Various testing methods are employed to validate the functionality and reliability of alternators. Some of the most common methods include:

- Elektrische Prüfung: Measures output voltage and current to ensure the alternator is functioning correctly.

- Belastungstest: Simulates real-world conditions to assess performance under stress.

- Haltbarkeitsprüfung: Involves subjecting the alternator to extreme conditions (temperature, vibration) to ensure it can withstand operational challenges.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure they align with industry standards.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Verifying a supplier’s quality control practices is essential for ensuring the reliability of alternators. Here are some effective strategies:

Durchführung von Lieferantenaudits

Regular audits of suppliers can help B2B buyers assess compliance with quality standards. These audits can focus on:

Illustrative image related to cost to replace an alternator

- Manufacturing Processes: Evaluating the efficiency and effectiveness of production methods.

- Quality Management Systems: Reviewing documentation and processes related to ISO certifications.

- Testing Protocols: Ensuring that appropriate testing methods are in place and consistently applied.

Anforderung von Qualitätsberichten

Suppliers should provide detailed quality reports that outline their QC processes and test results. This documentation can help buyers assess the quality of the alternators and the reliability of the supplier.

Einsatz von Inspektionen durch Drittparteien

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These inspections can cover everything from material quality to final product testing, offering additional assurance to buyers.

Was sind die Feinheiten der Qualitätskontrolle für internationale Käufer?

For B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is crucial.

- Einhaltung gesetzlicher Vorschriften: Different regions may have unique regulations regarding automotive parts. Buyers should ensure that suppliers are compliant with local laws and standards.

- Kulturelle Unterschiede bei den Qualitätserwartungen: Perceptions of quality can vary by region. B2B buyers should communicate their specific quality expectations clearly to avoid misunderstandings.

- Logistische Überlegungen: The supply chain can influence quality control; longer shipping times may increase the risk of defects. Buyers should consider suppliers’ logistics capabilities as part of their evaluation.

By understanding these nuances, B2B buyers can make more informed decisions and establish stronger partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost to replace an alternator’

Einführung

This guide serves as a practical checklist for B2B buyers seeking to understand and manage the costs associated with replacing an alternator. Whether you are sourcing for a fleet of vehicles or managing repairs in an automotive business, this step-by-step approach will help you make informed decisions, ensuring you get the best value and quality.

Schritt 1: Define Your Vehicle Requirements

Understanding the specific make and model of the vehicles in your fleet is critical. Different vehicles have varying alternator types, and costs can fluctuate dramatically based on these specifications. Ensure you know whether you need OEM, remanufactured, or aftermarket parts, as this will significantly impact your sourcing strategy.

Schritt 2: Forschung Marktpreise

Conduct thorough research to establish a baseline for alternator replacement costs in your region. Prices can vary widely based on geographic location, vehicle type, and availability of parts. Gathering quotes from multiple suppliers will help you identify competitive pricing and avoid overpaying for services.

Schritt 3: Potenzielle Lieferanten bewerten

Before making any commitments, it’s essential to vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses in similar industries or regions. This step ensures that the suppliers have a proven track record of reliability and quality.

- Look for certifications: Verify that suppliers have the necessary certifications that demonstrate compliance with industry standards.

- Review warranty options: Inquire about warranties on parts and labor, as these can provide peace of mind and additional value.

Schritt 4: Assess Quality of Parts

Evaluate the types of alternators offered by suppliers. OEM parts are generally more reliable but come at a higher cost, while aftermarket and remanufactured options can save money but may vary in quality. Engage with your mechanic to understand which type would be the best fit for your vehicles, as their expertise can guide you toward the best choice.

Schritt 5: Consider Labor Costs and Complexity

Labor costs can significantly affect the total price of alternator replacement. Understand the complexity of the installation process for your specific vehicle models, as some require more time and specialized skills than others. Ensure you factor in both the hourly rate and the estimated time to complete the replacement when budgeting.

- Get multiple labor quotes: This can help you gauge the average labor costs and ensure you’re not being overcharged.

Schritt 6: Explore Financing Options

If the replacement costs are substantial, consider exploring financing options with your suppliers. Some may offer payment plans or financing solutions that can help manage cash flow while ensuring your vehicles are operational. Discuss these options upfront to avoid any surprises later in the procurement process.

Schritt 7: Review and Finalize Your Agreement

Once you have all the necessary information, review your agreements carefully before finalizing any purchases. Ensure that all terms, including pricing, warranties, and delivery timelines, are clearly outlined. This diligence will help mitigate risks and establish a solid working relationship with your chosen supplier.

By following these steps, B2B buyers can effectively navigate the complexities of procuring alternator replacements, ensuring they make informed and strategic decisions.

Comprehensive Cost and Pricing Analysis for cost to replace an alternator Sourcing

What Are the Key Cost Components in Replacing an Alternator?

When evaluating the cost to replace an alternator, it’s crucial to understand the various components involved in pricing. The primary cost components include:

-

Materialien: This encompasses the alternator itself, which can vary significantly in price based on whether it is an OEM (Original Equipment Manufacturer), aftermarket, or remanufactured part. Prices can range from approximately $100 for basic aftermarket options to over $1,500 for high-end OEM parts.

-

Arbeit: Labor costs are highly variable, influenced by the complexity of the installation. Typically, labor can range from $100 to $300, depending on the vehicle model and the shop’s hourly rate. Accessibility of the alternator within the engine bay plays a crucial role—some vehicles require extensive disassembly, leading to increased labor time.

-

Fertigungsgemeinkosten und Werkzeugbau: These costs include expenses related to facility maintenance, equipment, and tooling necessary for production and assembly. This can add 10-20% to the overall manufacturing cost of the alternator.

-

Qualitätskontrolle (QC): Ensuring that each alternator meets quality standards can incur additional costs. High-quality manufacturers often implement rigorous QC processes, which can justify higher pricing for reliable parts.

-

Logistik: Shipping and handling costs can vary based on the origin of the parts, especially for international buyers. Costs can increase significantly if the alternator must be imported, factoring in customs duties and freight charges.

-

Marge: Suppliers typically add a margin to cover business expenses and profit. This can vary widely based on market conditions and supplier relationships, often ranging from 15% to 30%.

What Influences Pricing for Alternator Replacement?

Several factors can influence pricing for alternator replacement, especially for international B2B buyers:

-

Volumen und Mindestbestellmenge (MOQ): Purchasing in bulk can lead to significant discounts, making it essential for businesses to assess their long-term needs against pricing structures.

-

Spezifikationen und Anpassung: Special requests for alternators, such as specific performance characteristics or custom branding, can lead to increased costs. It’s advisable to clearly communicate requirements to avoid unexpected expenses.

-

Qualität und Zertifizierungen: Higher-quality alternators that meet specific industry standards or certifications can command a premium price. Buyers should consider the long-term benefits of investing in certified parts for reliability.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can greatly affect pricing. Established suppliers may offer better warranties and service, justifying a higher cost.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) can impact total costs. Buyers must account for shipping responsibilities, which can vary based on the agreed Incoterms.

What Are the Best Practices for B2B Buyers Seeking Cost-Efficiency?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should adopt the following strategies to enhance cost-efficiency:

-

Preise verhandeln: Engage in negotiations with suppliers to secure better rates. Leverage volume purchases or long-term contracts to gain favorable pricing.

-

Berücksichtigen Sie die Gesamtbetriebskosten (Total Cost of Ownership, TCO): Evaluate the TCO instead of just the initial price. Higher-quality alternators may have a higher upfront cost but can result in lower maintenance and replacement costs over time.

-

Preisdifferenzen verstehen: Be aware of regional pricing differences. For example, European markets may have stricter regulations and higher quality standards, affecting costs compared to other regions.

-

Recherche bei lokalen Anbietern: Local sourcing can reduce logistics costs and lead times, providing a competitive advantage. Additionally, local suppliers may have better knowledge of specific vehicle needs in the region.

Haftungsausschluss

The prices mentioned are indicative and can vary based on specific circumstances, including vehicle make and model, geographic location, and market conditions. Always consult with a qualified mechanic or supplier for the most accurate estimates tailored to your specific needs.

Alternatives Analysis: Comparing cost to replace an alternator With Other Solutions

Exploring Alternative Solutions to Alternator Replacement Costs

In the automotive industry, particularly for B2B buyers, understanding the cost implications of alternator replacement is crucial. However, there are alternative solutions that can serve similar purposes, potentially offering cost savings or enhanced performance. This analysis compares the cost to replace an alternator with two viable alternatives: upgrading to a high-efficiency alternator und utilizing a battery management system.

| Vergleichsaspekt | Cost To Replace An Alternator | Upgrading to High-Efficiency Alternator | Utilizing a Battery Management System |

|---|---|---|---|

| Leistung | Standard performance | Improved efficiency, longer lifespan | Enhanced battery longevity and efficiency |

| Kosten | $450 – $2,200+ | $600 – $1,800 | $300 – $1,000 |

| Einfache Implementierung | Mäßig (erfordert professionelle Installation) | Moderate (professional help recommended) | Easy to moderate (DIY possible) |

| Wartung | Low (generally long-lasting) | Low (with proper installation) | Moderate (requires periodic checks) |

| Bester Anwendungsfall | Standard vehicle operation | High-demand electrical systems | Fleets or vehicles with frequent stop-and-go use |

What Are the Benefits of Upgrading to a High-Efficiency Alternator?

Upgrading to a high-efficiency alternator can be a strategic choice for businesses operating vehicles that require more robust electrical systems. These alternators are designed to produce more power at lower RPMs, which can enhance the vehicle’s electrical performance and battery life. The initial cost is higher compared to standard replacements, but the long-term savings from reduced wear on the battery and other electrical components can justify the investment. However, installation can be complex and may require professional help, which adds to the overall cost.

How Does a Battery Management System Compare to Alternator Replacement?

A battery management system (BMS) focuses on optimizing battery usage and lifespan, particularly in vehicles that experience frequent stopping and starting, such as delivery vans or taxis. BMS monitors battery health, temperature, and charge cycles, ensuring that the battery operates at peak efficiency. While the initial investment is lower than a full alternator replacement, the BMS requires regular maintenance checks and potential software updates, which can add to the total cost over time. Additionally, while it enhances battery performance, it does not replace the need for a functioning alternator.

How Should B2B Buyers Choose Between These Solutions?

When evaluating whether to replace an alternator or consider alternative solutions, B2B buyers should assess their specific operational needs. For fleets or vehicles that frequently operate under high electrical loads, upgrading to a high-efficiency alternator might offer superior performance and reliability. Conversely, for businesses looking to enhance battery longevity and efficiency in stop-and-go environments, a battery management system could provide a cost-effective solution.

Ultimately, each option presents unique advantages and potential drawbacks. A thorough analysis of operational requirements, budget constraints, and long-term maintenance considerations will help buyers make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for cost to replace an alternator

What Are the Key Technical Properties of Alternators Relevant to Replacement Costs?

When evaluating the cost to replace an alternator, several technical properties come into play that significantly impact both the price and performance. Here are critical specifications to consider:

-

Materialzusammensetzung

The materials used in alternator construction can vary widely. High-quality alternators typically use durable metals such as aluminum or copper, which enhance conductivity and longevity. In contrast, cheaper models may utilize lower-grade materials that can lead to premature failure. For B2B buyers, understanding material quality helps in selecting reliable components that reduce long-term costs associated with repairs and replacements. -

Power Output Rating

Alternators are rated by their power output, usually measured in amps. This rating indicates how much electrical power the alternator can generate to support a vehicle’s electrical systems. Selecting an alternator with the appropriate power output is crucial; insufficient output can lead to battery drainage and electrical issues. For businesses, ensuring that the correct power output aligns with vehicle specifications can prevent operational downtime. -

Spannungsregelung

Voltage regulation ensures that the alternator maintains a consistent voltage output, typically around 14.4 volts for most vehicles. This is important for charging the battery and powering electrical components without causing damage. Understanding voltage regulation standards can guide B2B buyers in selecting alternators that meet safety and efficiency requirements, ultimately contributing to better performance. -

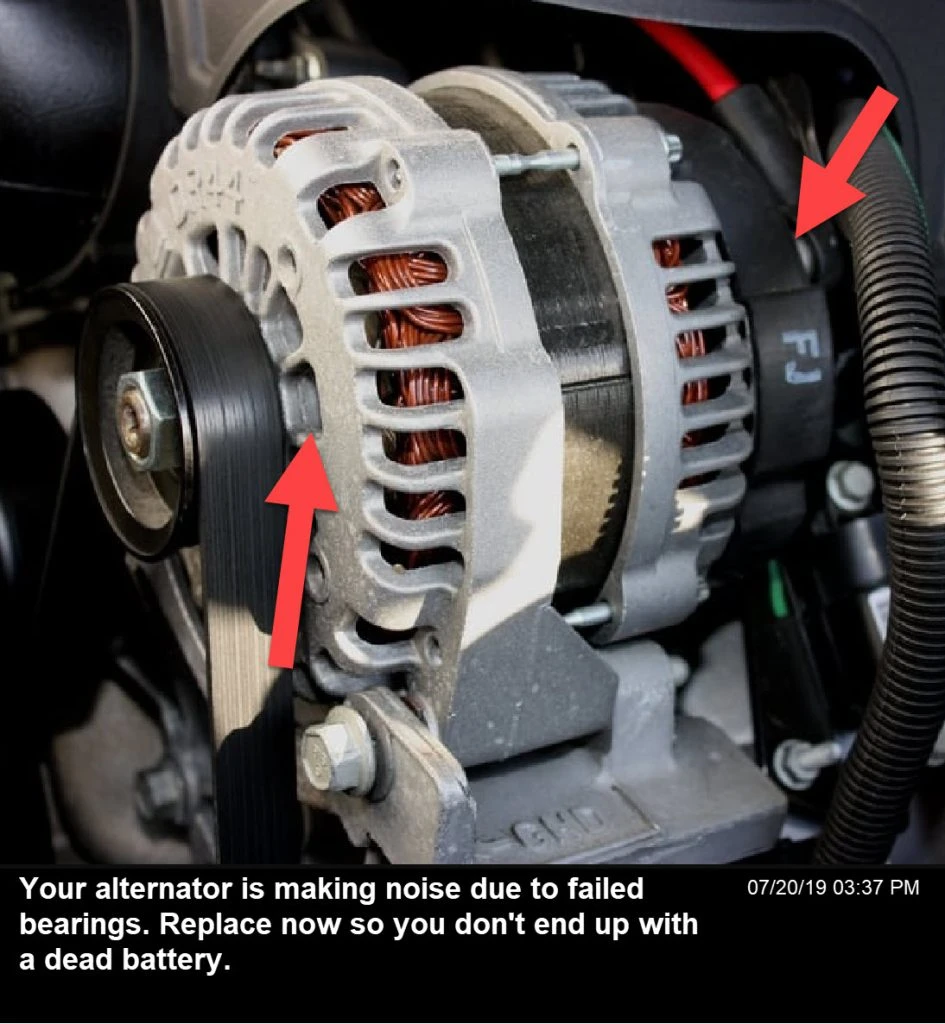

Lagertyp

The type of bearings used in an alternator affects its durability and noise levels. Alternators may use either ball bearings or sleeve bearings. While ball bearings tend to offer better performance and longevity, they can also increase costs. For B2B buyers, recognizing the bearing type can lead to more informed purchasing decisions that balance cost with performance longevity. -

Mechanismus der Kühlung

Some alternators include built-in cooling mechanisms to prevent overheating during operation. This is especially relevant for high-performance vehicles or those used in demanding conditions. Understanding the cooling features can help businesses assess the suitability of an alternator for specific applications, minimizing the risk of heat-related failures.

What Are Common Trade Terms Related to Alternator Replacement Costs?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms to know:

-

OEM (Originalgerätehersteller)

OEM parts are produced by the vehicle manufacturer and are designed to meet original specifications. While typically more expensive, they guarantee compatibility and quality. For B2B buyers, choosing OEM parts can be a prudent investment for maintaining vehicle integrity. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses that want to manage inventory costs effectively. It allows buyers to negotiate terms that align with their operational needs. -

RFQ (Angebotsanfrage)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. This process enables buyers to compare costs and terms across various suppliers, ensuring they receive competitive pricing for alternator replacements. -

Incoterms (Internationale Handelsklauseln)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers understand their obligations regarding shipping, insurance, and tariffs, ultimately facilitating smoother logistics in procuring alternators. -

Ersatzteilmarkt

Aftermarket parts are produced by third-party manufacturers and are designed to fit a specific vehicle model. These parts can be more cost-effective than OEM parts. For B2B buyers, evaluating aftermarket options can lead to significant savings while still maintaining acceptable quality. -

Labor Rate

This term refers to the cost charged by mechanics or technicians for their work, typically expressed as an hourly rate. Understanding labor rates is essential for estimating the total cost of alternator replacement, as they can vary widely based on the complexity of the job and the location of the service provider.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that optimize both cost and performance in alternator replacements.

Navigating Market Dynamics and Sourcing Trends in the cost to replace an alternator Sector

What Are the Current Market Dynamics and Key Trends Affecting the Cost to Replace an Alternator?

The global automotive aftermarket is witnessing significant changes that impact the cost to replace an alternator. The increasing complexity of vehicles, including the integration of advanced electrical systems, is driving up both the cost of parts and labor. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must navigate these evolving market dynamics carefully. For instance, OEM parts for luxury vehicles can exceed $2,000, while aftermarket options remain more affordable but may vary widely in quality.

Emerging trends include the growing reliance on e-commerce platforms for sourcing automotive parts. Digital marketplaces are allowing buyers to compare prices and specifications quickly, facilitating more informed purchasing decisions. Additionally, the trend toward remanufactured alternators is gaining traction, providing a cost-effective solution while maintaining quality standards. This shift is particularly relevant in regions with a focus on sustainability and cost reduction.

Furthermore, regional factors such as local labor costs and part availability can significantly influence pricing. Urban areas often have higher labor rates compared to rural regions, and the scarcity of specific alternator models can lead to price surges. International buyers should also consider the geopolitical landscape, as tariffs and trade policies can impact sourcing strategies and pricing structures.

How Does Sustainability and Ethical Sourcing Impact the Cost to Replace an Alternator?

Sustainability is becoming increasingly important in the automotive sector, particularly regarding the sourcing of components like alternators. Buyers are increasingly prioritizing suppliers that practice ethical sourcing, which can influence the overall cost of replacement. Ethical supply chains not only enhance brand reputation but also align with the growing consumer demand for environmentally responsible practices.

The environmental impact of sourcing alternators cannot be overlooked. The production and disposal of automotive parts contribute to significant waste and carbon emissions. Many manufacturers are now adopting “green” certifications and utilizing recycled materials in their products to mitigate these effects. For instance, opting for remanufactured alternators can reduce the demand for new raw materials and lower the carbon footprint associated with manufacturing.

B2B buyers should also be aware of regulations and standards related to environmental sustainability, as non-compliance can lead to penalties and supply chain disruptions. Engaging with suppliers who demonstrate a commitment to sustainability can offer a competitive edge in the marketplace and foster long-term partnerships.

Illustrative image related to cost to replace an alternator

What is the Evolution of the Alternator Replacement Market?

The alternator replacement market has evolved significantly since the introduction of the automotive alternator in the early 1960s. Initially, alternators were simple devices that converted mechanical energy into electrical energy. Over time, advancements in technology have led to the development of more sophisticated alternators that support a myriad of electronic features in modern vehicles.

In the late 20th century, the introduction of microprocessor-controlled alternators marked a pivotal change, allowing for better efficiency and performance. The rise of electric vehicles has further transformed the market, as these vehicles often require more advanced alternator technology to support their unique power needs. This evolution necessitates that B2B buyers stay informed about the latest advancements and trends in alternator technology to make educated sourcing decisions.

As the market continues to shift, understanding these historical developments can provide valuable context for current trends and pricing strategies, enabling international buyers to navigate the complexities of the alternator replacement landscape effectively.

Illustrative image related to cost to replace an alternator

Frequently Asked Questions (FAQs) for B2B Buyers of cost to replace an alternator

-

1. How do I determine the cost to replace an alternator for my fleet vehicles?

To accurately assess the cost of replacing alternators for your fleet, consider the make and model of each vehicle, as costs can vary significantly. Gather quotes from multiple suppliers for both OEM and aftermarket options. Factor in labor costs, which depend on the complexity of the installation. Additionally, consider the warranty coverage of your vehicles; repairs may be partially or fully covered if they are under warranty. It’s advisable to maintain a relationship with a trusted mechanic who can provide insights on potential cost-saving measures. -

2. What type of alternator should I source for my vehicle models?

Choosing between OEM, remanufactured, or aftermarket alternators depends on your budget and reliability requirements. OEM parts are generally the most reliable but come at a higher price. Remanufactured alternators offer a balance between cost and quality, as they are rebuilt to factory standards. Aftermarket options can be cheaper, but ensure they meet quality standards to avoid future issues. Collaborate with your mechanic to determine the best option based on your specific vehicle requirements and performance expectations. -

3. What factors influence the cost of alternator replacement in different regions?

The cost of alternator replacement can vary widely based on geographic location due to labor rates, parts availability, and local market conditions. Urban areas may have higher labor costs but better access to parts. Additionally, tariffs and import duties can affect the pricing of alternators sourced from different countries. It’s essential to research local suppliers and compare costs while also considering logistics expenses if parts are being imported. Understanding regional pricing dynamics will help you budget more effectively. -

4. How can I vet suppliers for alternators?

When vetting suppliers for alternators, assess their reputation and reliability by checking customer reviews and industry certifications. Request samples of their products to evaluate quality firsthand. It’s also beneficial to inquire about their sourcing practices, warranty policies, and return processes. Building relationships with suppliers who demonstrate transparency and responsiveness can lead to better long-term partnerships. Consider attending industry trade shows or forums to connect with reputable suppliers and gather insights on their offerings. -

5. What are the minimum order quantities (MOQ) for sourcing alternators?

Minimum order quantities for alternators can vary significantly by supplier and type of alternator. Some manufacturers may require MOQs of 10-50 units, while others might offer more flexible terms for smaller orders. When negotiating with suppliers, communicate your needs clearly, especially if you’re looking to source alternators for a fleet. Understanding MOQ can help you manage inventory more effectively and reduce upfront costs, especially if you are exploring bulk purchasing options. -

6. What payment terms should I negotiate when sourcing alternators?

Negotiating favorable payment terms is crucial for managing cash flow in B2B transactions. Standard terms may include net 30, 60, or even 90 days, depending on your relationship with the supplier. Consider discussing options like partial upfront payments or discounts for early payment to improve your financial flexibility. Additionally, ensure that the payment method is secure and offers protection against potential fraud. Establishing clear terms in the contract can safeguard both parties and foster trust. -

7. How can I ensure quality assurance when sourcing alternators?

To ensure quality assurance when sourcing alternators, request detailed specifications and quality certifications from your suppliers. Establish a quality control process that includes inspections of incoming parts and testing before installation. Consider implementing a return policy for defective items to mitigate losses. Engaging with suppliers who provide warranties can also offer peace of mind, as it indicates their confidence in the quality of their products. Regular communication with suppliers can help address any quality concerns promptly. -

8. What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping costs, customs duties, and delivery times. Partner with a reliable logistics provider familiar with international shipping regulations to ensure compliance and timely delivery. It’s essential to plan for potential delays at customs, which can impact your operations. Additionally, evaluate whether to use air freight for faster delivery or sea freight for cost savings, depending on your urgency and budget. Understanding these logistics elements will help streamline your supply chain management.

Top 4 Cost To Replace An Alternator Manufacturers & Suppliers List

1. Toyota - RAV4 Lichtmaschine Ersatz

Domäne: reddit.com

Einleitung: 2006 Toyota RAV4, alternator replacement, $450 total cost including labor.

2. JD Power - Kosten für den Austausch der Lichtmaschine

Domäne: jdpower.com

Registriert: 1995 (30 Jahre)

Einleitung: Alternator replacement costs range from $350 to $900, with parts alone costing between $100 to $350 on average, and luxury models costing $500 to $700. Labor costs can add another $350 to $500 if done at a dealership. Rebuilt alternators, which are made from original equipment replacement parts and come with a warranty, are a cost-effective option. DIY installation can save on labor costs, but req…

3. Facebook – Alternator Replacement Cost

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, Facebook – Alternator Replacement Cost, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. CarTalk – Alternator Replacement Costs

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: The cost to replace an alternator ranges from approximately $600 to $1,500. An alternator is a critical component that converts mechanical force into electrical energy, powering various systems in the vehicle, including the engine and lights, and charging the battery. Symptoms of a failing alternator include a check engine light, dimming headlights, and the need for jump-starts. Alternators can fa…

Strategic Sourcing Conclusion and Outlook for cost to replace an alternator

In conclusion, understanding the costs associated with alternator replacement is crucial for international B2B buyers. The price can range significantly based on vehicle make and model, the type of alternator selected, and labor costs, which vary by region. Strategic sourcing plays a pivotal role in managing these costs effectively. By evaluating options between OEM, remanufactured, and aftermarket alternators, buyers can identify the best value while ensuring reliability.

Moreover, partnering with specialized automotive repair centers can streamline the replacement process and potentially reduce labor expenses. For businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, leveraging local knowledge and supplier relationships can lead to significant savings and improved service quality.

As you move forward, consider implementing a strategic sourcing approach that prioritizes quality and cost-effectiveness. Engaging with trusted suppliers and mechanics will not only enhance your operational efficiency but also position your business for sustainable growth in an increasingly competitive landscape. Take proactive steps today to optimize your alternator replacement strategy and drive your business forward.

Illustrative image related to cost to replace an alternator

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.